Patents

Literature

57results about How to "High surface coverage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

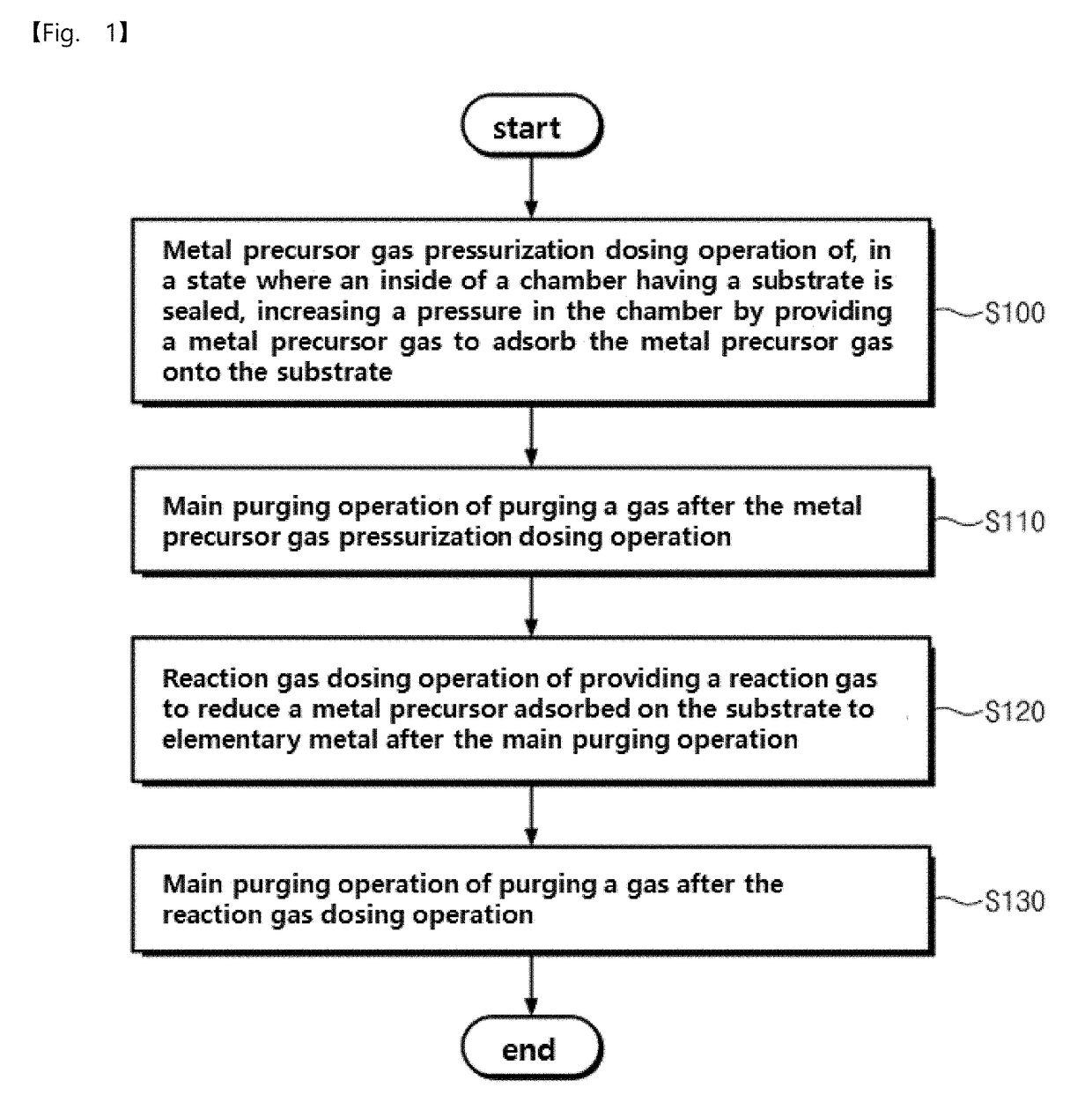

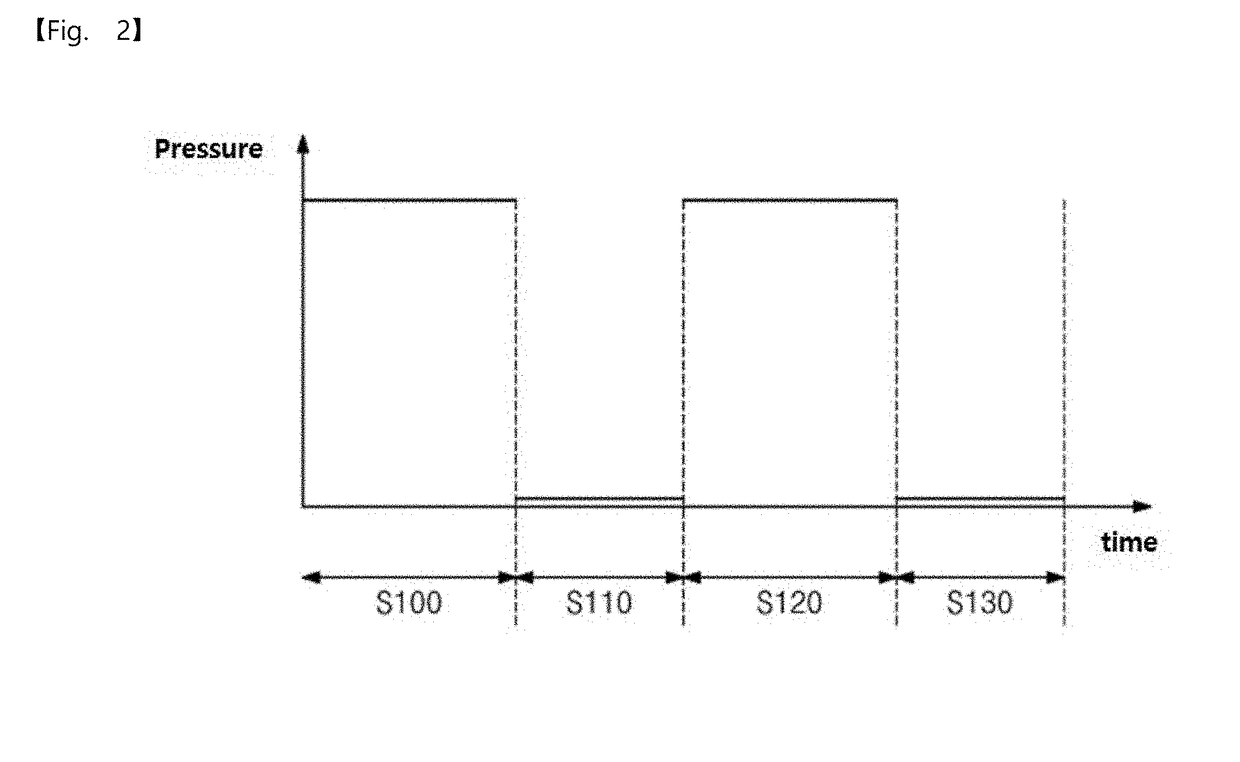

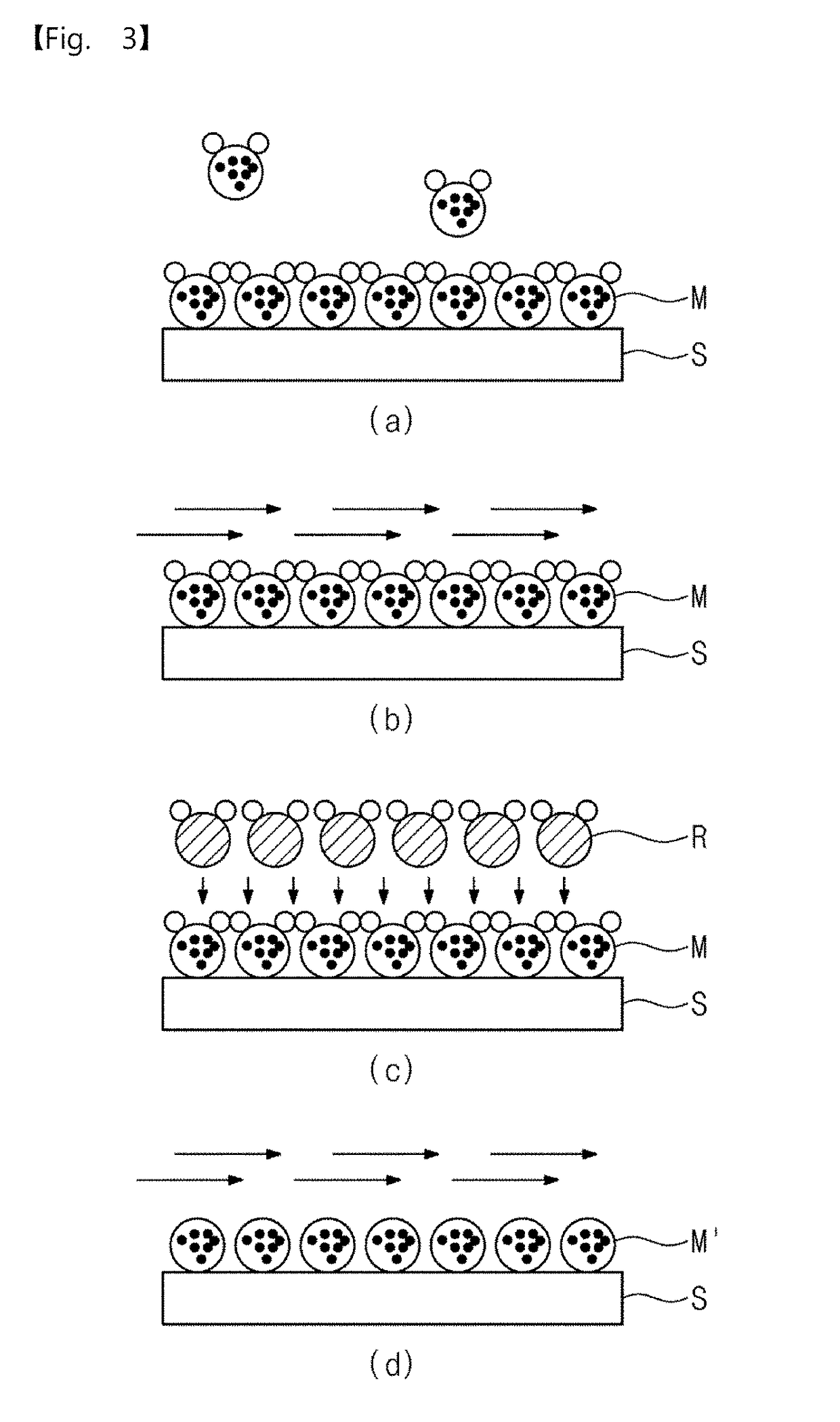

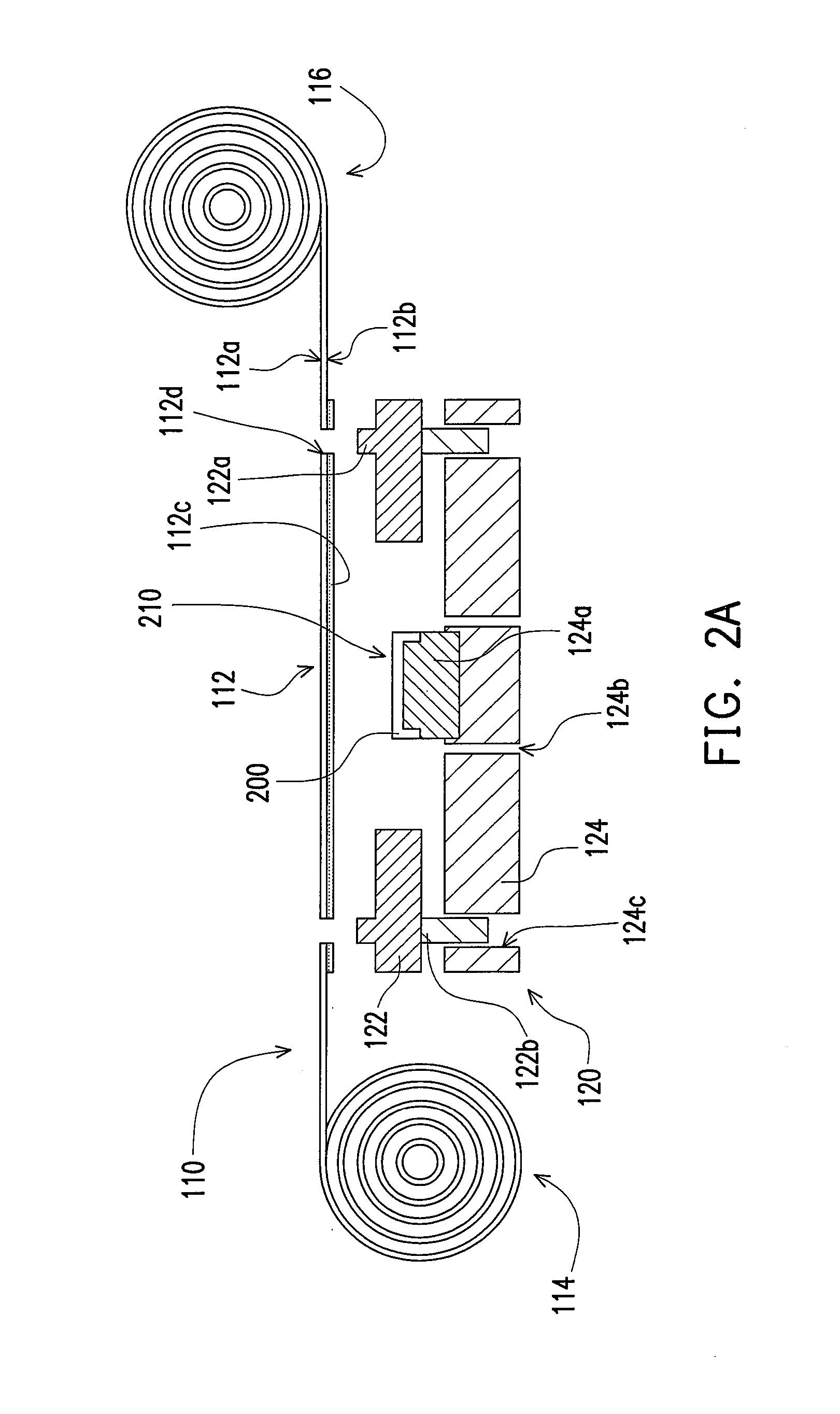

Pressurization type method for manufacturing metal monoatomic layer, metal monoatomic layer structure, and pressurization type apparatus for manufacturing metal monoatomic layer

ActiveUS20190062917A1High surface coverageReduce surface roughnessChemical vapor deposition coatingPressure/vacuum vesselsProduct gasMaterials science

A pressurization type method for manufacturing elementary metal may include a metal precursor gas pressurization dosing operation of, in a state where an outlet of a chamber having a substrate is closed, increasing a pressure in the chamber by providing a metal precursor gas consisting of metal precursors, thereby adsorbing the metal precursors onto the substrate, a main purging operation of purging a gas after the metal precursor gas pressurization dosing operation, a reaction gas dosing operation of providing a reaction gas to reduce the metal precursors adsorbed on the substrate to elementary metal, after the main purging operation, and a main purging operation of purging a gas after the reaction gas dosing operation.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

