Lubricating oil composition and preparation method thereof

A lubricating liquid composition and liquefied technology, which is applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of not having the anti-corrosion and compatibility of aluminum alloy at the same time, so that it is not easy to delaminate and has good economy , the effect of uniform dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

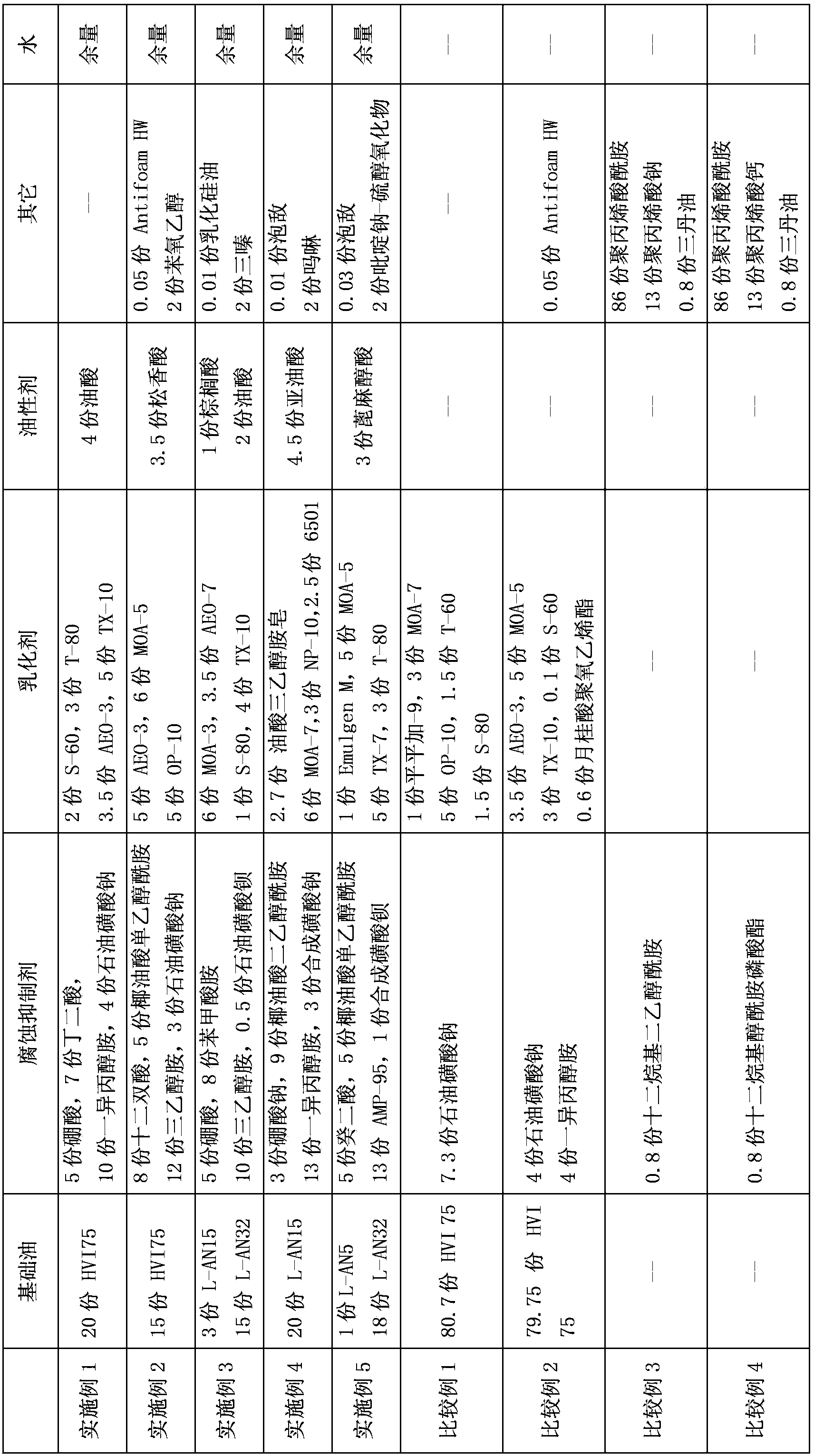

[0022] Pump the base oil into the blending kettle, turn on the stirrer and the heating switch, and when the oil is heated to 40°C, add the required amount of each component in turn, and keep stirring at 40°C for 3 hours to obtain a light yellow uniform liquid. The liquid was diluted with water at a ratio of 10% by weight and then tested for performance. The components and contents in the lubricating fluid composition are shown in Table 1, and the corresponding performance indexes are shown in Table 2. in FIG. 1,

[0023] T-80, sorbitol oleate polyoxyethylene ether, Tianjin Auxiliary Factory

6501, dodecyldiethanolamide, Shanghai No. 2 Auxiliary Factory

S-80, Sorbitan Oleate, Tianjin Auxiliary Factory

Emulgen M, fatty acid ethoxylates, Clariant Corporation

S-60, sorbitan oleate, Tianjin Auxiliary Factory

OP-10, polyoxyethylene sec-octylphenol ether-10, Lushun Chemical Plant

TX-10, octylphenol polyoxyethylene ether 10, Shanghai High Chemi...

