Polyimide film and preparation method thereof

A technology of polyimide film and polyamic acid, which is applied in the field of polyimide film and its preparation, can solve problems such as low mechanical properties, particle agglomeration, and decreased mechanical properties, so as to achieve good mechanical properties and improve thermal conductivity , evenly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

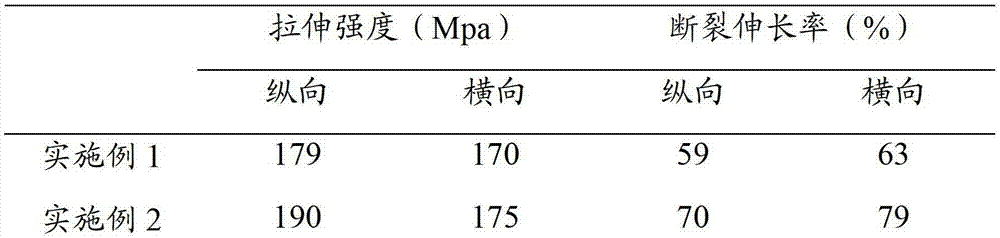

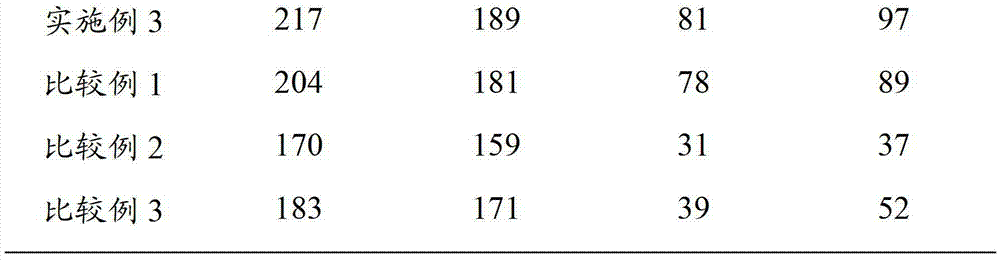

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of polyimide film, comprises the following steps:

[0023] Mix and grind thermally conductive fillers, solvents and coupling agents to obtain slurry;

[0024] Diamine and dianhydride are reacted in a solvent to obtain polyamic acid resin;

[0025] Mixing the slurry and polyamic acid resin, defoaming, and casting to obtain a polyamic acid film;

[0026] Imidating the polyamic acid film to obtain a polyimide film;

[0027] The thermally conductive filler includes a first thermally conductive filler with a particle size of 100nm-200nm, a second thermally conductive filler with a particle size of 50nm-100nm, and a third thermally conductive filler with a particle size of 10nm-50nm.

[0028] In the present invention, the thermally conductive filler, solvent and coupling agent are firstly mixed and ground to obtain a slurry; the thermally conductive filler preferably includes a first thermally conductive filler with a part...

Embodiment 1

[0042] 1kg of 3-aminopropyltriethoxysilane, N, N-dimethylacetamide 100kg, 35kg of aluminum nitride with an average particle diameter of 200nm, 10kg of aluminum nitride with an average particle diameter of 100nm, and an average particle diameter of 5kg of 50nm aluminum nitride, mixed evenly by a high-speed disperser, then transferred to a horizontal sand mill for grinding, and the dispersion and distribution of nano-aluminum nitride were detected by a particle size analyzer. When the polydispersity index is less than 1.05, the grinding is stopped, and the slurry is obtained.

[0043] Stir to dissolve 43.06kg of 4,4'-diaminodiphenyl ether and 360kg of N,N-dimethylacetamide to obtain a mixed solution, then gradually add 46.94kg of pyromellitic dianhydride to the above solution In, obtain the polyamic acid resin that viscosity is 60000CP.

[0044] Add 30 kg of the slurry into the above polyamic acid resin, stir and mix evenly to obtain the polyamic acid resin filled with aluminum...

Embodiment 2

[0047] 1kg of 3-aminopropyltriethoxysilane, N, N-dimethylacetamide 100kg, 35kg of aluminum nitride with an average particle diameter of 200nm, 10kg of aluminum nitride with an average particle diameter of 100nm, and an average particle diameter of 5kg of 50nm aluminum nitride, mixed evenly by a high-speed disperser, then transferred to a horizontal sand mill for grinding, and the dispersion and distribution of nano-aluminum nitride were detected by a particle size analyzer. When the polydispersity index is less than 1.05, the grinding is stopped, and the slurry is obtained.

[0048] Stir to dissolve 43.06kg of 4,4'-diaminodiphenyl ether and 360kg of N,N-dimethylacetamide to obtain a mixed solution, then gradually add 46.94kg of pyromellitic dianhydride to the above solution , Obtaining the polyamic acid resin that viscosity is 50000CP.

[0049] Add 20kg of the slurry into the above polyamic acid resin, stir and mix evenly to obtain the polyamic acid resin filled with aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com