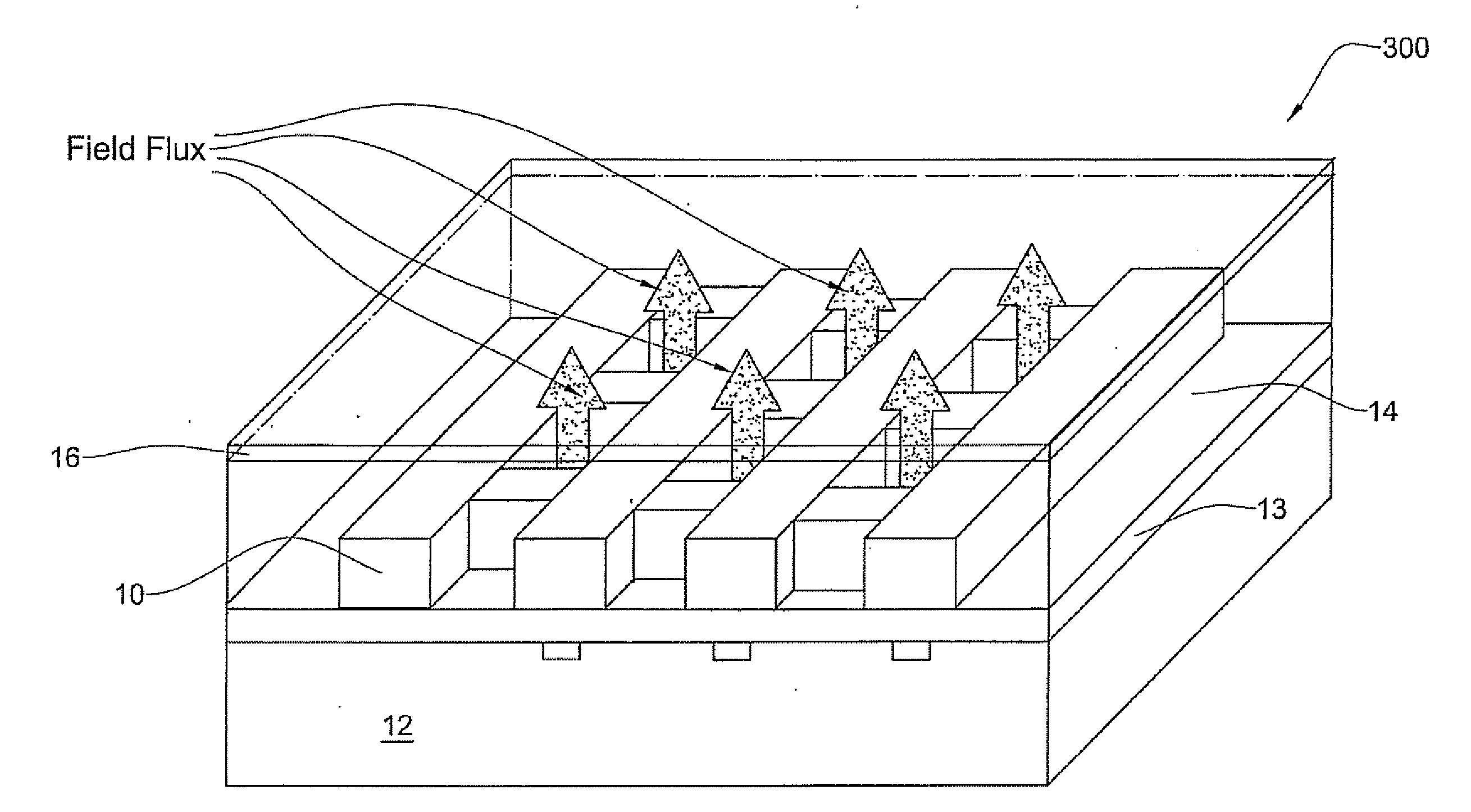

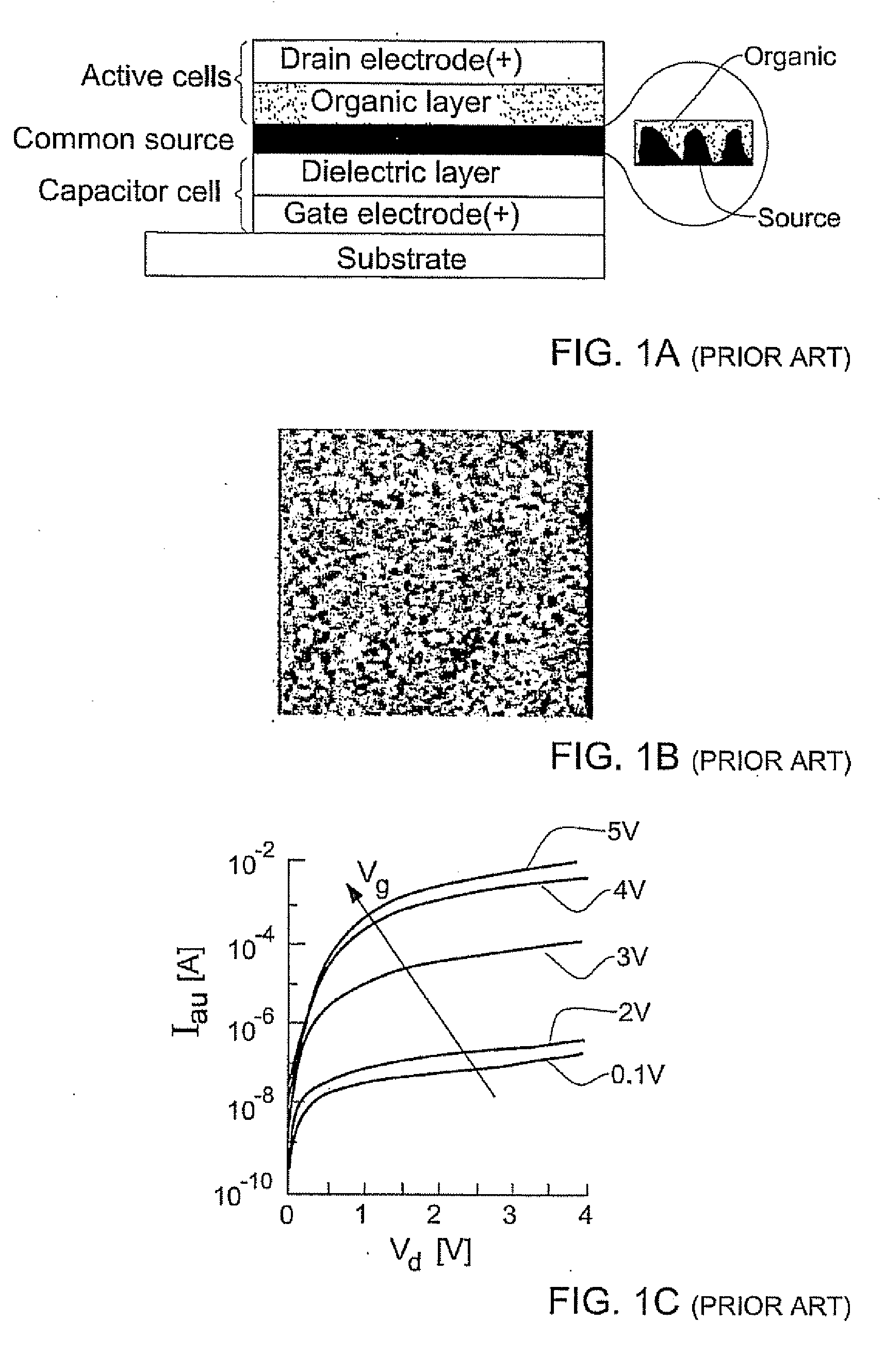

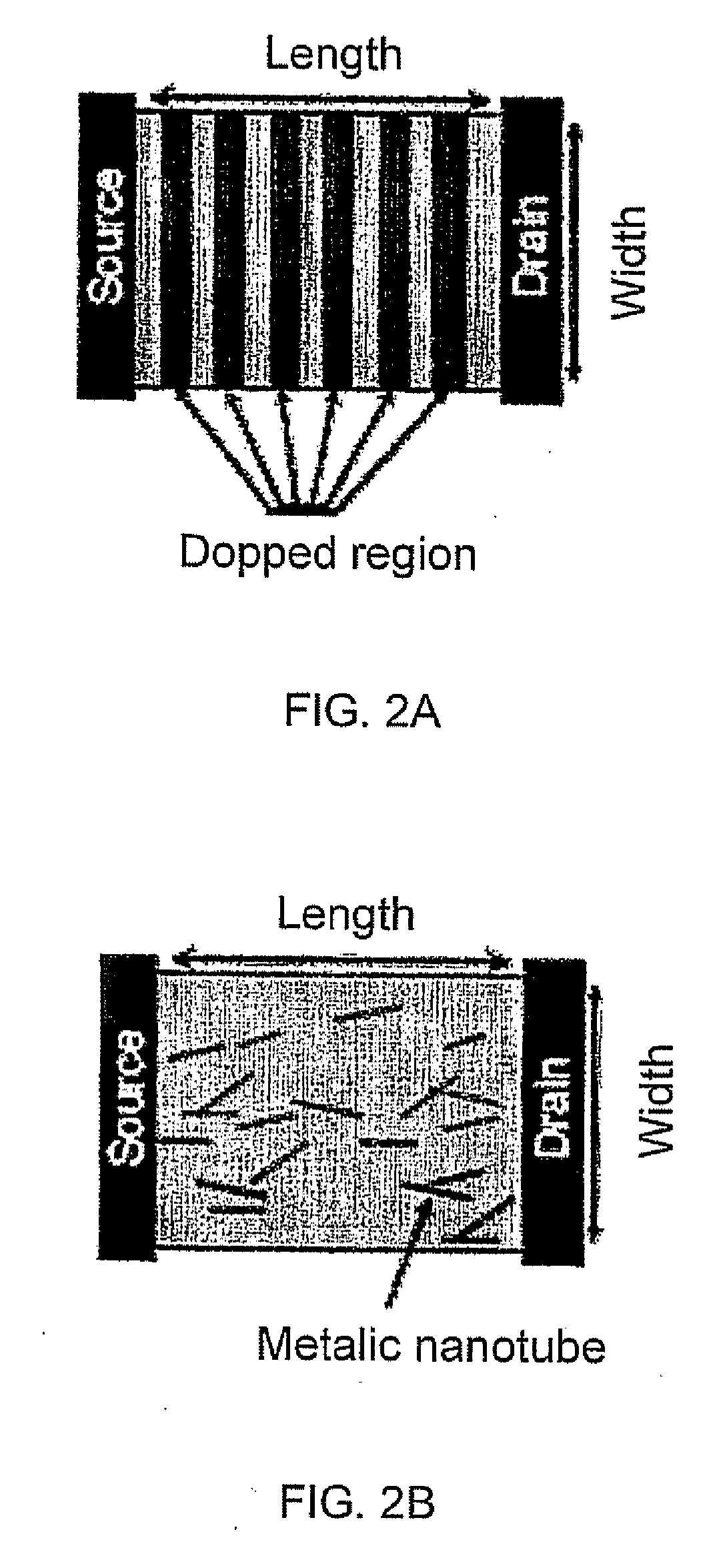

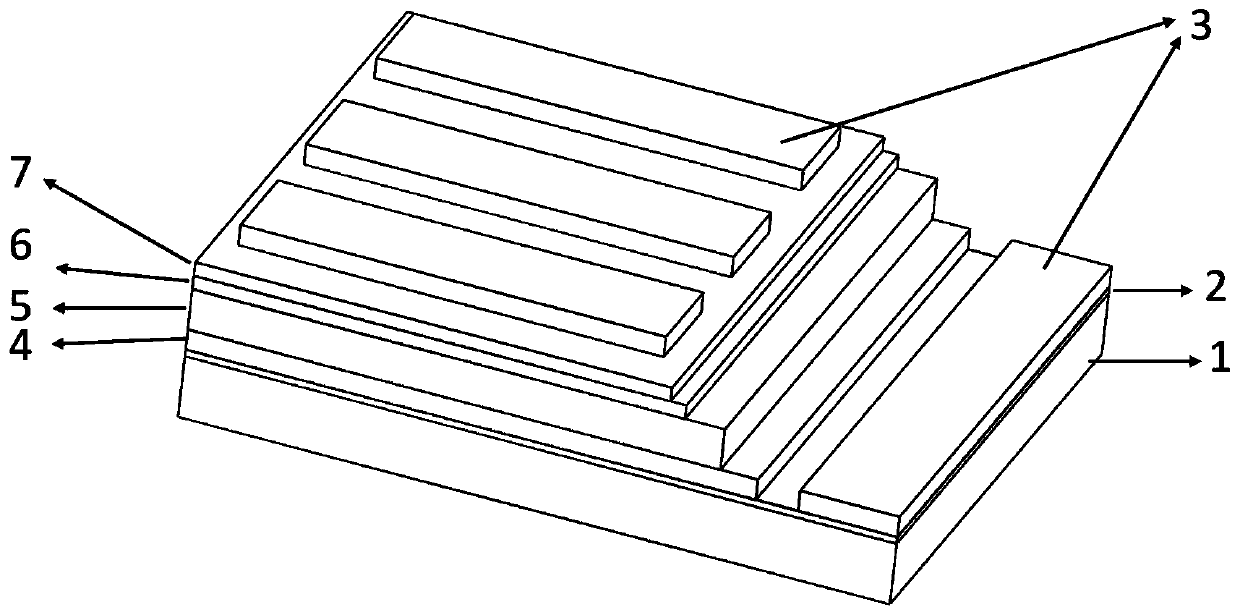

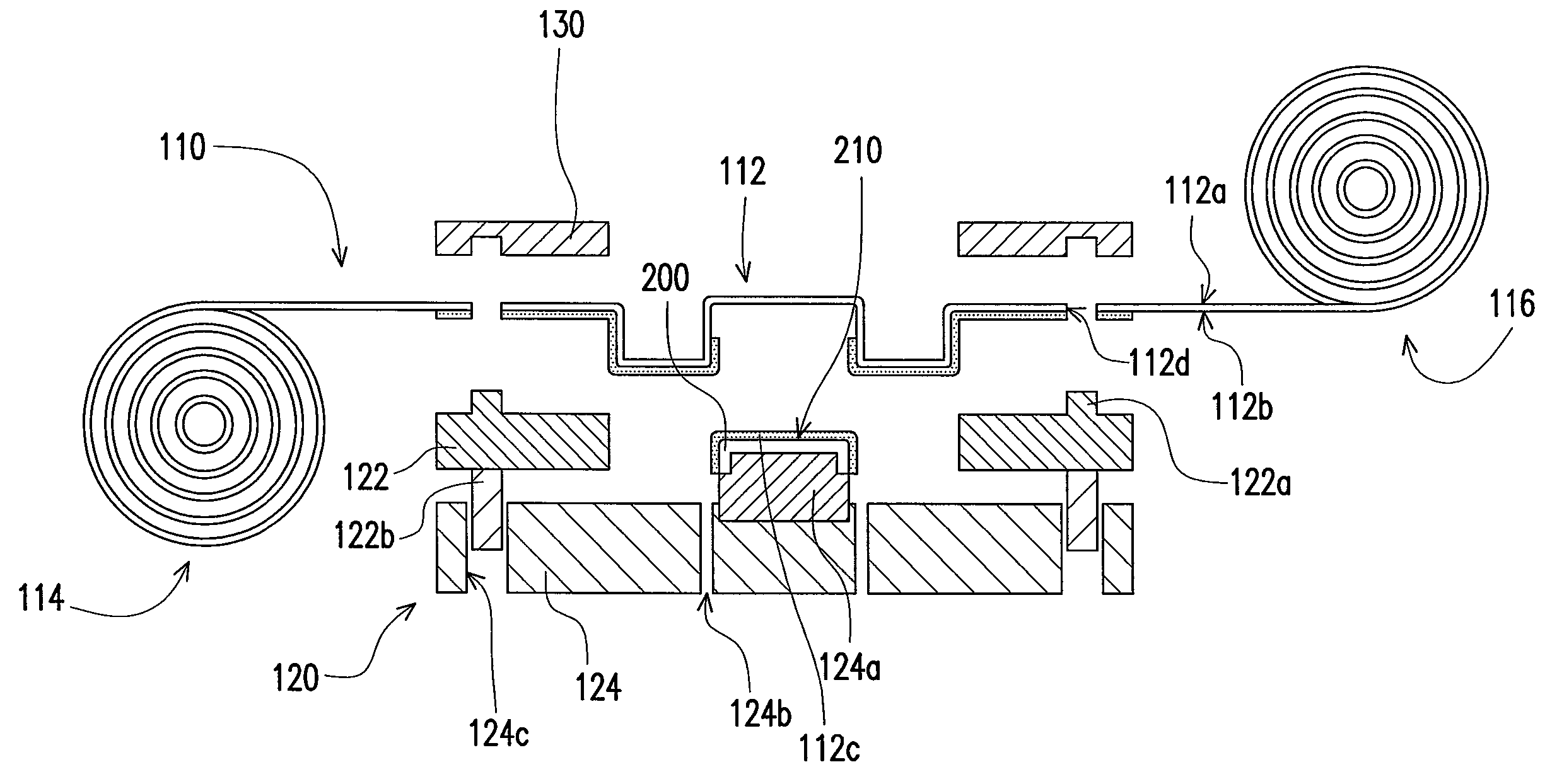

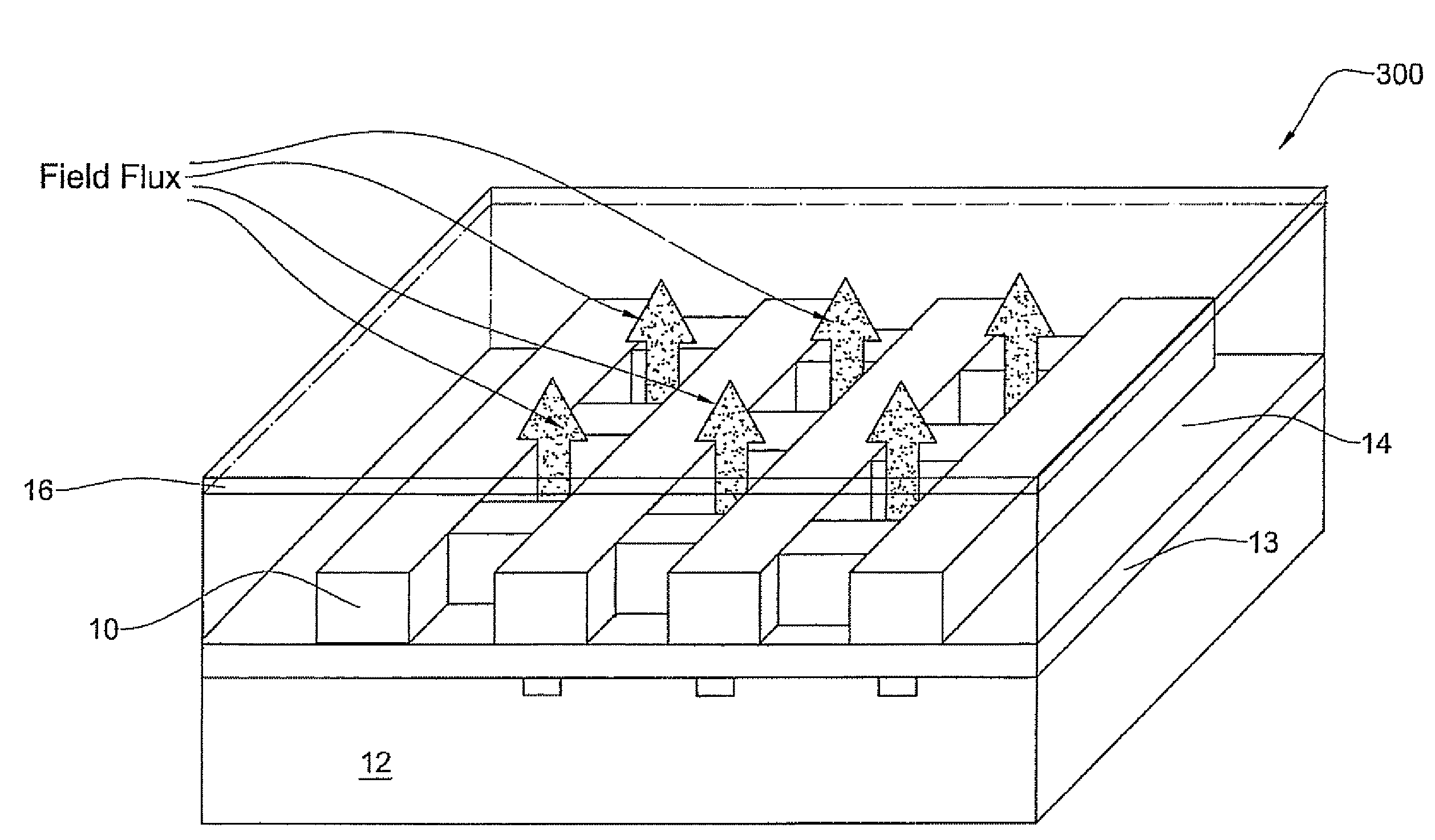

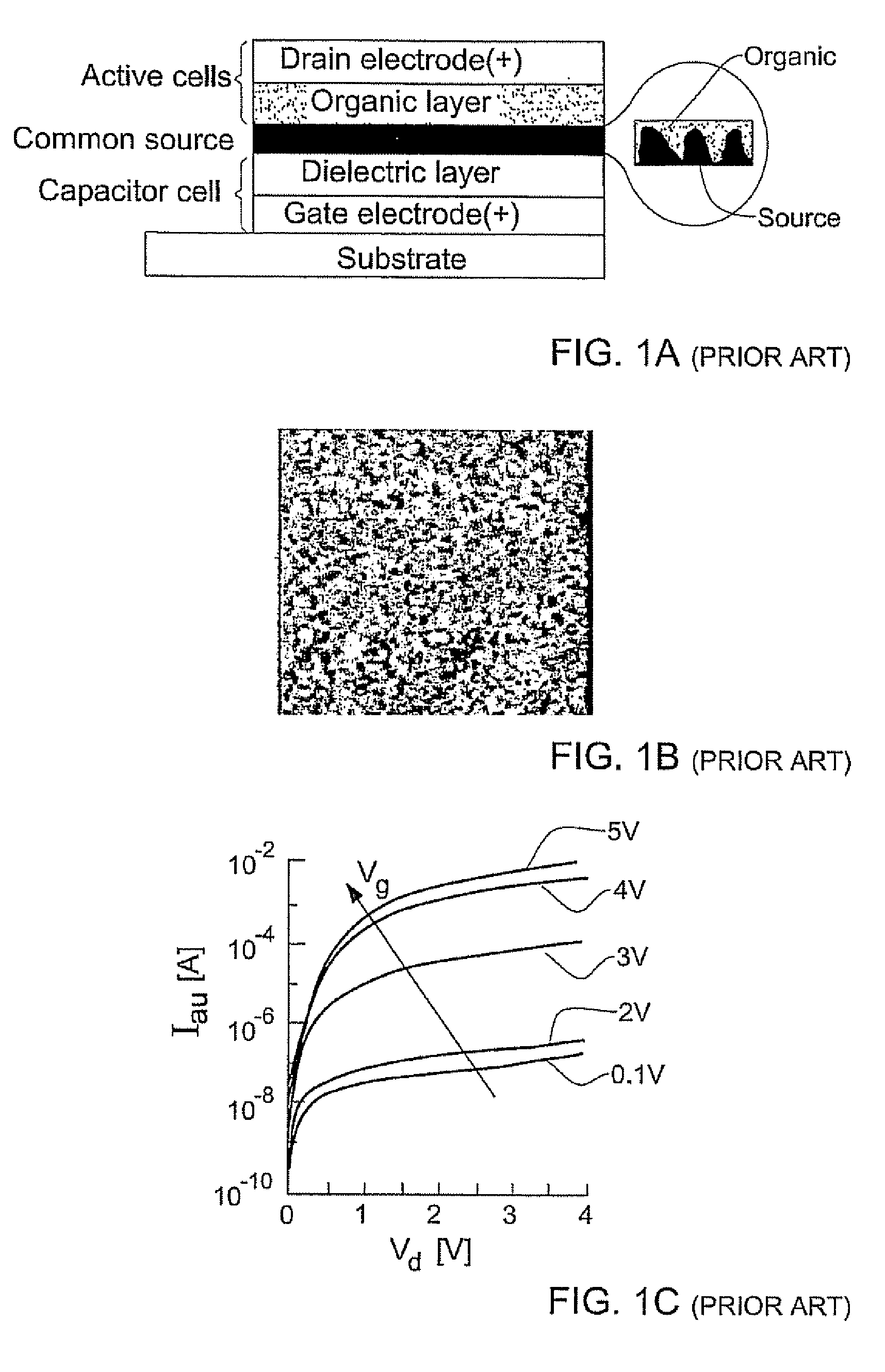

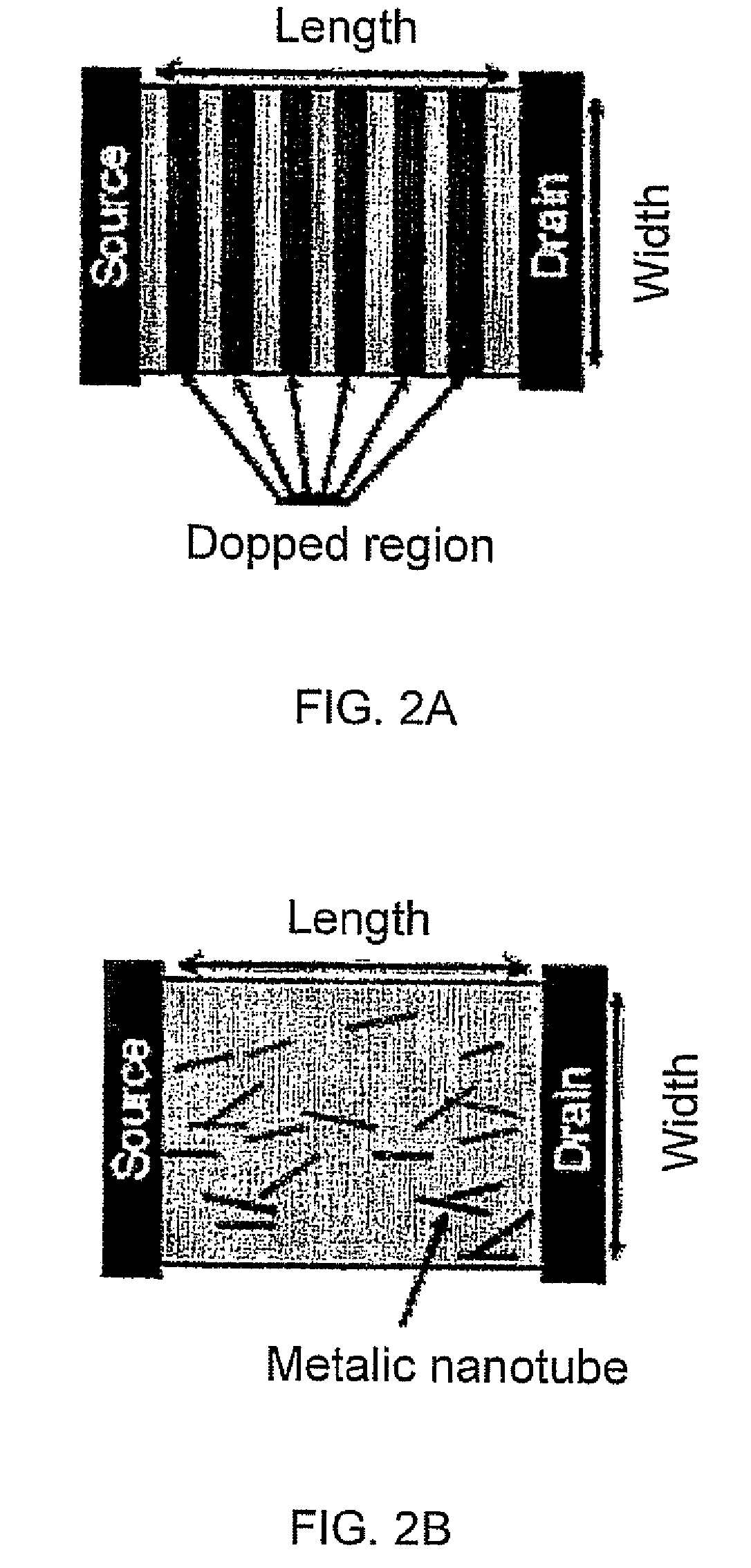

Transistor Structures and Methods of Fabrication Thereof

ActiveUS20090008634A1Reduce stepsReducing “ effective length ”TransistorNanoinformaticsElectronTransistor

An electronic device is presented, such as a thin film transistor. The device comprises a patterned electrically-conductive layer associated with an active element of the electronic device. The electrically-conductive layer has a pattern defining an array of spaced-apart electrically conductive regions. This technique allows for increasing an electric current through the device.

Owner:TECHNION RES & DEV FOUND LTD

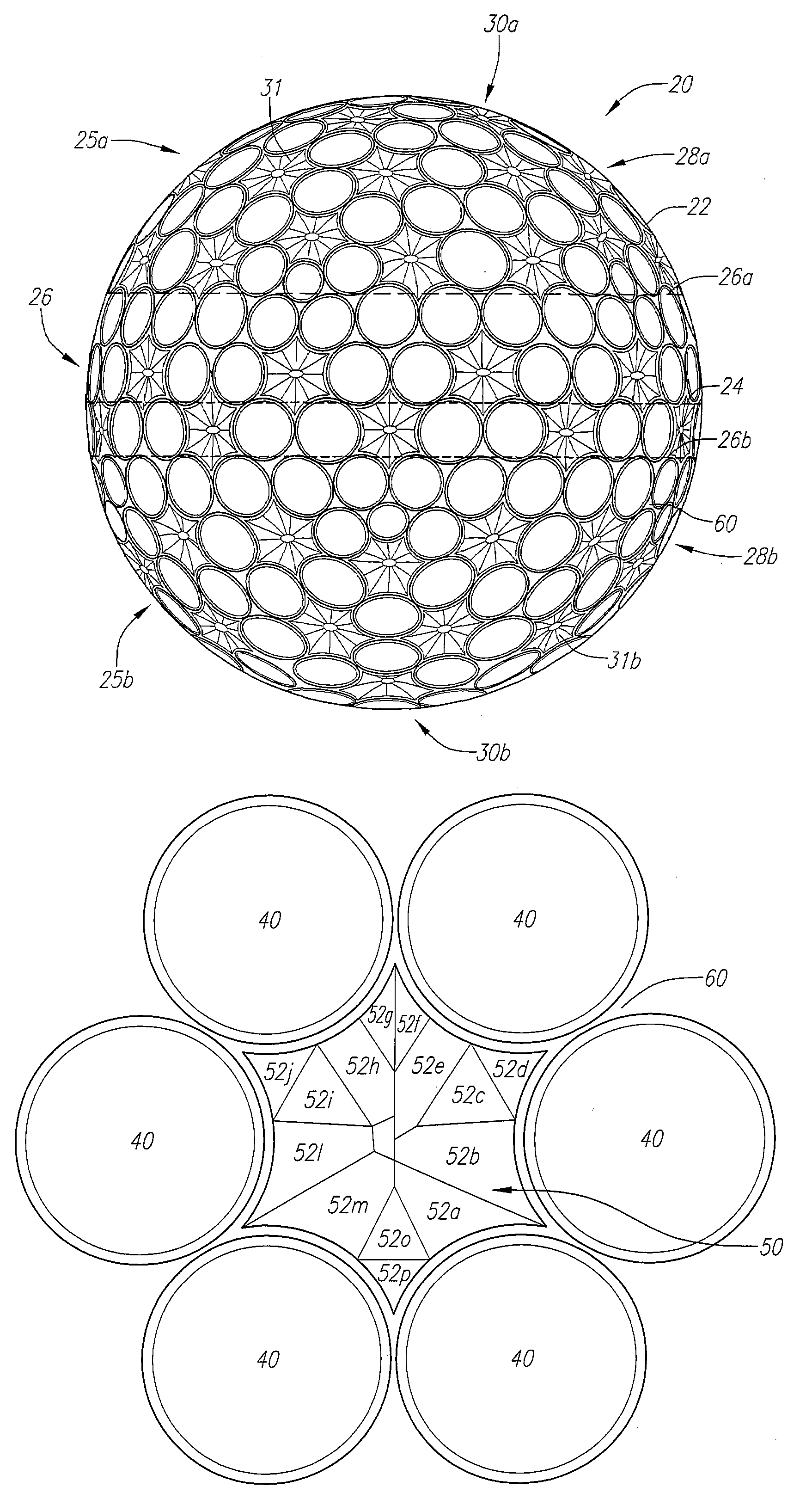

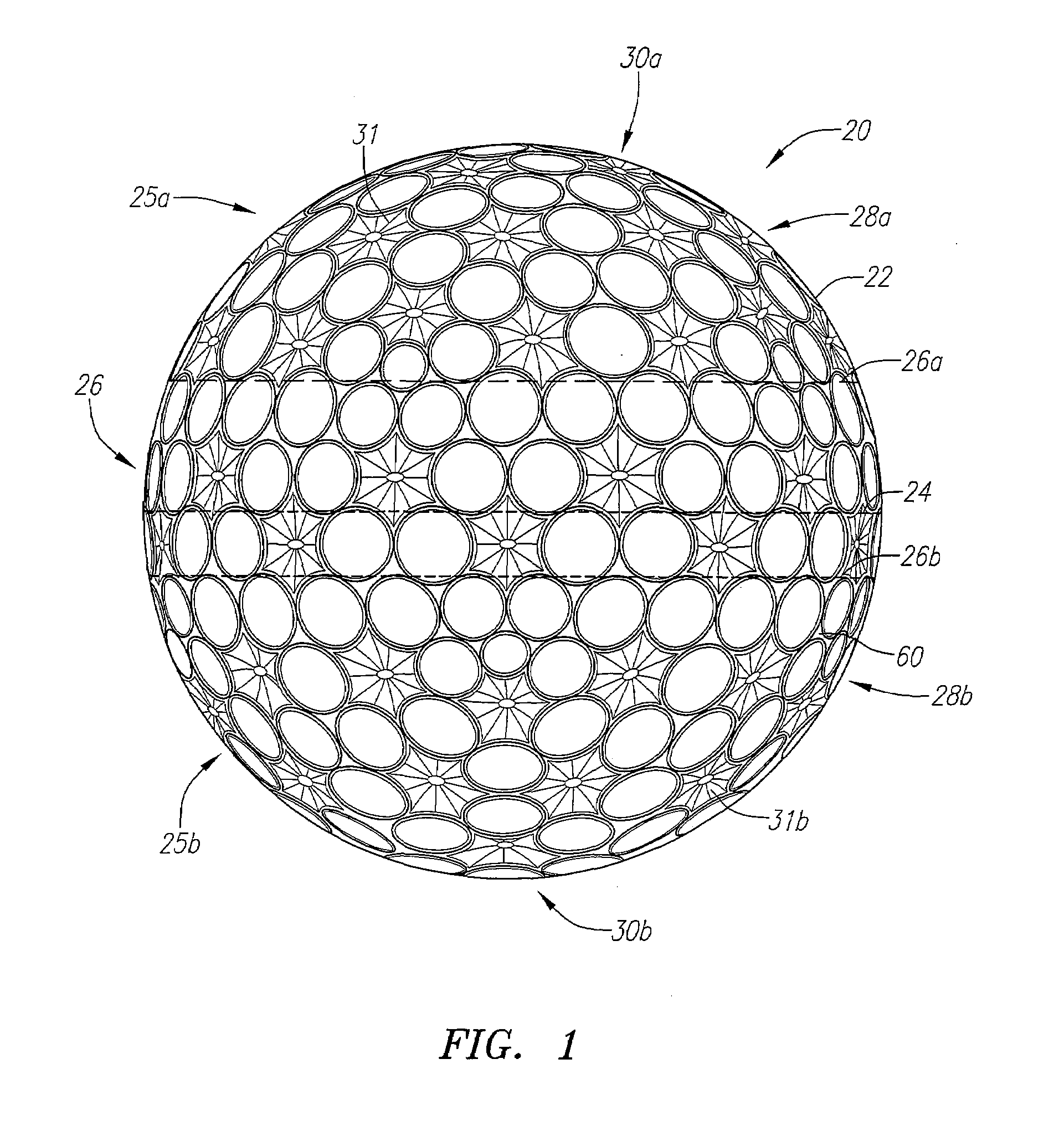

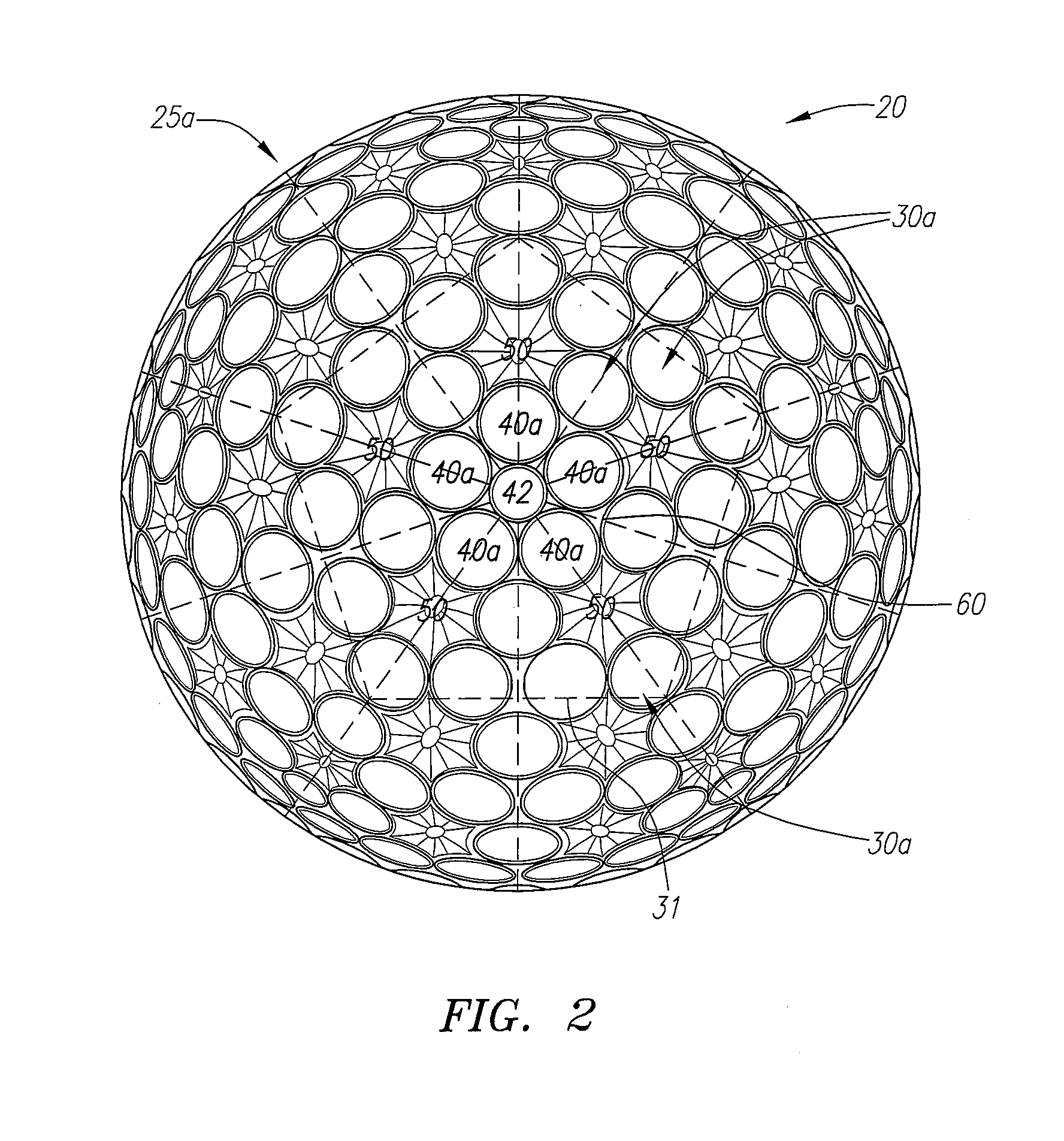

Aerodynamic pattern for a golf ball

A golf ball having traditional dimples and a tubular lattice structure is disclosed herein. The golf ball has dimples and a plurality of lattice members that form multi-faceted polygons. Each of the plurality of lattice members has an apex and the golf ball of the present invention conforms with the 1.68 inches requirement for USGA-approved golf balls. The interconnected lattice members form a plurality of polygons, preferably hexagons and pentagons. Each of the lattice members preferably has a continuous contour.

Owner:TOPGOLF CALLAWAY BRANDS CORP

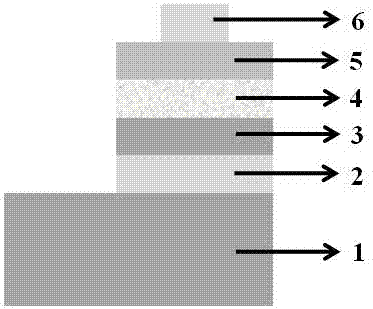

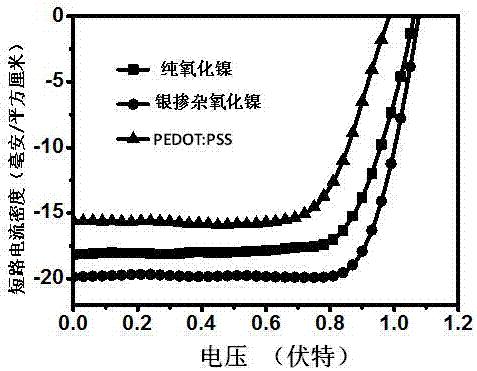

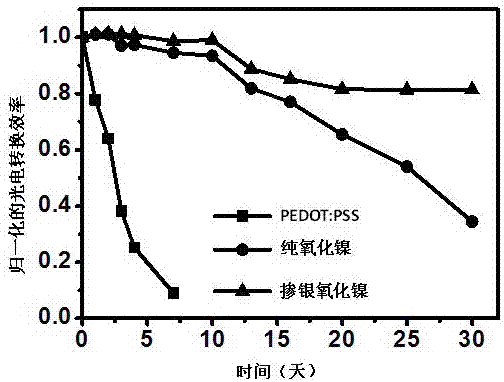

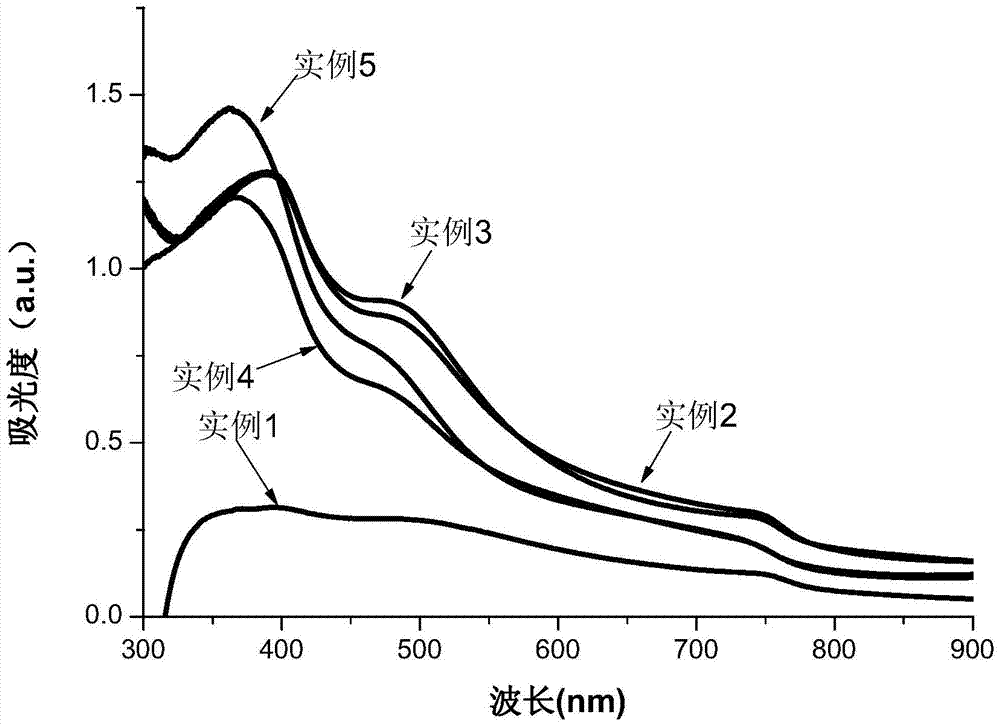

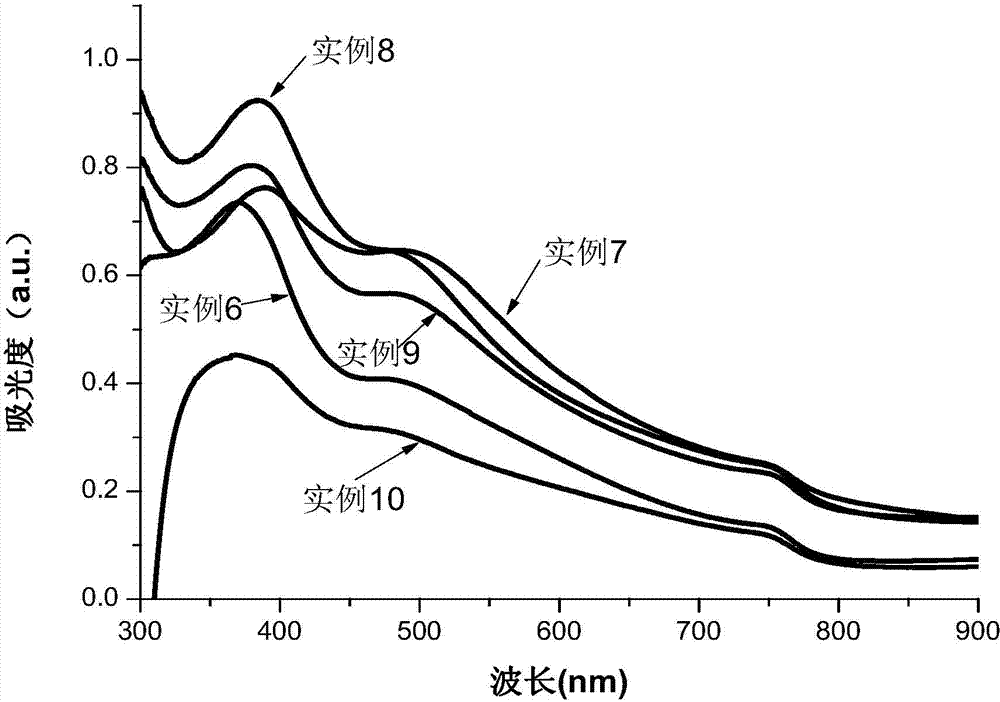

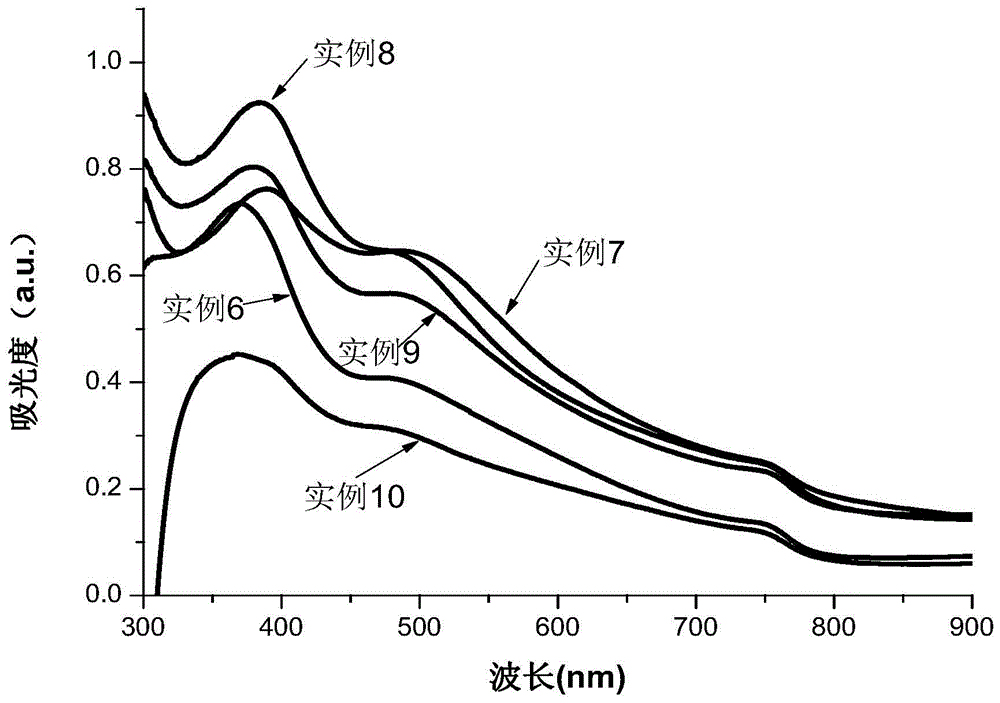

Preparation of silver-doped nickel oxide film and application of nickel oxide film in perovskite solar cell as hole transport layer

ActiveCN106972102AGood light transmissionGood hole transport propertiesSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerSpin coating

The invention provides preparation of a silver-doped nickel oxide film and an application of the nickel oxide film in a perovskite solar cell as a hole transport layer. The preparation of the silver-doped nickel oxide film includes: dissolving nickel nitrate hexahydrate and silver nitrate in a diethylamine-containing glycol solution, stirring the mixture at a room temperature for 12-16 h, preparing a mixed precursor solution of nickel nitrate and silver nitrate with the metallic ion total concentration of 0.5-1.5 M, wherein the ratio of Ag to Ni is 1-2:100; and performing spin coating of the mixed precursor solution of nickel nitrate and silver nitrate on a substrate with the rotating speed of 2500-3500 rmp, and then performing heating at the temperature of 300 DEG C for 60-80 min. According to the silver-doped nickel oxide film, the light transmission and the hole transport capability are better, the degree of crystallization and the surface coverage rate of the perovskite film grown on the silver-doped nickel oxide film are higher compared with the pure nickel oxide film, and the reverse planar perovskite solar cell prepared by the nickel oxide film as the hole transport layer is advantaged by higher photoelectric conversion efficiency and environmental stability.

