Olefin polymer and preparation method thereof

An olefin polymerization and olefin technology, applied in the field of olefin polymers and their preparation, can solve the problems of high polymerization efficiency, difficulty in hydrogenation sensitivity, difficulty in obtaining propylene polymers with high melt mass flow index, etc., and achieve high Polymerization efficiency, effect of good hydrogenation sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

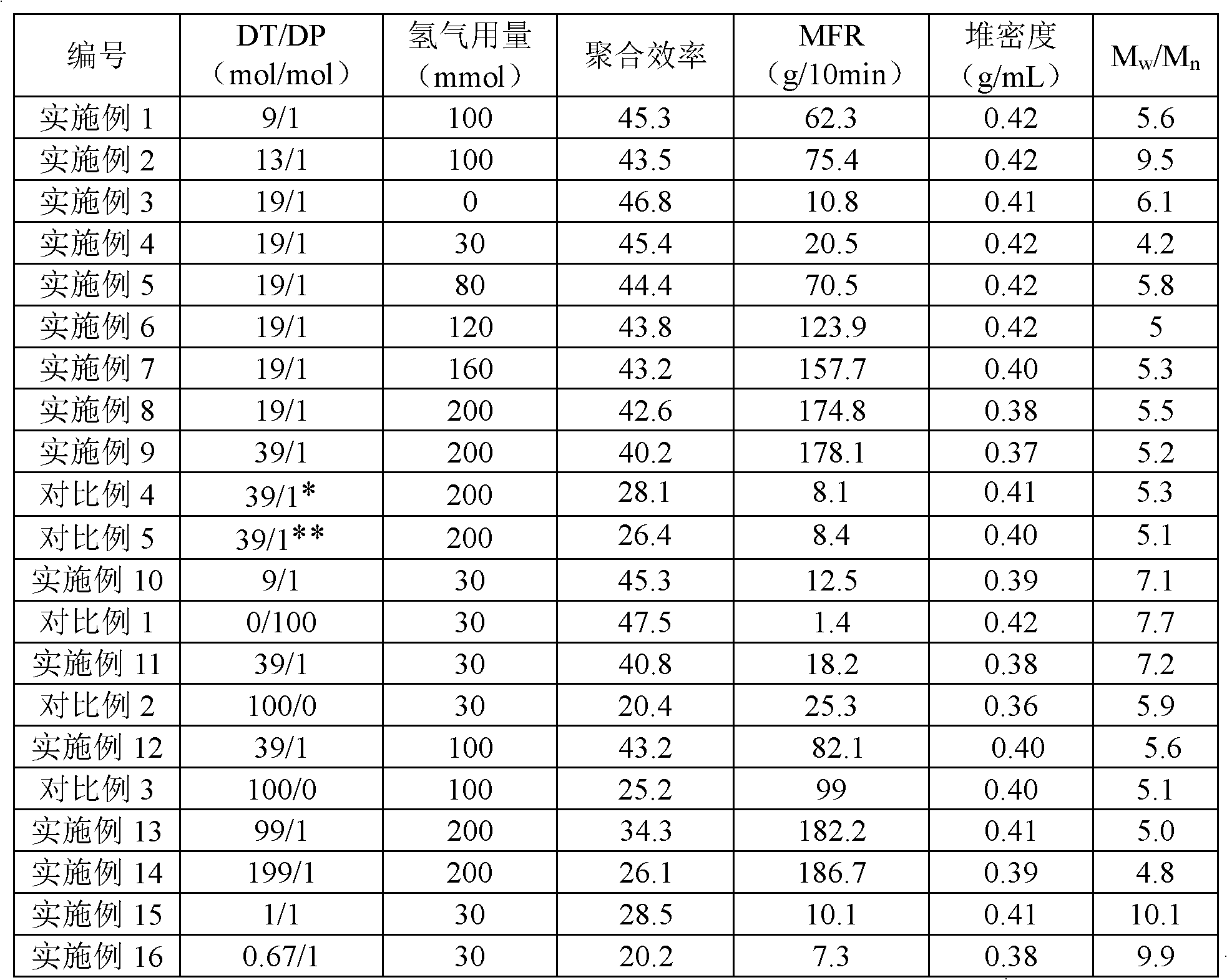

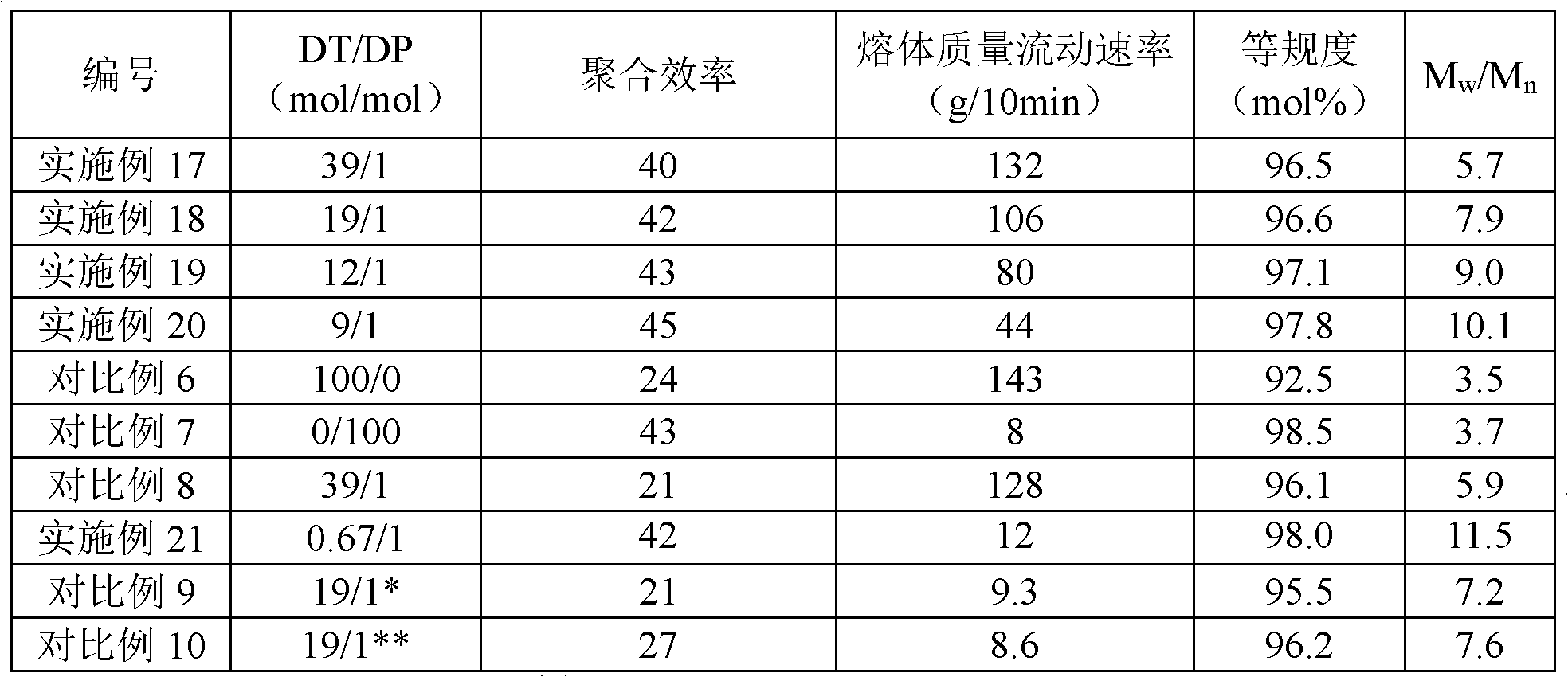

Examples

preparation example Construction

[0034] According to the present invention, various methods known to those skilled in the art can be used to prepare the solid component. For example, the preparation method of the solid component may include: contacting the magnesium compound with a titanium compound and an internal electron donor compound in an organic solvent, followed by solid-liquid separation, washing and drying. According to the present invention, the amount of the titanium compound, the internal electron donor compound and the magnesium compound is based on the content of each component in the final solid component meeting the specific use requirements. Preferably, the molar ratio of the titanium compound, the internal electron donor compound and the magnesium compound is 0.01-0.5:0.01-50:1.

[0035] According to the method of the present invention, the preparation method of the solid component is preferably: in the presence of a hydrocarbon solvent, at a temperature of 110-150 ° C, contacting the magne...

preparation example 1

[0067] (1) Preparation of magnesium chloride alcoholate

