Method for preparing organic silicon modified propenoic ester copolymer emusion by fine emulsion polymerizing method

A technology of miniemulsion polymerization and acrylate, which is applied in the field of preparing silicone-modified acrylate copolymer emulsion, which can solve the problems of affecting the effect of silicone modification, increasing silicon-containing branch chains, and difficulty in stretching, so as to reduce the dosage, High system stability, easy to control the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

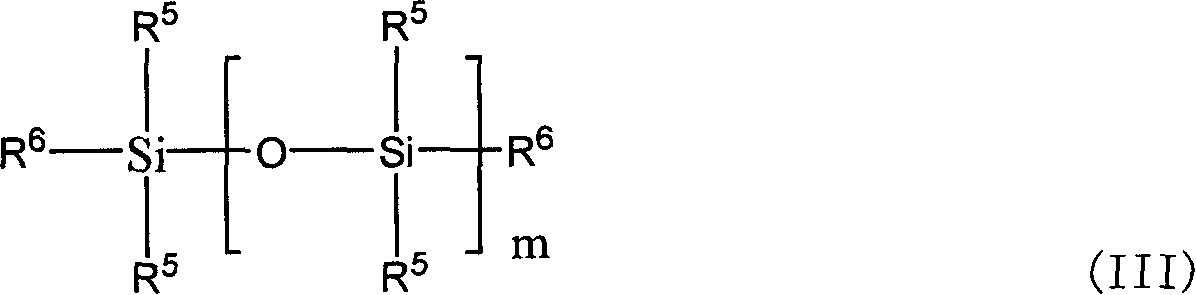

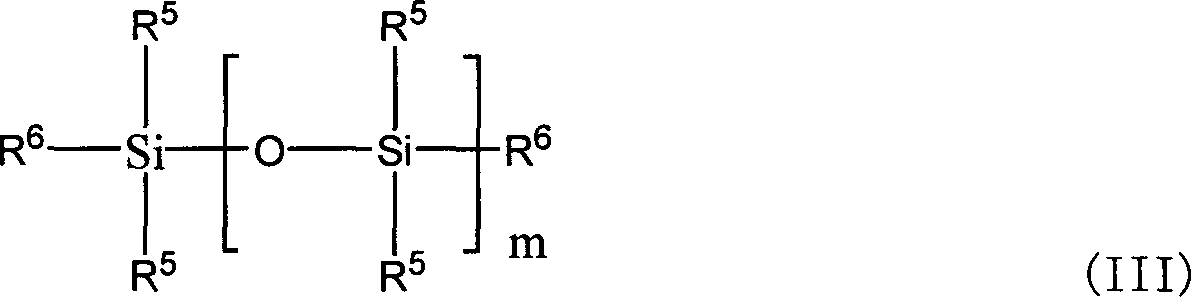

Method used

Image

Examples

Embodiment 1

[0030] 1) 0.8 gram of sodium lauryl sulfate is dissolved in 75 grams of water to form an aqueous phase solution;

[0031] 2) Mix and stir 10 grams of styrene, 10 grams of butyl acrylate, 0.3 grams of vinyltriethoxysilane, 1 gram of methyltrimethoxysilane, and 1 gram of dimethyldimethoxysilane to form an oil phase solution ;

[0032]3) Mix the above water phase solution and oil phase solution, stir magnetically in an ice-water bath for 10 minutes, and then use Ningbo Kesheng KS-600 Sonifier (amplitude 70%, 600W) to ultrasonically pulverize for 15 minutes to form a fine emulsion;

[0033] 4) The fine emulsion is moved into a reactor equipped with a mechanical stirring condensing reflux device, a nitrogen gas inlet, and a feeding port. After 30 minutes of deoxygenation with nitrogen gas, it is passed into a 60°C hot water bath, and an aqueous solution of potassium persulfate (0.15 grams of dissolved Initiate polymerization in 5 grams of water), and after 3 hours of polymerizatio...

Embodiment 2

[0035] 1) 0.8 gram of sodium lauryl sulfate is dissolved in 75 grams of water to form an aqueous phase solution;

[0036] 2) Mix 10 grams of methyl styrene, 10 grams of butyl acrylate, 0.3 grams of vinyltriethoxysilane, 1 gram of methyltrimethoxysilane, 1 gram of dimethyldimethoxysilane, 0.4 grams of sixteen Alkanes are mixed and stirred to form an oil phase solution;

[0037] 3) Mix the above water phase solution and oil phase solution, stir magnetically in an ice-water bath for 10 minutes, and then use Ningbo Kesheng KS-600 Sonifier (amplitude 70%, 600W) to ultrasonically pulverize for 15 minutes to form a fine emulsion;

[0038] 4) The fine emulsion is moved into a reactor equipped with a mechanical stirring condensing reflux device, a nitrogen gas inlet, and a feeding port. After 30 minutes of deoxygenation with nitrogen gas, it is passed into a 60°C hot water bath, and an aqueous solution of potassium persulfate (0.15 grams of dissolved Initiate polymerization in 5 grams...

Embodiment 3

[0040] 1) 0.8 gram of sodium lauryl sulfate is dissolved in 75 grams of water to form an aqueous phase solution;

[0041] 2) Mix 10 grams of methylstyrene, 10 grams of butyl acrylate, 0.3 grams of γ-methacryloxypropyltrimethoxysilane, 1 gram of methyltrimethoxysilane, 1 gram of dimethyldimethoxy Silane and 0.4 gram of stearyl alcohol are mixed and stirred to form an oil phase solution;

[0042] 3) Mix the above water phase solution and oil phase solution, stir magnetically in an ice-water bath for 10 minutes, and then use Ningbo Kesheng KS-600 Sonifier (amplitude 70%, 600W) to ultrasonically pulverize for 15 minutes to form a fine emulsion;

[0043] 4) The fine emulsion is moved into a reactor equipped with a mechanical stirring condensing reflux device, a nitrogen gas inlet, and a feeding port. After 30 minutes of deoxygenation with nitrogen gas, it is passed into a 60°C hot water bath, and an aqueous solution of potassium persulfate (0.15 grams of dissolved Initiate polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com