Owner:NANCHANG UNIV

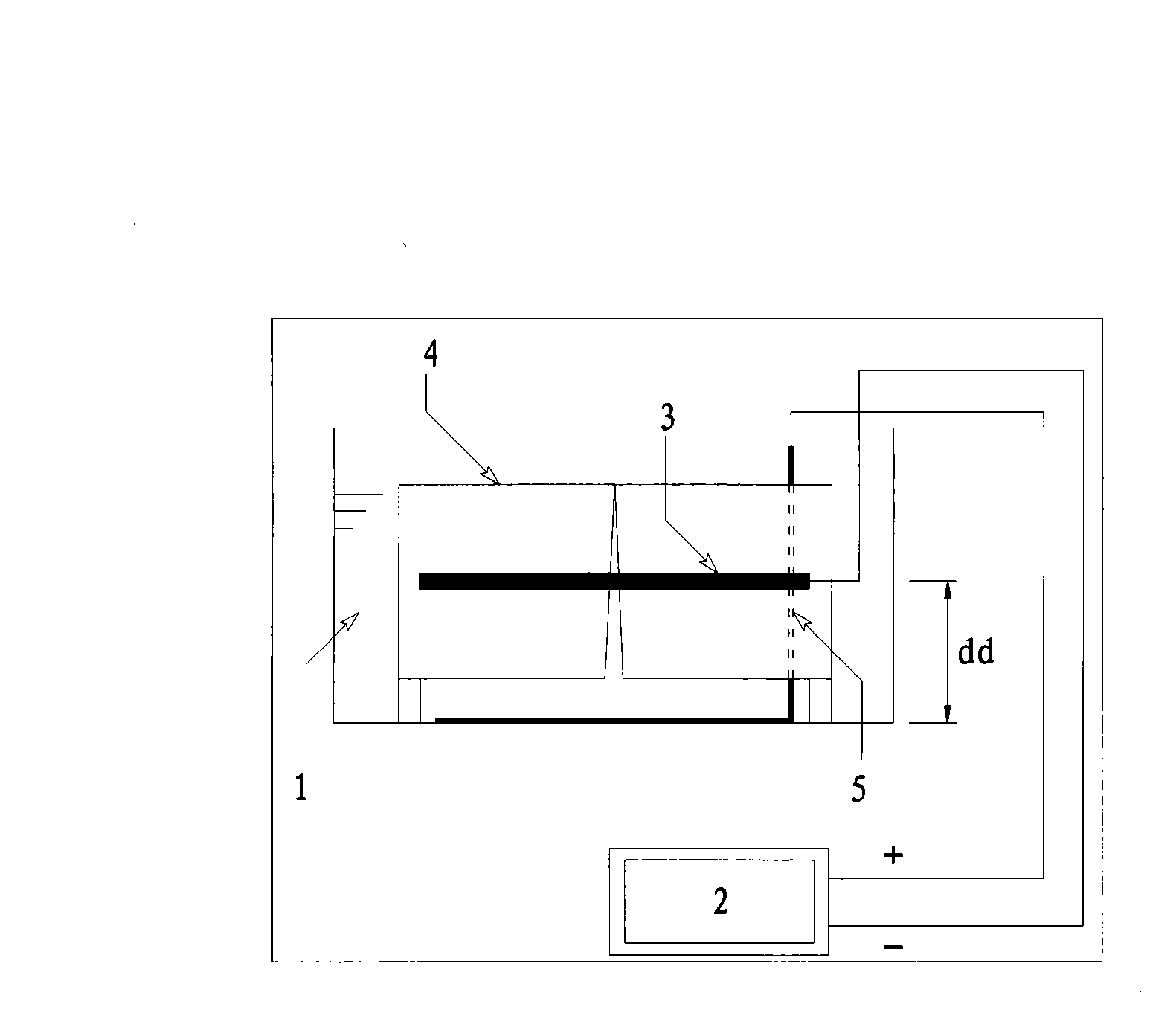

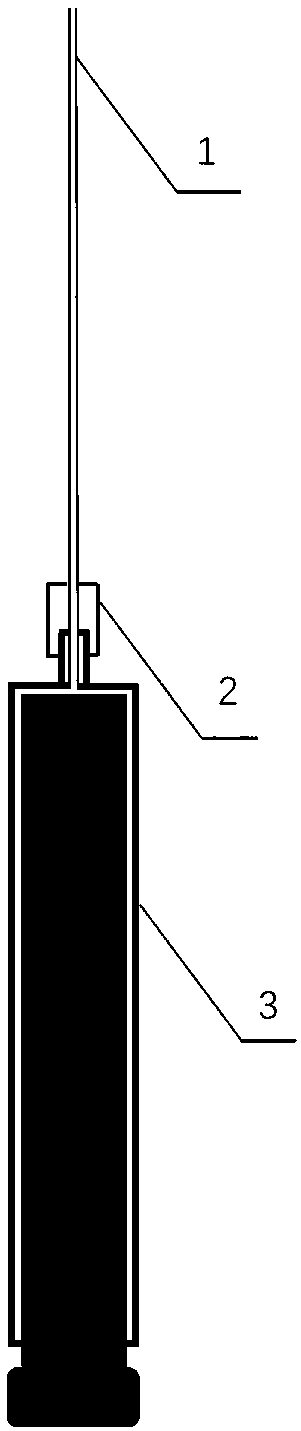

Method and device for repairing concrete crack by pulse electrodeposition

InactiveCN101418595AIncreased quality gainHigh surface coverageMarine site engineeringBuilding insulationsAmpereRebar

The invention discloses a method for repairing a concrete crack by means of pulse electrodeposition, wherein a reinforcing steel bar in concrete is taken as a cathode and a titanium screen is taken as an anode, and the reinforcing steel bar and the titanium screen are arranged near the concrete; a 0.05-0.50 mol per liter zinc saline solution or magnesium saline solution is taken as an electrodeposition solution, and the concrete is immersed into the electrodeposition solution; a pulse power source is adopted, and the on / off time of pulse is between 0.6 and 1 ms; the current density exerted on the surface of the concrete is between 0.25 and 3 amperes per square meter; and the concrete provided with the crack is repaired by means of electrodeposition. The invention also discloses an applicable device for the method for repairing the concrete crack by means of pulse electrodeposition. The method for repairing the concrete crack by means of pulse electrodeposition and the repairing device thereof have the advantages of simple structure, convenient operation, low cost, good effect and so on, and are suitable for concrete structures in a water environment and concrete structures which are difficult to be repaired by the prior repairing technology or have high repairing cost.

Owner:HOHAI UNIV

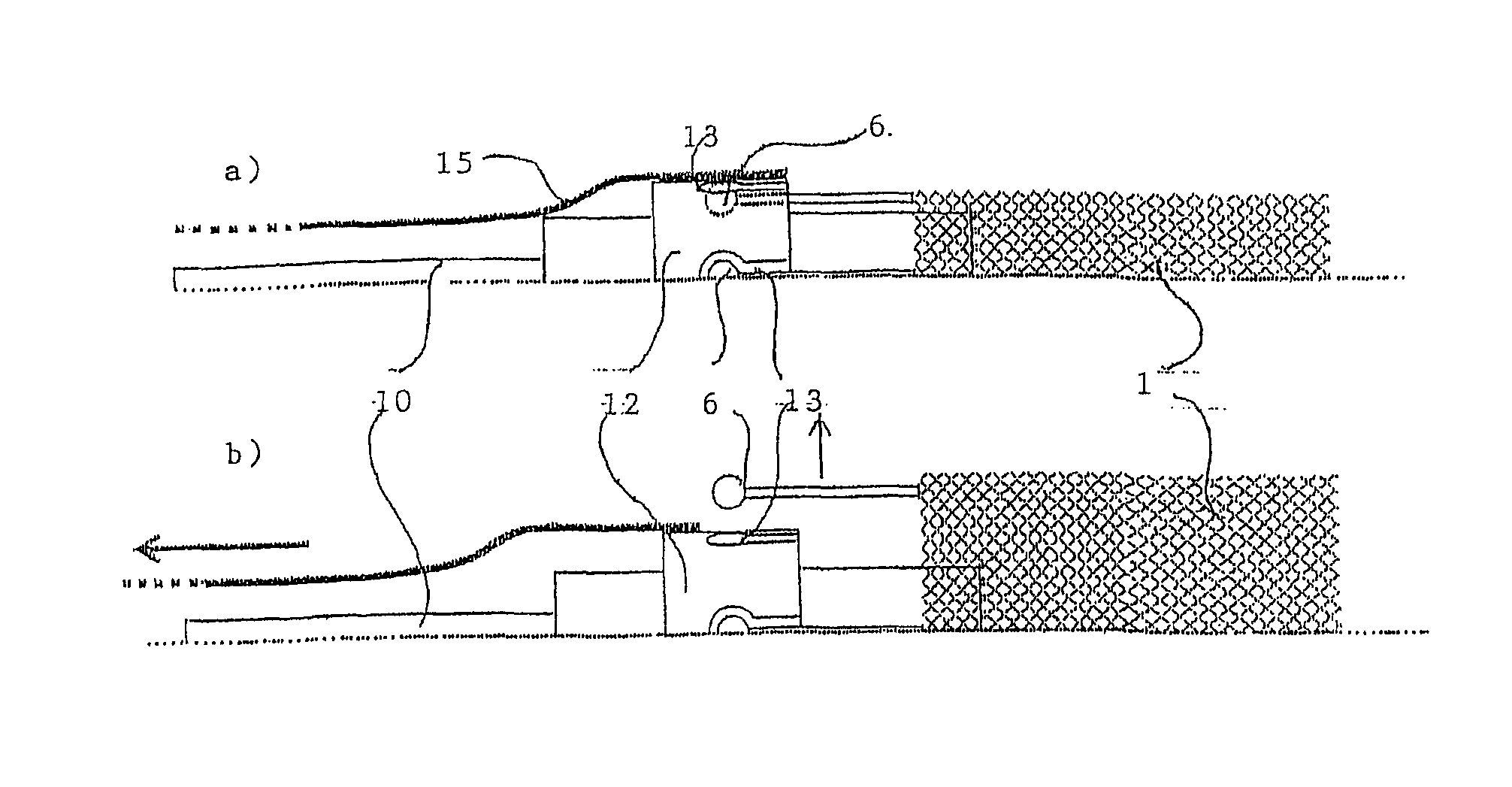

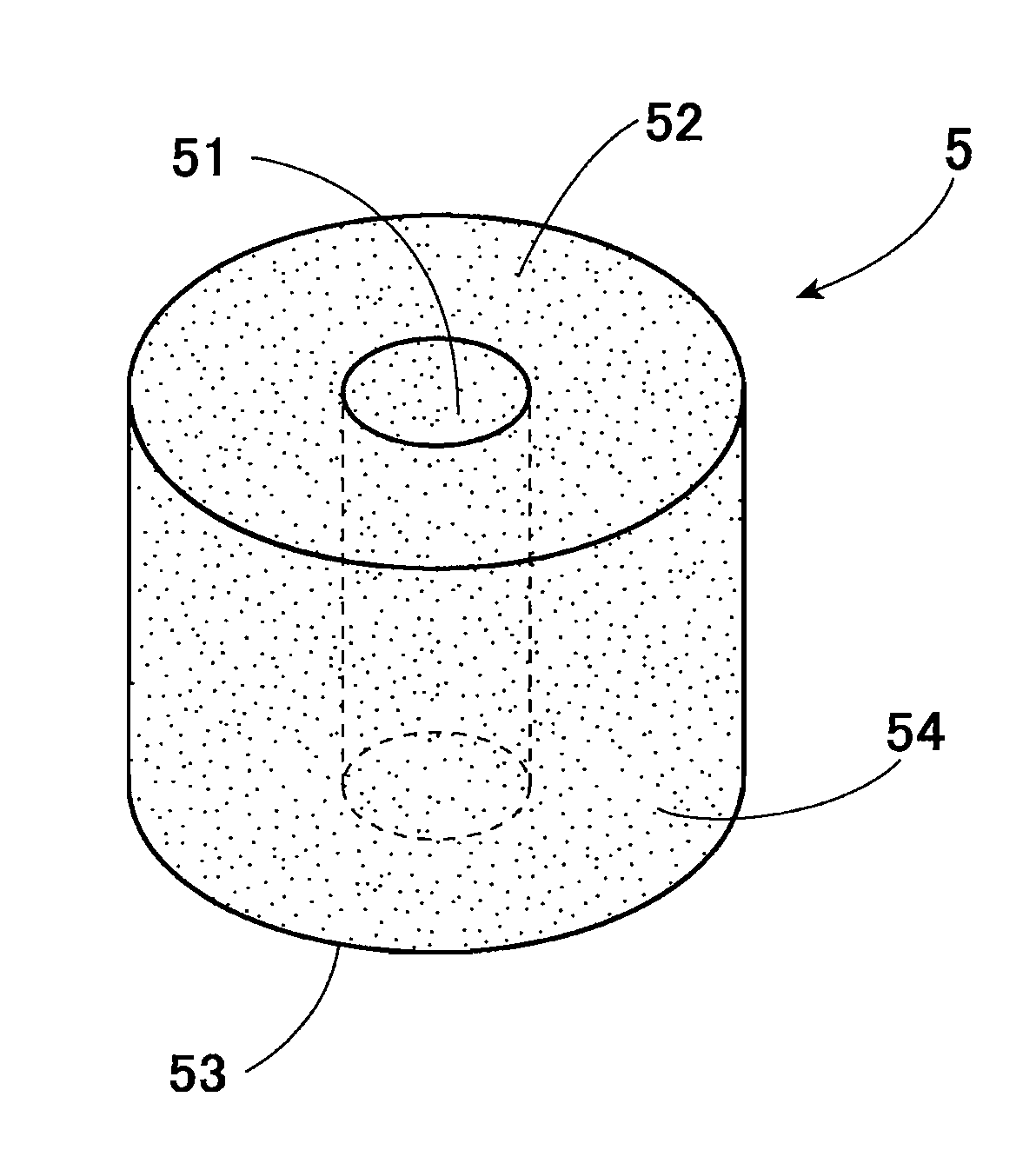

Implant for influencing blood flow

An implant for blood vessels, in particular to influence the flow of blood in the area of arteriovenous malformations. The implant has a wall comprising individual filaments combined so as to form a circular braiding, the circular braiding being positioned in elongated form and with a reduced diameter in an insertion catheter and expanding at the placement site thus adapting to the vessel diameter and increasing its braiding density.

Owner:PHENOX

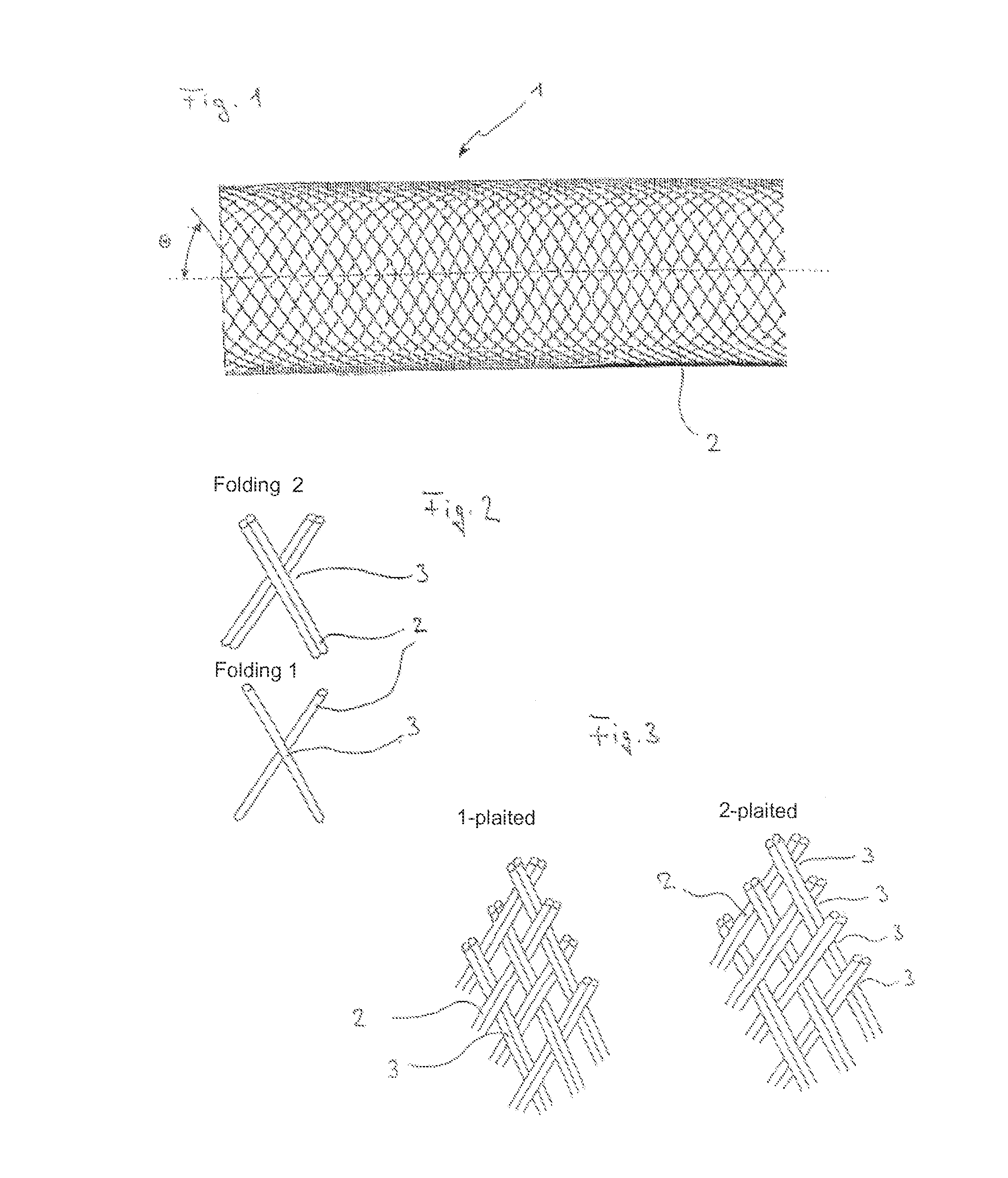

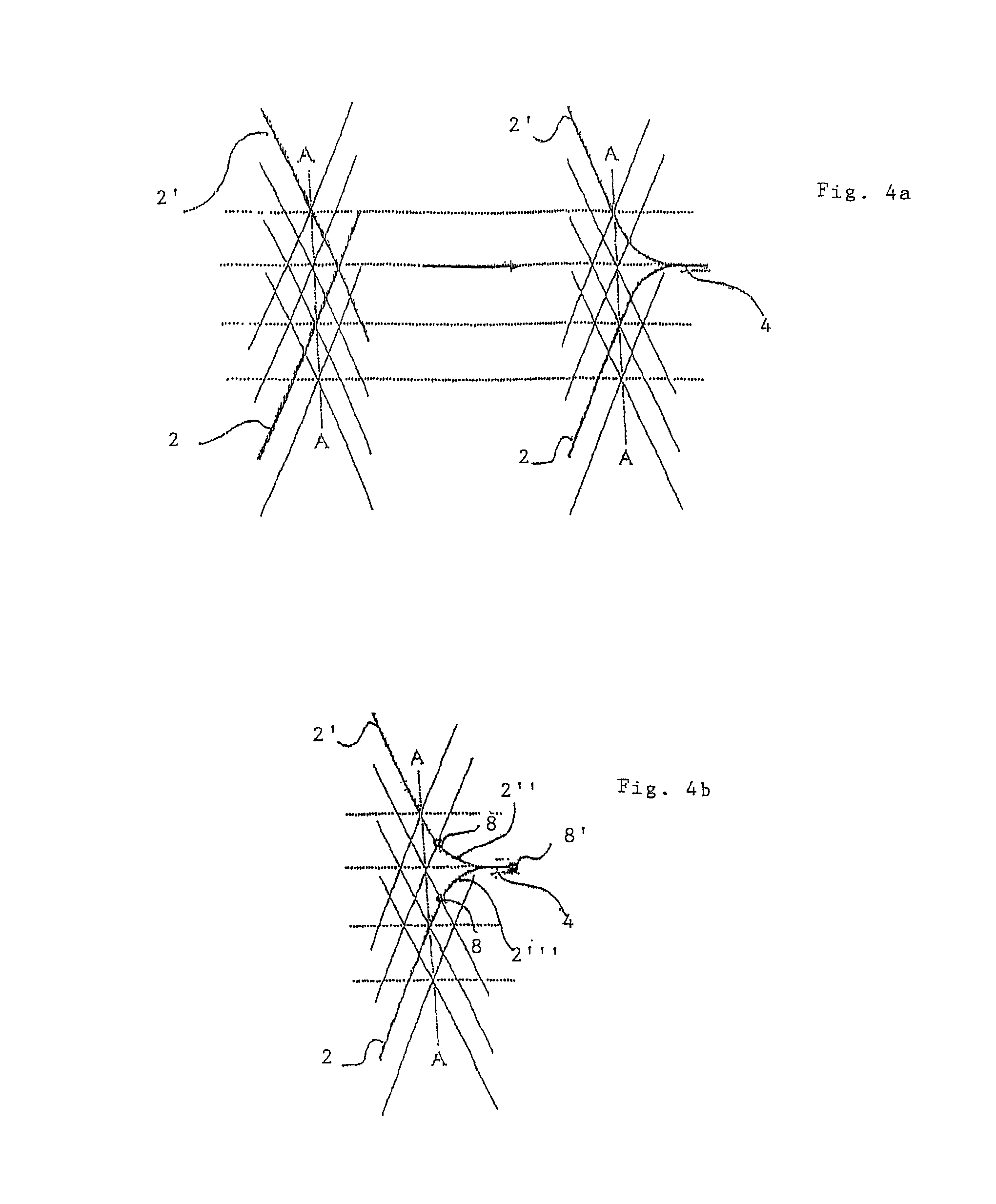

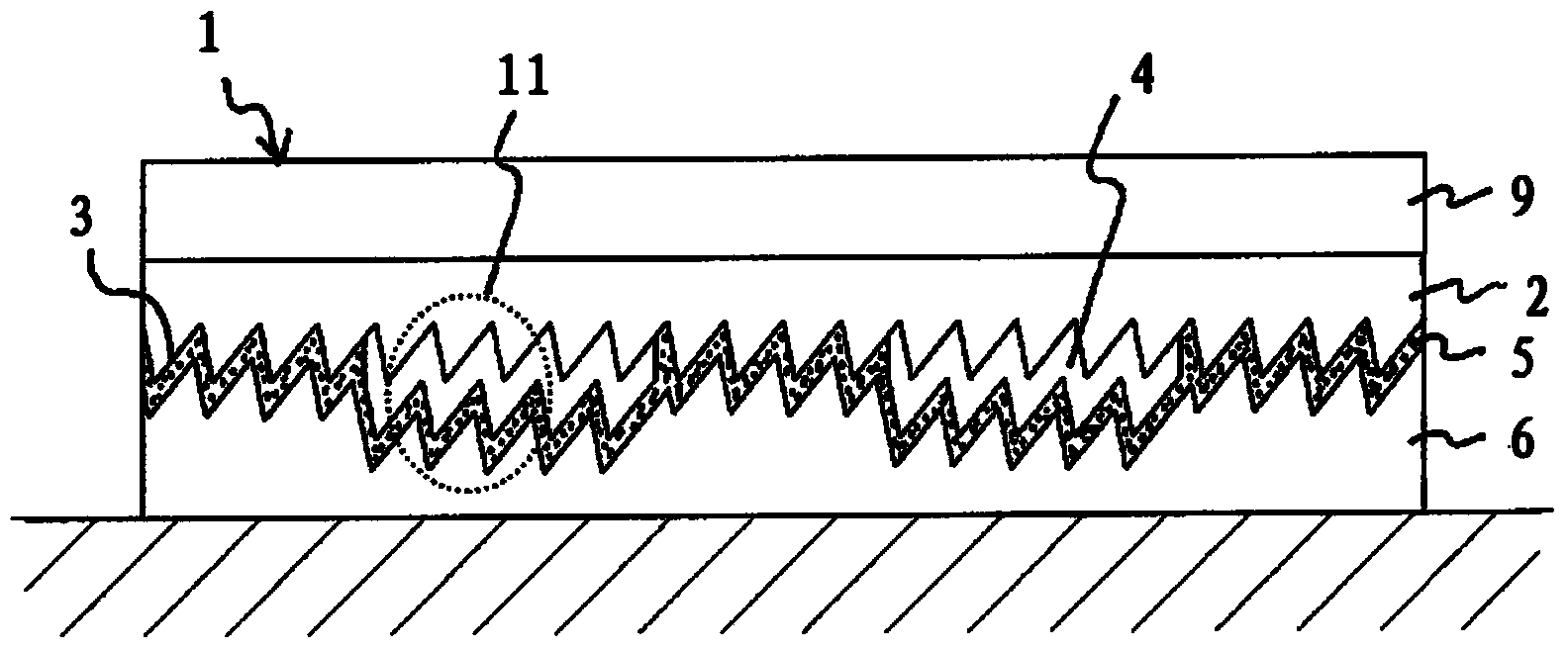

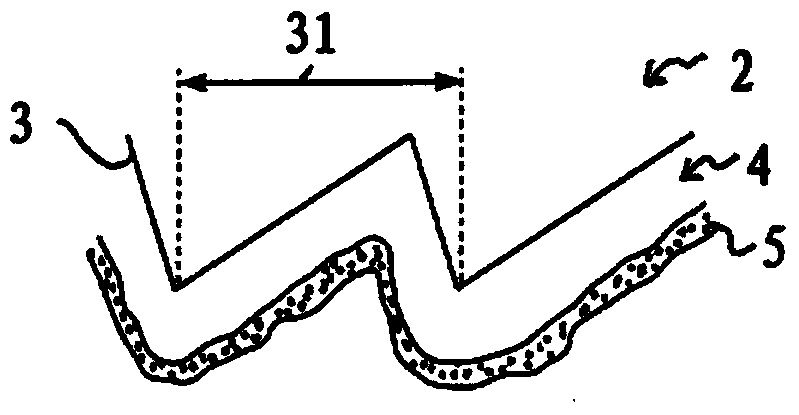

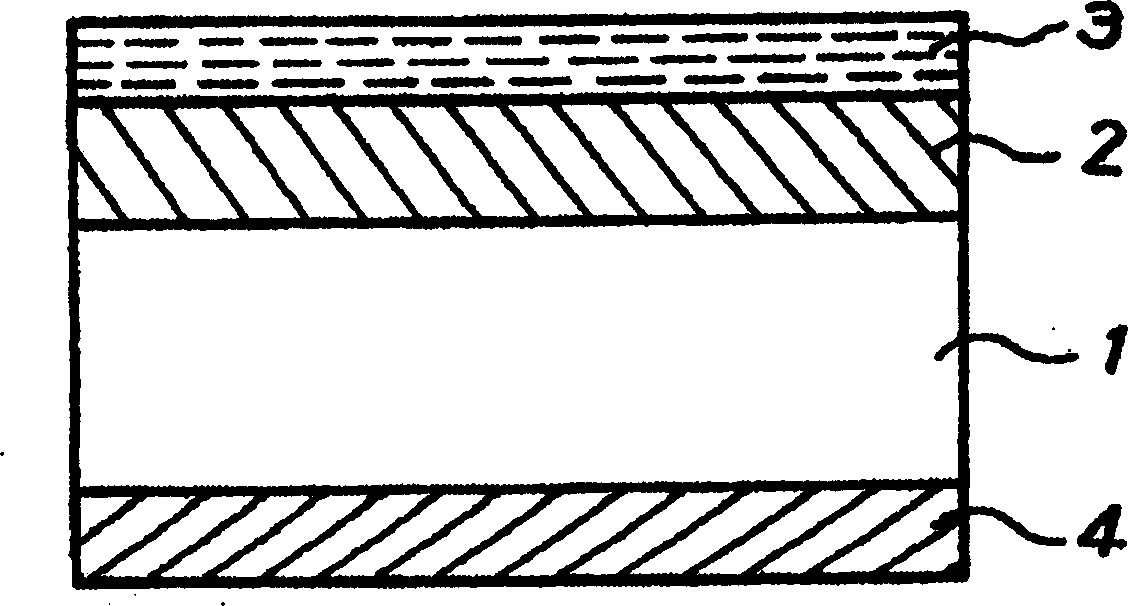

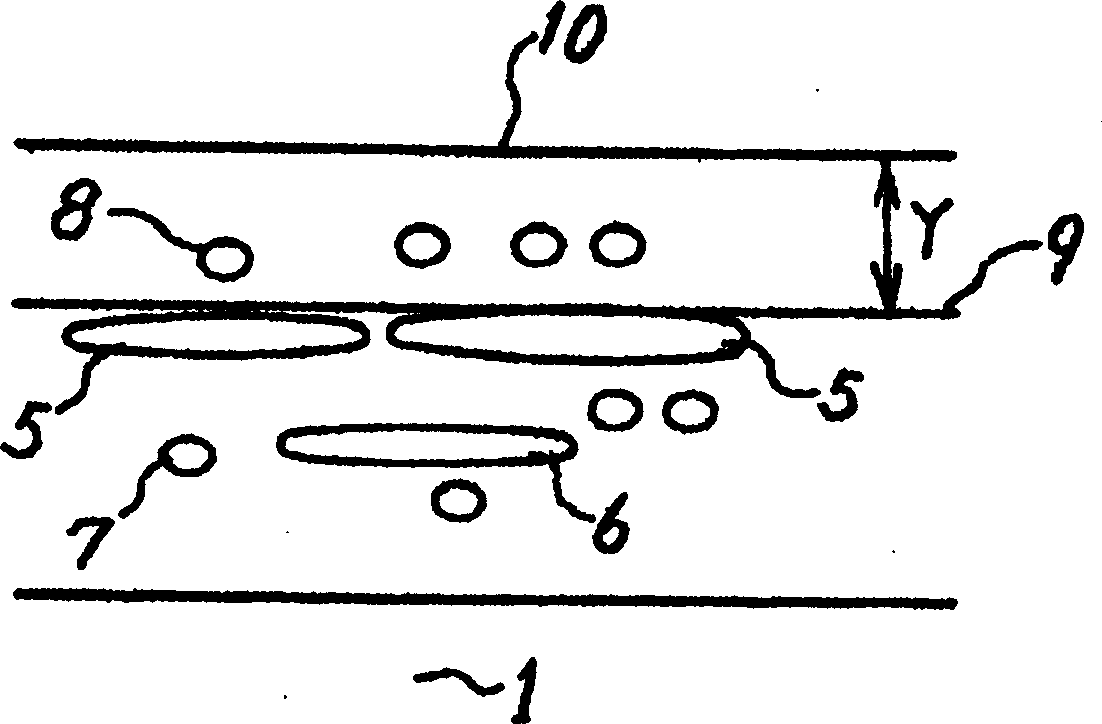

Film and method for producing same

ActiveCN103702841AIncrease flexibilityAchieve colorfulOther printing matterPattern printingLacquerReflective layer

The invention relates to a film (1) and to a method for producing same. The film (1) comprises a translucent replication lacquer layer (2) with a diffractive relief structure (3) formed in a first face (21) of the replication lacquer layer (2), and the film comprises a translucent color lacquer layer (4) which lies on the relief structure (3) and which is formed only in certain regions. The film also comprises a reflective layer (5) which lies on the first face (21) of the replication lacquer layer (2) and which is formed at least in certain regions. The color lacquer layer (4) lies between the replication lacquer layer (2) and the reflective layer (5) in film (1) regions (63) where the color lacquer layer (4) and the reflective layer (5) overlap.

