Viscosity reduction type polycarboxylate superplasticizer with microcrosslinking structure and preparation method of viscosity reduction type polycarboxylate superplasticizer

A viscous polycarboxylic acid and micro-crosslinking technology, applied in the field of concrete admixtures, can solve the problems of increasing the thickness of the admixture adsorption layer on the surface of cement particles, reducing the viscosity of concrete, etc., to improve the polymerization efficiency and effective molecular structure arrangement, The effect of reducing the viscosity and increasing the thickness of the adsorption layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

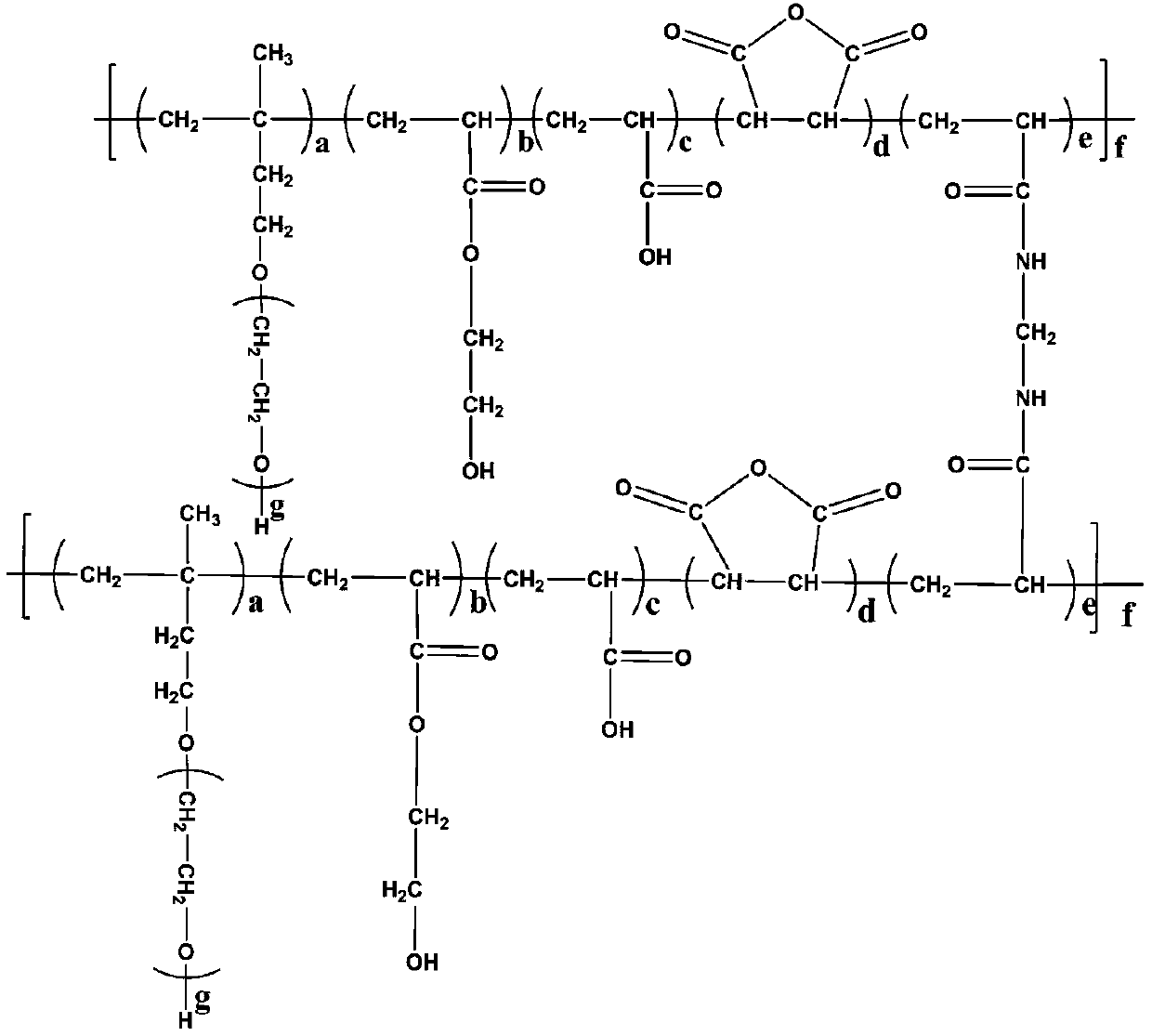

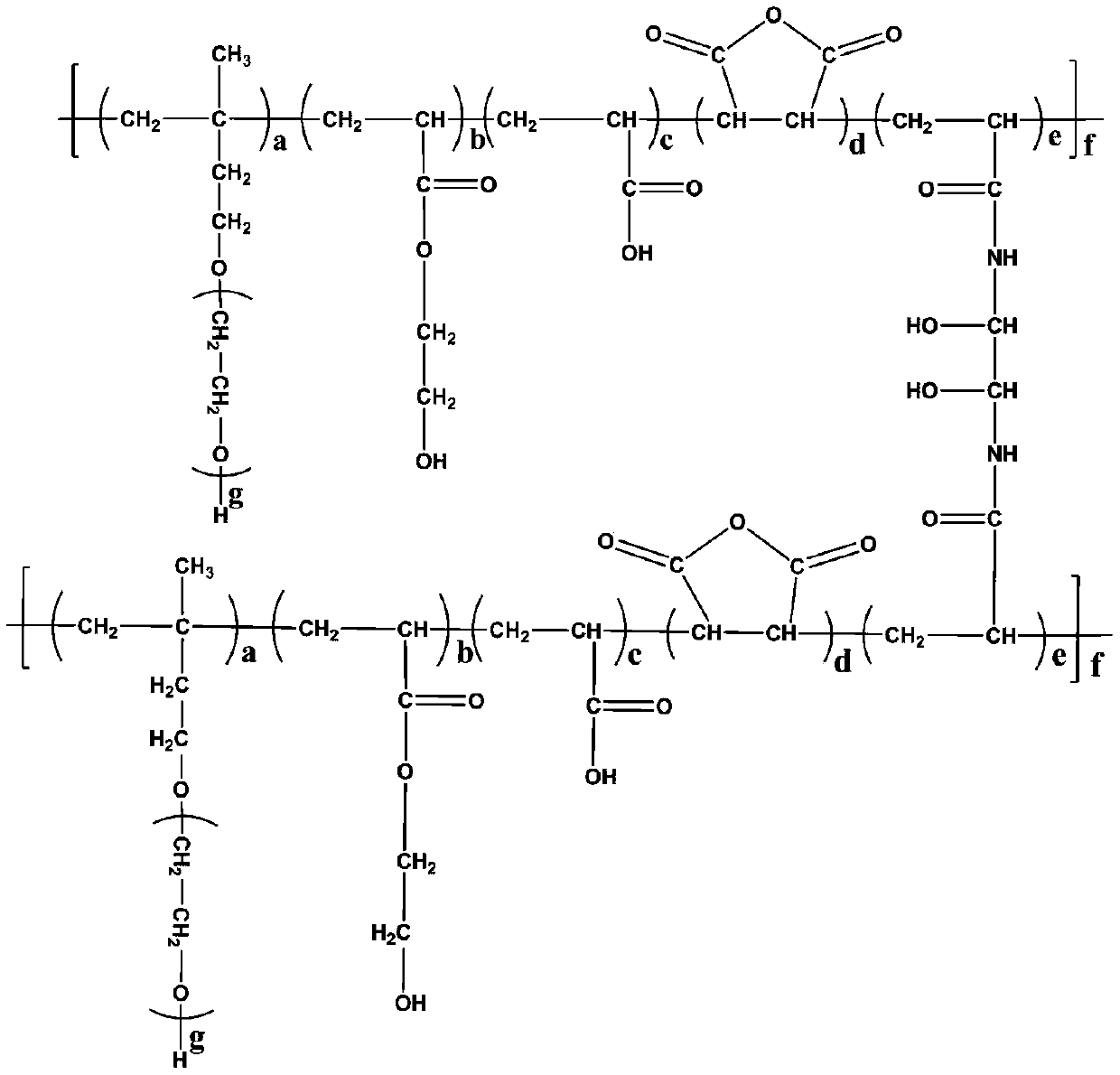

[0030] A micro-crosslinked viscosity-reducing polycarboxylate water reducer, the mass percentage of the monomer components used in the polymerization reaction: 