Embodiment 6

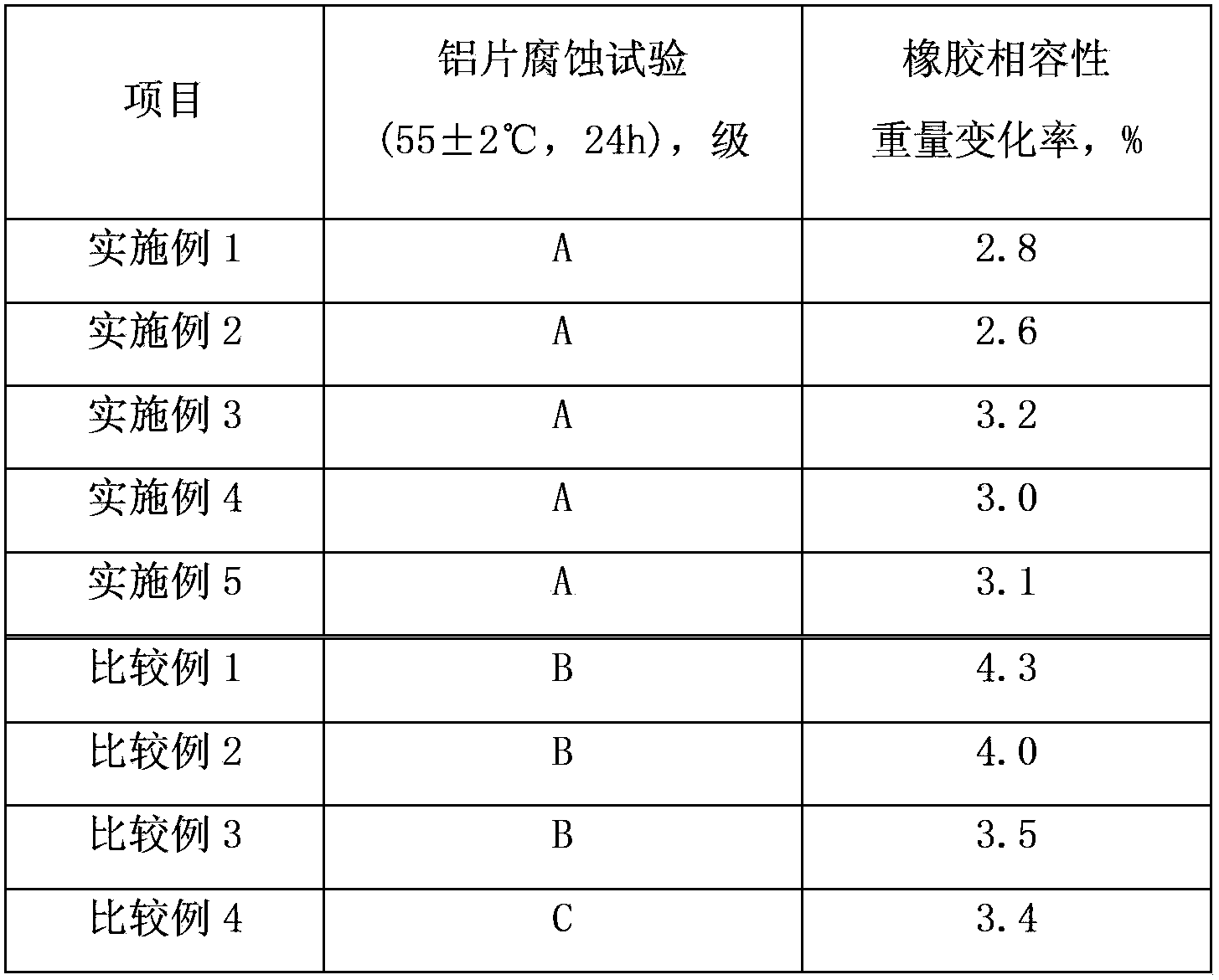

[0031] The lubricating liquid compositions of [Examples 1 to 5] were diluted with water in a proportion of 10% by weight, and then used for assembly lubrication of automobile tires. During use, it shows good lubricating performance, saving time and effort. After the tires are assembled and placed for 30 days, the aluminum alloy rims are as shiny as new, the assembly fluid has played a role in rust prevention and protection, and at the same time has good compatibility with tire rubber, and the tire has good air tightness.

[0032] Table 1

[0033]

[0034] Table 2

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com