Owner:LEONHARD KURZ STIFTUNG & CO KG

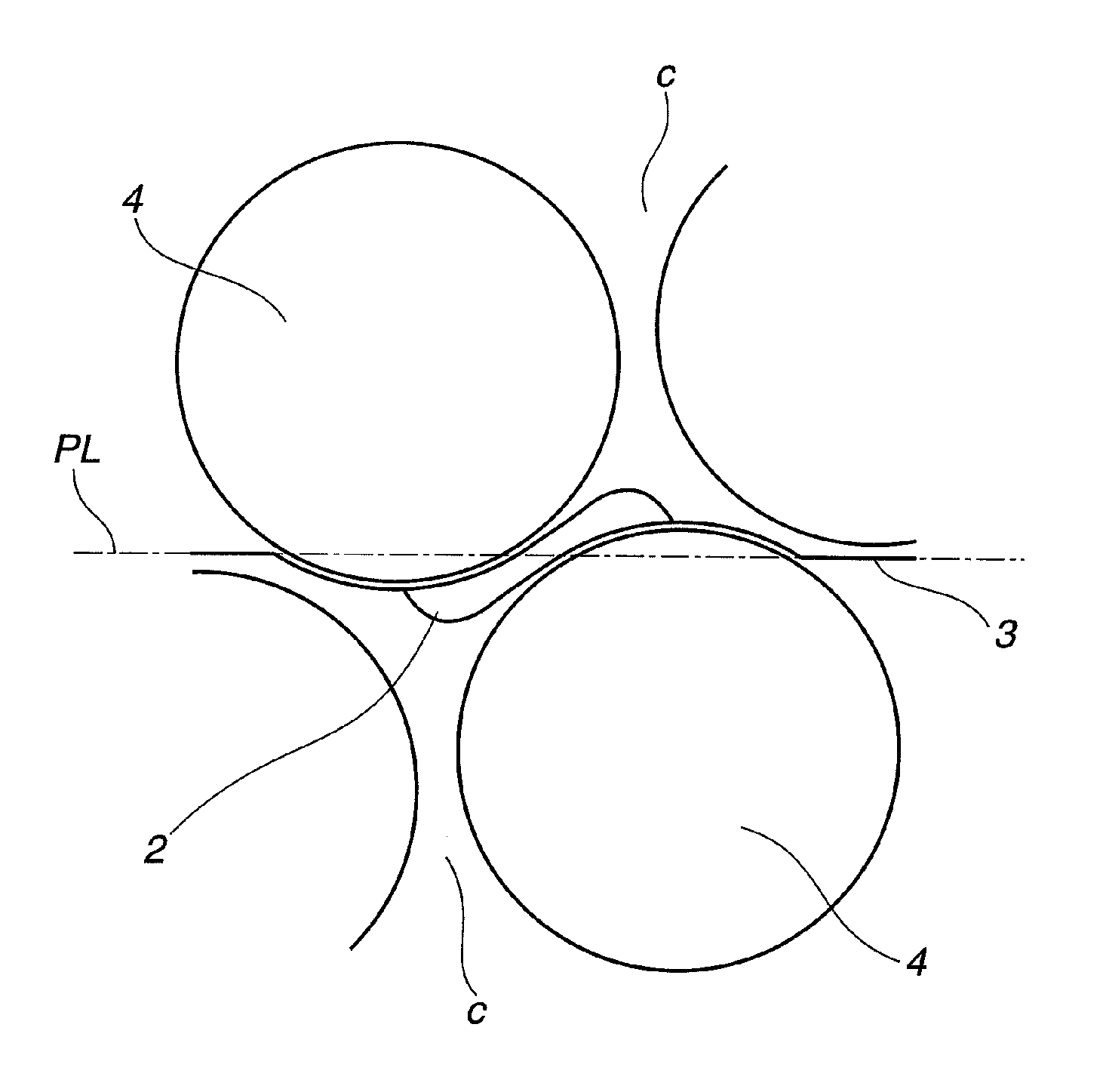

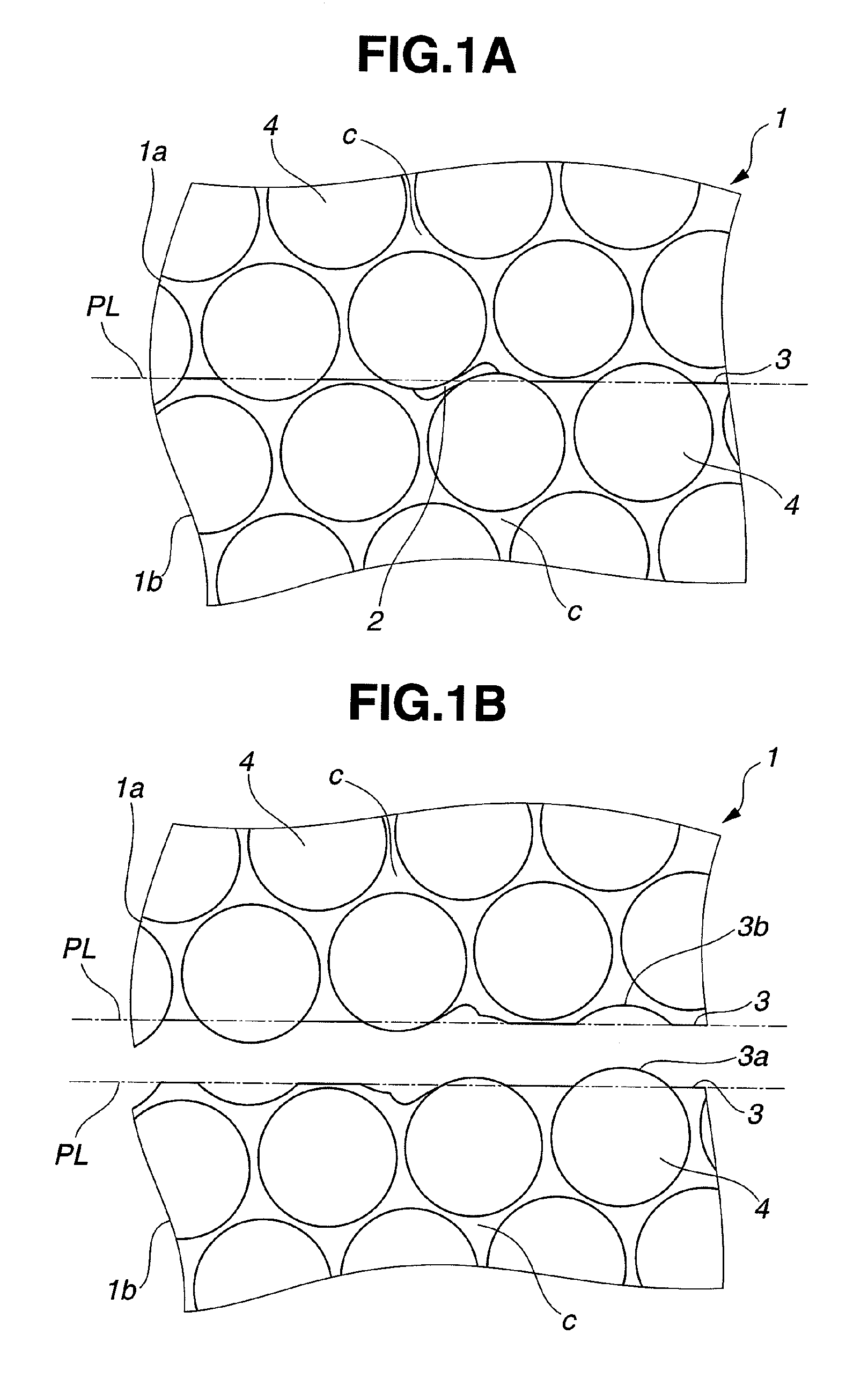

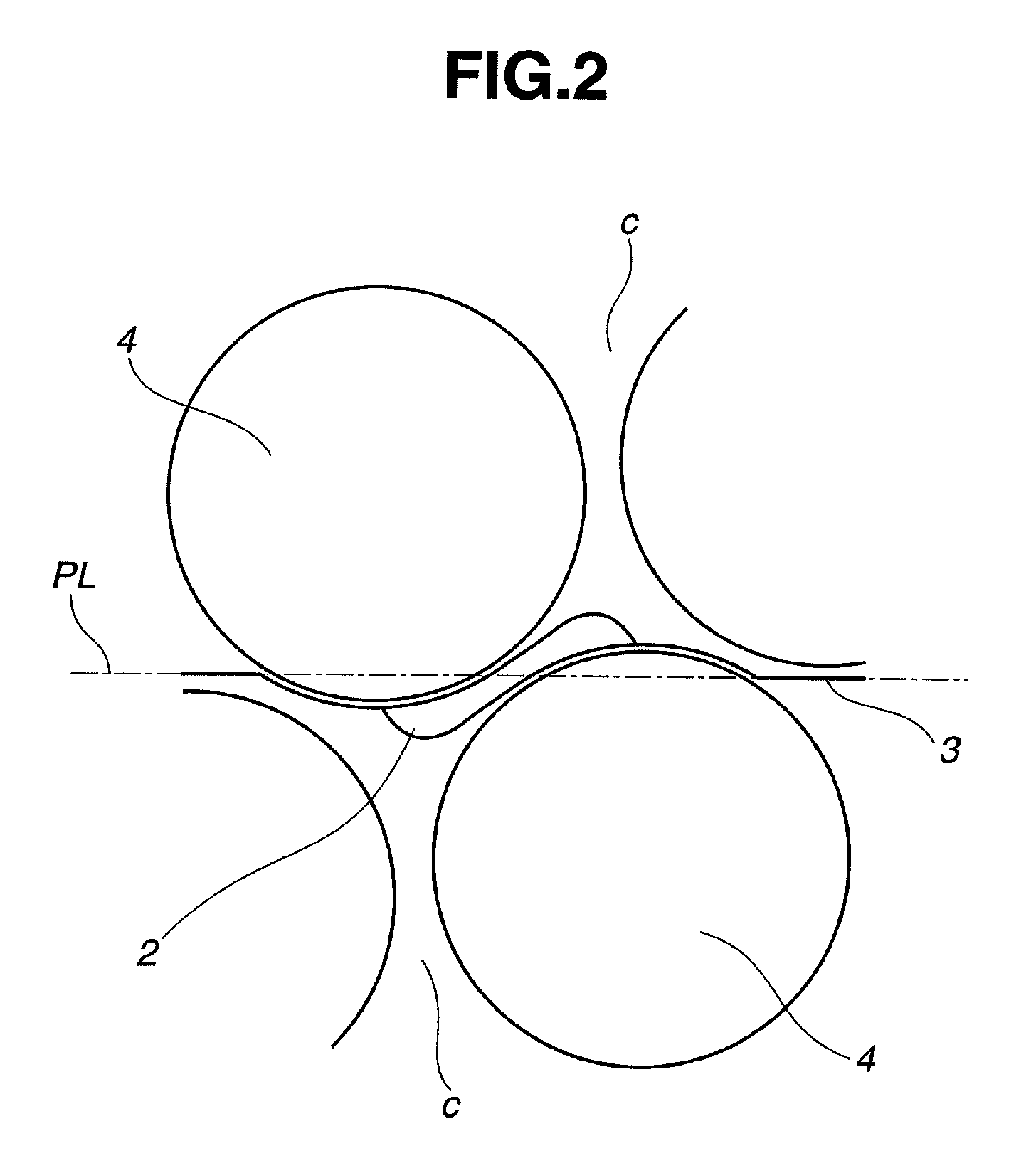

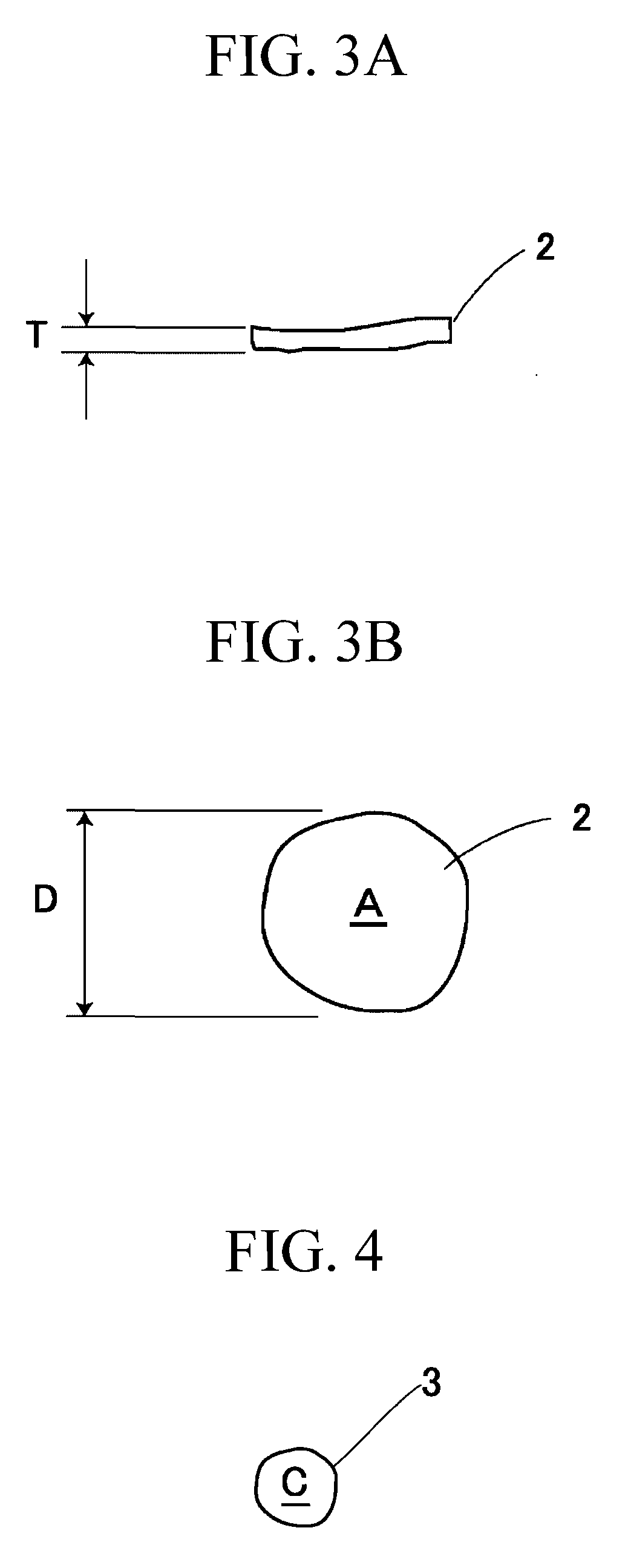

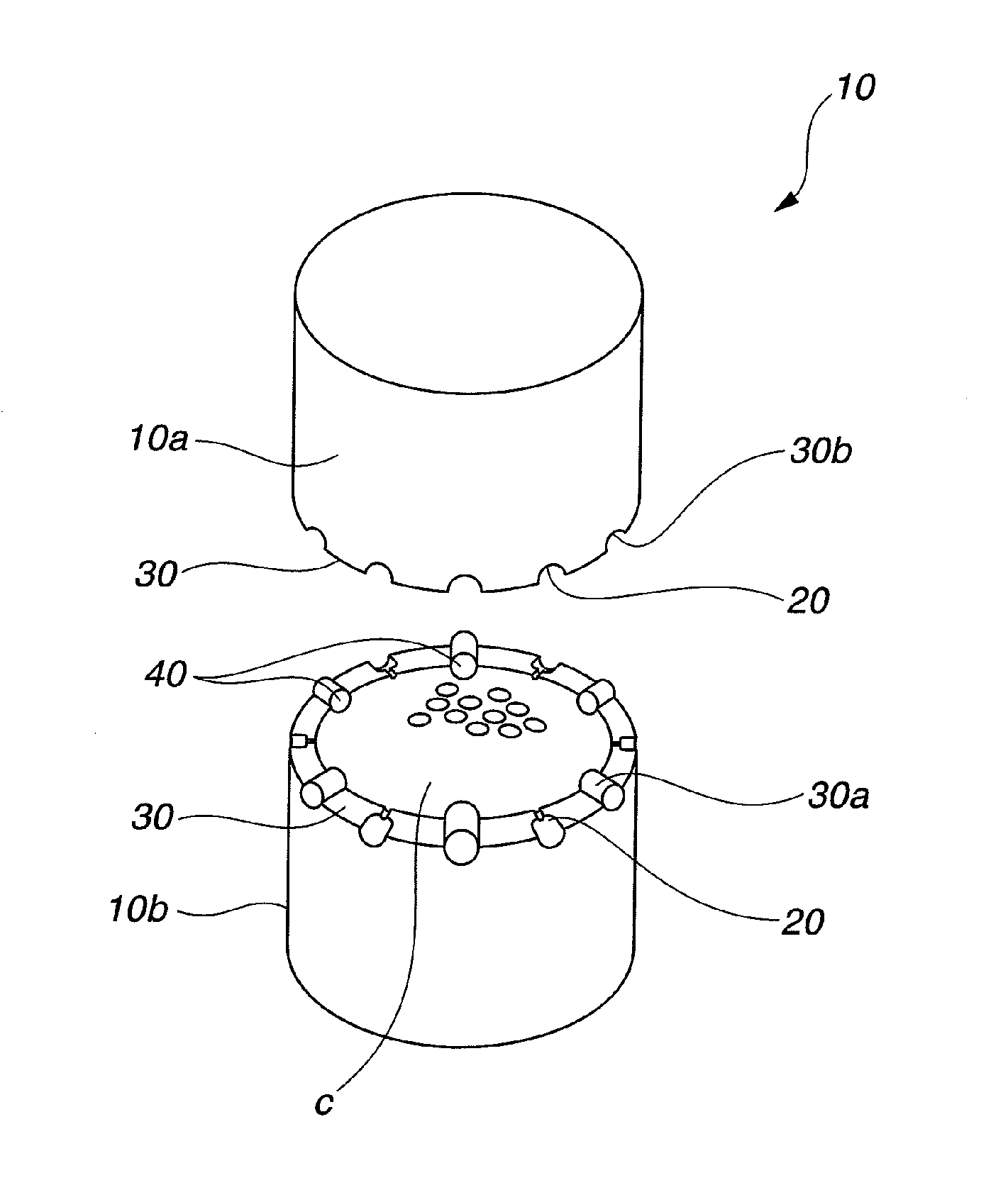

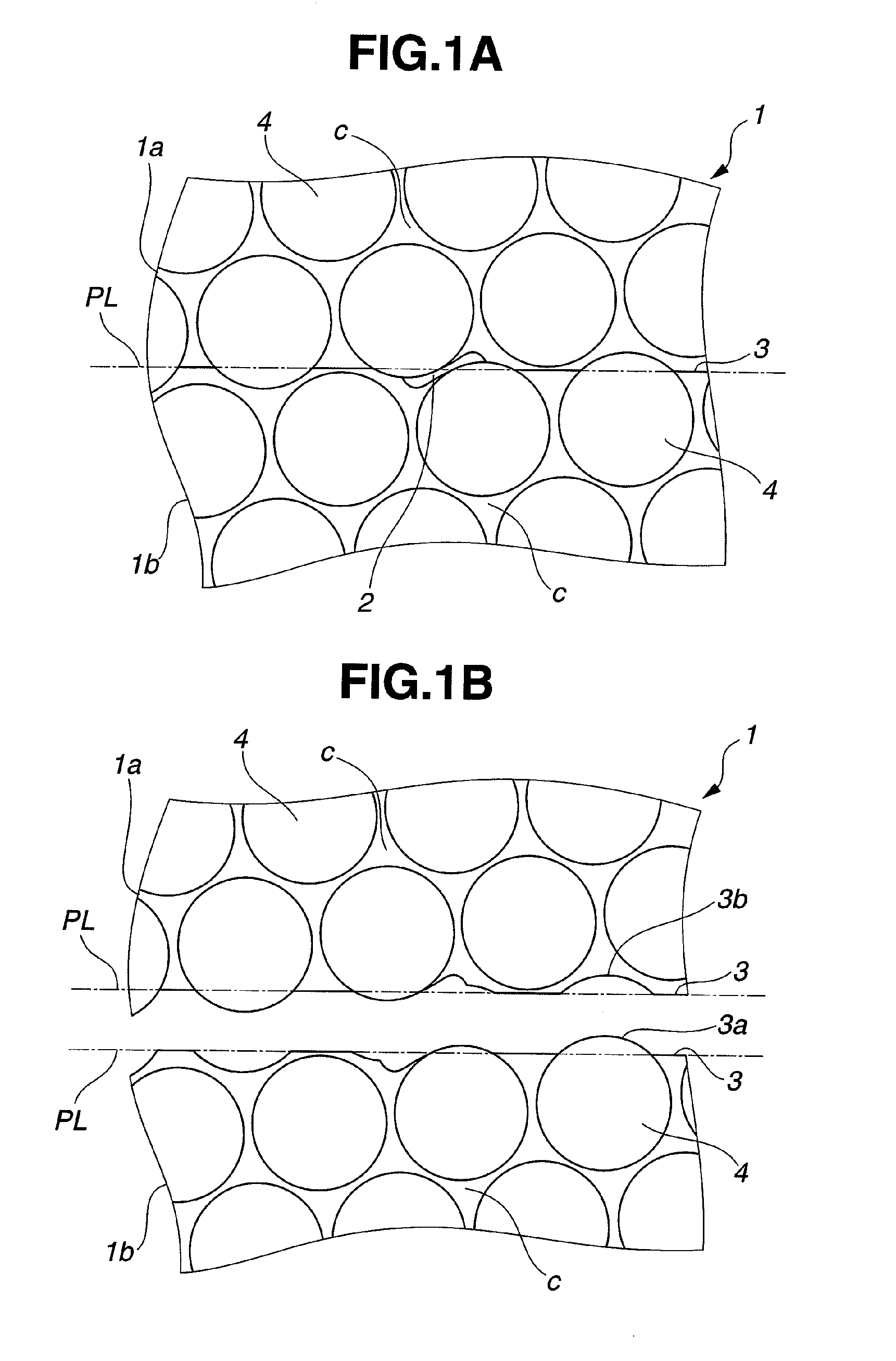

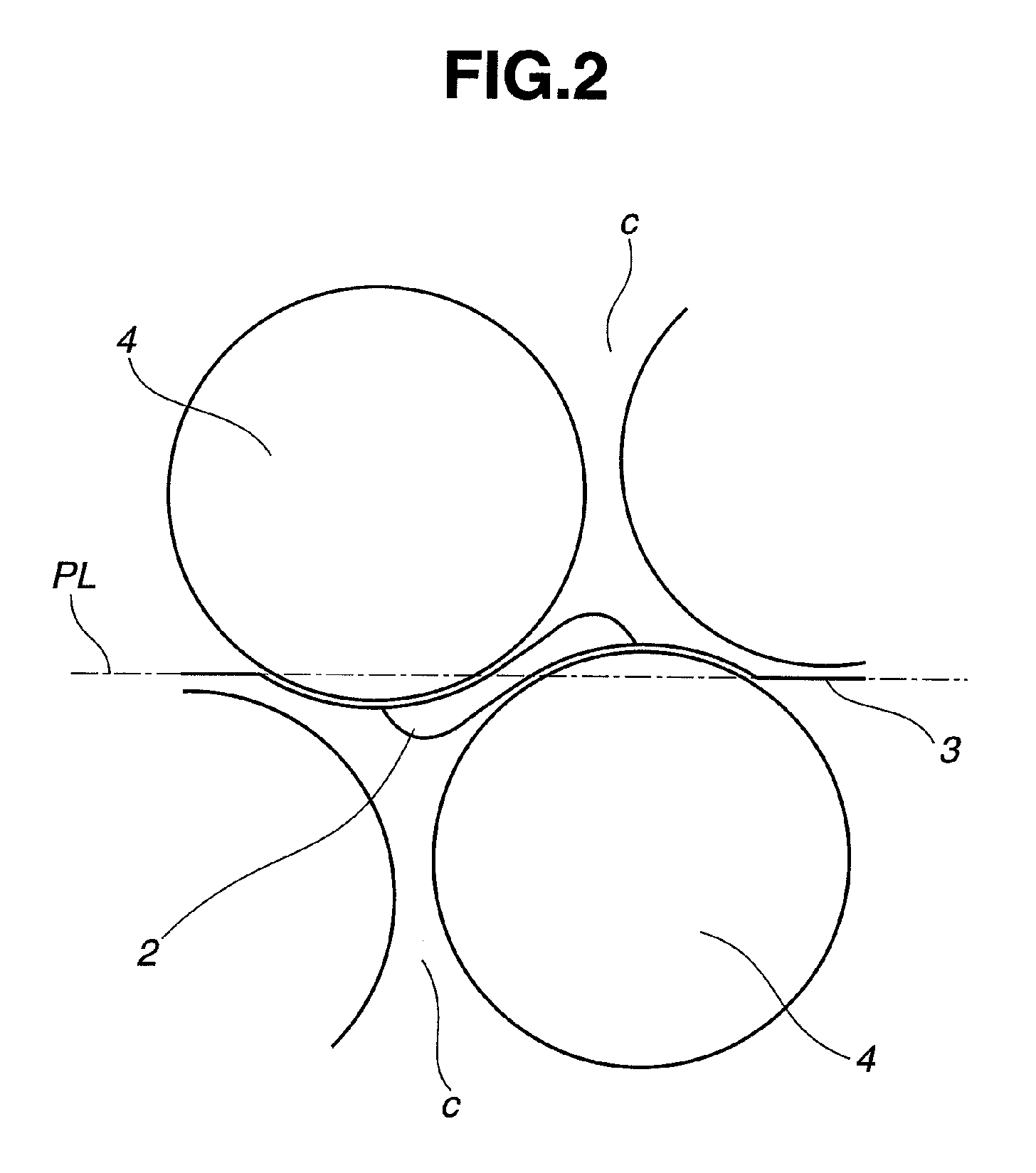

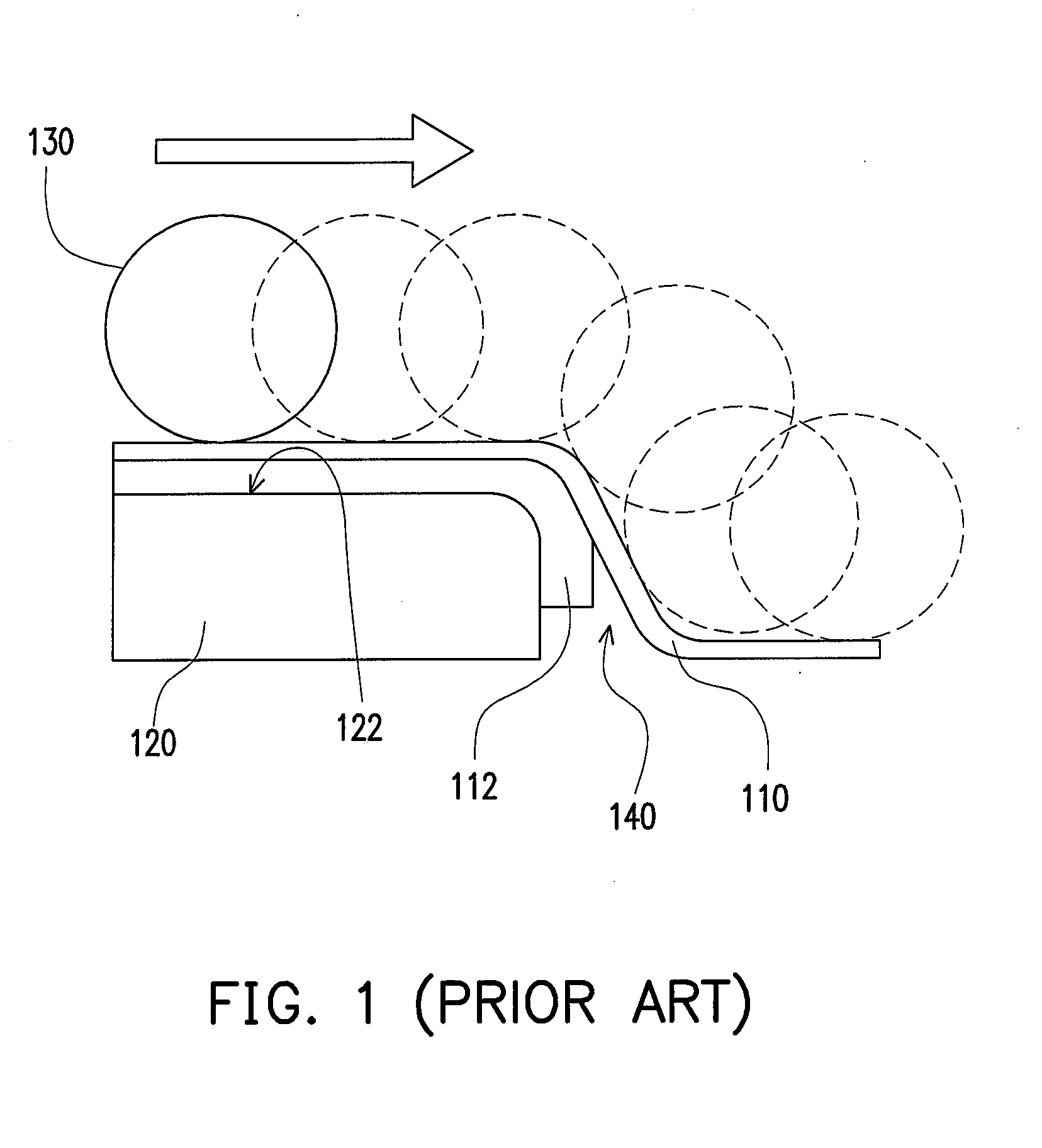

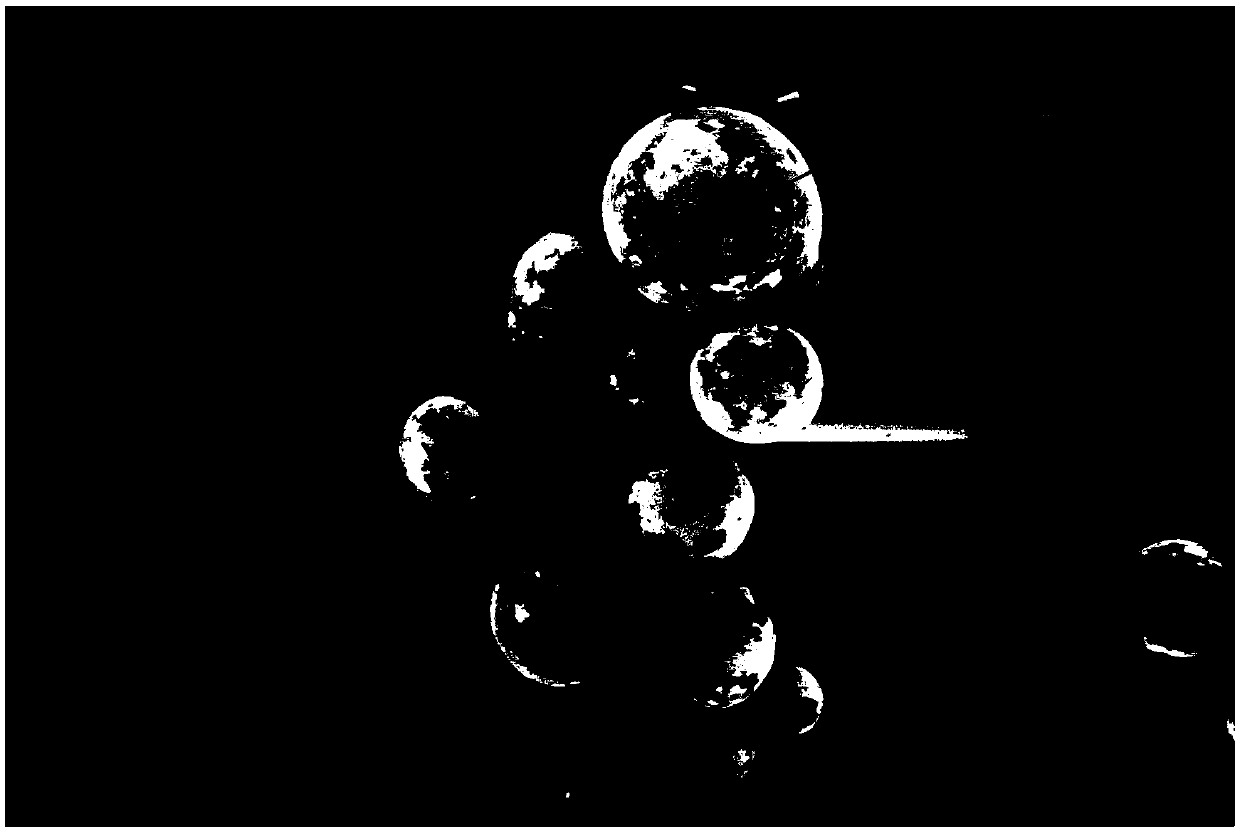

Golf ball mold, golf ball and method of manufacturing a golf ball

ActiveUS8083977B2Easy to liftMolding stabilityTailstocks/centresConfectioneryInjection pressureInjection port

