Lithium battery positive electrode slurry and preparation method thereof

A positive electrode slurry, lithium battery technology, applied in the direction of battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of conductive agents and other solid substances that cannot be uniformly and stably dispersed, poor battery capacity performance, and fast capacity decay speed , to achieve the effect of long service life, convenient operation and high capacity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

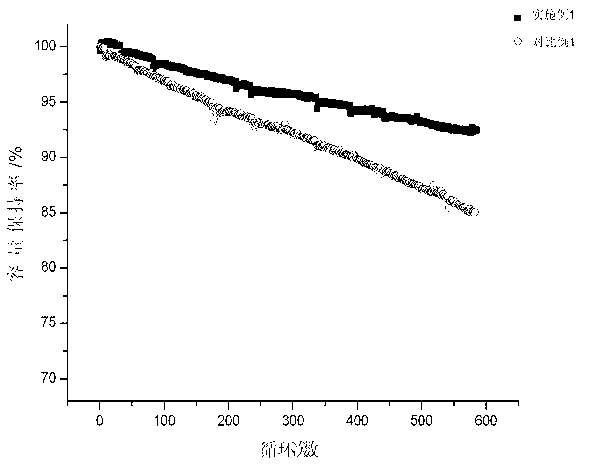

Embodiment 1

[0033] Firstly, various substances required for preparing positive electrode materials were weighed in proportion, and the specific proportions are shown in Table 1, and ordinary planetary slurry mixer was used for stirring.

[0034] First add 5% N-methylpyrrolidone of the mass of the positive electrode material into the stirring tank of the planetary slurry mixer, then add the conductivity enhancer and dispersant to obtain the first slurry, and measure the fineness every 10 minutes after stirring until the first The fineness of the slurry is 150nm; then add the binder and stir until the binder dissolves; then add the conductive agent and N-methylpyrrolidone which is 40% of the mass of the positive electrode material to obtain the second slurry, and measure the fineness every 10 minutes after stirring. until the fineness of the second slurry is 150nm; finally add the positive active material to obtain the coarse slurry, and measure the fineness every 10min after stirring until ...

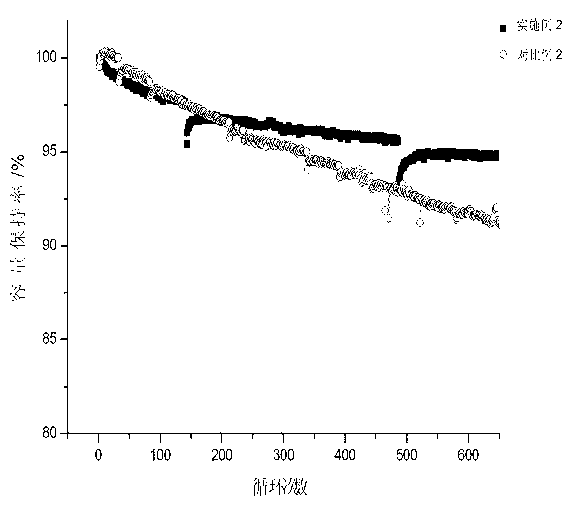

Embodiment 2

[0040] Firstly, various substances required for preparing positive electrode materials were weighed in proportion, and the specific proportions are shown in Table 1, and ordinary planetary slurry mixer was used for stirring.

[0041] First add 25% N-methylpyrrolidone of the mass of the positive electrode material into the stirring tank of the planetary slurry mixer, then add the conductivity enhancer and dispersant to obtain the first slurry, and measure the fineness every 20 minutes until the first The fineness of the slurry is 20 μm; then add the binder and stir until the binder dissolves; then add the conductive agent and N-methylpyrrolidone which is 60% of the mass of the positive electrode material to obtain the second slurry, and measure the fineness every 20 minutes after stirring. until the fineness of the second slurry is 20 μm; finally add the positive active material to get the coarse slurry, and measure the fineness every 20 minutes until the fineness of the coarse ...

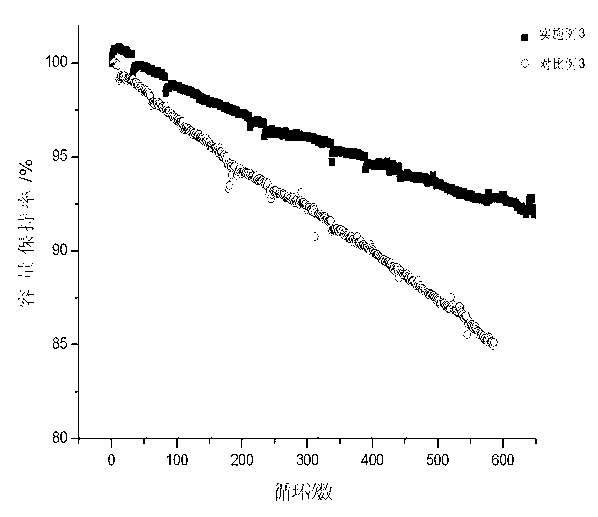

Embodiment 3

[0047] Firstly, various substances required for preparing positive electrode materials were weighed in proportion, and the specific proportions are shown in Table 1, and ordinary planetary slurry mixer was used for stirring.

[0048] First add N-methylpyrrolidone which is 20% of the mass of the positive electrode material into the stirring tank of the planetary slurry mixer, then add the conductivity enhancer and dispersant to obtain the first slurry, and measure the fineness every 15 minutes after stirring until the first The fineness of the slurry is 250nm; then add the binder and stir until the binder dissolves; then add the conductive agent and N-methylpyrrolidone which is 45% of the mass of the positive electrode material to obtain the second slurry, and measure the fineness every 15 minutes after stirring. until the fineness of the second slurry is 10 μm; finally add the positive active material to obtain the coarse slurry, and measure the fineness every 12 minutes until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com