Method for preparing phosphosilicate based glass

A phosphosilicate-based and silicic acid-based technology, which is applied in the field of preparation of phosphosilicate-based glass, can solve the problems of slow degradation rate, narrow component range, high reaction temperature, etc., and achieve good biocompatibility and small cytotoxicity , the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of phosphosilicate-based glass

[0026] According to the P in the phosphosilicate-based glass sample prepared in Table 1 2 o 5 , SiO 2 and CaO molar percentage content, the corresponding content of the precursor (phytic acid, ethyl orthosilicate and calcium nitrate tetrahydrate) is prepared into a gel precursor solution (calcium nitrate tetrahydrate is replaced by calcium chloride or calcium nitrate does not affect the results). First, take the precursor phytic acid in a 10ml sample bottle, and then add tetraethyl orthosilicate (TEOS), ethanol and water in sequence (the volume ratio is about 1:1, and the amount added should be enough to dissolve the aforementioned precursor), Stir for 30min, add Ca(NO 3 ) 2 4H 2O (or calcium chloride, or calcium nitrate), to obtain the gel precursor sol solution. Place the prepared gel precursor sol solution at room temperature until it gels (usually takes 2-10 days, depending on the ratio between the precu...

Embodiment 2

[0031] Embodiment 2: biological activity test

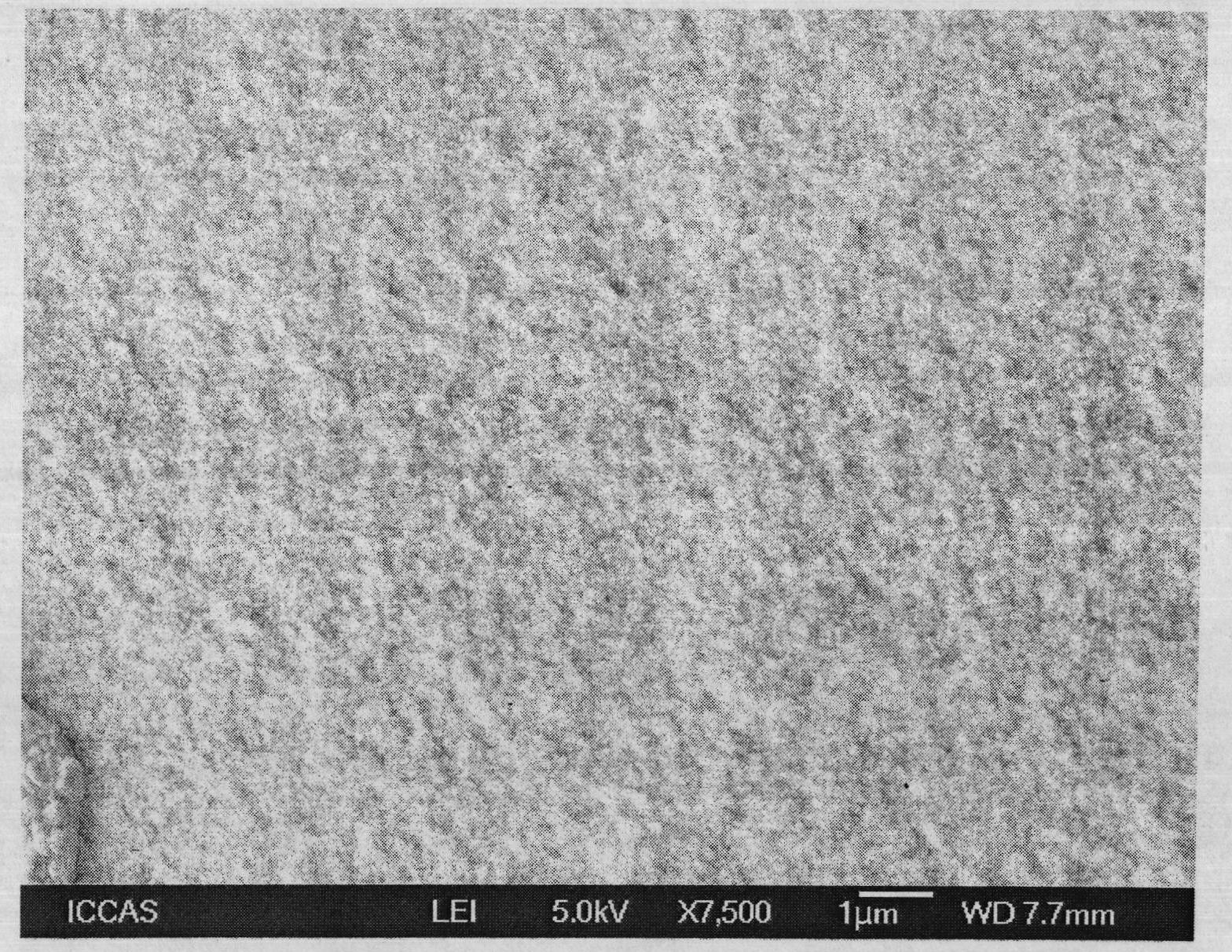

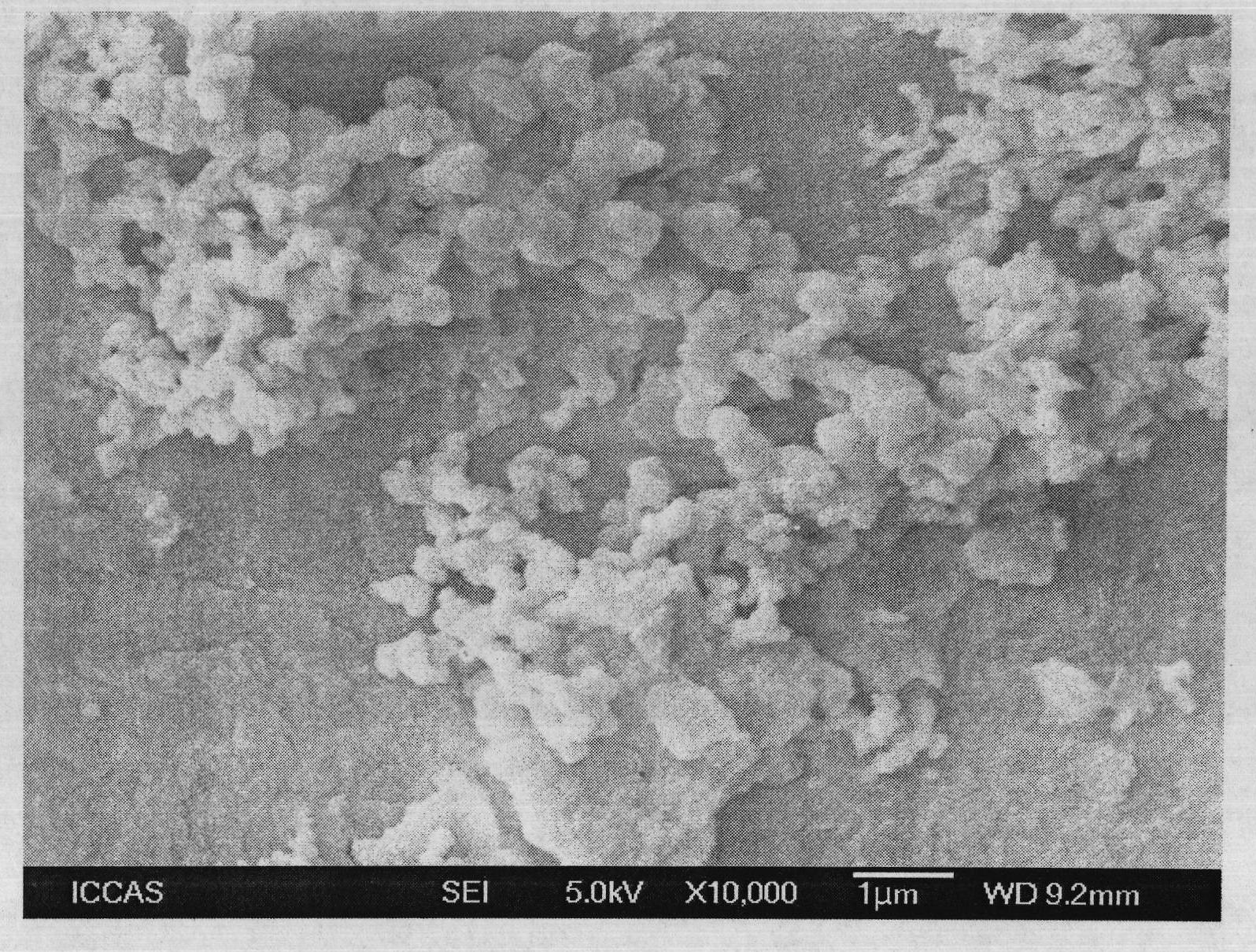

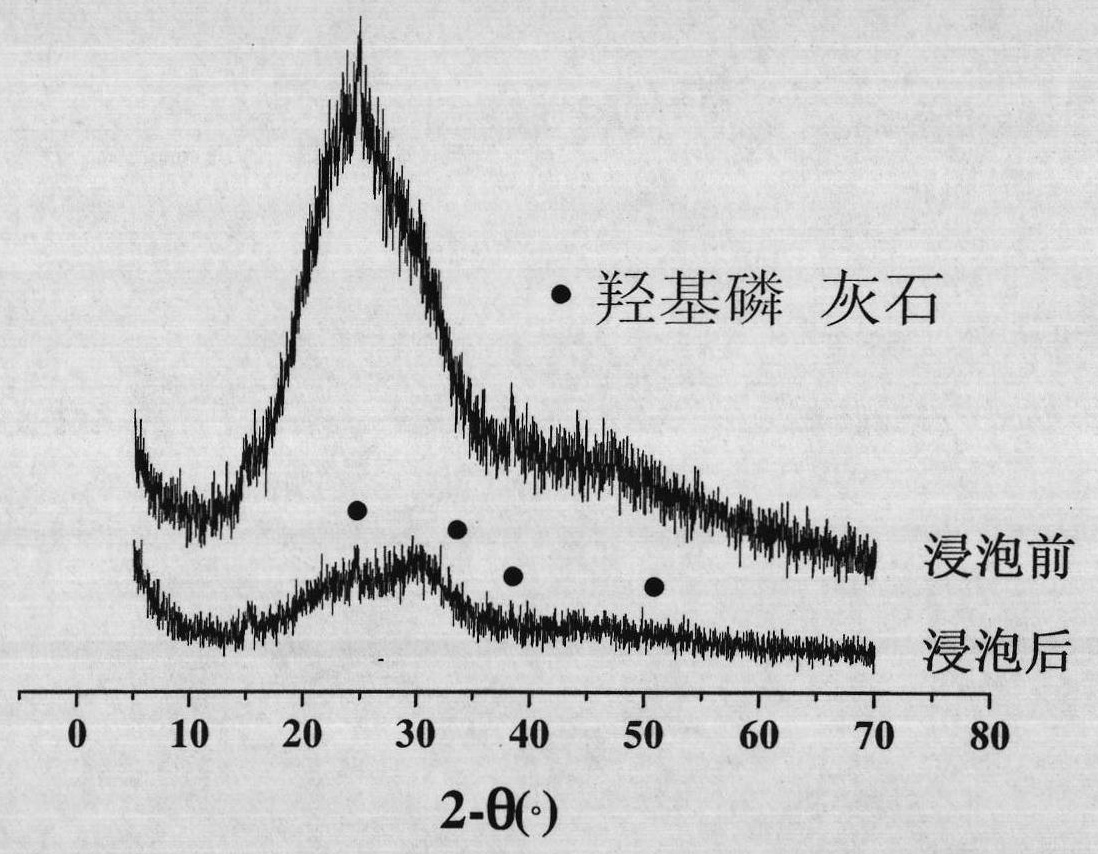

[0032] The phosphosilicate-based glass sample 2 (P 2 o 5 -24.4%, SiO 2 -40.6%, CaO-35.0%) soaked in simulated body fluid (SBF in Table 2) (37.0±0.5°C) for 14 days, a layer of dense and uniform hydroxyapatite formed on the surface of the sample. The microscopic morphology before and after soaking is as follows: Figure 1a and Figure 1b shown. The X-ray diffraction patterns before and after soaking are as follows: figure 2 shown.

[0033] Table 2: Ion concentrations in plasma (human body) and simulated human body fluid

[0034]

Embodiment 3

[0035] Embodiment 3: biological activity test

[0036] The bioactive phosphosilicate-based glass sample 3 (P 2 o 5 -16.6%, SiO 2 -18.4%, CaO-65.0%) soaked in simulated body fluid (SBF in Table 2) (37.0±0.5°C) for 14 days, a layer of dense and uniform hydroxyapatite formed on the surface of the sample. The microscopic morphology before and after soaking is as follows: Figure 3a and Figure 3b shown. The X-ray diffraction patterns before and after soaking are as follows: Figure 4 shown. and figure 2 It can be seen from the comparison of the X-ray diffraction pattern that the hydroxyapatite formation rate of sample 3 is faster than that of sample 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com