A golf ball mold that is composed of a plurality of mold parts which removably mate to form a cavity having an inner wall with a plurality of dimple-forming protrusions thereon, wherein a non-circular resin injection port is formed between a plurality of mutually adjoining dimple-forming protrusions which include dimple-forming protrusions that lie across a parting line of the mold. Also provided is a golf ball molded using such a mold, and a golf ball manufacturing method which uses such a mold. By using the mold of the invention, even when manufacturing golf balls with a high dimple surface coverage on which the dimples are tightly arranged particularly up to the vicinity of the resin injection port, imbalances in the resin injection pressure and flow rate during injection molding are suppressed, enabling golf balls to be manufactured without production problems such as molding defects, scorching, core deformation and core eccentricity.

Owner:BRIDGESTONE SPORTS

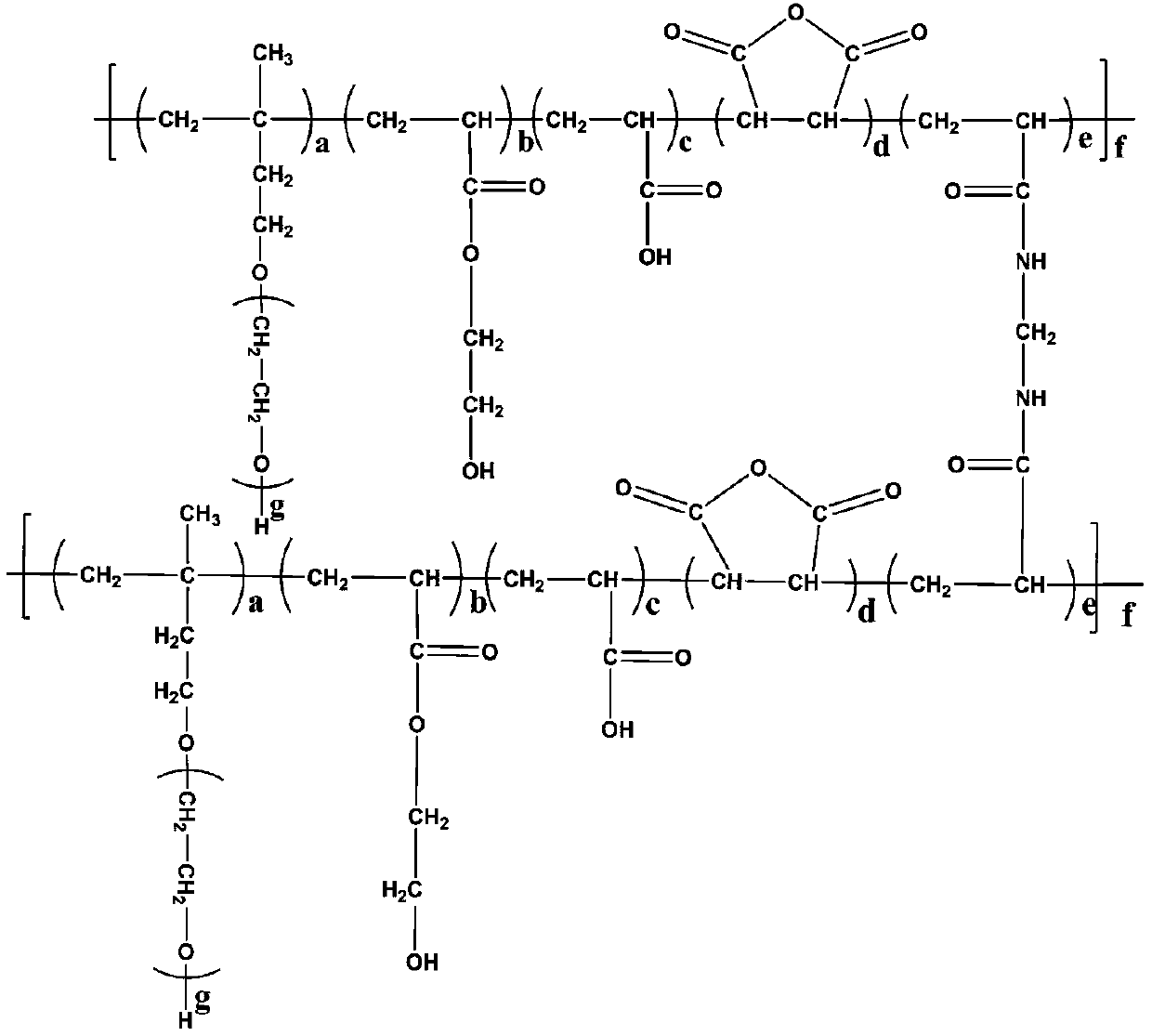

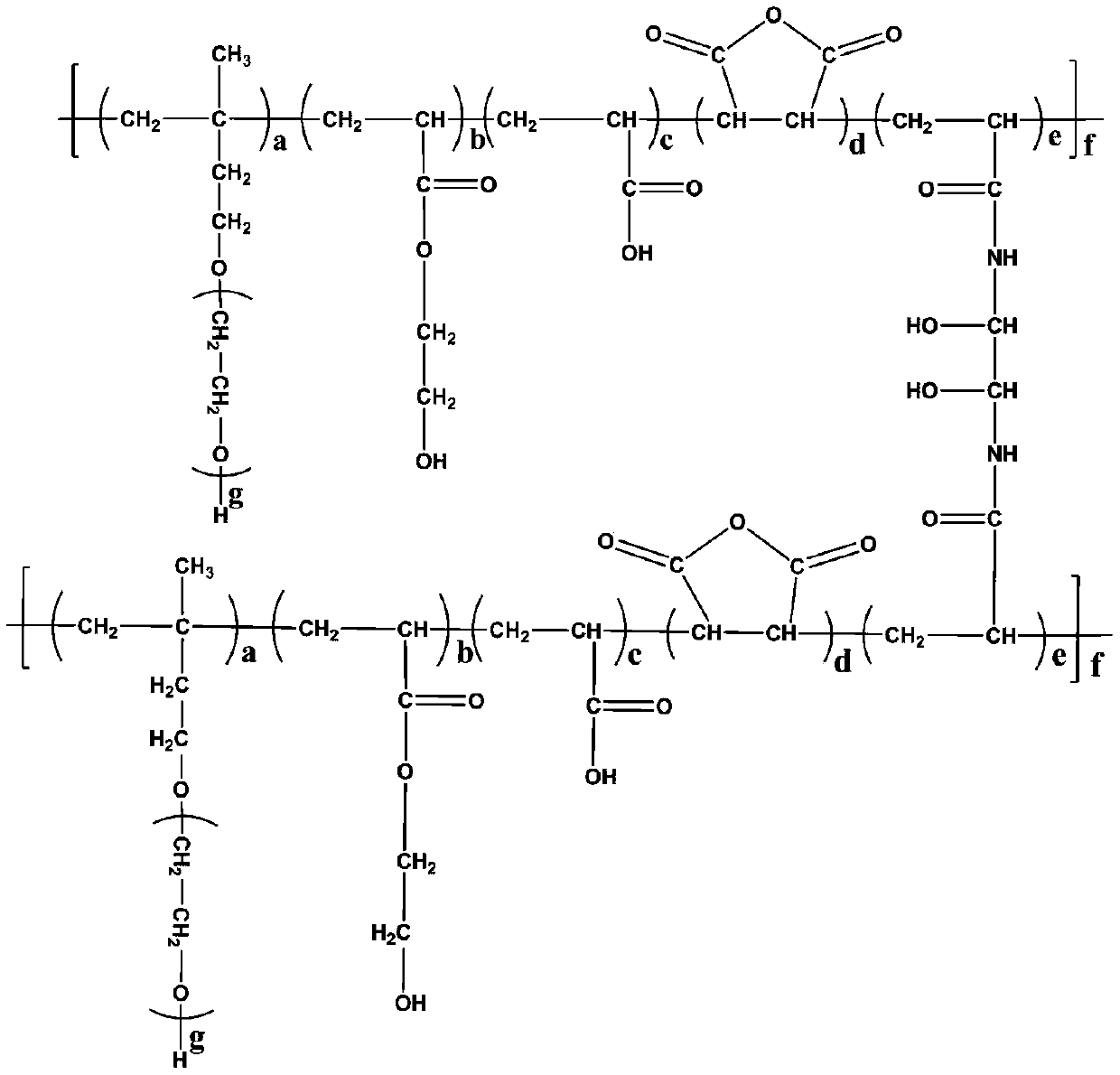

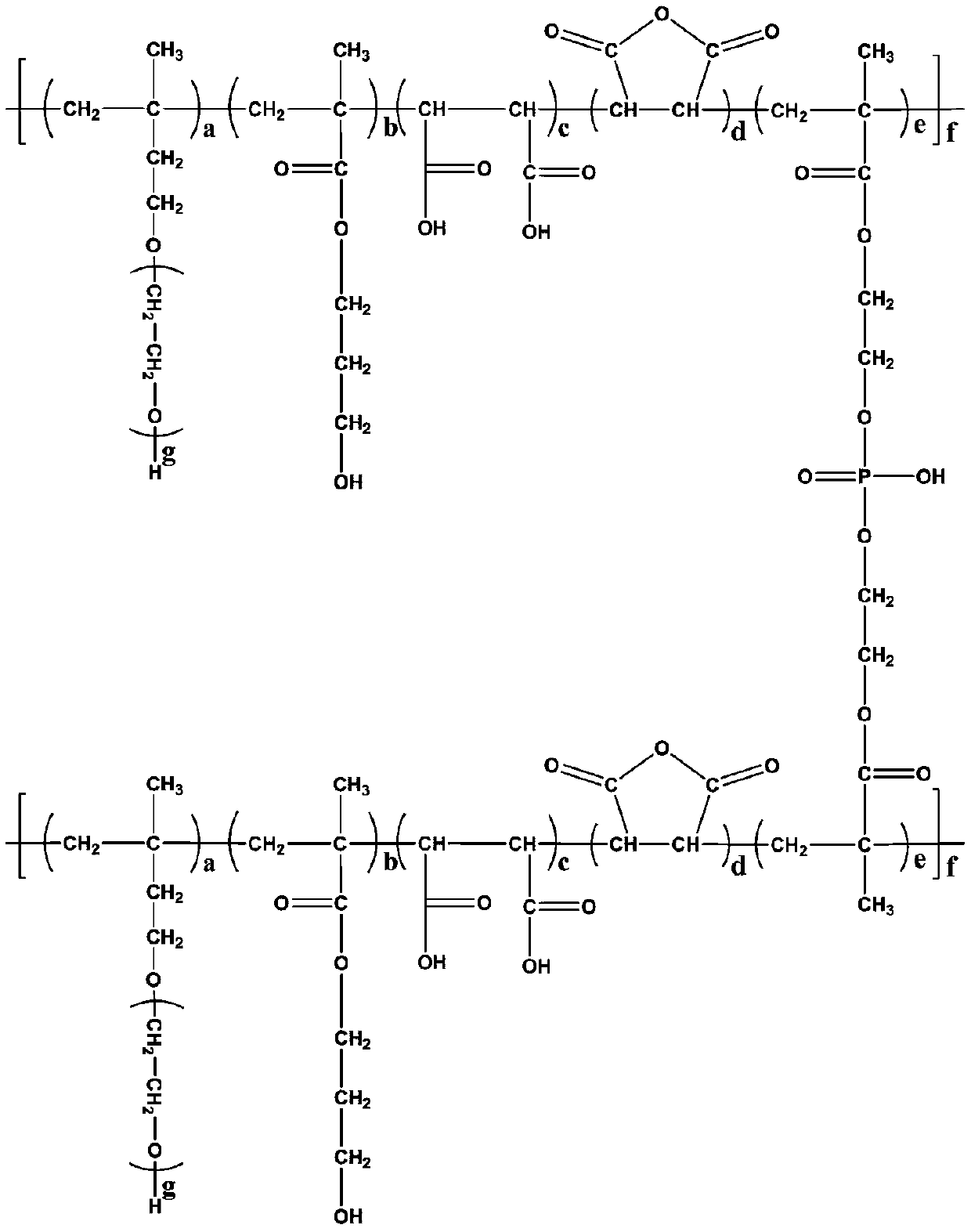

Viscosity reduction type polycarboxylate superplasticizer with microcrosslinking structure and preparation method of viscosity reduction type polycarboxylate superplasticizer

ActiveCN110790872AImprove molecular structureIncreasing the thicknessPolymer scienceSuperplasticizer

The invention discloses a viscosity reduction type polycarboxylate superplasticizer with a microcrosslinking structure. The viscosity reduction type polycarboxylate superplasticizer is prepared from unsaturated acids, unsaturated anhydride, isopentene polyoxyethylene ether, a crosslinking agent and a reactive cosolvent as polymerization raw materials through free radical pauperization under actions of an initiator and chain transfer, components and structures take mutual synergetic effects into play, and compared with a viscosity reduction type polycarboxylate superplasticizer synthesized in the prior art, the viscosity reduction type polycarboxylate superplasticizer has an excellent viscosity reduction effect and has collapse prevention and regulation and control on early strength functions as well; meanwhile, due to introduction of the structure, the thickness of an adsorption layer on the surface of cement granules can be increased, the cement granule surface covering rate can be increased, the concentration of the polycarboxylate superplasticizer retained in a cement pore liquid can be reduced, surface activation performance of the polycarboxylate superplasticizer can be enhanced, and a good viscosity reduction effect can be achieved. Due to adoption of the reactive cosolvent, the intermiscibility of monomers can be effectively improved, and the polymerization efficiency ofa polymer and structure arrangement of effective molecules can be improved. Due to adoption of a bifunctionality crosslinking agent in the polycarboxylate superplasticizer, the molecular structure ofthe polycarboxylate superplasticizer can be improved, and the viscosity reduction performance of the polycarboxylate superplasticizer can be improved.

Owner:CHINA WEST CONSTR GRP +2

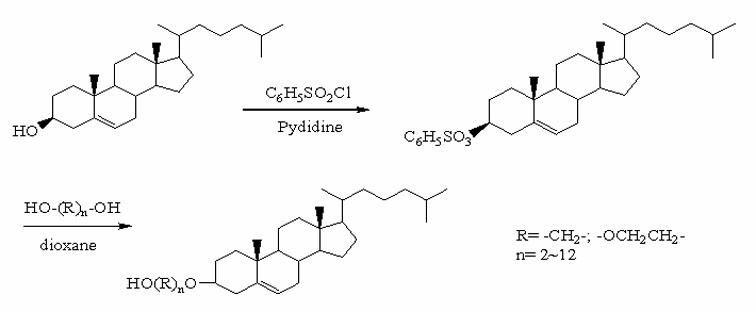

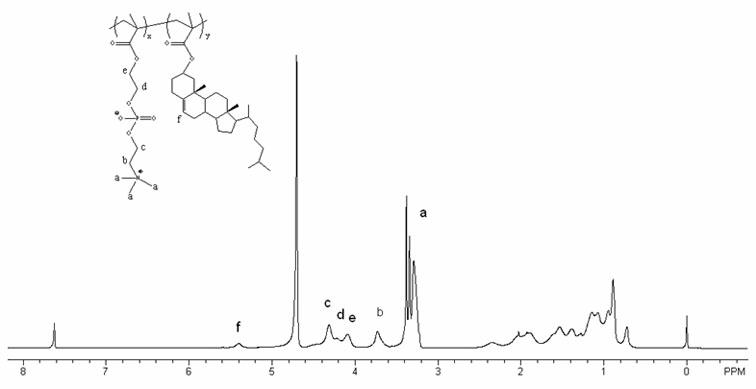

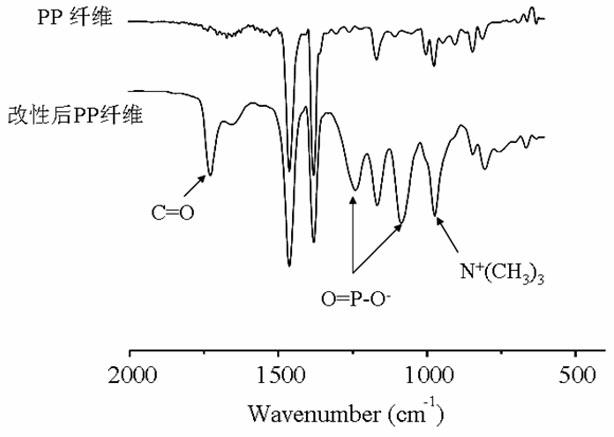

Biomimetic polymer, and preparation method and application thereof

The invention discloses a copolymer shown as a structure general formula (I). In the formula, x and y are integers between 10 and 1,000, the molar content of x is 30 to 80 percent, and the molar content of y is 20 to 70 percent; R1 and R2 are H or CH3; W is a hydrophilic group connected with 2 to 8 carbon atom chains, and the hydrophilic group is a phosphorylcholine group, a carboxylic acid betaine group, a sulfobetaine group, a quaternary ammonium group or a sulfonic acid group; and Z is a hydrophobic rigid group connected with 0 to 12 carbon atom chains, and the hydrophobic rigid group is a cholesterol group, a dihydrocholesterol group, a beta-sitosterol group, a stigmasterol group, a 7-dehydrocholesterol group or an ergot sitosterol group. The minimum content of hydrophilic groups such as phosphorylcholine and the like in the polymer is 30 percent; and the coating prepared by the method has high surface coverage rate of hydrophilic groups as well as good hydrophilic nature and high biocompatibility, and can be widely applied to the hydrophilic treatment of the surfaces of materials and the biocompatibility modification of the surfaces of biomedical materials.

Owner:NORTHWEST UNIV

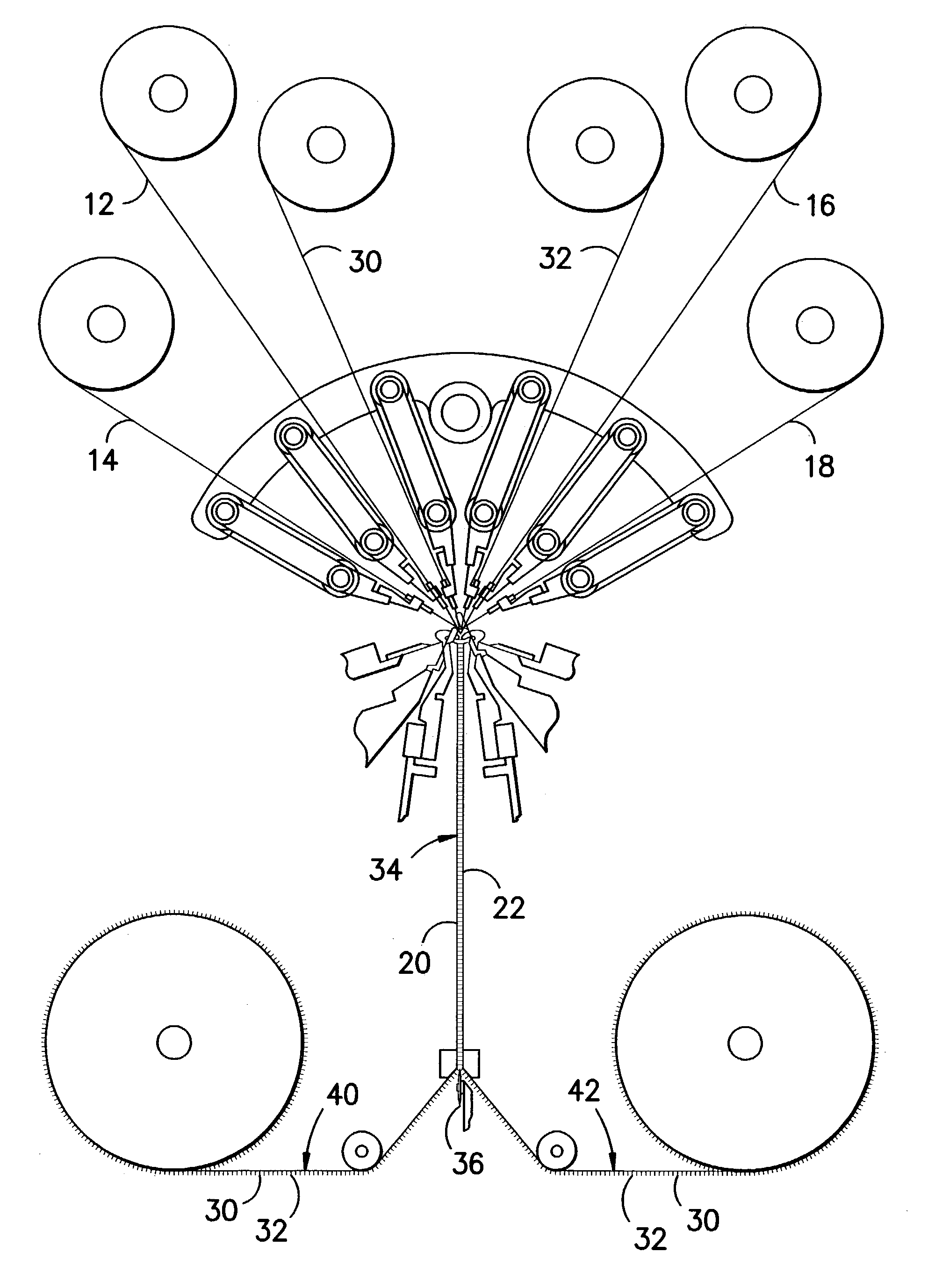

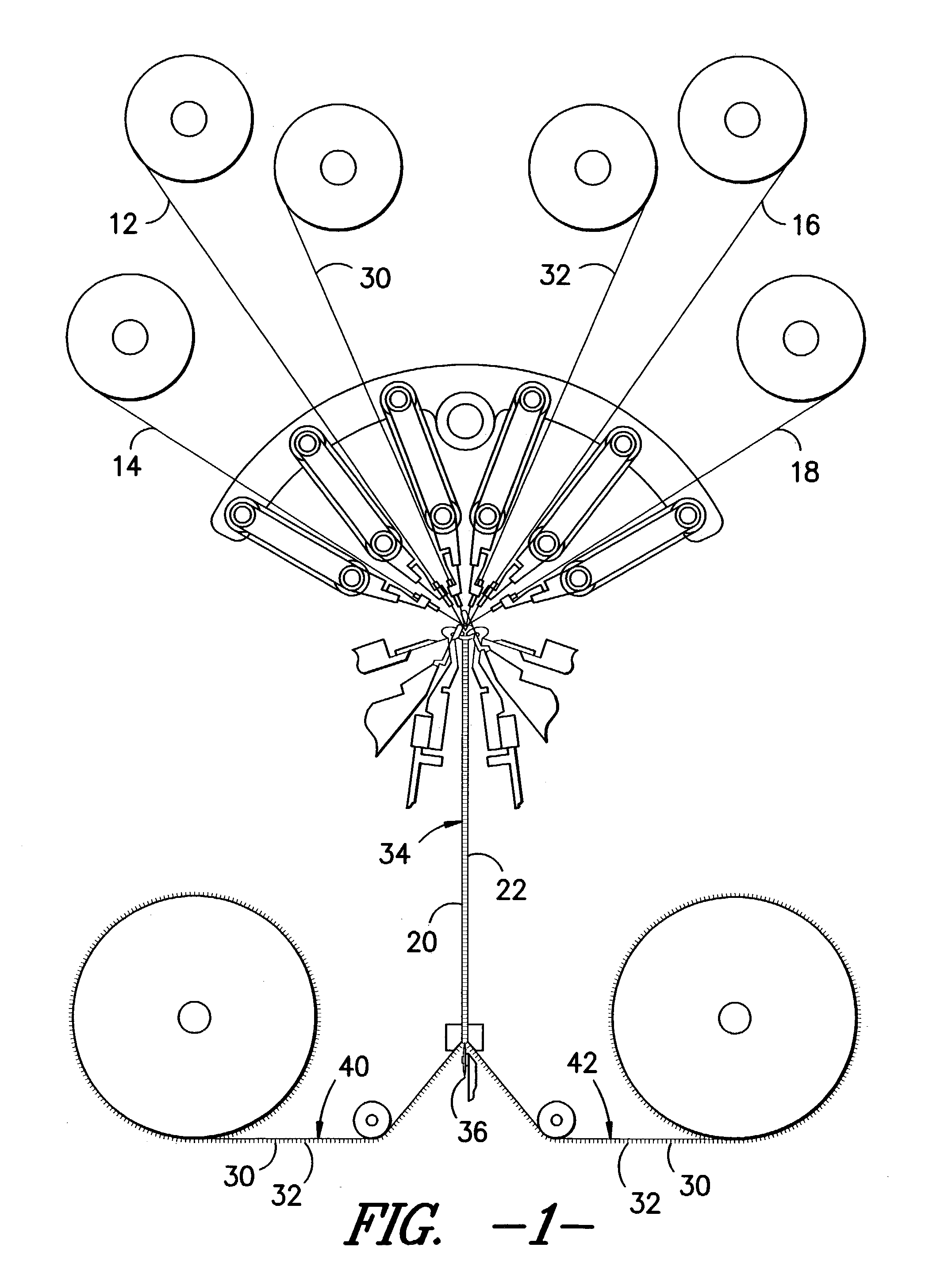

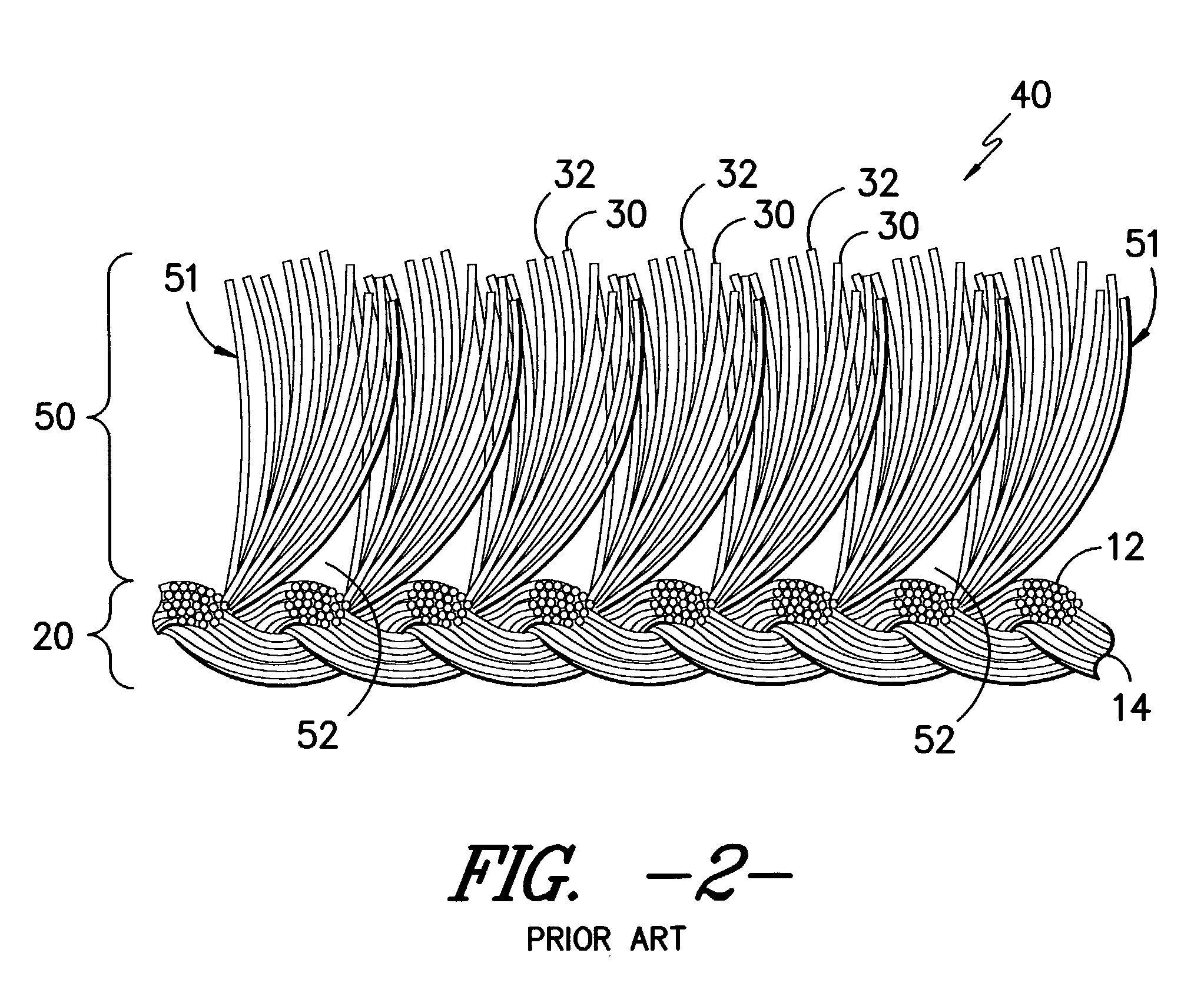

Pile fabric

ActiveUS7086423B2High surface coverageSoft touchWarp knittingPile-fabric loomsFiberMechanical engineering

A pile fabric such as may be used in automotive and furniture upholstery and other applications which fabric incorporates a pile surface formed from variable height fibers. The pile is made up of a first group of fibers having a first height and at least a second group of fibers having a second height which is on average less than the height of the first group. A method of formation is also provided.

