Low cost recyclable conductive paste and preparation method thereof

A conductive paste, low-cost technology, applied to conductive layers on insulating carriers, cable/conductor manufacturing, circuits, etc., can solve problems such as environmental pollution, high cost of high-performance conductive pastes, and low safety in use. Solve the effect of high price, fast film forming speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

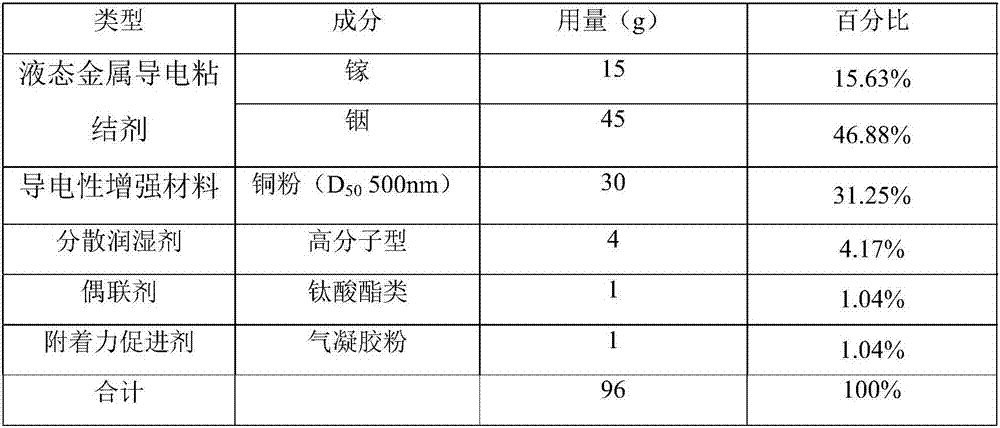

[0032] The formula composition of the low-cost recyclable high-conductivity paste of this embodiment is shown in the following table:

[0033]

[0034] The preparation method of this conductive paste is:

[0035] Step 1: smelting of the liquid metal conductive adhesive, the liquid metal raw materials (elemental gallium, elemental indium) are respectively subjected to reduction treatment in a reduction furnace under the protection of hydrogen to remove oxides on the surface of the raw materials. Proportional sampling and weighing of the two raw materials after reduction treatment are put together into a vacuum melting furnace or an atmosphere furnace for melting. The smelted alloy liquid is poured into ingots or filled into containers in a vacuum furnace or an atmosphere furnace for later use.

[0036] Step 2: Weigh the above-mentioned liquid metal conductive adhesive according to the proportion, add it into a container protected by an inert gas, heat until it is 10°C to 20...

Embodiment 2

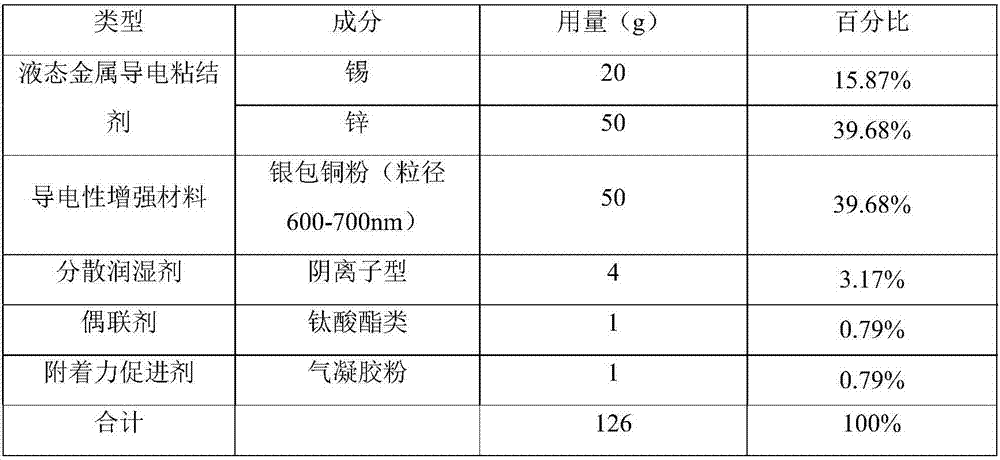

[0039] The formula composition of a low-cost recyclable high-conductivity paste is shown in the following table:

[0040]

[0041] In the preparation step 2, the smelted liquid metal conductive adhesive is weighed according to the proportion, added into a container protected by an inert gas, and heated until it is 10°C to 200°C above its melting point (heating temperature is 230°C). The grinding time is 3.5h (the amount of conductive enhancing material is large, and the particle size is slightly larger, so it needs to be grinded for about 0.5h). Other operations are the same as in Example 1.

Embodiment 3

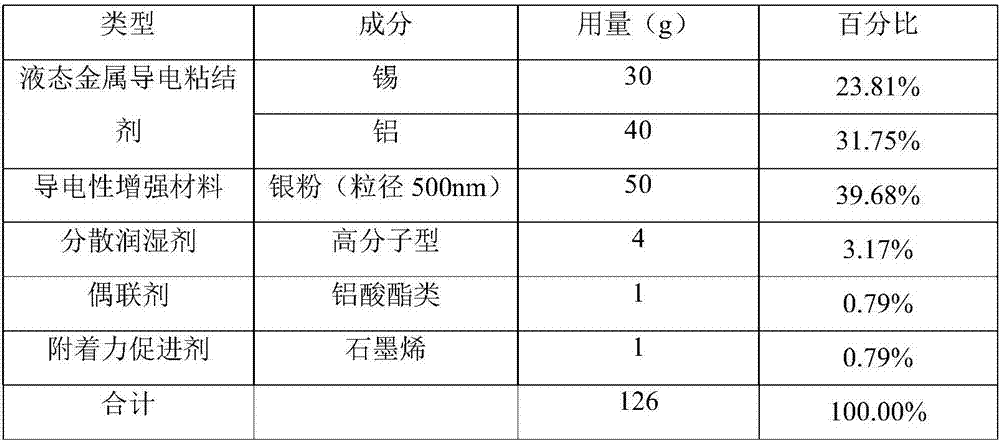

[0043] The formula composition of a low-cost recyclable high-conductivity paste is shown in the following table:

[0044]

[0045] The dispersing and wetting agent in the table is BYK-190, a non-ionic polymer dispersing agent.

[0046]In this embodiment, silver powder is used as the conductive enhancing material. Silver powder has the characteristics of good conductivity and strong oxidation resistance. The contact resistance between the interfaces of the conductive paths formed together is small. In addition, the silver powder used in the present invention has the characteristics of high sphericity and uniform particle size distribution, so it is easy to disperse evenly, significantly reducing the amount of non-conductive dispersing wetting agent and coupling agent; The conductivity of alkene is relatively good, and the material of this embodiment has better conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com