Mechanical steam recompressing evaporation system and energy saving method

A technology of mechanical steam and evaporation system, applied in steam pressurized evaporation, evaporator accessories, etc., can solve the problems of unreasonable use of MVR, increase in energy consumption and cost, and high compression ratio of compressors, so as to increase the effective evaporation area , reducing the volume and cost, the effect of reducing the heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

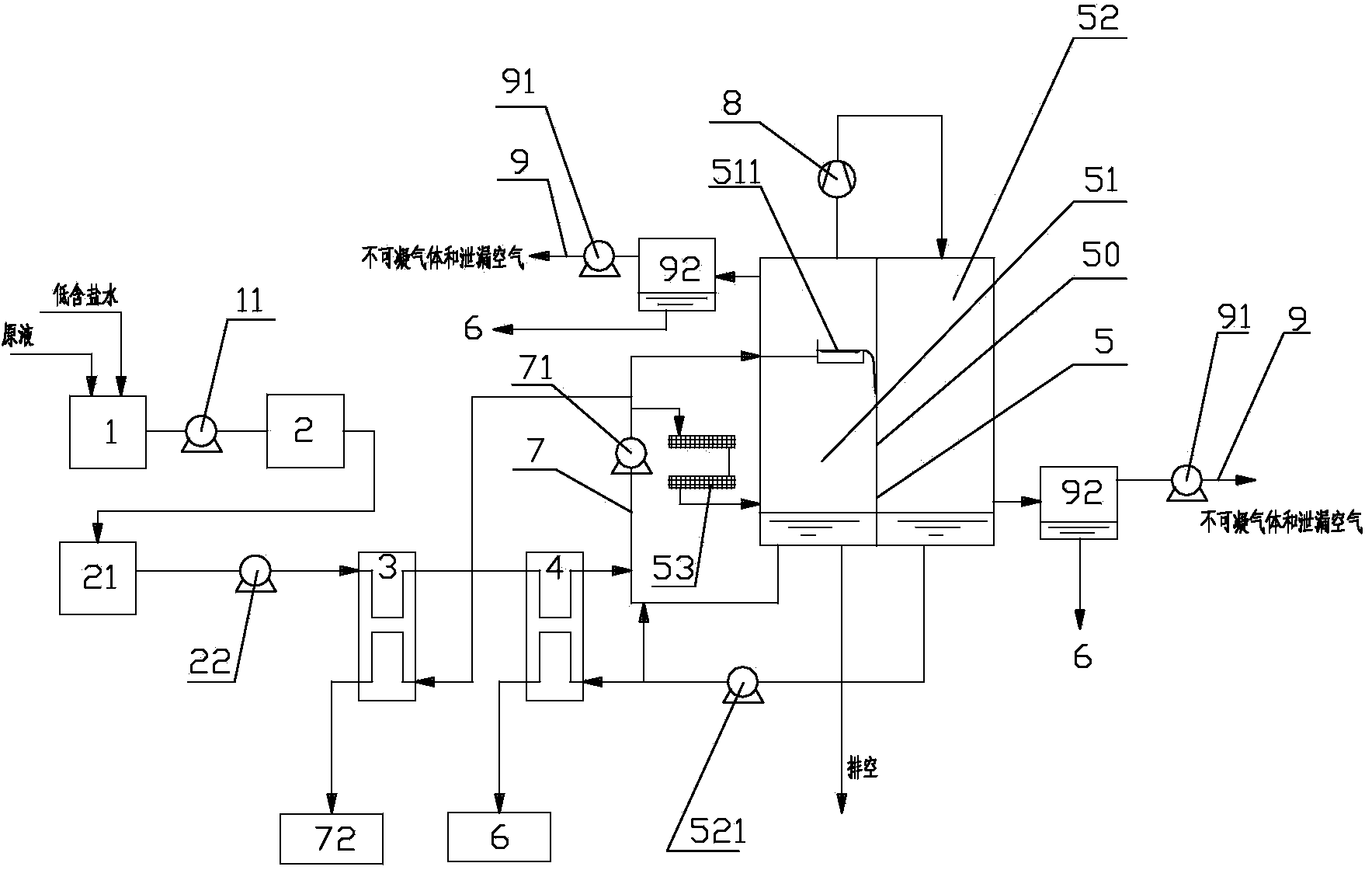

[0059] This embodiment provides a mechanical vapor recompression evaporation system, the flow and structure of the mechanical vapor recompression evaporation system are as follows Figure 1 to Figure 4 As shown, it includes a raw liquid storage tank 1 , a preprocessor 2 , a first heat exchanger 3 and a second evaporator 4 , an evaporative condensation device 5 and a condensed water recovery tank 6 connected in sequence according to the liquid flow direction.

