Liquid crystal medium composite as well as liquid crystal display using same and manufacturing method of liquid crystal medium composite

A liquid crystal display and liquid crystal medium technology, applied in chemical instruments and methods, liquid crystal materials, instruments, etc., can solve problems such as price reduction damage, lack of mass production, uneven RM reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

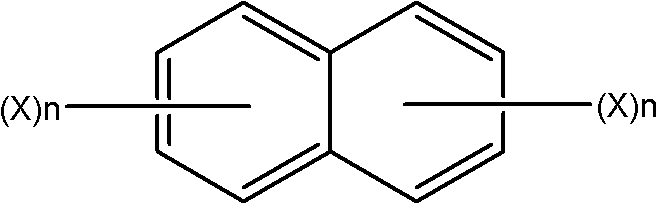

[0120] Make the upper and lower substrates. There are Data lines, Gate lines, TFT arrays, ITO pixel electrodes and common electrodes on the lower substrate. The surface of the substrate is coated with an alignment layer; there are black matrix and R, G, B pixels on the upper substrate. The spacing support, the common electrode, the outermost surface of which is also coated with an alignment layer; a negative type liquid crystal material is used and mixed with a polymerizable monomer, a sensitizer and a stabilizer to obtain a liquid crystal medium composition. Wherein the molecular structure of the sensitizer is as follows:

[0121]

[0122] The addition amount of the sensitizer in the liquid crystal medium composition is 70ppm. After the upper and lower substrates are combined with the liquid crystal medium to form a panel, ultraviolet light with a wavelength of 310-380nm is used to irradiate the panel from the direction of the upper substrate, so that the polymerizable mon...

Embodiment 2-7

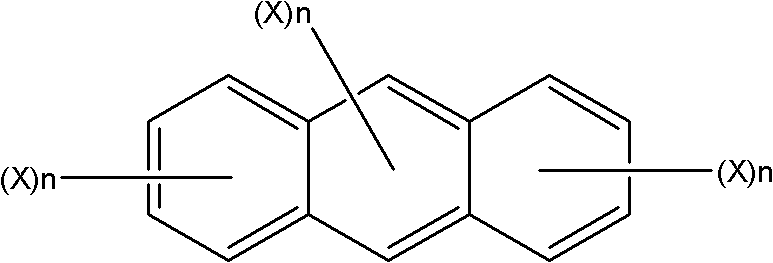

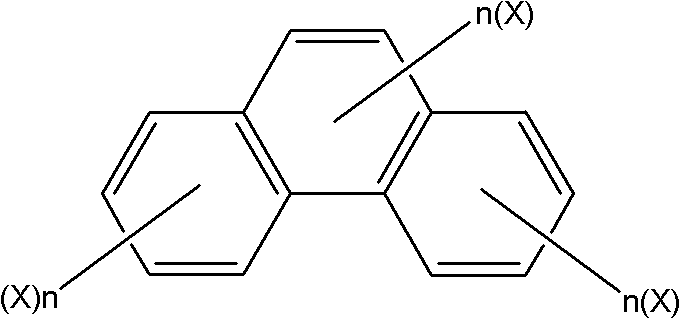

[0124] Referring to Example 1, the difference is that the molecular structure and content of the sensitizer and the wavelength range of ultraviolet light are different, see Table 1 below for details.

[0125] Table 1. The sensitizer molecular structure, content and ultraviolet light wavelength range of embodiment 2-7

[0126]

[0127]

[0128] In summary, the liquid crystal medium composition of the present invention moves the reaction wavelength of the polymerizable monomer from 200-300nm to 300-380nm by adding a sensitizer, avoiding the absorption band of the liquid crystal material, and improving the polymerizable Monomer reaction efficiency and uniformity. The liquid crystal display made of the liquid crystal medium composition adopts ultraviolet light with a wavelength of 300-380nm, which avoids the absorption band of the liquid crystal material, and greatly reduces the damage of the ultraviolet light to the liquid crystal material and the alignment material PI of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com