Coating composition, it's coating layer, antireflection coating, antireflection film, image display and intermediate product

a technology of coating composition and coating layer, applied in the direction of cellulosic plastic layered products, physical/chemical process catalysts, instruments, etc., can solve the problems of poor efficiency in using coating liquid, difficult to enlarge the area of a thin layer of high refractive index layer and middle refractive index layer, and increase production costs. , to achieve the effect of good refractory performance, good refractory performance and good refractory performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0221](1) Preparation of Coating Composition

[0222]As the rutile-type titanium oxide, rutile-type titanium oxide (TTO51 (C), manufactured by Ishihara Sangyo Corporation, Ltd.) in which the titanium oxide content is 79 to 85%, its surface had been treated with Al2O3 and stearic acid, the primary particle size is 0.01 to 0.03 μm, the specific surface area is 50 to 60 m2 / g, the oil absorption is 24 to 30 g / 100 g, and its surface shows water-repellency was provided. As the binder component having an ionizing radiation-curing property, pentaerythritol triacrylate (PET30, manufactured by Nippon Kayaku Co., Ltd.) was provided. As the dispersing agent having an anionic polar group, a block copolymer showing affinity with a pigment (Disperbyk 163, manufactured by BYK-Chemie Japan) was provided. As the photo-initiator, 1-hydroxy-cyclohexyl-phenyl-ketone (Irgacure 184, manufactured by Nippon Chiba Geigy) was provided. As the organic solvent, methyl isobutyl ketone was provided.

[0223]The rutile ...

