Method for synthesizing polyacrylate soap-free emulsion through micro-reactor

A technology of polyacrylate and micro-reactor, which is applied in the field of soap-free emulsion preparation, can solve the problems of low heat transfer efficiency, long reaction time, complicated operation, etc., and achieve the effect of improving operation efficiency, fast reaction speed and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

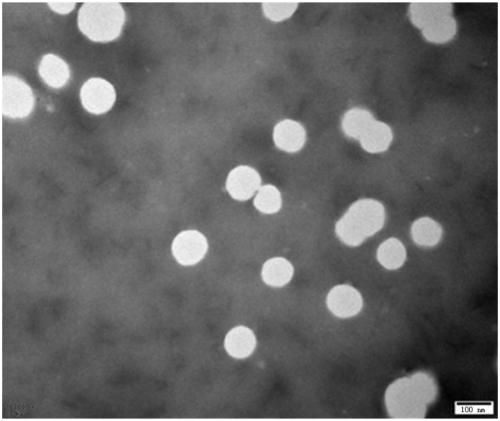

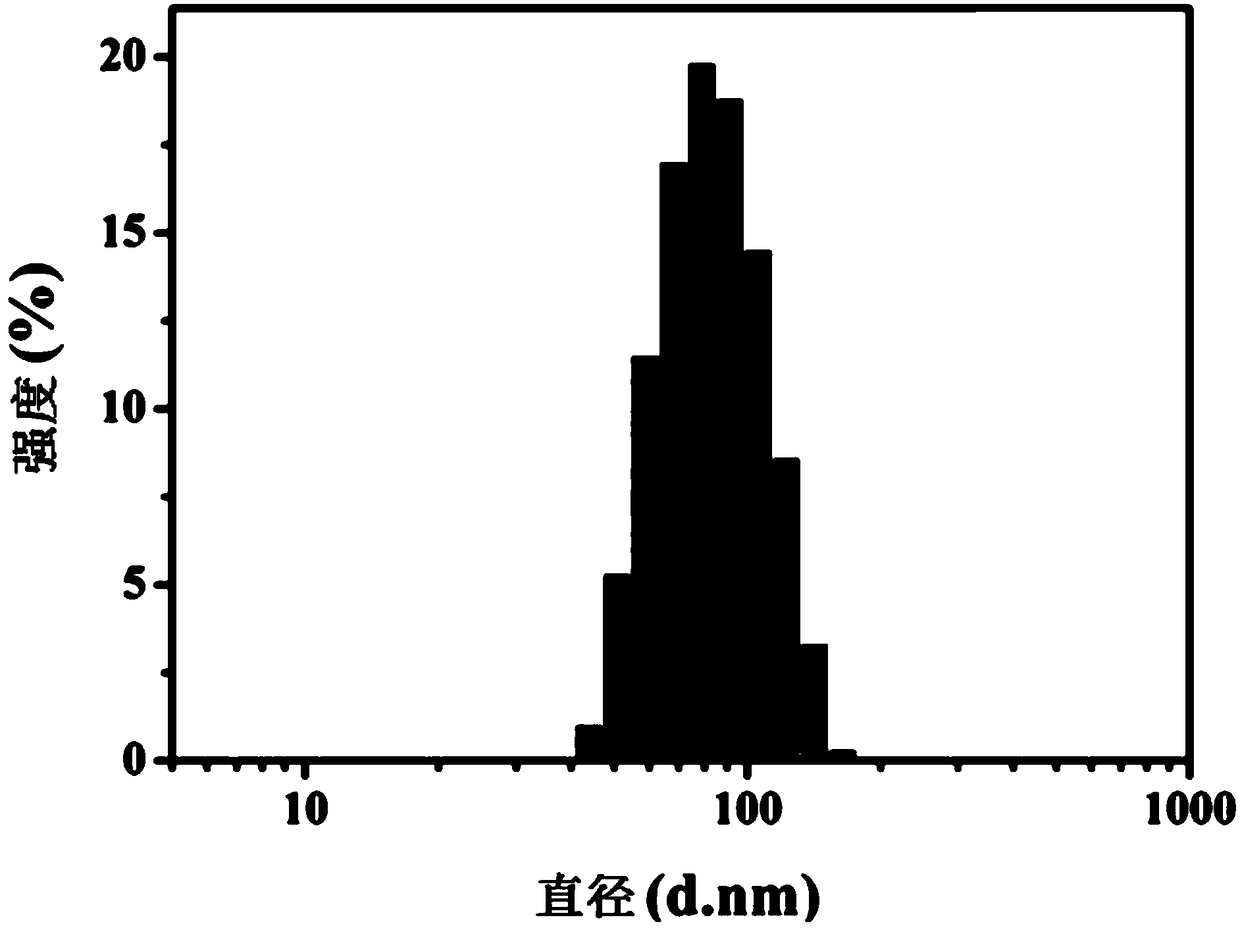

Image

Examples

Embodiment 1

[0034] The preparation method of the polyacrylate soap-free emulsion of the present embodiment may further comprise the steps:

[0035] Step 1. Prepare pre-emulsion

[0036] According to the mass ratio of 3:4, methyl methacrylate and butyl acrylate were weighed and mixed to prepare a mixed monomer as the oil phase. The emulsifier alkyl vinyl sulfonate: deionized water was 1 according to the mass ratio: 30 Prepare an emulsifier aqueous solution as the water phase, pump the oil phase and the water phase into the micro-mixer of the micro-reactor at a flow rate of 1.2:1, mix and then emulsify in the residence reaction tube. The inner diameter of the micro-mixer is 50 μm; The inner diameter of the residence reaction tube is 3mm, the residence time is 14.4s, the reaction pressure is 1MPa, and the reaction temperature is about 25°C. Under the above conditions, the pre-emulsion is prepared.

[0037] Step 2, preparing initiator aqueous solution

[0038] Prepare the initiator aqueous ...

Embodiment 2

[0042] The preparation method of the polyacrylate soap-free emulsion of the present embodiment may further comprise the steps:

[0043] Step 1. Prepare pre-emulsion

