Method for preparing nano Fe3O4/SiO2 composite aerogel granule by supercritical process

A composite aerogel, supercritical technology, applied in chemical instruments and methods, colloidal chemistry, colloidal chemistry, etc., can solve problems such as uneven distribution of nanoparticles that are easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

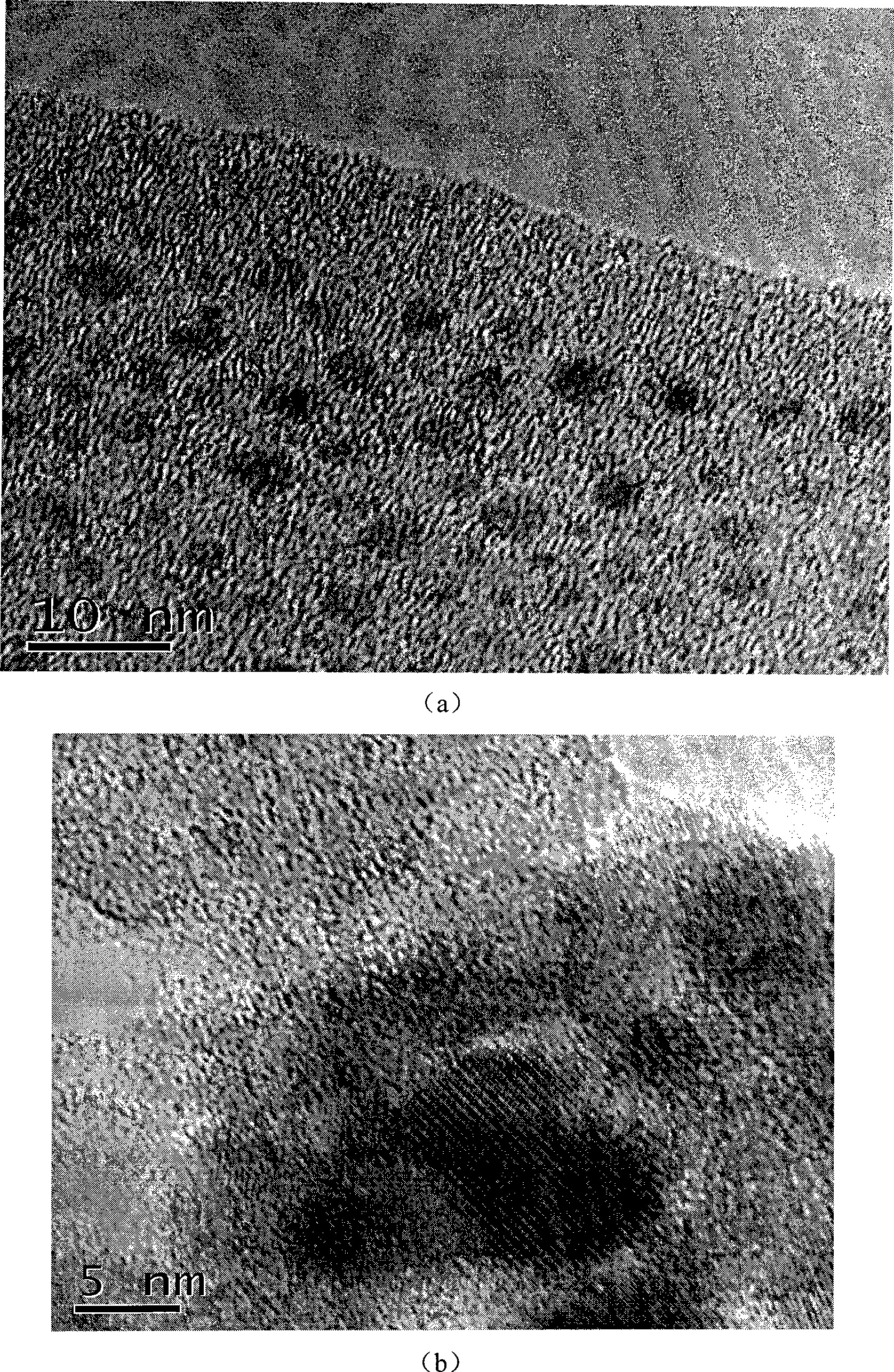

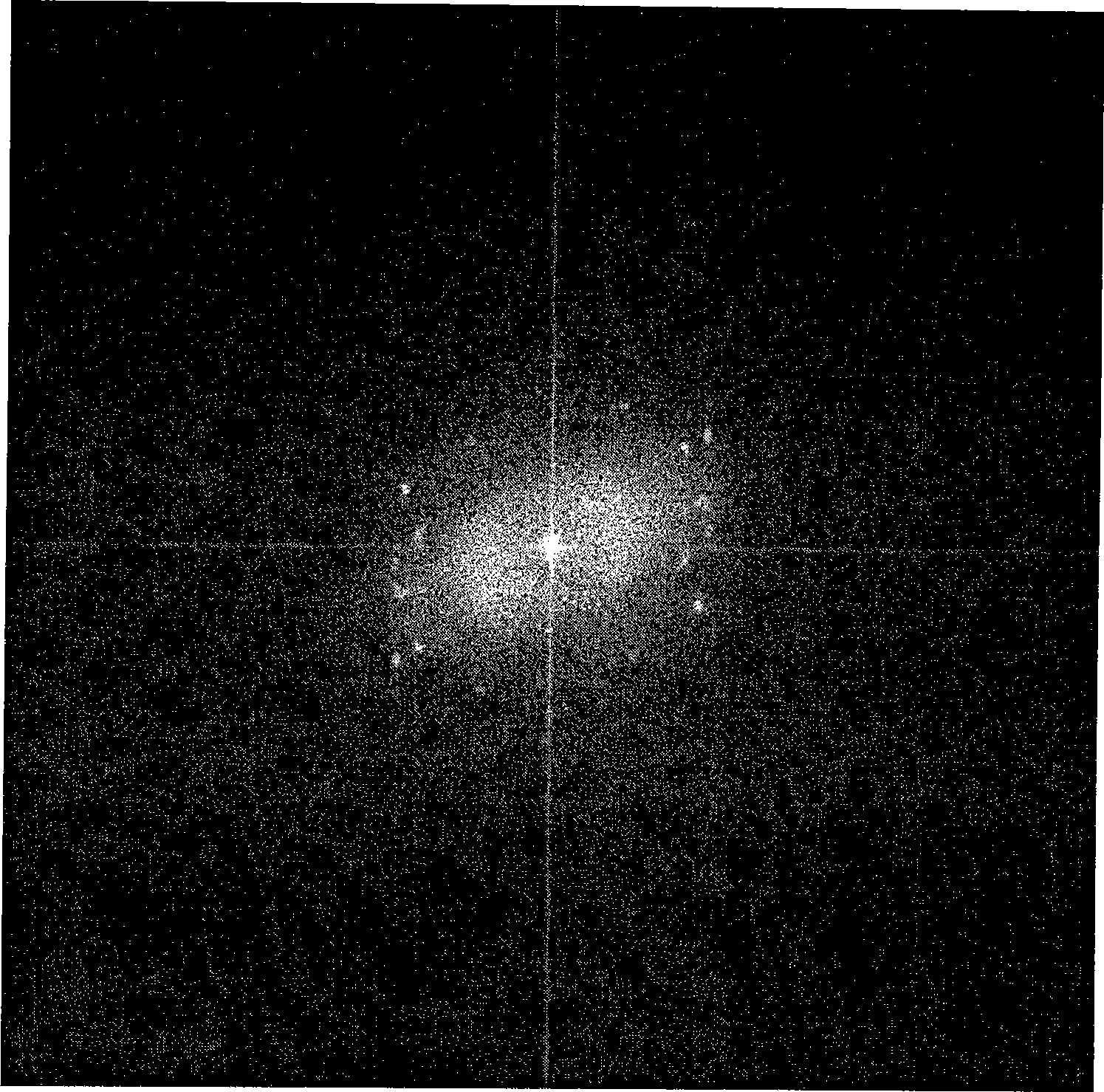

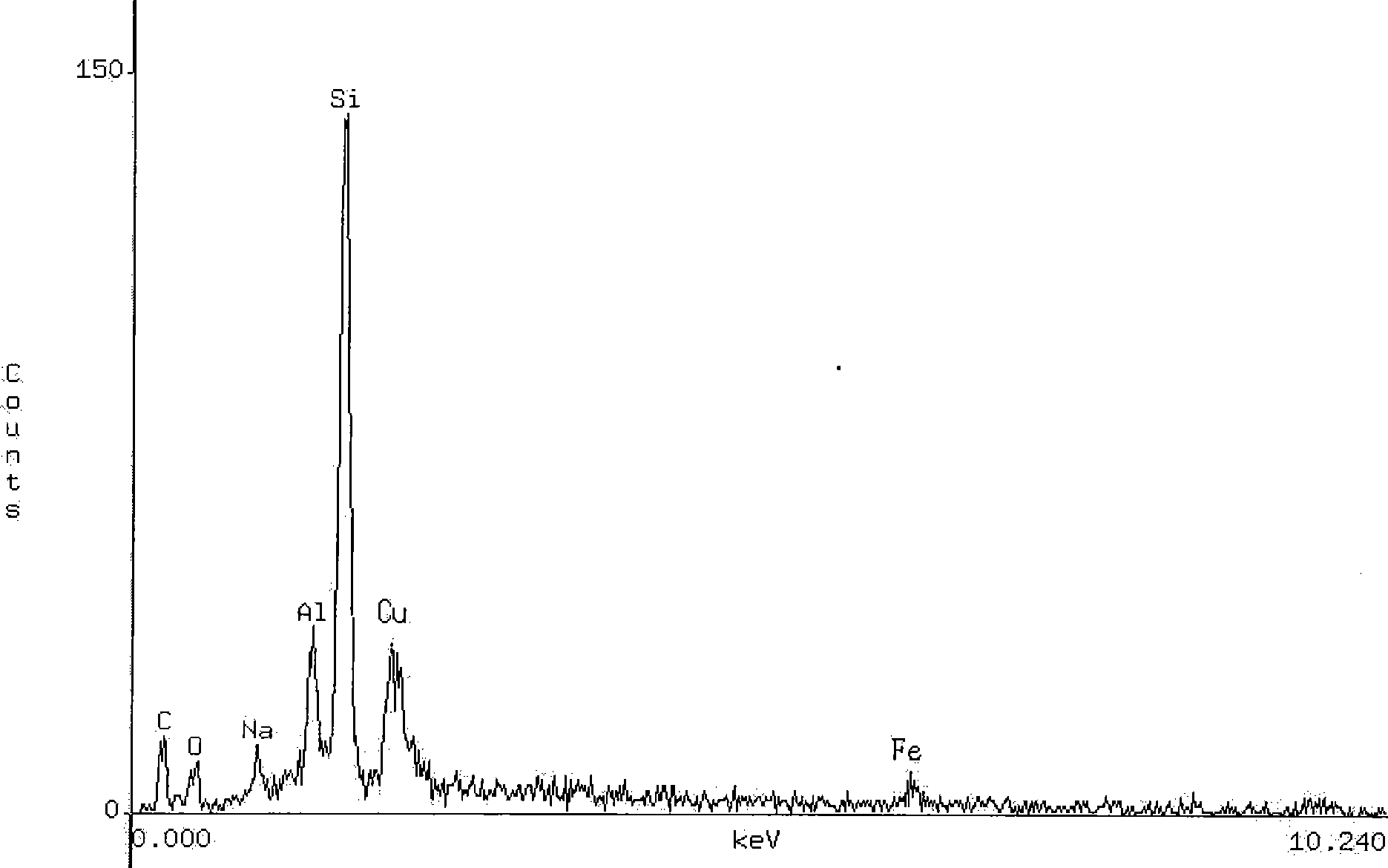

Embodiment 1

[0034] Prepare FeCl according to the condition that the total iron concentration is 0.5mol / L 2 4H 2 O and FeCl 3 ·6H 2 Mixed aqueous solution of O, where Fe 2+ with Fe 3+ The molar ratio is 8:1, stir to dissolve, then add 20mL 1mol / L NaOH ethanol solution, stir rapidly, wash the mixed colloid with absolute ethanol 3 times, ultrasonically break, the ultrasonic frequency is 