[0068] The three-neck flask equipped with a stirrer and a thermometer was replaced with nitrogen three times, and then 5 g of anhydrous magnesium chloride, 30 mL of n-decane and 23 mL of ethanol were added. The temperature was raised to 130°C while stirring, and the reaction was carried out at this temperature for 2 hours. 1.5 mL of tetrabutyl titanate and 2 mL of diisobutyl phthalate were added to 5 mL of toluene in advance, and the reaction was stirred at room temperature for 0.5 hours. Add the above toluene solution into the three-necked flask, and continue to react at 130° C. for 1 hour. After the reaction is completed, cool to room temperature to form a stable and uniform magnesium chloride alcoholate solution.

[0069] (2) Preparation of the solid component of the catalyst

[0070] The reactor equipped with stirrer and thermometer was replaced with nitrogen three times, then 200 mL of titanium tetrachloride was a...

preparation example 2

[0072] (1) Preparation of magnesium chloride alcoholate

[0073] Adopt the same method as step (1) in the preparation example 1 to prepare magnesium chloride alcoholate, the difference is, use di-n-butyl phthalate instead of diisobutyl phthalate, thereby prepare magnesium chloride alcoholate solution .

[0074] (2) Preparation of the solid component of the catalyst

[0075] The solid component of the catalyst is prepared in the same manner as step (2) in Preparation Example 1, except that di-n-butyl phthalate is used instead of diisobutyl phthalate to obtain the solid component of the catalyst point. The content of Ti in this solid component was 2.12 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com