[0044] According to the mass ratio of 2:3, methyl methacrylate and methyl acrylate were weighed and mixed to prepare a mixed monomer as the oil phase. The emulsifier alkyl vinyl sulfonate: deionized water was 1 according to the mass ratio: 25 Prepare an emulsifier aqueous solution as the water phase, pump the oil phase and the water phase into the micro-mixer of the micro-reactor at a flow rate of 1.5:1, mix and then emulsify in the residence reaction tube. The inner diameter of the micro-mixer is 100 μm; The inner diameter of the residence reaction tube is 2mm, the residence time is 20s, the reaction pressure is 1.5MPa, and the reaction temperature is 20°C. Under the above conditions, the pre-emulsion is prepared.

[0045] Step 2, preparing initiator aqueous solution

[0046] Prepare the initiator aqueous soluti...

Embodiment 3

[0050] The preparation method of the polyacrylate soap-free emulsion of the present embodiment may further comprise the steps:

[0051] Step 1. Prepare pre-emulsion

[0052] According to the mass ratio of 4:7, respectively weigh butyl methacrylate and ethyl acrylate and mix them to prepare a mixed monomer as the oil phase. Use the emulsifier alkyl vinyl sulfonate: deionized water according to the mass ratio of 1: 27 Prepare an emulsifier aqueous solution as the water phase, pump the oil phase and the water phase into the micro-mixer of the micro-reactor at a flow rate of 1.3:1, mix and then emulsify in the residence reaction tube. The inner diameter of the micro-mixer is 200 μm; The inner diameter of the residence reaction tube was 1.5mm, the residence time was 25s, the reaction pressure was 2MPa, and the reaction temperature was 23°C. Under the above conditions, a pre-emulsion was prepared.

[0053] Step 2, preparing initiator aqueous solution

[0054] Prepare the initiator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com