Quantum dot film and preparation method thereof

A quantum dot film and quantum dot technology are applied in the field of quantum dot film and its preparation to achieve the effects of reducing processes, reducing energy consumption and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

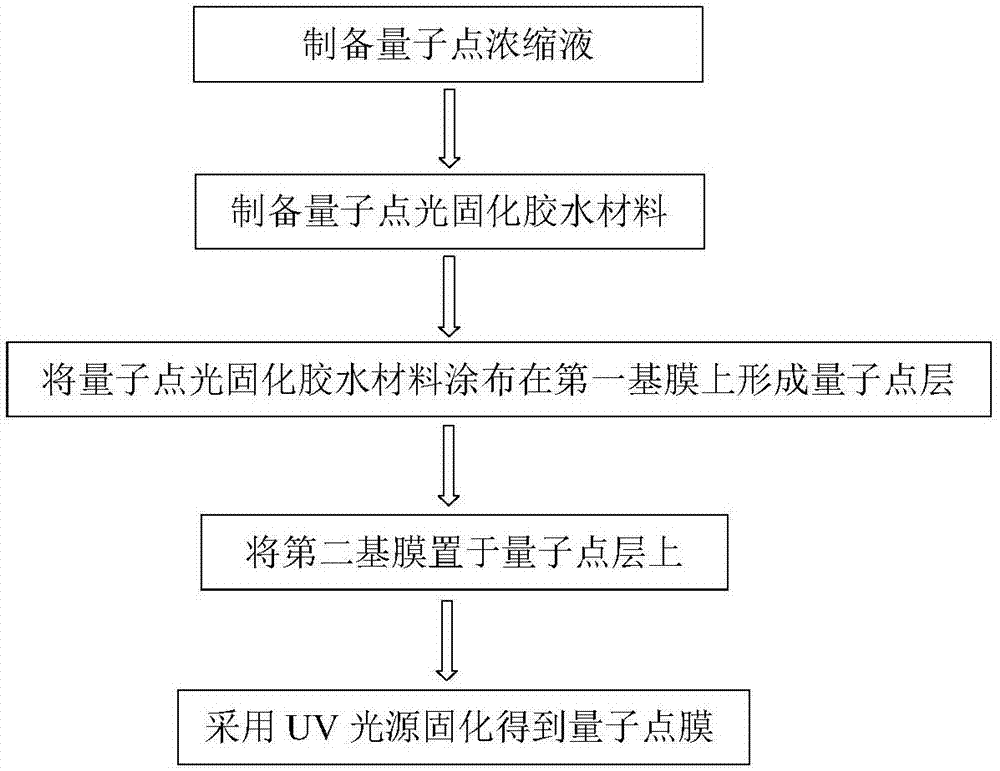

Method used

Image

Examples

Embodiment 1

[0032] Example 1 A light-curable glue was formulated from 50g of isobornyl acrylate, 36g of aliphatic urethane acrylate, and 3.2g of photoinitiator 1173, with a refractive index of 1.52 and a viscosity of about 1000cPs. Take a quantum dot product containing 0.08 g of quantum dots, remove the organic solvent by rotary evaporation, then add 0.72 g of isobornyl acrylate, stir first and then ultrasonically disperse to obtain a quantum dot concentrate. Add the quantum dot concentrate and 10 g of light diffusing agent into the light-curable glue, stir first and then ultrasonically disperse to obtain the quantum dot light-curable glue material. Coat the above-mentioned quantum dot light-curable glue material on the PET base film to form a quantum dot layer, then place another PET base film on the quantum layer by rolling method, and irradiate with LED UV light source to cure the quantum dot layer , to obtain the quantum dot film, wherein the thickness of the quantum dot layer after c...

Embodiment 2

[0033] Example 2 A photocurable glue was prepared from 60g of lauryl methacrylate, 26g of aliphatic urethane acrylate, and 3.2g of photoinitiator 1173, with a refractive index of 1.50 and a viscosity of about 700cPs. Take a quantum dot product containing 0.08 g of quantum dots, remove the organic solvent by rotary evaporation, then add 0.72 g of lauryl methacrylate, stir first and then ultrasonically disperse to obtain a quantum dot concentrate. Add the quantum dot concentrate and 10 g of light diffusing agent into the light-curable glue, stir first and then ultrasonically disperse to obtain the quantum dot light-curable glue material. Coat the above-mentioned quantum dot light-curable glue material on the PET base film to form a quantum dot layer, then place another PET base film on the quantum layer by rolling method, and irradiate with LED UV light source to cure the quantum dot layer , to obtain the quantum dot film, wherein the thickness of the quantum dot layer after cur...

Embodiment 3

[0034] Example 3 A photocurable glue was prepared from 60g of isobornyl acrylate, 26g of epoxy acrylate, and 3.2g of photoinitiator 184, with a refractive index of 1.50 and a viscosity of about 800cPs. Take a quantum dot product containing 0.08 g of quantum dots, remove the organic solvent by rotary evaporation, then add 0.72 g of isobornyl acrylate, stir first and then ultrasonically disperse to obtain a quantum dot concentrate. Add the quantum dot concentrate and 10 g of light diffusing agent into the light-curable glue, stir first and then ultrasonically disperse to obtain the quantum dot light-curable glue material. Coat the above-mentioned quantum dot light-curable glue material on the PET base film to form a quantum dot layer, then place another PET base film on the quantum layer by rolling method, and irradiate with LED UV light source to cure the quantum dot layer , to obtain the quantum dot film, wherein the thickness of the quantum dot layer after curing is 40 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com