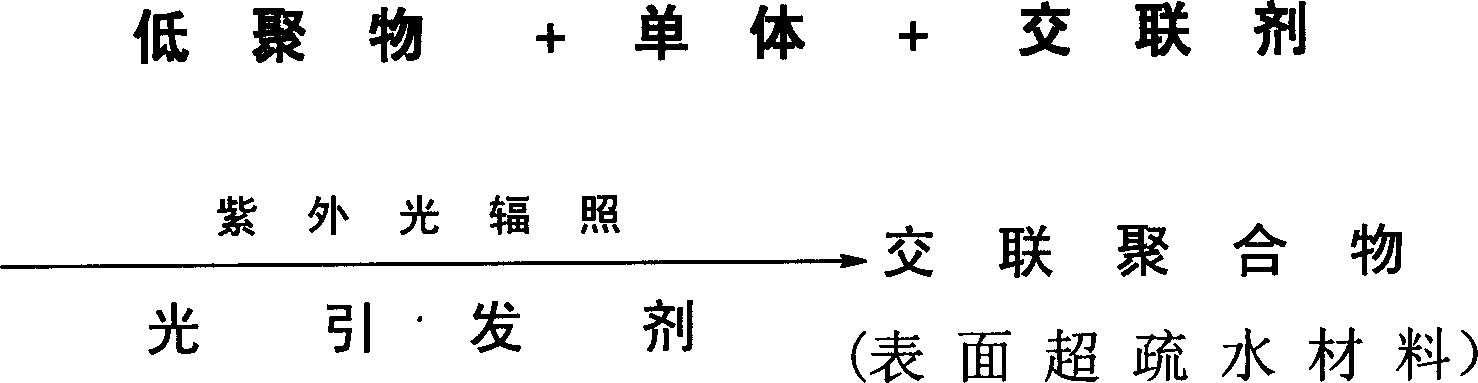

Soft template and ultraviolet curing process to prepare surface super hydrophobic material

A soft template and super-hydrophobic technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of complex process and equipment requirements, reduced super-hydrophobic performance, and insufficiently low surface energy, achieving low cost and low pollution , the effect of high polymerization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

