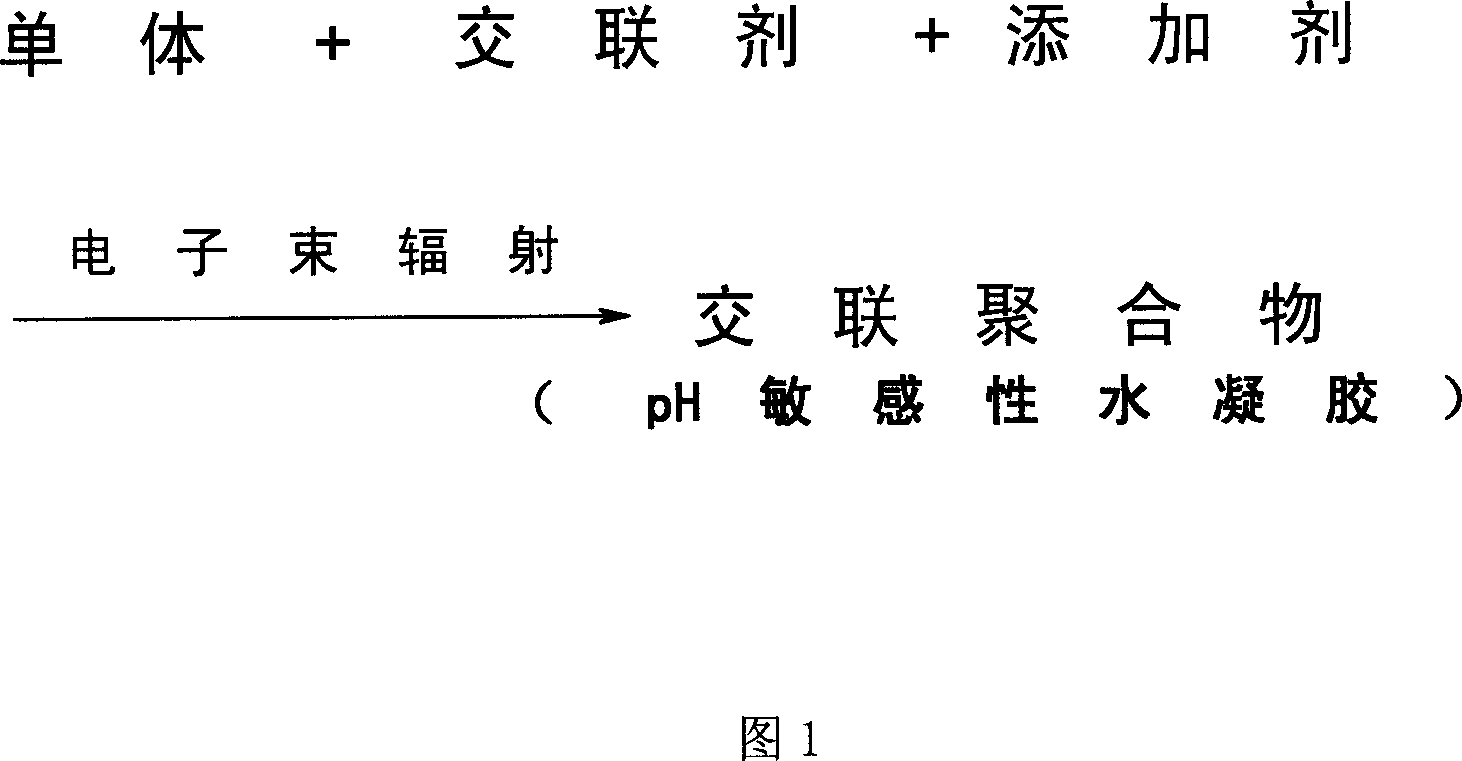

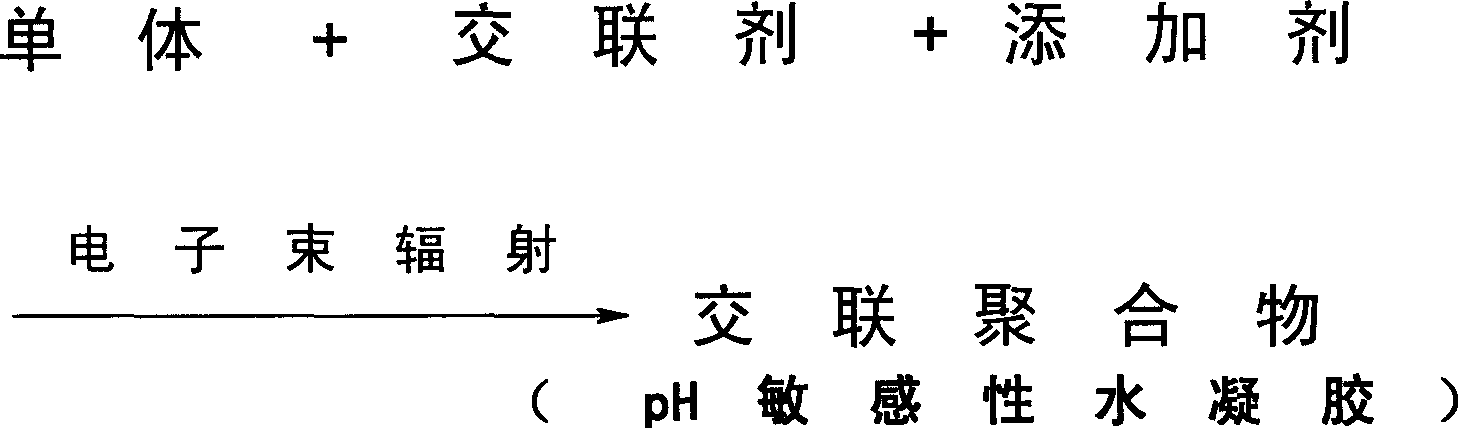

Electronic beam radiopolymerization process of directly synthesizing pH sensitive polymer hydrogel

An electron beam radiation, polymer technology, applied in the field of electron beam radiation polymerization to directly synthesize pH-sensitive polymer hydrogels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 5g monomer (acrylic acid), 1.3g monomer (2-methacryloyloxyethyltrimethylammonium chloride), 0.35g monomer (methacrylic acid), 0.45g monomer (maleic anhydride ), 0.25g of cross-linking agent (tetrapolyethylene glycol diacrylate), 0.05g of additive (methylolacrylamide), and 0.025g of additive (chitosan) were dissolved in 16mL of deionized water. The prepared solution is placed in a beaker, and the cross-linked polymer is obtained by electron beam radiation. Put the cross-linked polymer into a Soxhlet extractor and extract it with boiling deionized water for 24 hours, take it out and put it into a vacuum oven to dry to obtain a pH-sensitive hydrogel.

Embodiment 2