6% of unsaturated carboxylic acid, 1.3% of unsaturated acid anhydride, 91% of isopentenol polyoxyethylene ether , crosslinking agent 1.2%, reactive co-solvent 0.5%, the total is 100%. The preparation method steps are as follows:

[0031] S1. Weigh 202g of prenol polyoxyethylene ether monomer with a molecular weight of 2400 and 2.88g of maleic anhydride in 205g of deionized water, raise the temperature to 50°C and keep the temperature constant to obtain solution A.

[0032] S2. Weigh 13.3g of acrylic acid, 2.66g of N,N'-methylenebisacrylic acid amide, 1.1g of hydroxyethyl acrylate and 0.38g of chain transfer agent mercaptoethanol, and dissolve them in 30g of water to obtain solution B.

[0033] S3. Weighing 1.66g of ammonium persulfate and 0.36g of azobisisobutylamidine hydrochloride were dissolved in 30g of water to ob...

Embodiment 2

[0039] A micro-crosslinked viscosity-reducing polycarboxylate water reducer, the mass percentage of the monomer components used in the polymerization reaction: 5.7% unsaturated carboxylic acid, 2.4% unsaturated acid anhydride, 90% isopentenol polyoxyethylene ether , crosslinking agent 1.4%, reactive co-solvent 0.5%, the total is 100%. The preparation method steps are as follows:

[0040] S1. Weigh 200g of isopentenol polyoxyethylene ether monomer with a molecular weight of 2400 and 5.33g of maleic anhydride, dissolve it in 205g of deionized water, raise the temperature to 50°C and keep the temperature constant to obtain solution A.

[0041] S2. Weigh 12.65g of acrylic acid, 3.1g of N,N'-(1,2-dihydroxyethylene) diacrylamide, 0.89g of hydroxyethyl acrylate and 0.38g of chain transfer agent thioglycolic acid, and dissolve them in 30g of water to obtain a mixed solution B;

[0042] S3. Weighing 1.46g of ammonium persulfate and 0.4g of sodium persulfate were dissolved in 30g of wa...