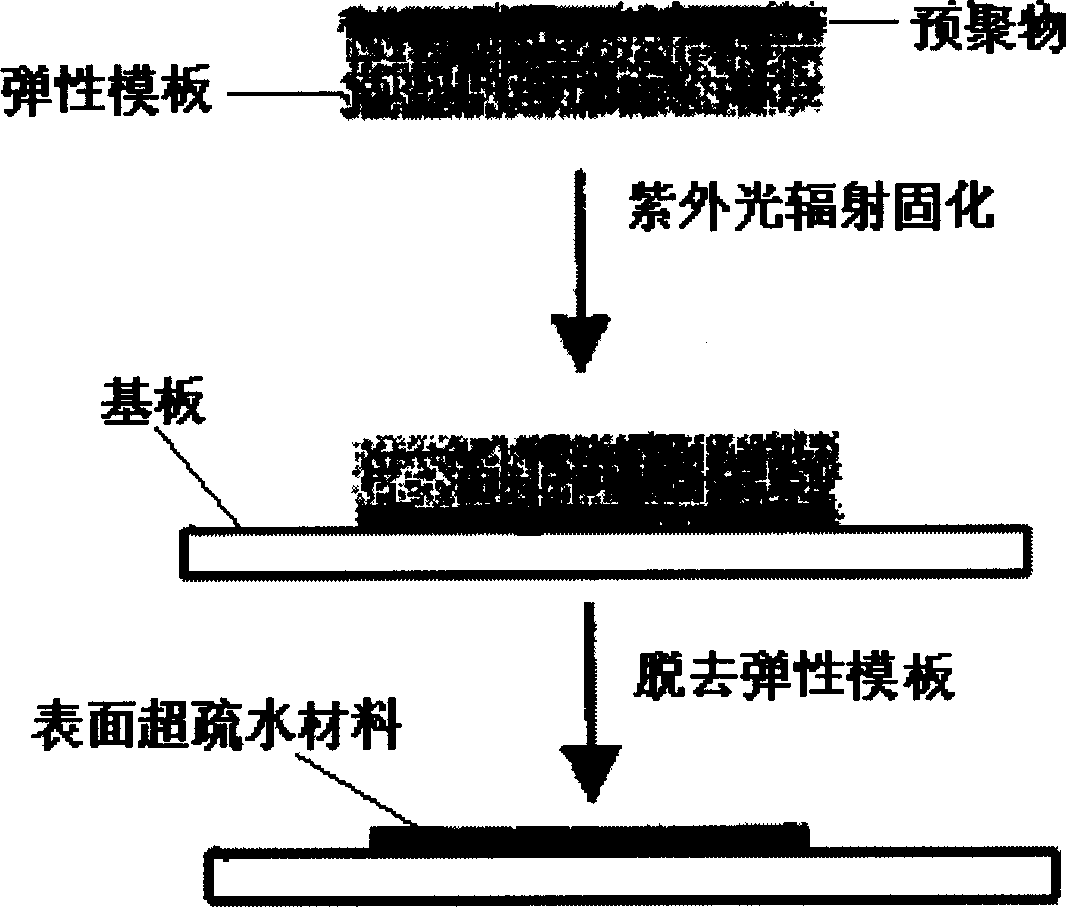

[0035] Mix polydimethylsiloxane (PDMS, sylgard 184, purchased from Dow Corning Company) prepolymer (siliconeelastomer base) and crosslinking agent (silicone elastomer curing agent) in a mass ratio of 10:1, pour until clean On the flat surface of the lotus leaf, after standing for 20 minutes, it will become an elastomer after being heated and cured. The reaction temperature is 40°C, and the reaction time is 4 hours; After curing, the PDMS elastic template can be obtained by peeling off.

[0036] Oligomer EMA 2g, oligomer UA 1g; monomer IBA 0.5g, monomer AE 0.5g; crosslinking agent N, N'-methylenebisacrylamide 0.25g; photoinitiator α-hydroxycyclohexyl 0.2 g of phenyl ketone was mixed uniformly to prepare a prepolymer. Place the prepolymer between the glass substrate and the elastic template, and expose it to ultraviolet light for 8 minutes. The light source is a high-pressure mercury lamp with a main emission wavelength of 365nm, and the intensity of ultraviolet light is I=10mW...

Embodiment 2

[0038] Mix the prepolymer and crosslinking agent of polydimethylsiloxane (PDMS, sylgard 184, purchased from Dow Corning Company) uniformly in a mass ratio of 3:1, pour it on the clean and flat lotus leaf surface, and let it stand for 10 Minutes later, it becomes an elastomer after being heated and cured. The reaction temperature is 30°C, and the reaction time is 2 hours; After curing, the PDMS elastic template can be obtained by peeling off.

[0039] Mix oligomer EA 1g, oligomer SUA 5g; monomer MDA 0.5g, monomer IBA 0.3g; crosslinking agent diethylene glycol diacrylate 1.2g; photoinitiator benzoin dimethyl ether 0.25g and mix well, Prepared as a prepolymer. Place the prepolymer between the silicon substrate and the elastic template, and expose it to ultraviolet light for 2 minutes. The light source is a high-pressure mercury lamp with a main emission wavelength of 365nm, and the intensity of ultraviolet light is I=10mW / cm 2 , the prepolymer is polymerized and cross-linked, a...

Embodiment 3

[0041] Mix the prepolymer and crosslinking agent of polydimethylsiloxane (PDMS, sylgard 184, purchased from Dow Corning Company) in a mass ratio of 7:1, pour it onto the clean and flat lotus leaf surface, and let it stand for 40 Minutes later, it will become an elastomer after being heated and solidified. The reaction temperature is 50°C and the reaction time is 6 hours; After curing, the PDMS elastic template can be obtained by peeling off.

[0042] Oligomer EMA 0.5g, oligomer SUA 6g, oligomer EA 1g; monomer IBA 0.5g, monomer MA 0.3g, monomer PEA 0.2g, monomer IBA 0.25g, monomer MDA 0.5g; Crosslinking agent dipentaerythritol pentaacrylate 0.5g; Photoinitiator [α-hydroxyl, α-phenylpropiophenone] 0.25g, photoinitiator 1-hydroxycyclohexyl benzophenone 0.15g, photoinitiator 2-hydroxyl- 0.1 g of 2-methyl-1-phenylacetone was uniformly mixed to prepare a prepolymer. Place the prepolymer between the quartz substrate and the elastic template, and expose it to ultraviolet light for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com