[0028] 5g monomer (acrylic acid), 2.53g monomer (2-methacryloyloxyethyltrimethylammonium chloride), 0.33g monomer (methacrylic acid), 0.52g monomer (maleic anhydride ), 0.018g of crosslinking agent (N,N'-methylenebisacrylamide), 0.053g of additive (methylolacrylamide) were dissolved in 15mL of deionized water. The prepared solution is placed in a beaker, and the cross-linked polymer is obtained by electron beam radiation. Put the cross-linked polymer into a Soxhlet extractor and extract it with boiling deionized water for 24 hours, take it out and put it into a vacuum oven to dry to obtain a pH-sensitive hydrogel.

Embodiment 3

[0030] 5g monomer (acrylic acid), 1.2g monomer (2-methacryloyloxyethyltrimethylammonium chloride), 0.23g monomer (methacrylic acid), 0.51g monomer (maleic anhydride ), 0.24g of crosslinking agent (tripolyethylene glycol diacrylate), 0.05g of additive (polyvinyl alcohol), and 0.015g of additive (N-isopropylacrylamide) were dissolved in 16mL of deionized water. The prepared solution is placed in a beaker, and the cross-linked polymer is obtained by electron beam radiation. Put the cross-linked polymer into a Soxhlet extractor and extract it with boiling deionized water for 24 hours, take it out and put it into a vacuum oven to dry to obtain a pH-sensitive hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com