example 2

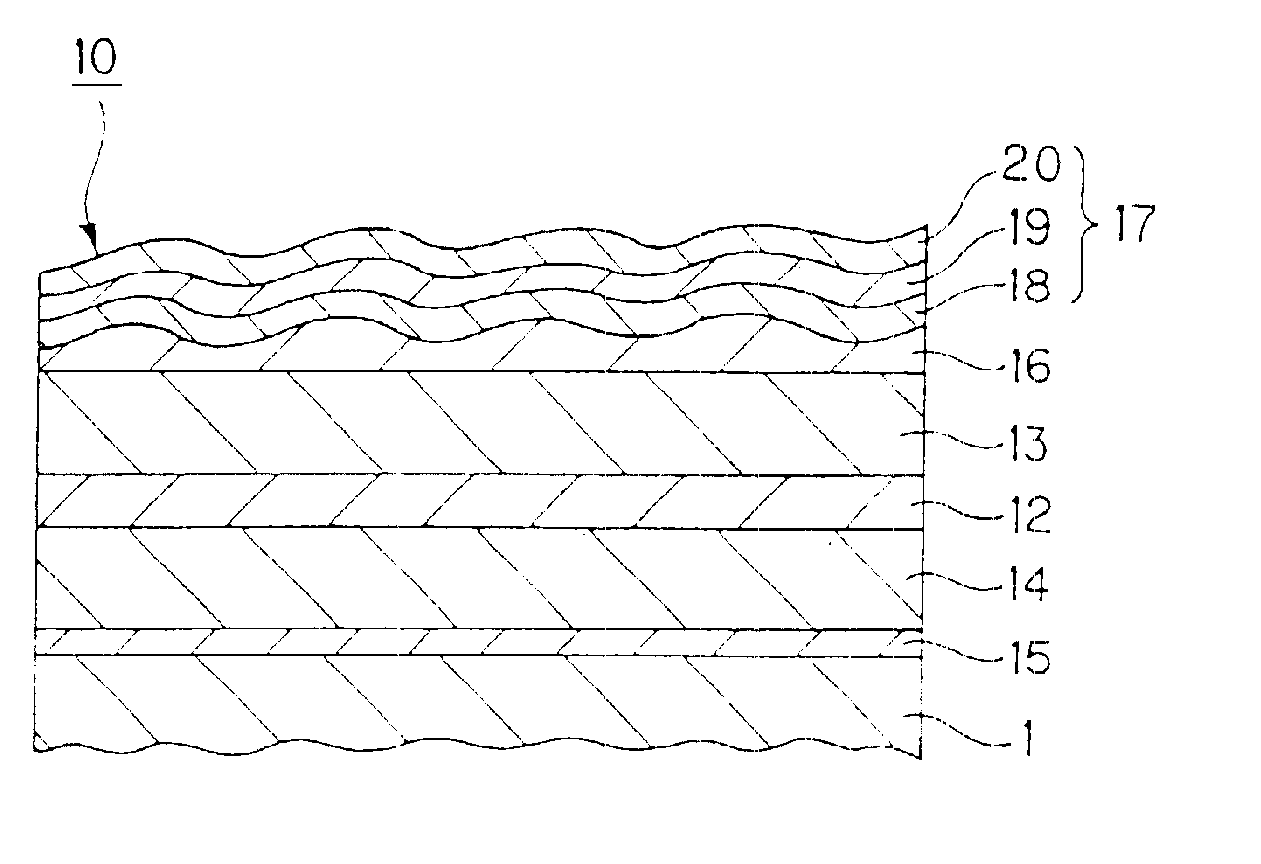

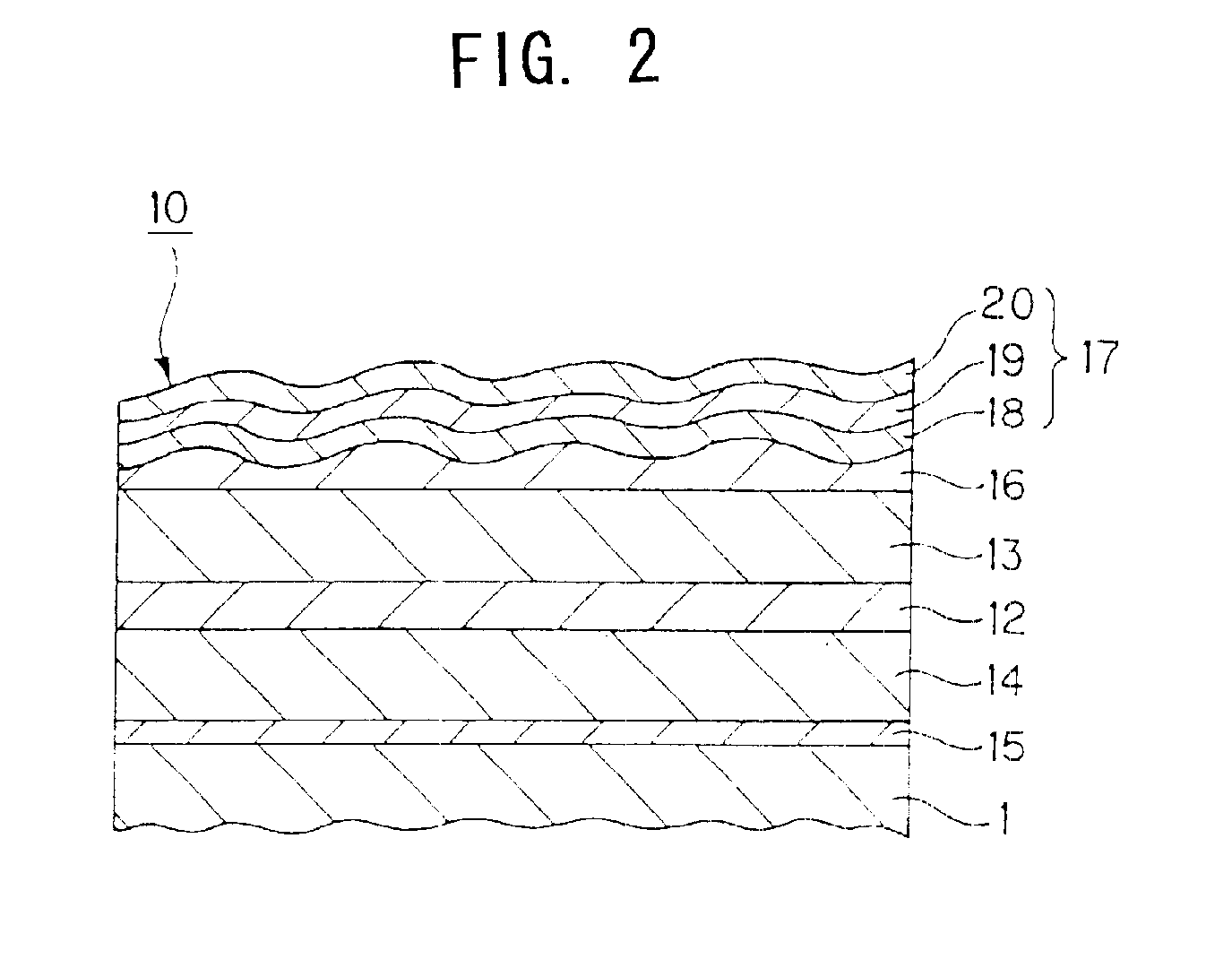

[0249]In this example, an antireflection film F1 having a constitution shown in FIG. 4 was produced. The antireflection film F1 has a constitution in which a clear hard coat layer 25, middle refractive index layer 26, high refractive index layer 27 and low refractive index layer 28 are laminated sequentially on a substrate film 24, and of them, the high refractive index layer and middle refractive index layer were formed by using the coating composition of the present invention.

[0250](1) Preparation of Coating Liquid for High Refractive Index Layer

[0251]As the rutile-type titanium oxide, rutile-type titanium oxide having a primary particle size of about 0.03 μm, coated with Al2O3 and stearic acid, was provided in an amount of 100 parts. As the binder component having an ionizing radiation-curing property, pentaerythritol triacrylate (PET30, manufactured by Nippon Kayaku Co., Ltd.) was provided in an amount of 20 parts. As the dispersing agent, a dispersing agent having an ethylene o...

example 3

[0271]In this example, an antireflection film F2 having a constitution shown in FIG. 5 was produced. The antireflection film F2 has a constitution in which a clear hard coat layer 25, high refractive index layer 27 and low refractive index layer 28 are laminated sequentially on a substrate film 24, and of them, the high refractive index layer was formed by using the coating composition of the present invention.

[0272](1) Preparation of Coating Liquid for High Refractive Index Layer

[0273]As the rutile-type titanium oxide, rutile-type titanium oxide having a primary particle size of about 0.03 μm, coated with ZrO2 and stearic acid, was provided in an amount of 100 parts. As the binder component having an ionizing radiation-curing property, pentaerythritol triacrylate (PET30, manufactured by Nippon Kayaku Co., Ltd.) was provided in an amount of 40 parts. As the dispersing agent, a dispersing agent having an ethylene oxide chain and having an anionic polar group was provided in an amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com