20KHz, and the ultrasonic time is 10min, so that the colloid is uniform Dispersion in ethanol, where Fe(OH) 2 with Fe(OH) 3 The molar ratio is 8:1. Add 50mL of absolute ethanol, 2mL of 1mol / L HCl solution and 5.4mL of twice distilled water to 11.2mL tetraethyl orthosilicate, heat and stir for 6.5h, control the temperature at 85°C, and completely hydrolyze tetraethyl orthosilicate to form Si(OH) 4 . Fe(OH) 2 with Fe(OH) 3 The mixed colloids are quickly added to the Si(OH) 4 , stirring continuously, adding 1:2 KOH ethanol solution to adjust the pH value to 8.9, and keeping the temperature in a const...

Embodiment 2

[0039] Prepare FeSO under the condition that the total iron concentration is 0.1mol / L 4 ·6H 2 O and Fe(NO 3 ) 3 9H 2 Mixed aqueous solution of O, where Fe 2+ with Fe 3+ The molar ratio is 1:1, stir quickly to dissolve, then add 60mL0.1mol / L ammonia water ethanol solution, stir quickly, wash the mixed colloid with absolute ethanol 5 times, ultrasonically break, the ultrasonic dispersion frequency is 60KHz, and the ultrasonic time is 6min , so that the colloid is uniformly dispersed in ethanol, where Fe(OH) 2 with Fe(OH) 3 The molar ratio is 1:1. in Na 2 SiO 4Add 1 mL of 1.5 mol / L HCl solution and 7 mL of distilled water into the ethanol solution, heat and stir for 1 h, and control the temperature at 70 °C to make Na 2 SiO 4 Complete hydrolysis to Si(OH) 4 . Fe(OH) 2 with Fe(OH) 3 The mixed colloids are quickly added to the Si(OH) 4 , stirring continuously, adding 1:50 NaOH ethanol solution to adjust the pH value to 7.8, keeping the temperature in a constant temp...

Embodiment 3

[0043] Prepare FeCl according to the condition that the total iron concentration is 0.1mol / L 2 4H 2 O and FeCl 3 ·6H 2 Mixed ethanol solution of O, where Fe 2+ with Fe 3+ The molar ratio is 1:4, stir quickly to dissolve, then add 10mL1.2mol / L NaOH ethanol solution, stir quickly, wash the mixed colloid with absolute ethanol 3 times, ultrasonically break, ultrasonic dispersion frequency is 100KHz, ultrasonic time is 4min, Make the colloid evenly dispersed in ethanol, where Fe(OH) 2 with Fe(OH) 3 The molar ratio is 1:4. Add 0.6 mL of 1 mol / L HCl solution and 5.4 mL of distilled water into the ethanol solution of tetraethyl orthosilicate, heat and stir for 1 hour, and control the temperature at 60°C to completely hydrolyze tetraethyl orthosilicate to generate Si(OH) 4 . Fe(OH) 2 with Fe(OH) 3 The mixed colloids are quickly added to the Si(OH) 4 , stirring continuously, adding 1:20 ammonia water ethanol solution to adjust the pH value to 8.6, and keeping the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com