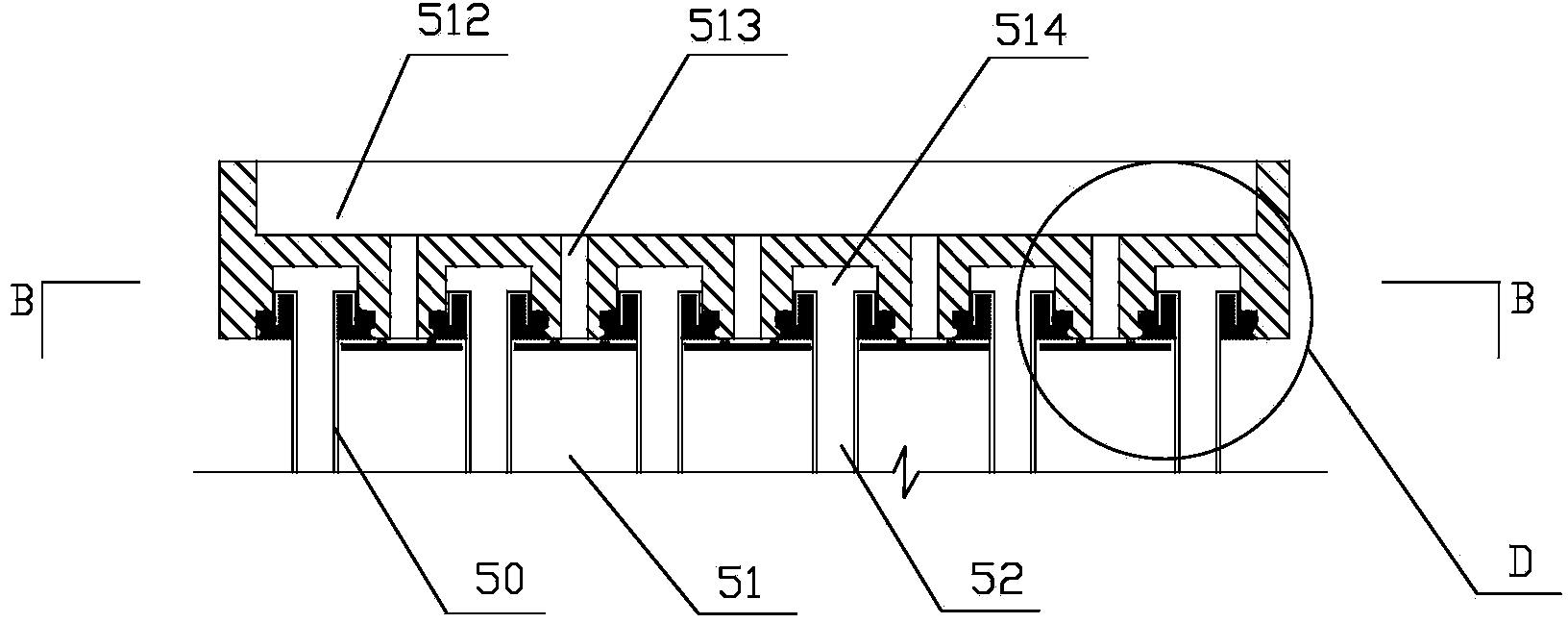

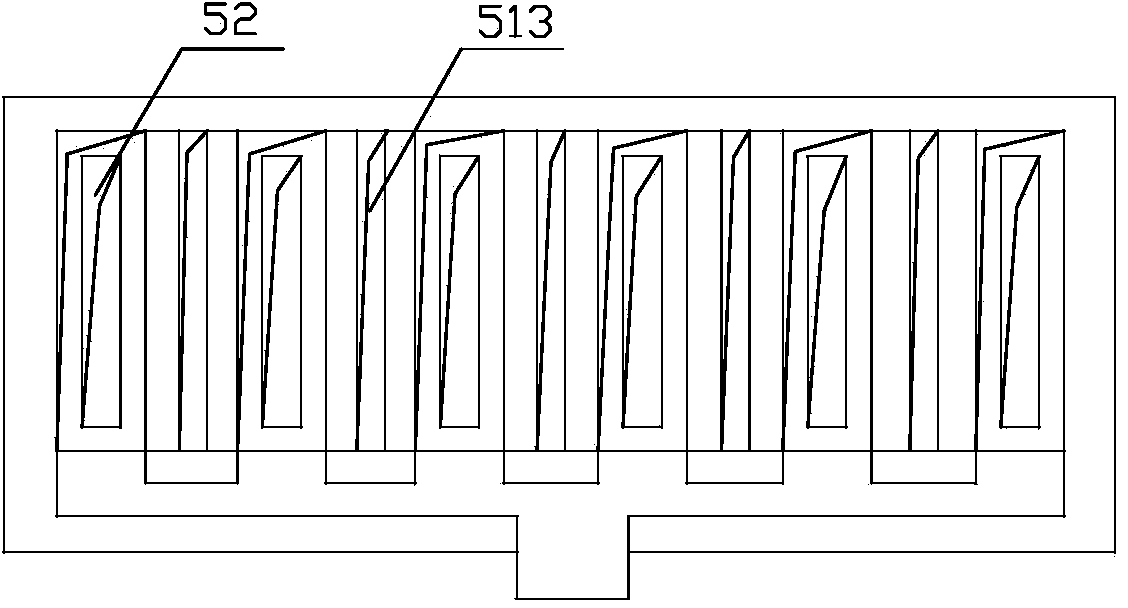

[0060] The structure of evaporative condensation device 5 is as Figure 2-Figure 4 As shown, the evaporation and condensation device 5 includes an evaporator 51 and a condenser 52 separated by a plurality of polymer films 50 and a heater 53 that provides heat to the evaporator 51 . The evaporator 51 is also provided with an overflow liquid distributor 511 , a liquid pan 512 , a long liquid slit 513 , and an air intake channel 514 , and the overflow liquid distributor 511 is provided with a liquid distribution plate 5110 ...

Embodiment 2

[0074] This embodiment provides an energy-saving method for a mechanical vapor recompression evaporation system. Under the condition of the same evaporation Q value, according to the formula: Q=K×A×ΔT and Pc=C×Q×ΔT (wherein, Q is the evaporation amount, K is the heat transfer coefficient, A is the evaporation surface area, and △T is the heat transfer coefficient. Heat temperature difference, Pc is fan power consumption, C is fan coefficient), can increase the effective evaporation area A of the evaporator, reduce the heat transfer temperature difference ΔT of the evaporator, and the decrease of ΔT directly leads to the decrease of Pc.

[0075] Among them, the heat transfer temperature difference of the evaporator is reduced to 2-3°C. The reduction of the heat transfer temperature difference can reduce the energy consumption and cost of the fan, thereby reducing the energy consumption and investment cost of the MVR system. Due to the low price of the polymer film, although the...

Embodiment 3

[0077] This embodiment provides an energy-saving method for a mechanical vapor recompression evaporation system, that is, to transfer the working point of the mechanical vapor recompression evaporation system to an environment with negative pressure and a temperature range of 40-70°C.

[0078] Under the same heat transfer temperature difference, the pressure difference between the evaporator and the condenser is reduced, which reduces the power consumption of the fan, thereby reducing the energy consumption and investment cost of the MVR system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com