Owner:SAGE AUTOMOTIVE INTERIORS INC

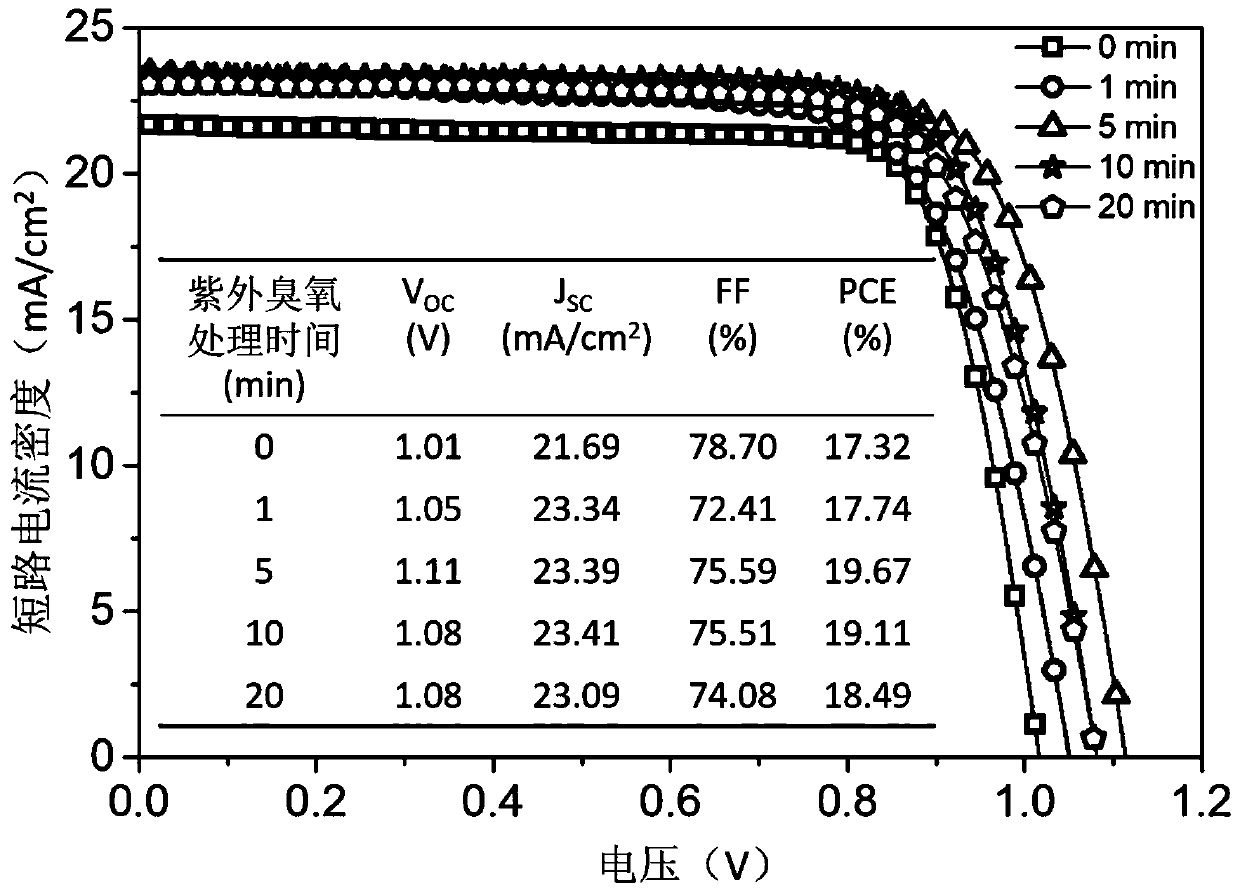

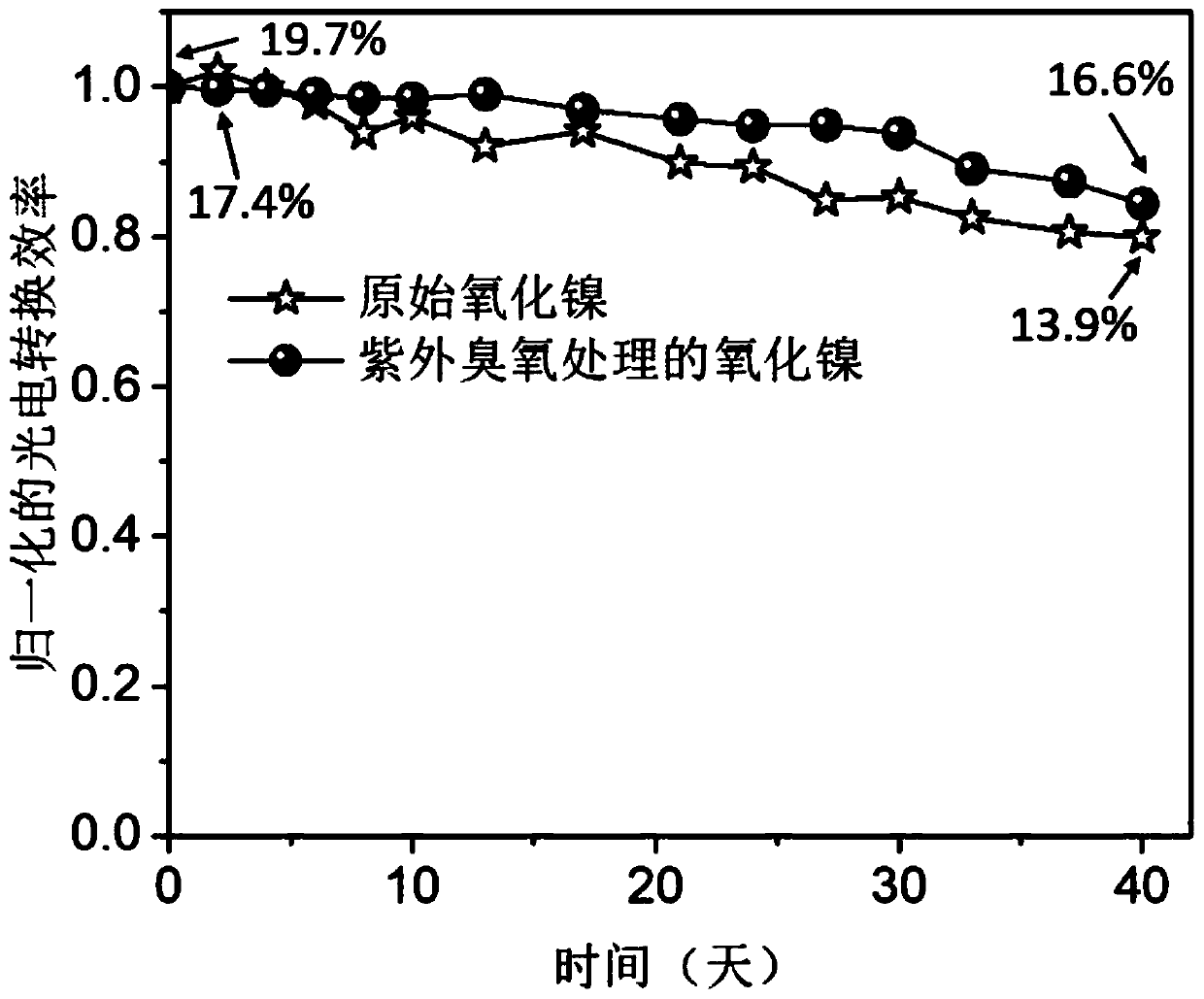

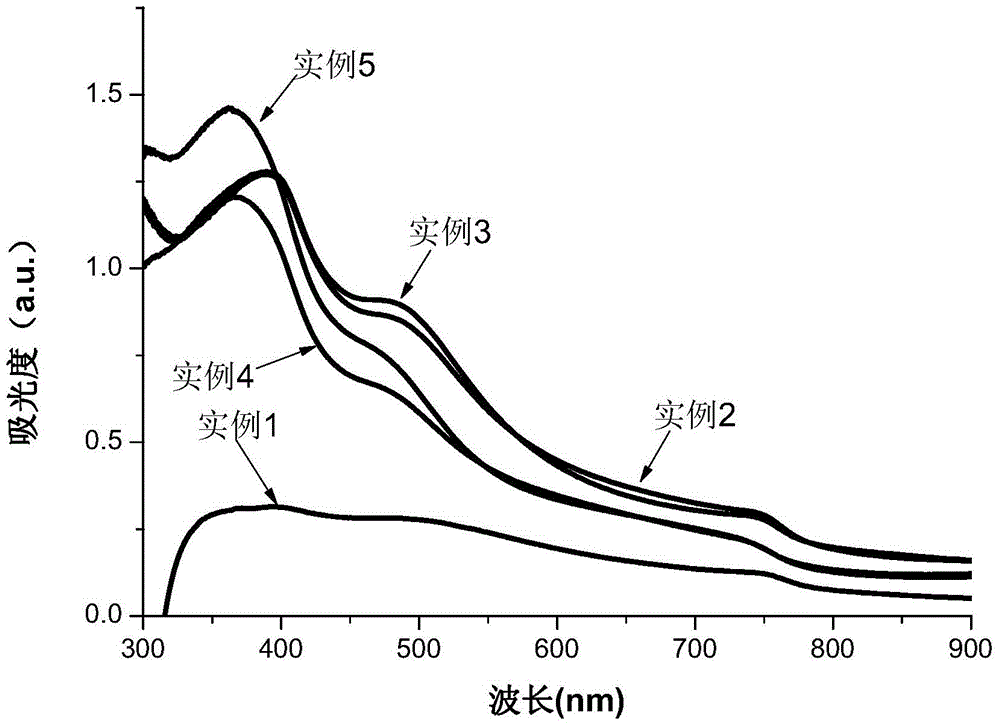

Preparation method of perovskite solar cell based on nickel oxide hole transport layer

InactiveCN109841740AImprove conductivityHigh crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellNanoparticle

The invention discloses a preparation method of a perovskite solar cell based on a nickel oxide hole transport layer. The core innovation of the preparation method is to add an ultraviolet ozone surface treatment technology in the preparation step of a hole transport layer. The problem that the thickness is not uniform and holes can be generated easily for a nickel oxide hole transport layer prepared by spin coating is solved, and the perovskite film in the device is prevented from directly contacting a transparent electrode to affect the performance of the device. Compared with the method ofmodifying a nickel oxide film by doping nanoparticles, a perovskite solar cell prepared by the method of the invention is more stable, and the difference between the devices prepared by the method issmaller.

Owner:SHANGHAI JIAO TONG UNIV

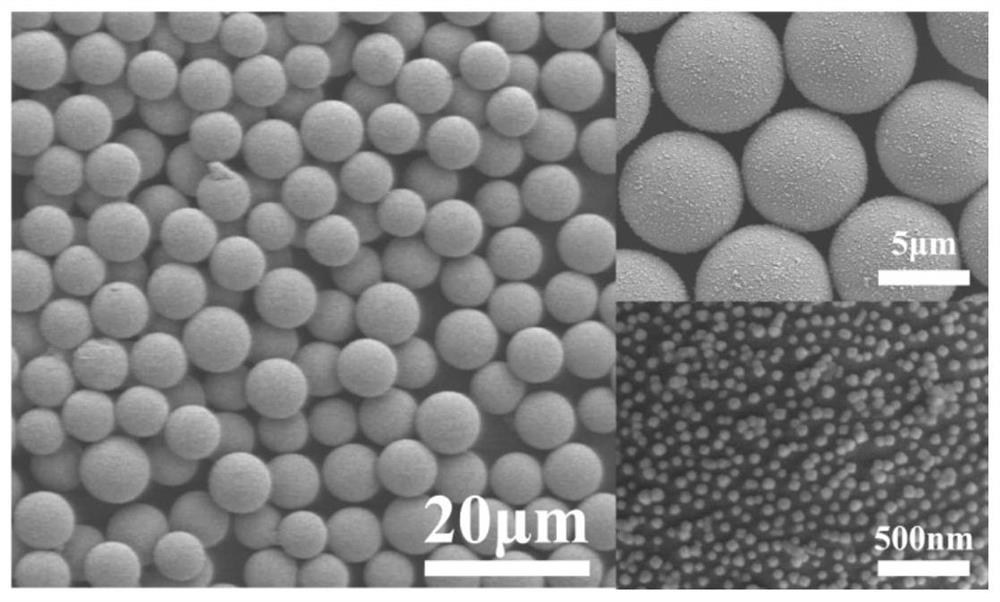

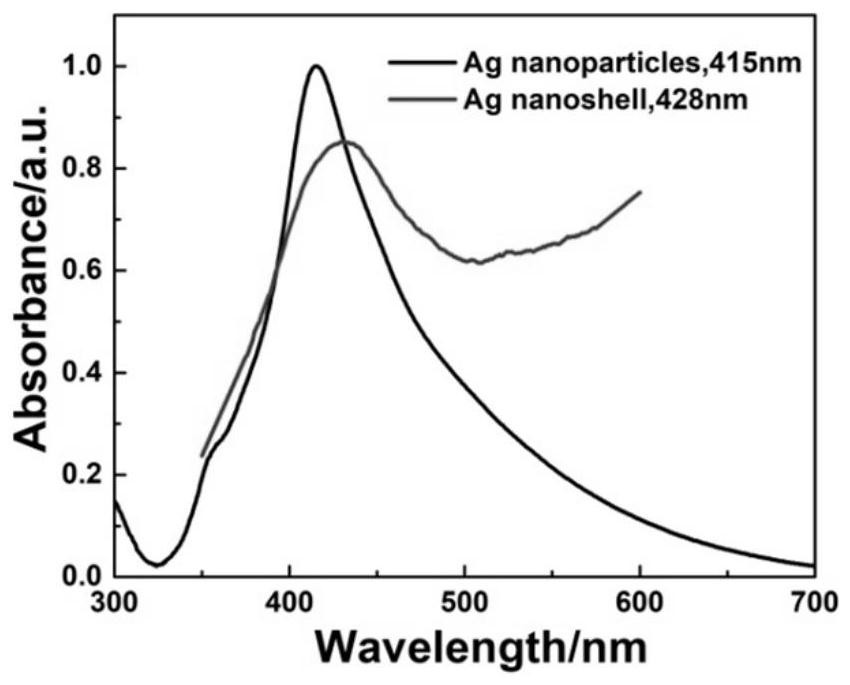

Preparation method of fluorescent coding microsphere coated with metal nano shell layer

ActiveCN113337271AImprove stabilityEasy to makeMaterial nanotechnologyTransportation and packagingMicrosphereSurface-active agents

The invention provides a preparation method of a fluorescent coding microsphere coated with a metal nano shell layer. Different types of fluorescent materials with different contents are doped into a polymer microsphere by using a metal nano material modified with a certain ligand as a new surfactant in an emulsification process through an SPG method so as to prepare the fluorescent coding microsphere with different fluorescent coding signals inside and uniformly coated with the metal nano shell layer on the surface in one step. The prepared fluorescence coding microsphere comprises the metal nano shell layer, a polymer and a fluorescence coding material, the particle size of the fluorescence coding microsphere is 1-20 [mu]m, the coefficient of variation (CV) is less than 10%, and the fluorescence coding microsphere can be used for detecting protein / nucleic acid. The preparation method is simple in preparation process, high in surface coating rate, good in uniformity and controllable in LSPR peak, and the problems of low surface coating rate, poor uniformity, complex preparation process, uncontrollable local surface plasma resonance (LSPR) peak and the like in the current common precious metal nano shell coating method are solved.

Owner:HANGZHOU SHINEDO BIOTECH CO LTD

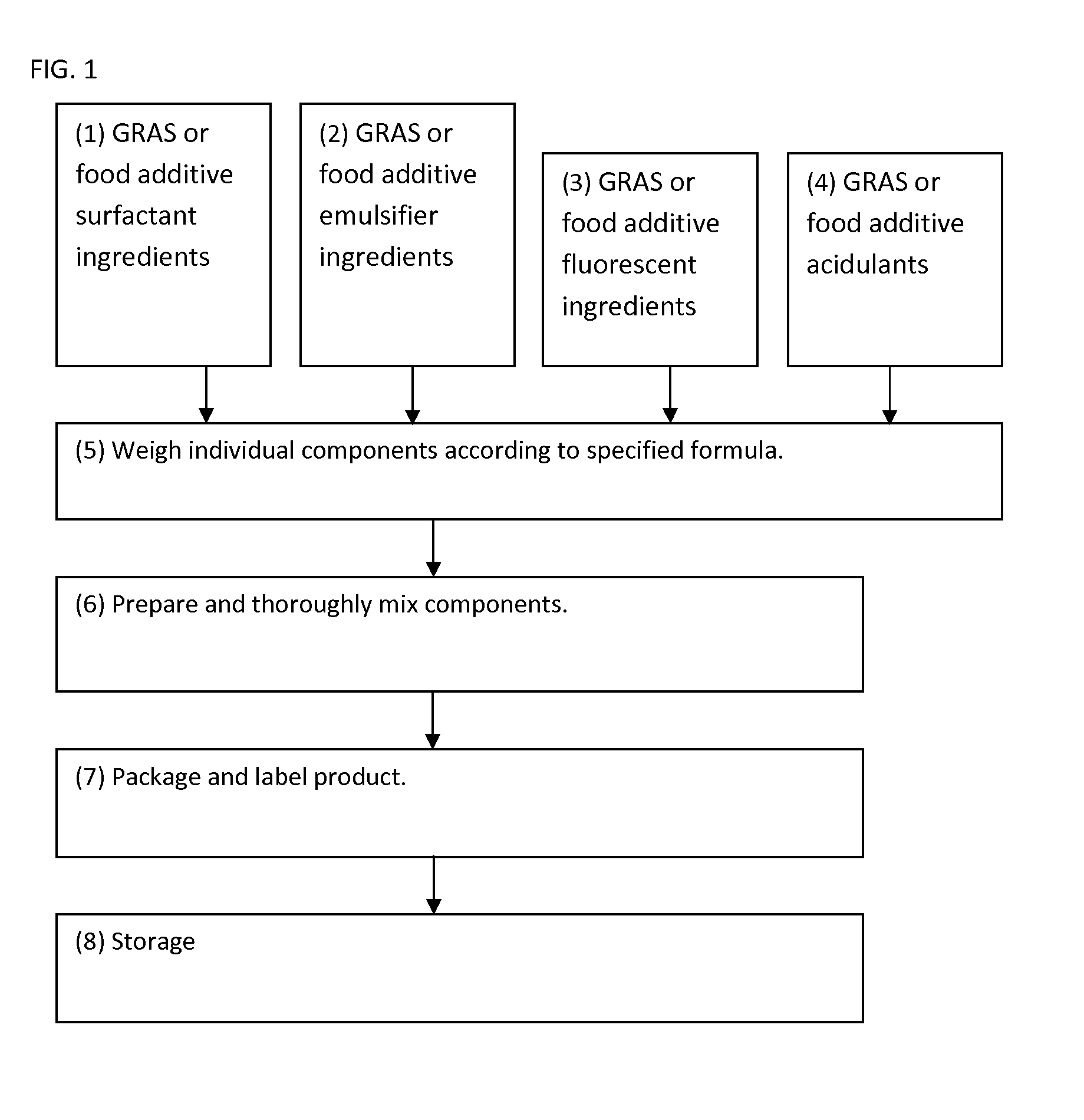

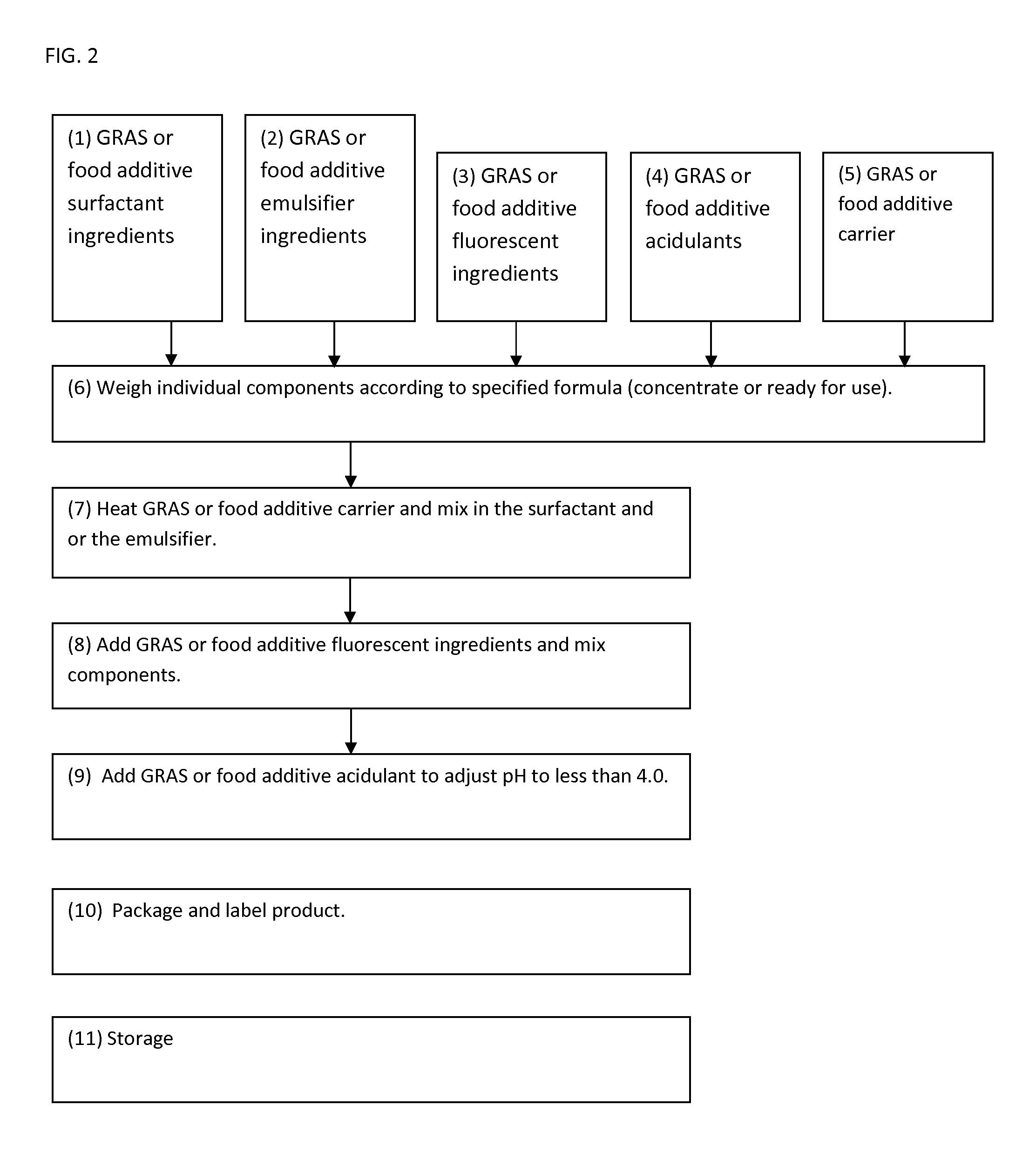

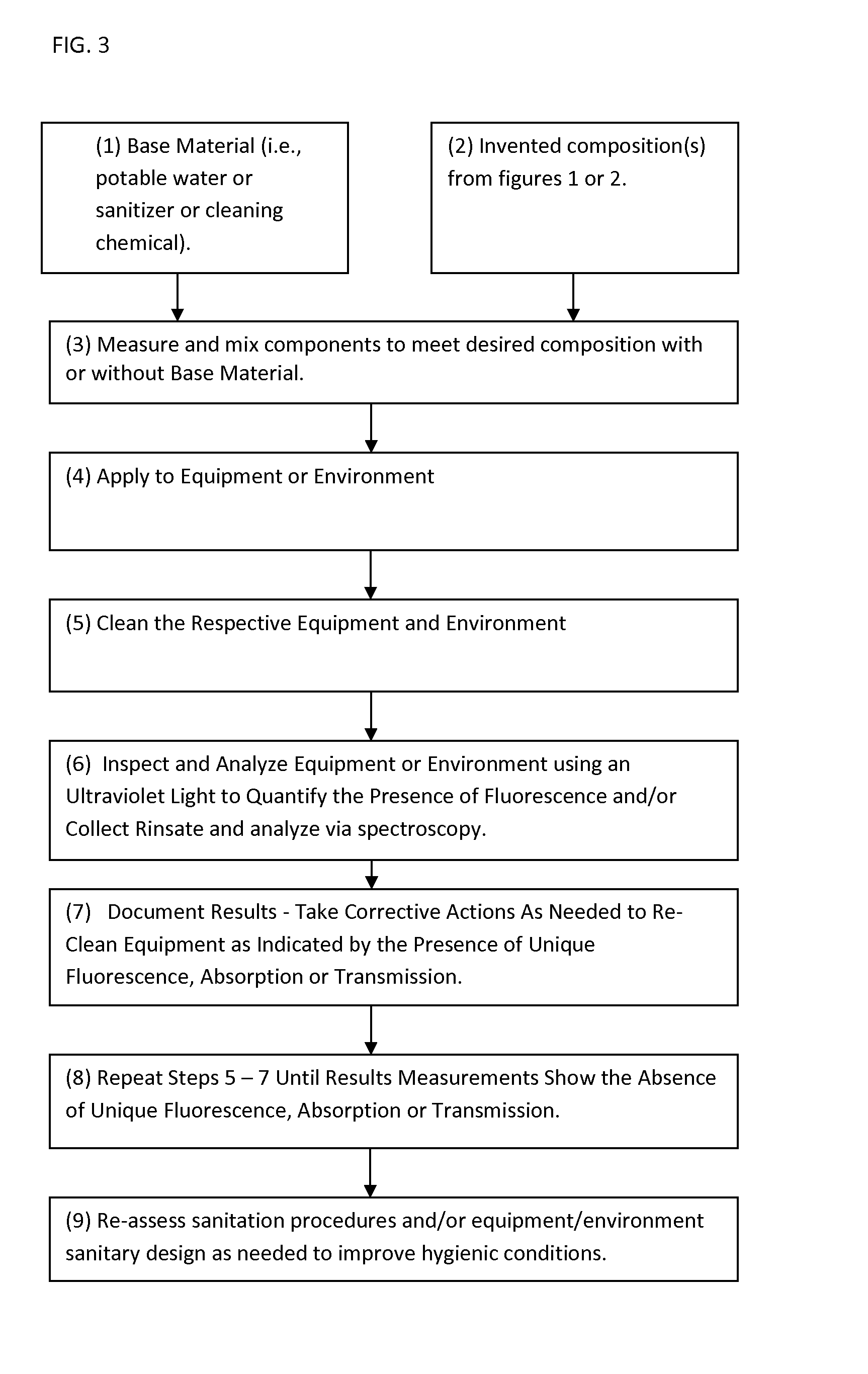

Compositions for visualization of cleaning efficacy and product coverage

InactiveUS20130108555A1Improve sanitationImprove performancePre-tanning chemical treatmentDetergent dyesFood additiveFood safety

The invention relates to cleaning and food processing aide applications whereby unique compositions of GRAS or food additives were developed to assess the effectiveness of cleaning procedures at various stages of the processes and to assess the delivery and adherence of food processing aides. Employing such solutions to clean and / or sanitize processing equipment provides a method to evaluate and enhance the effectiveness of procedures used to remove the respective fluorescent detergents, sanitizers or organic residues from equipment or niches and reduce contamination. Similar compositions were developed for assessing processing aide food surface coverage, contact time and adherence. In addition, unique compositions were invented that increase processing aide coverage and adherence. Quantification of the presence or absence of the fluorescent GRAS or food additive compositions produces results for validation, monitoring and / or verification of food safety intervention procedures / processes.