Embodiment 3

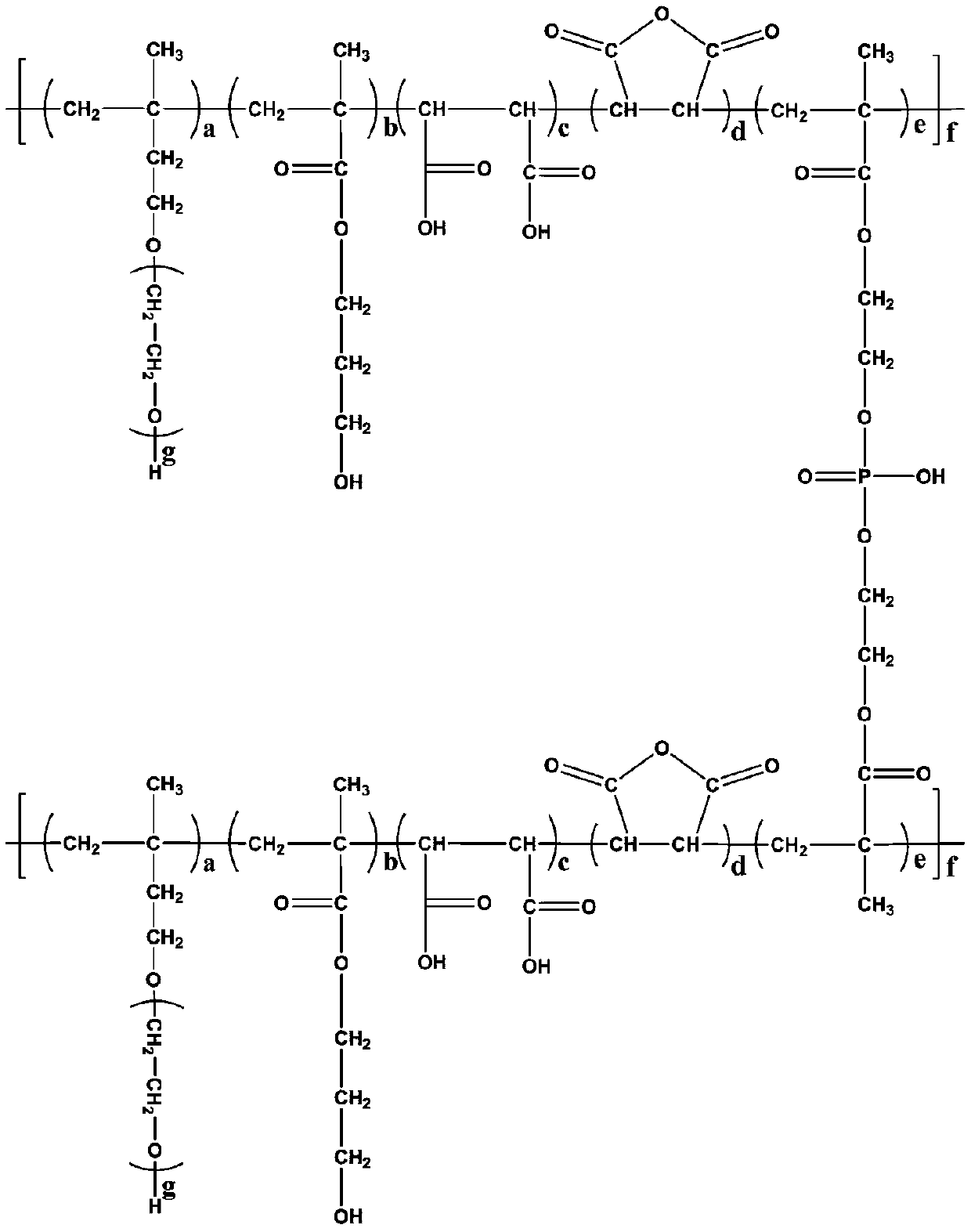

[0048] A micro-crosslinked viscosity-reducing polycarboxylate water reducer, the mass percentage of the monomer components used in the polymerization reaction: 5.7% of unsaturated carboxylic acid, 2.1% of unsaturated anhydride, 87.2% of isopentenol polyoxyethylene ether , crosslinking agent 4.5%, reactive co-solvent 0.5%, the total is 100%. The preparation method steps are as follows:

[0049] S1. Weigh 193g of prenol polyoxyethylene ether monomer with a molecular weight of 2400 and 3.33g of maleic anhydride in 205g of deionized water, heat up to 50°C and keep the temperature constant to obtain solution A.

[0050] S2. Weigh 12.65g of fumaric acid, 10g of diethylene glycol methacrylate phosphate, 0.89g of hydroxypropyl methacrylate and 0.38g of chain transfer agent mercaptopropionic acid, and dissolve them in 30g of water to obtain solution B.

[0051] S3. Dissolve 1.48g of potassium persulfate and 0.2g of azobisisoheptanonitrile in 30g of water to obtain solution C.

[0052...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com