Owner:LARY JR ROBERT YALE +1

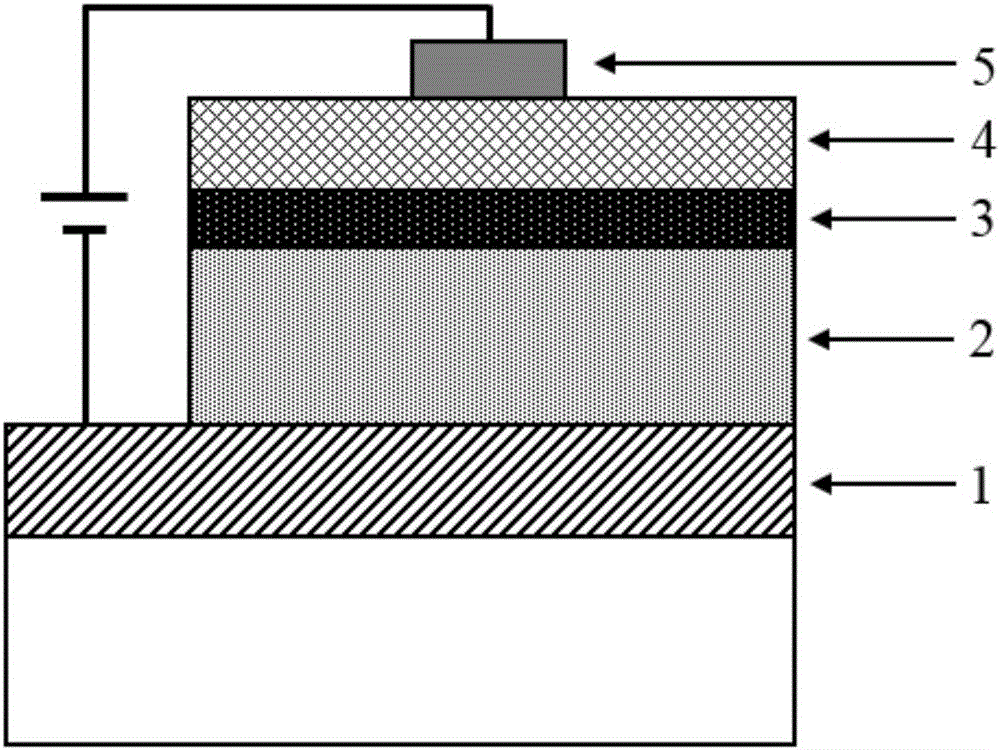

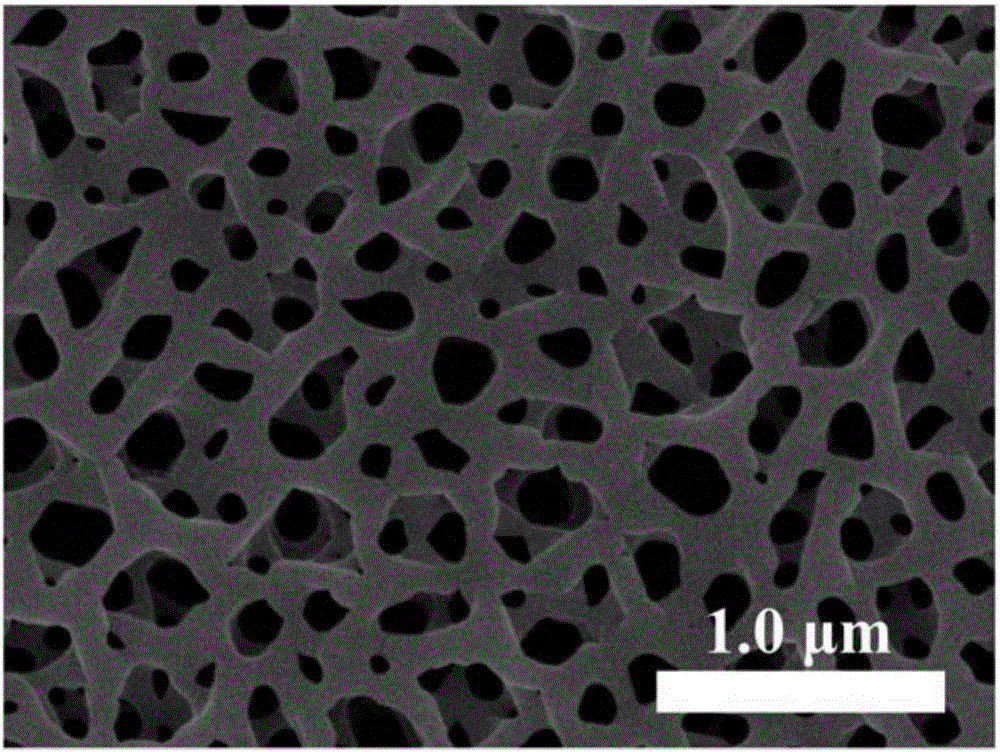

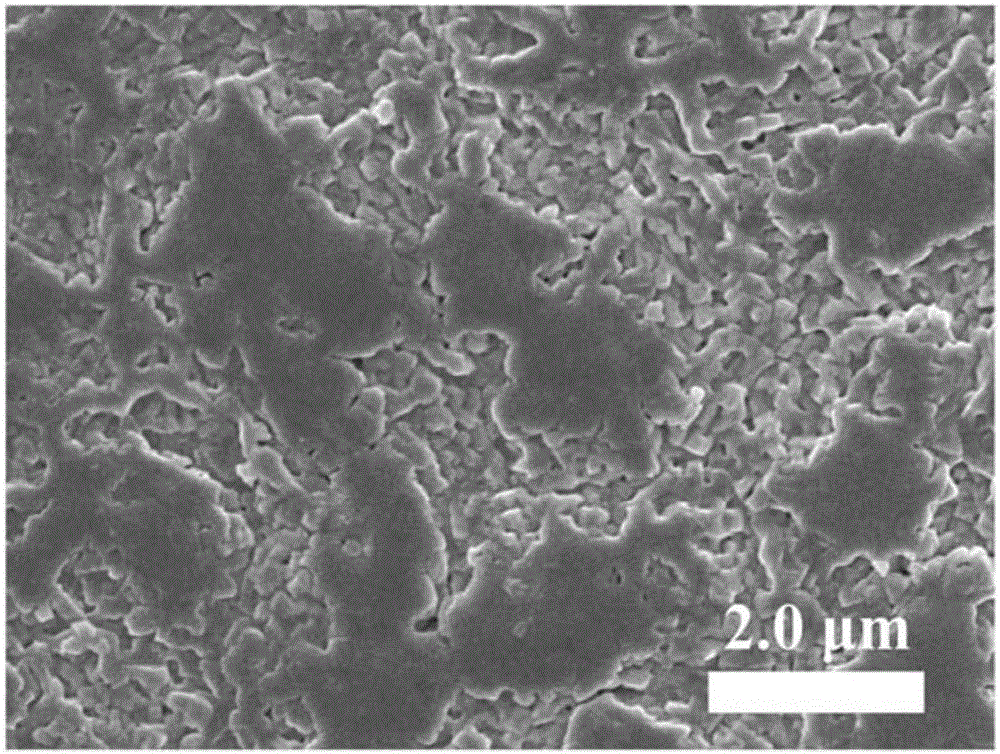

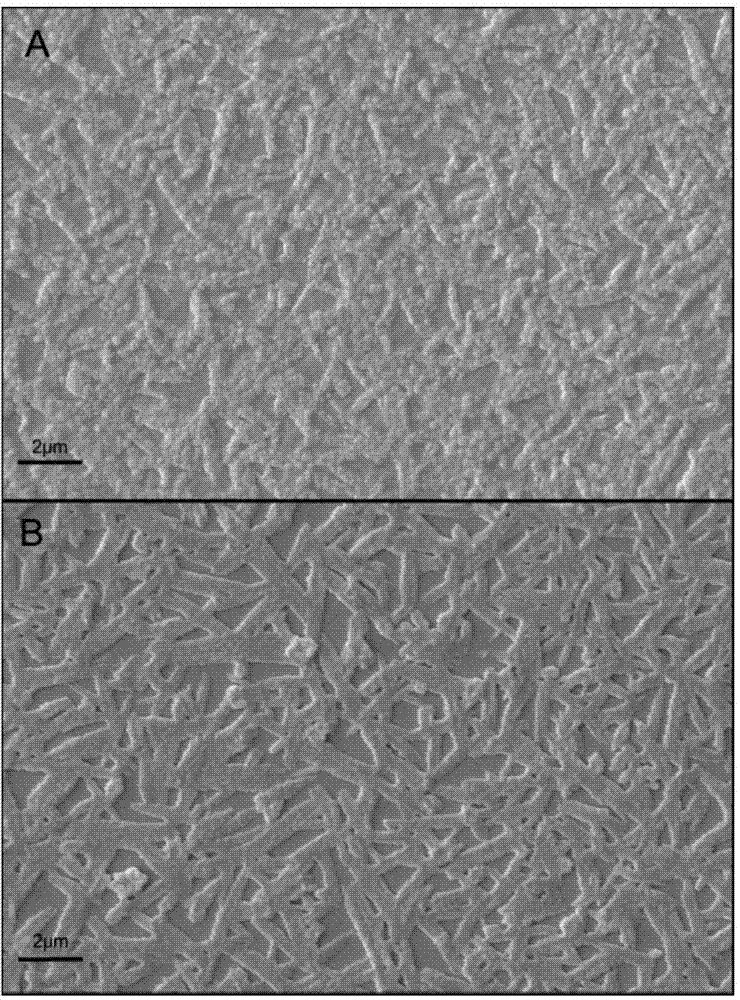

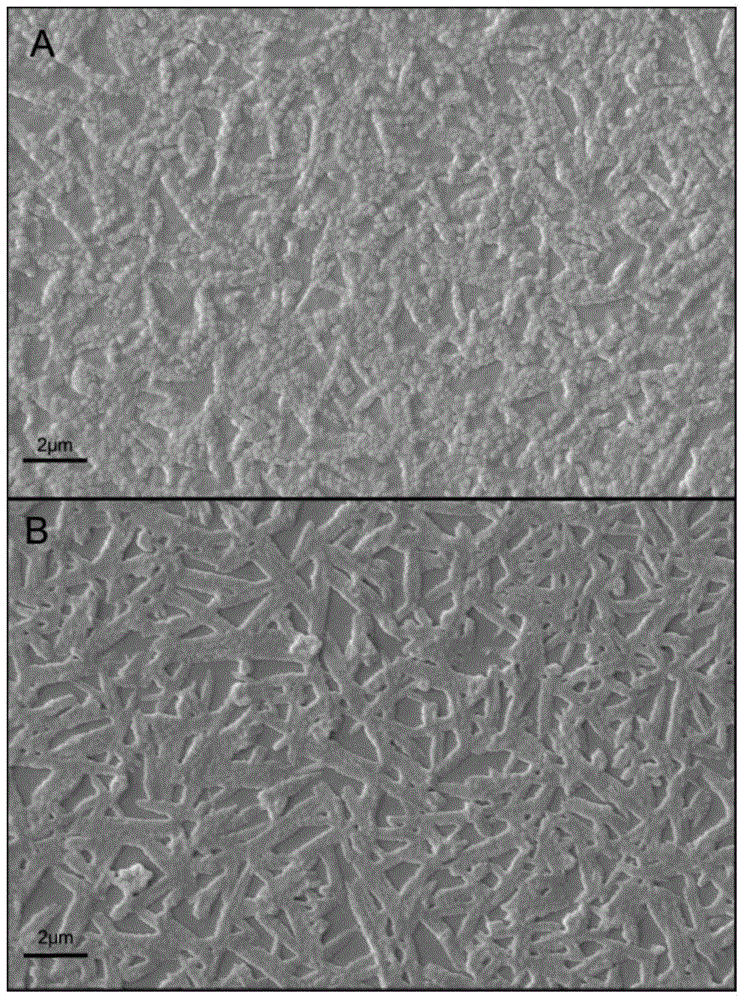

Perovskite LED taking ZnO nanometer wall network as electron injecting layer and preparation method thereof

ActiveCN105789398AHigh surface coverageEfficient Radiative RecombinationSemiconductor devicesQuantum efficiencyGeneration rate

The present invention provides a perovskite LED taking a ZnO nanometer wall network as an electron injecting layer and a preparation method thereof. The perovskite LED taking the ZnO nanometer wall network as the electron injecting layer and the preparation method thereof are able to effectively limit the generation of drain current in a device, reduce the generation rate of nonradiative recombination of a carrier, and finally realize the preparation of a high-external quantum efficiency perovskite green ray LED. The perovskite LED comprises a transparent conductive substrate, and the substrate is provided with an n-type ZnO nanometer wall network, a CH3NH3PbBr3 luminescent layer, a p-type cavity supplying layer and an electrode. The perovskite LED taking the ZnO nanometer wall network as the electron injecting layer and the preparation method thereof employ a two-dimensional ZnO nanometer wall network as the electron injecting layer of the perovskite green ray LED and adopt the nanometer wall network frame structure to limit the diffusion of the perovskite forerunner liquid in the stage of the solvent drying so as to improve the surface coverage rate of the CH3NH3PbBr3 luminescent layer. Besides, the defect of a traditional perovskite LED is overcome, the generation channel of drain current in a device is effectively inhibited, and the efficient radiative recombination of carriers in the condition of the electron injection is prompted.

Owner:ZHENGZHOU UNIV

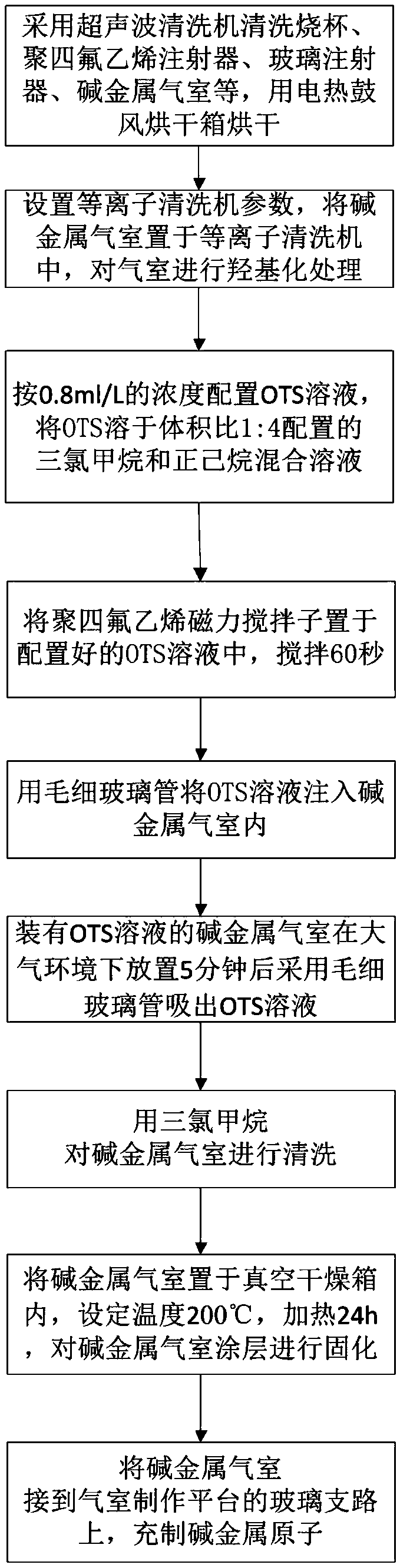

Alkali metal air chamber manufacturing method for improving relaxation resistance of coating based on Plasma hydroxylation

ActiveCN109518177AReduce pollutionImproved anti-relaxation propertiesMetallic material coating processesProblem of timeEngineering

The invention relates to an alkali metal air chamber manufacturing method for improving the relaxation resistance of a coating based on Plasma hydroxylation. According to the method, a plasma cleaningmachine is adopted for hydroxylating the inner surface of an air chamber; since a tail pipe of the alkali metal air chamber is thin, the operation that a thick cleaning solution needs to be extractedby adopting a capillary glass tube after cleaning through a traditional hydroxylation method is omitted, so that the air chamber is prevented from being pricked during a cleaning solution extractionprocess, and the problems of time waste, effort waste, nonideal consistency and nonideal relaxation resistance during the current air chamber manufacturing process are solved; and meanwhile, more hydroxide radicals can be formed on the glass surface, and no cleaning solution removal and follow-up drying is needed, so that the contact time of the hydroxide radicals and the outside environment is shortened, the hydroxide radical pollution is reduced, more hydroxide radical number can be maintained, a smooth and uniform covering surface is realized during the organochlorosilane reaction process,the surface covering rate on paramagnetic impurities is increased, and the relaxation resistance of the coating is improved. In addition, multiple air chambers can be processed at the same time, so that the consistency and the repeatability in manufacturing the coating are improved.

Owner:杭州诺驰生命科学有限公司

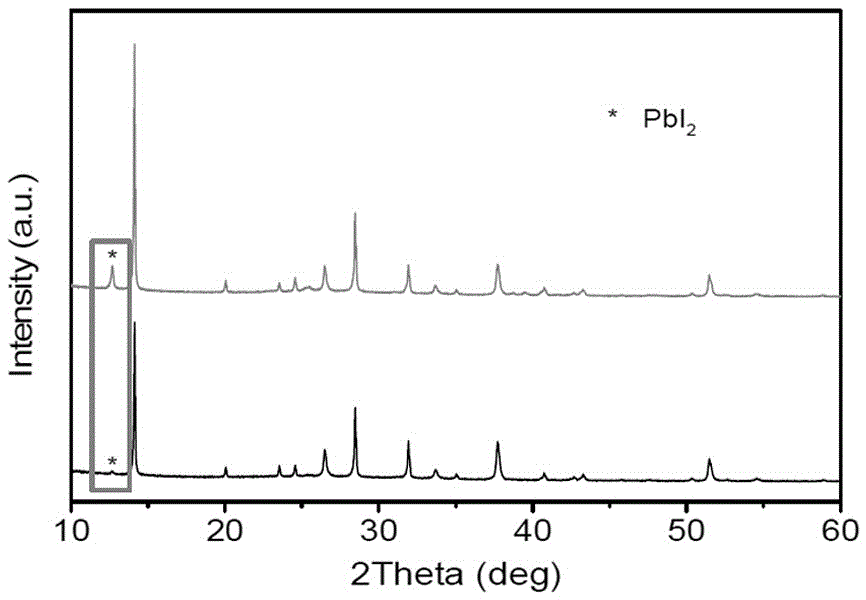

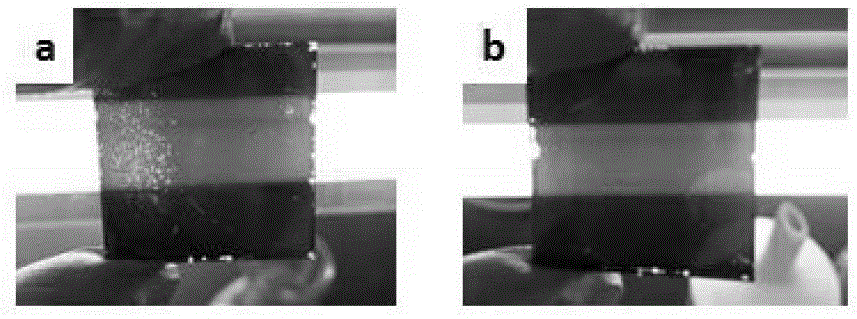

Preparation method for perovskite thin film capable of improving purity and reducing pin holes

ActiveCN105870339ALarge grain sizeHigh surface coverageSolid-state devicesSemiconductor/solid-state device manufacturingIsopropyl alcoholChemistry

The invention provides a preparation method for a perovskite thin film capable of improving purity and reducing pin holes. The preparation method specifically comprises the steps of dissolving CH<3>NH<3>X (x can be Cl, Br or I) powder into anhydrous isopropyl alcohol to form a CH<3>NH<3>X solution, and then spraying the solution on a substrate by a spray pyrolysis method to form a CH<3>NH<3>X film layer; then covering the CH<3>NH<3>X thin film with the substrate coated with a PbX<2> thin film; and carrying out high-temperature annealing to enable the CH<3>NH<3>X steam molecules to be dispersed in the PbX<2> thin film, wherein the PbX<2> existing in mesopores also can be fully reacted. According to the preparation method, the CH<3>NH<3>X is in contact reaction with the PbX<2> thin film in a form of thin film; and compared with the powder type contact, the point contact can be replaced by surface contact, so that the problem of the pin holes caused by uneven contact existing in the current powder contact method can be effectively solved.

Owner:HEBEI UNIVERSITY

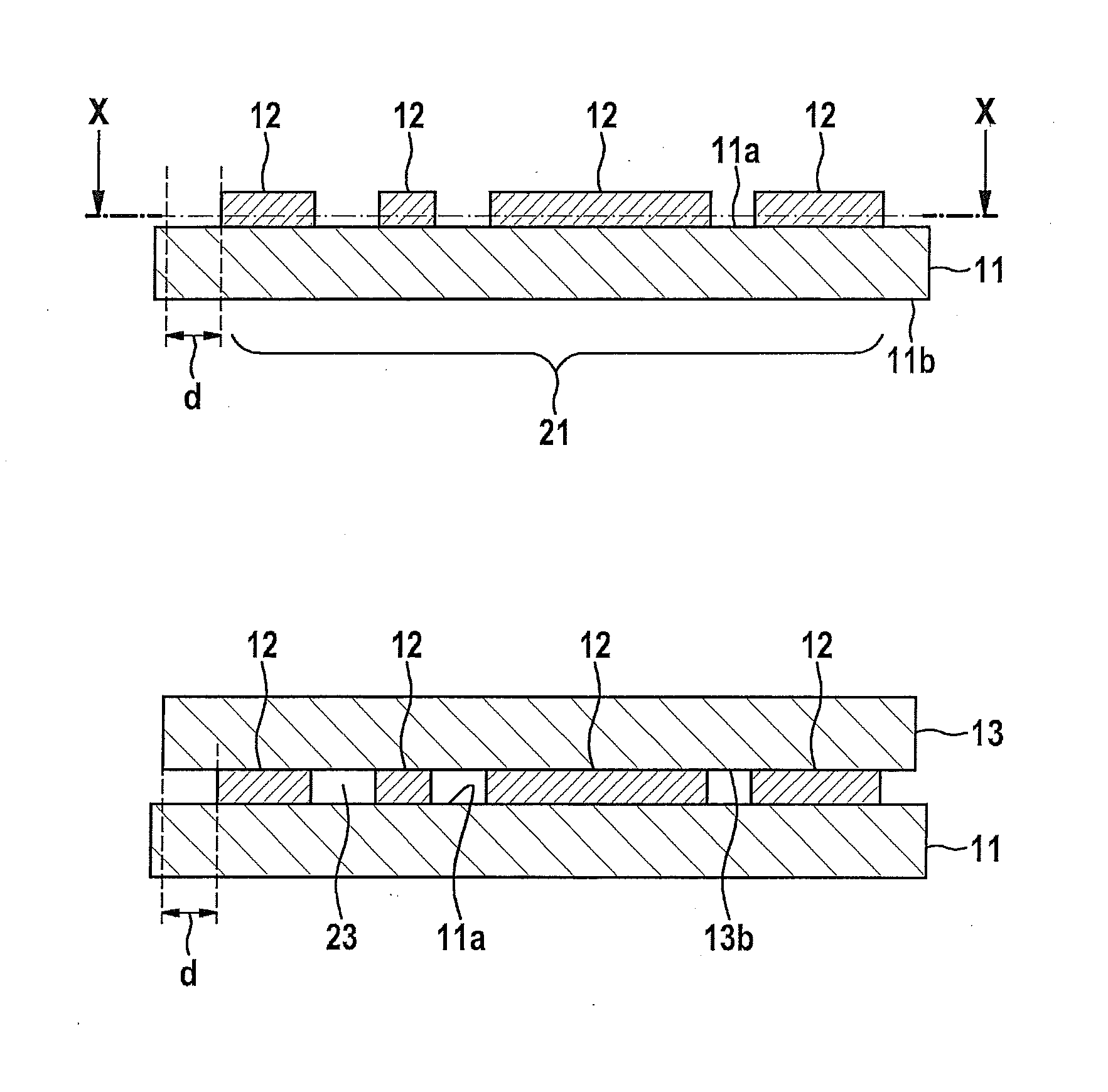

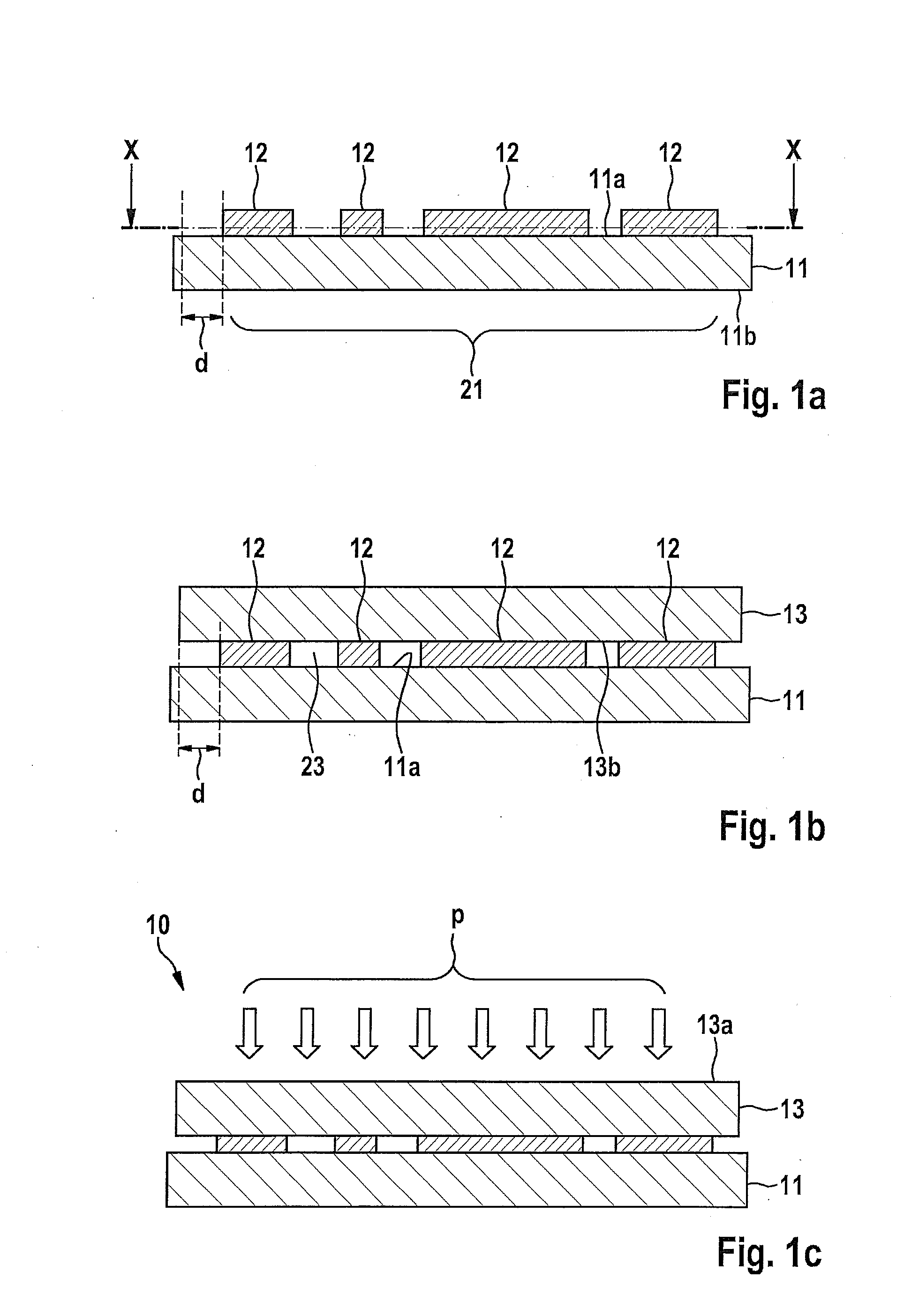

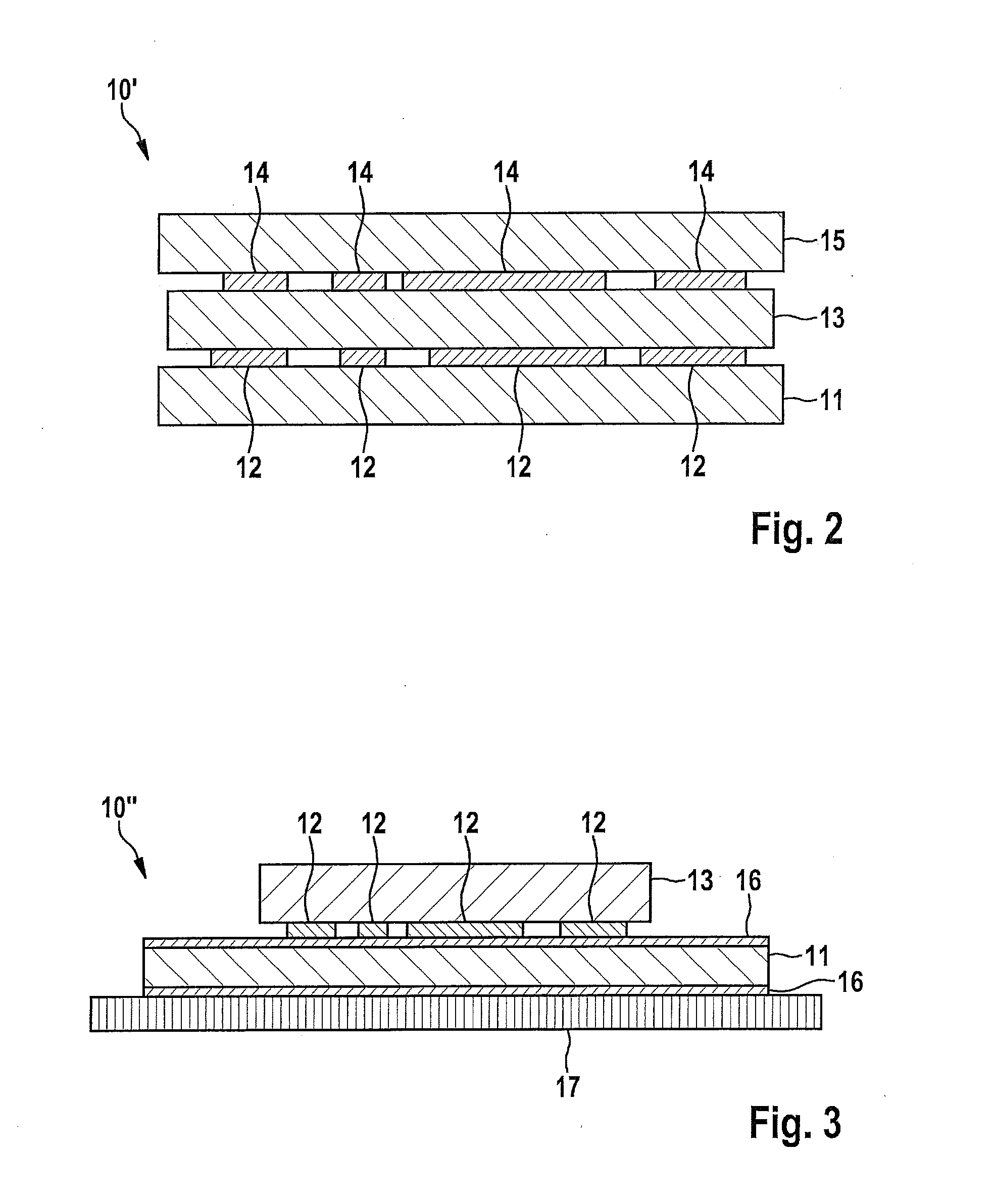

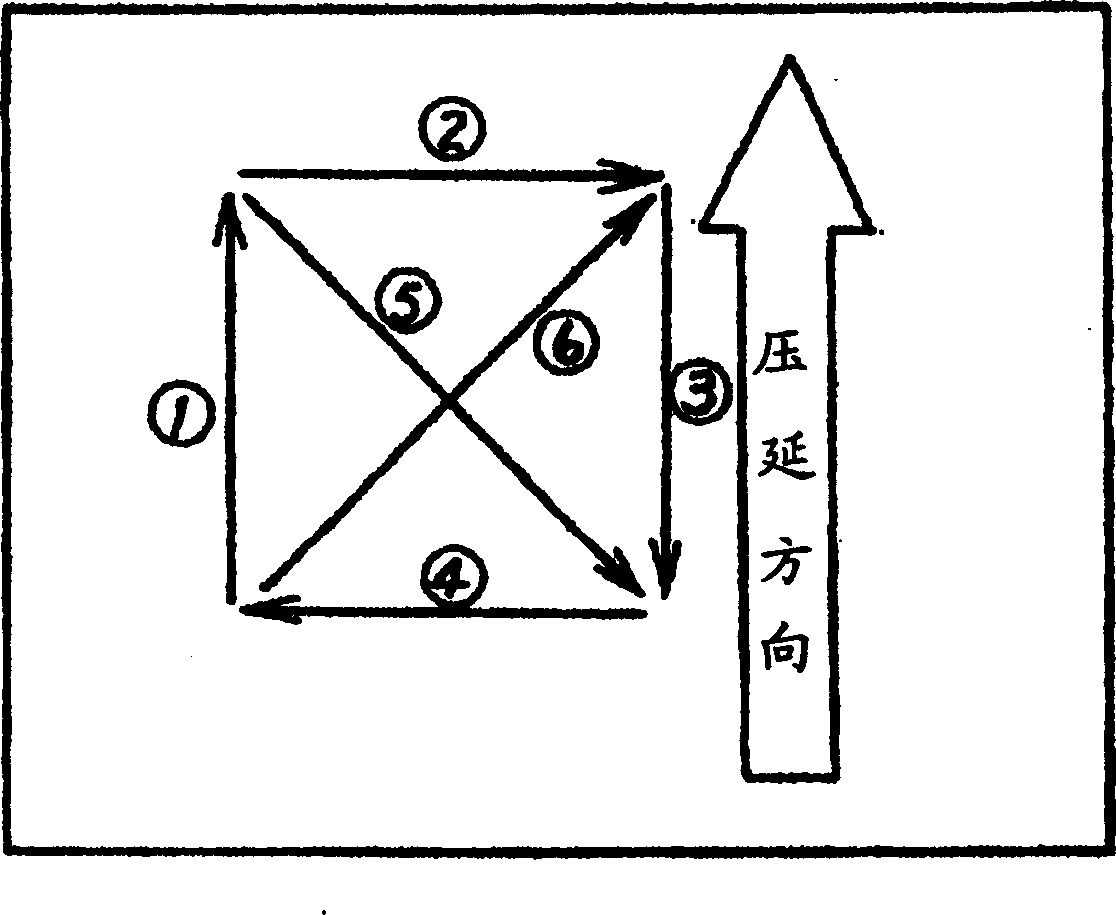

Method for Producing Structured Sintered Connection Layers, and Semiconductor Element Having a Structured Sintered Connection Layer

ActiveUS20140225274A1Satisfactory electric connectionSatisfactory thermal connectionSemiconductor/solid-state device detailsSolid-state devicesSurface coverMechanical tension

A method for producing a sinter layer connection between a substrate and a chip resulting in an electric and thermal connection therebetween and in reduced mechanical tensions within the chip. The method produces a sinter layer by applying a multitude of sinter elements of a base material forming the sinter layer in structured manner on a contact area of a main surface of a substrate; placing a chip to be joined to the substrate on the sinter elements; and heating and compressing the sinter elements to produce a structured sinter layer connecting the substrate and chip and extending within the contact area, the surface coverage density of the sinter elements on the substrate in a center region of the contact area being greater than the surface coverage density of the sinter elements in an edge region of the contact area, and at least one through channel, extending laterally as to the substrate's main surface being provided towards the contact area's edge. A large-area sinter element is situated in the contact area's center region, and circular sinter elements is situated in a contact area edge region. The sinter elements may also have notches. Also described is a related device.

Owner:ROBERT BOSCH GMBH

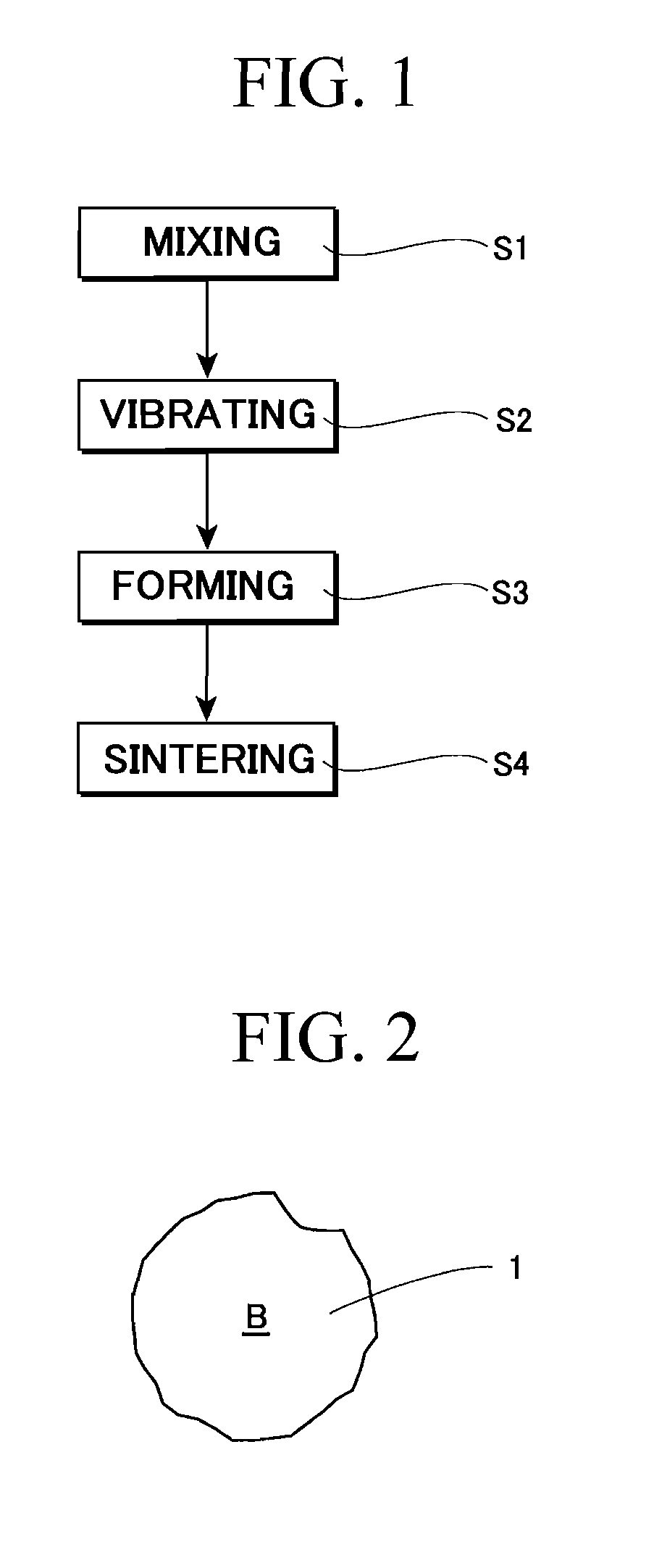

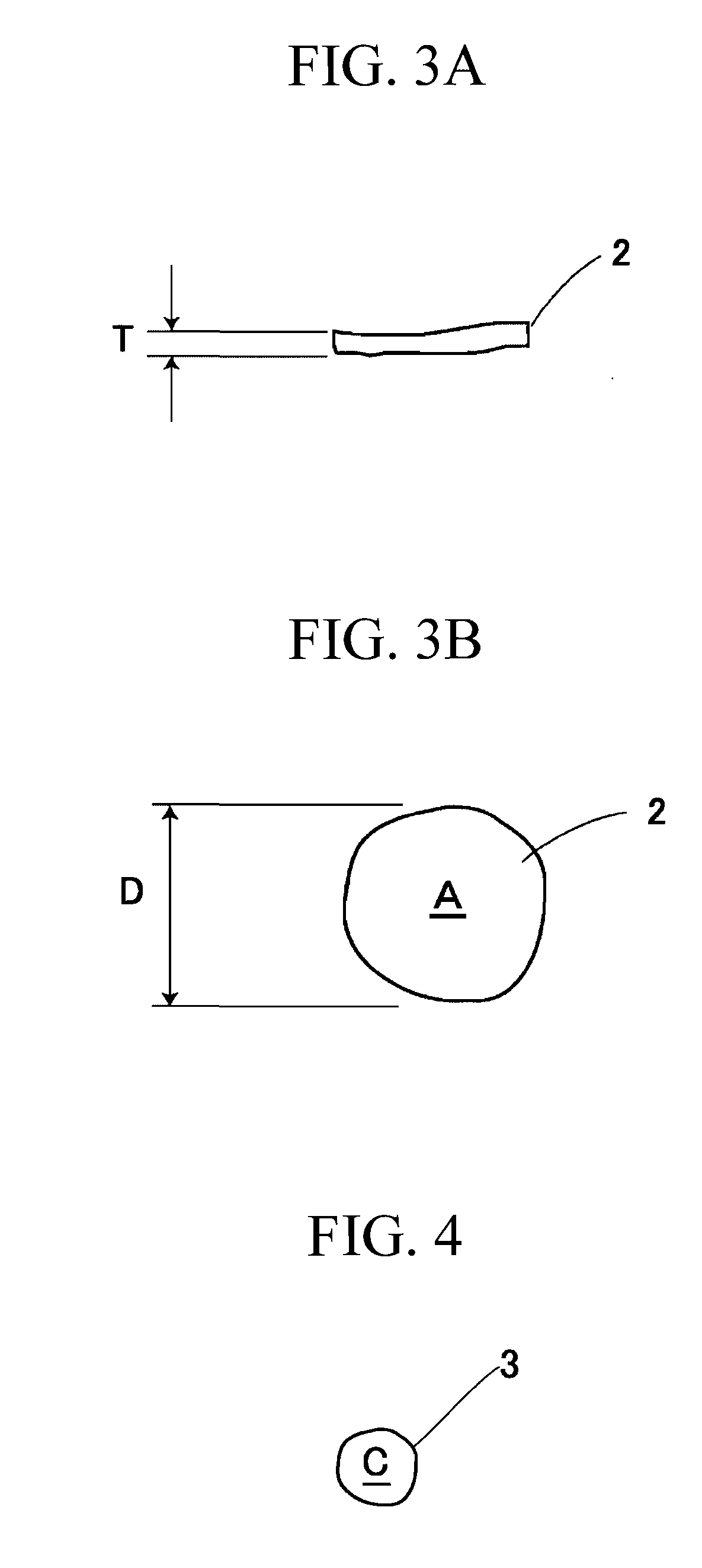

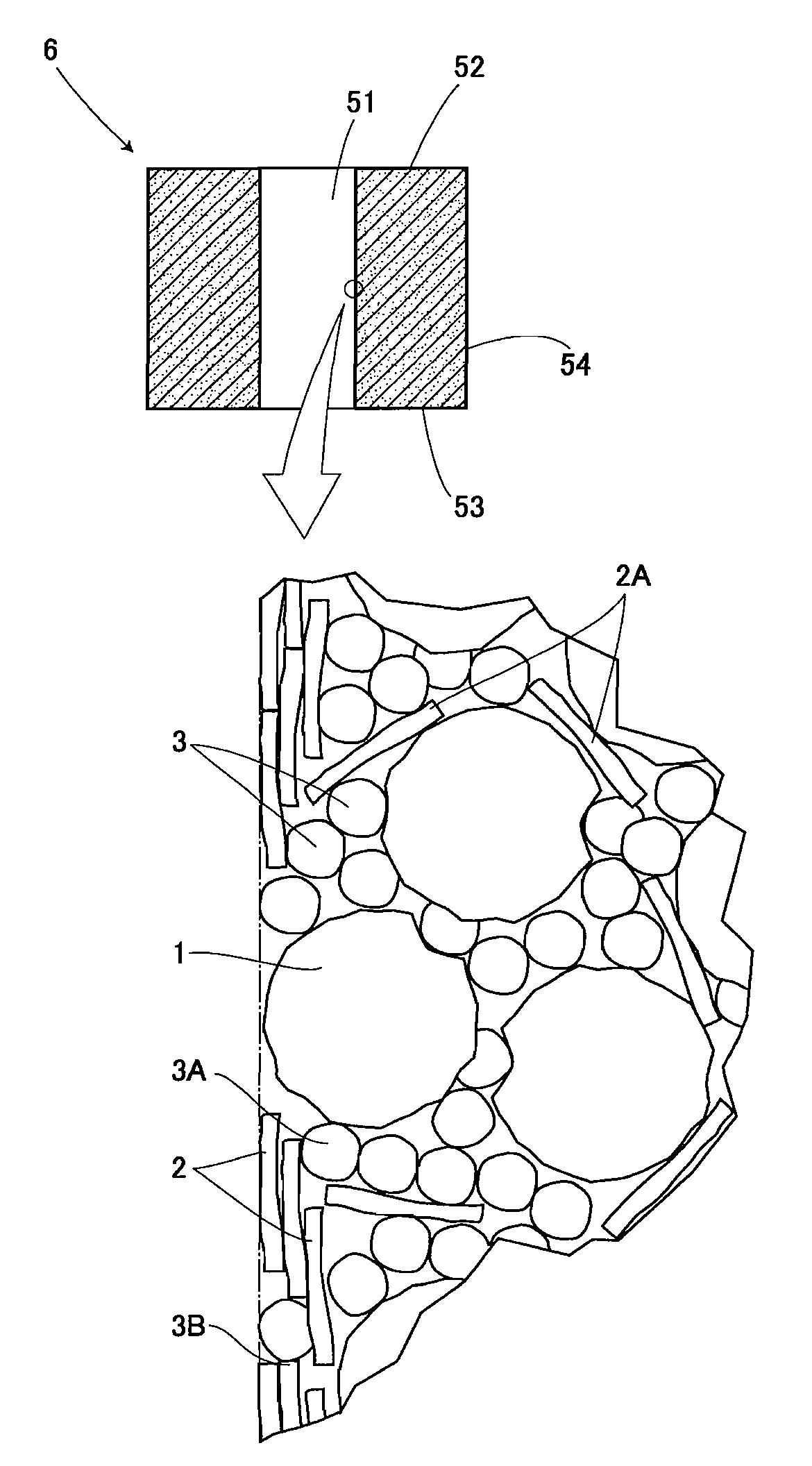

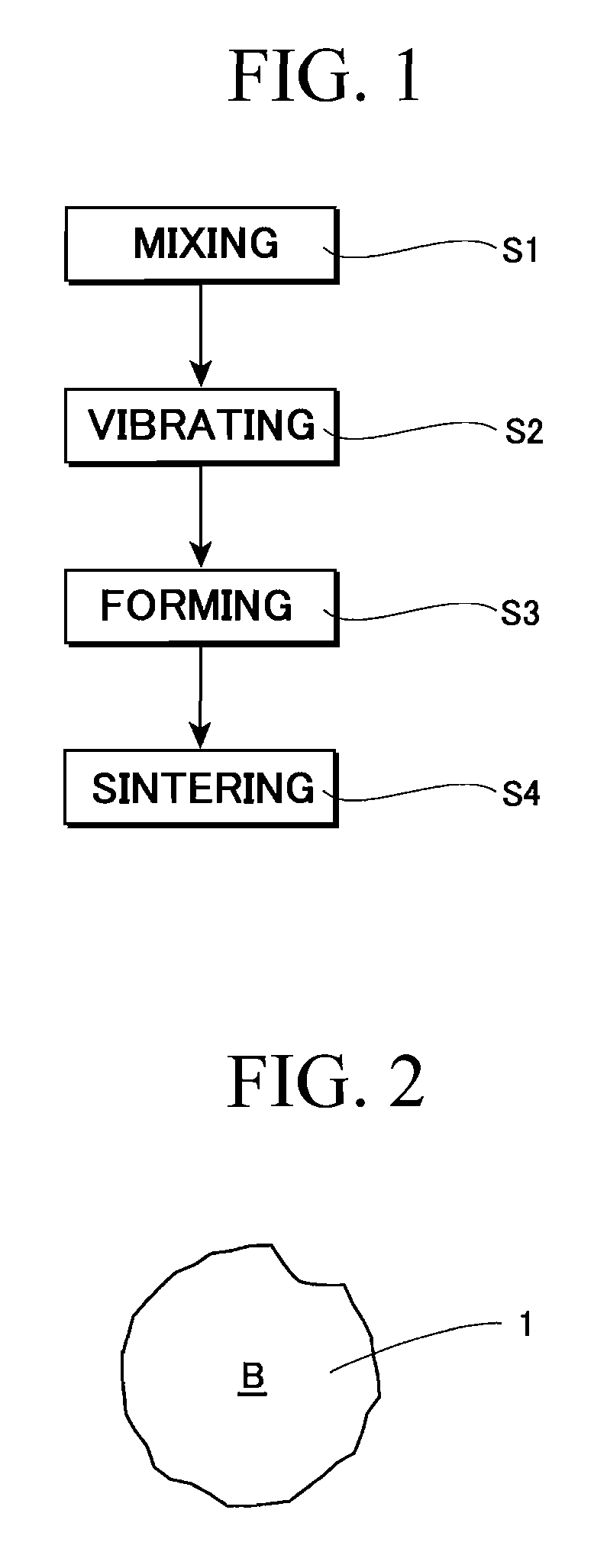

Sliding part and method of manufacturing the same

A sliding part in which a surface coverage ratio of copper in the sliding part increases. A bearing which is the sliding part is formed by filling the raw powder into the filling portion of the forming mold, compacting the raw powder to form a powder compact, and sintering the powder compact. A copper-based raw powder is composed of a copper-based flat raw powder having an average diameter smaller than that of an iron-based raw powder and an aspect ratio larger than that of the iron-based raw powder, and a copper-based small-sized raw powder having the average diameter is smaller than that of the copper-based flat raw powder. The copper segregates at the surface of the sliding part. In the bearing in which the copper-based flat powder segregates at the surface, the surface is covered with the copper-based small-sized raw powder that has emerged on the surface, as well as the copper-based flat raw powder, thereby it is possible to increase the surface coverage ratio of copper. Furthermore, containing calcium fluoride improves the seizure resistance.

Owner:DIAMET CORP

Sliding part and method of manufacturing the same

A sliding part in which a surface coverage ratio of copper in the sliding part increases. A bearing which is the sliding part is formed by filling the raw powder into the filling portion of the forming mold, compacting the raw powder to form a powder compact, and sintering the powder compact. A copper-based raw powder is composed of a copper-based flat raw powder having an average diameter smaller than that of an iron-based raw powder and an aspect ratio larger than that of the iron-based raw powder, and a copper-based small-sized raw powder having the average diameter is smaller than that of the copper-based flat raw powder. The copper segregates at the surface of the sliding part. In the bearing in which the copper-based flat powder segregates at the surface, the surface is covered with the copper-based small-sized raw powder that has emerged on the surface, as well as the copper-based flat raw powder, thereby it is possible to increase the surface coverage ratio of copper. Furthermore, containing calcium fluoride improves the seizure resistance.

Owner:DIAMET CORP

Golf ball mold, golf ball and method of manufacturing a golf ball

ActiveUS20110159989A1Easy to liftMolding stabilityTailstocks/centresConfectioneryInjection pressureInjection port

The invention provides a golf ball mold that is composed of a plurality of mold parts which removably mate to form a cavity having an inner wall with a plurality of dimple-forming protrusions thereon, wherein a non-circular resin injection port is formed between a plurality of mutually adjoining dimple-forming protrusions which include dimple-forming protrusions that lie across a parting line of the mold. Also provided is a golf ball molded using such a mold, and a golf ball manufacturing method which uses such a mold.By using the golf ball mold of the invention, even when manufacturing golf balls with a high dimple surface coverage on which the dimples are tightly arranged particularly up to the vicinity of the resin injection port, imbalances in the resin injection pressure and flow rate during injection molding are suppressed, enabling golf balls to be manufactured without production problems such as molding defects, scorching, core deformation and core eccentricity.

Owner:BRIDGESTONE SPORTS

Chitosan/perovskite nanometer composite film as well as preparation method and application thereof

The invention discloses a chitosan / perovskite nanometer composite film as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) preparing chitosan iodide; (2) dissolving methylamine salt, the chitosan iodide and lead iodide or lead chloride in DMF in a closed environment; introducing a protective gas; stirring for 6h to 10h at the temperature of 55 to 65 DEG C to prepare a perovskite precursor solution; (3) spin-coating the obtained perovskite precursor solution to obtain the chitosan / perovskite nanometer composite film. The prepared chitosan / perovskite nanometer composite film is applied to a solar photocell structure and has the advantages of effectively increasing the filling rate of a solar cell and also improving the energy transformation efficiency of the cell to a certain extent. The preparation method disclosed by the invention is clean, simple and free of pollution in preparation process and is suitable for large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

Additive and method for texturing of diamond wire cut polycrystalline silicon chip

InactiveCN108330545APromote absorptionChange surface tensionPolycrystalline material growthAfter-treatment detailsTriethanolamineSODIUM DODECYL BENZENE SULFONATE

The invention relates to an additive and a method for texturing of a diamond wire cut polycrystalline silicon chip. The additive is prepared from components as follows: acetic acid, triethanolamine, sodium dodecyl benzene sulfonate, polyethylene glycol, triamine citrate, perfluoropolyether, hydrofluoric acid and water in the mole ratio being (15-25):(10-25):(1-10):(15-25):(1-10):(1-10):(1-5):(2-100). The texturing additive can better refine the inside structure of an etch pit of the silicon chip to form more and smaller micro etch pits, the surface porosity is higher, the surface etch pit holes are denser, the size of the etch pits is reduced, small hole structures are produced on the edge and at the bottom of the etch pits, and the reflectivity of the silicon chip is greatly reduced.

Owner:浙江向日葵大健康科技股份有限公司

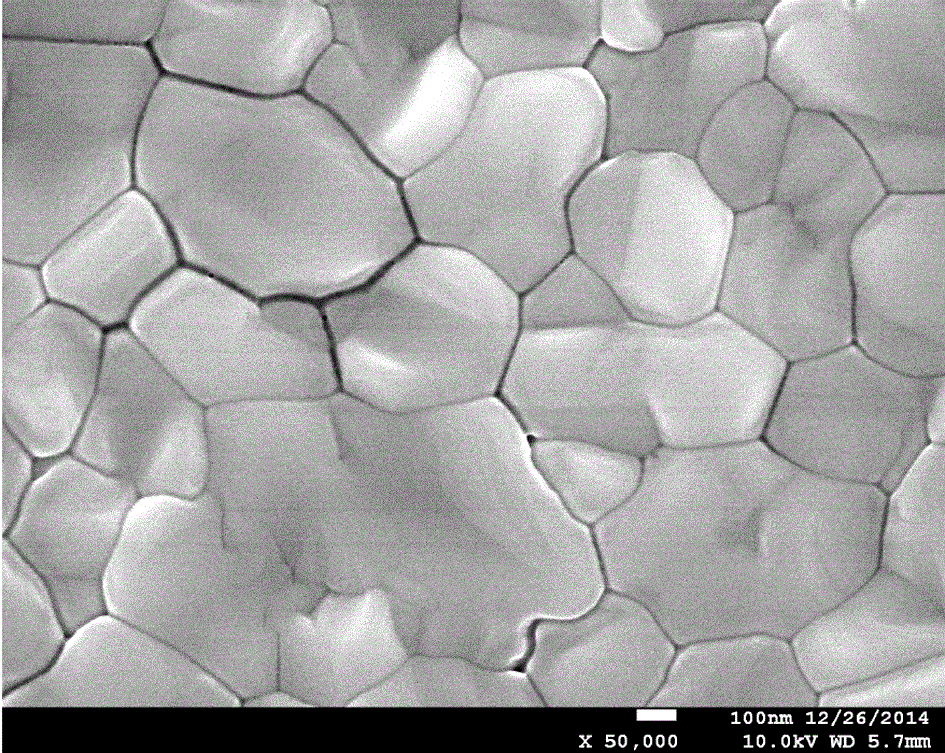

A kind of chitosan/perovskite nanocomposite film and its preparation method and application

ActiveCN104744714BHigh surface coverageSolve the problem of excessive surface voidsComposite filmIodide

The invention discloses a chitosan / perovskite nanometer composite film as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) preparing chitosan iodide; (2) dissolving methylamine salt, the chitosan iodide and lead iodide or lead chloride in DMF in a closed environment; introducing a protective gas; stirring for 6h to 10h at the temperature of 55 to 65 DEG C to prepare a perovskite precursor solution; (3) spin-coating the obtained perovskite precursor solution to obtain the chitosan / perovskite nanometer composite film. The prepared chitosan / perovskite nanometer composite film is applied to a solar photocell structure and has the advantages of effectively increasing the filling rate of a solar cell and also improving the energy transformation efficiency of the cell to a certain extent. The preparation method disclosed by the invention is clean, simple and free of pollution in preparation process and is suitable for large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

Apparatus and method of decorating a surface of a workpiece and decorated part

InactiveUS20090110947A1Keeps surface from damageAvoid contactDecorative surface effectsDwelling equipmentAirflowEngineering

Owner:COMPAL ELECTRONICS INC

Transistor structures and methods of fabrication thereof

ActiveUS8309953B2Reducing “ effective length ”Improve conductivityTransistorNanoinformaticsElectronTransistor

An electronic device is presented, such as a thin film transistor. The device comprises a patterned electrically-conductive layer associated with an active element of the electronic device. The electrically-conductive layer has a pattern defining an array of spaced-apart electrically conductive regions. This technique allows for increasing an electric current through the device.

Owner:TECHNION RES & DEV FOUND LTD

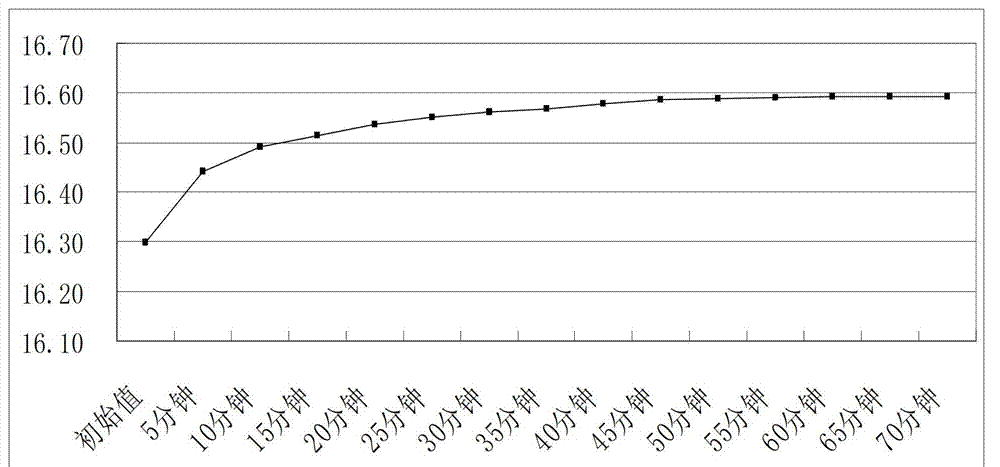

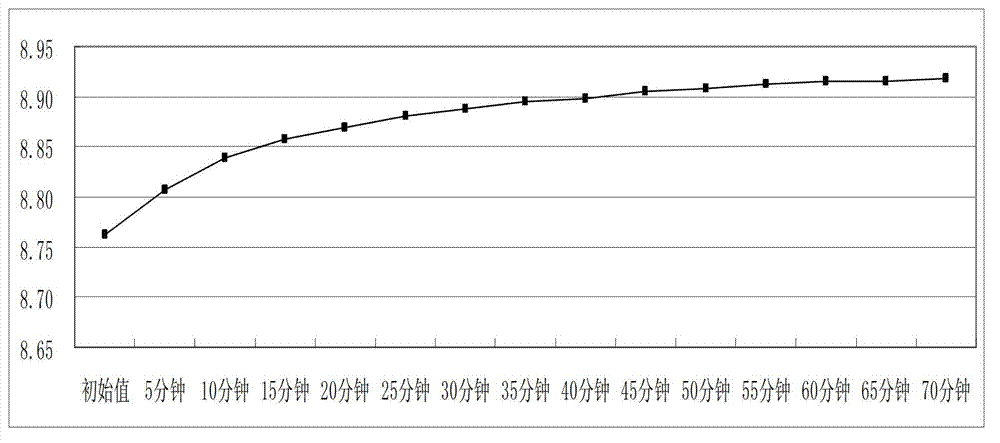

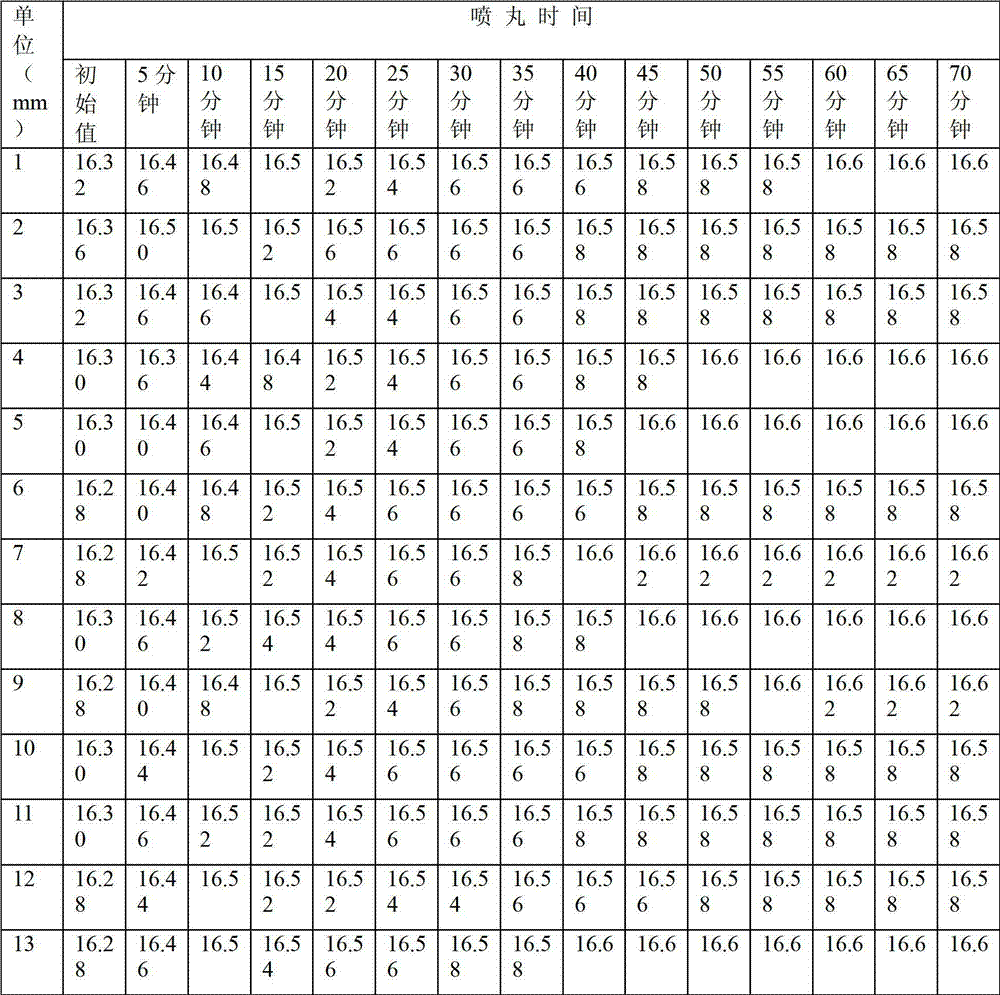

Method for saturated shot blasting of stainless steel spring

ActiveCN102925647AImprove stabilityIncrease coverageFurnace typesHeat treatment furnacesWork hoursMetallurgy

The invention relates to a method for saturated shot blasting of a stainless steel spring. The method is characterized by comprising the steps as follows: (1), steel shots are added in a shot blasting machine, and shot blasting is carried out on the stainless steel spring; and (2), the external diameter of the stainless steel spring is measured every five minutes, and when the variation values of the external diameters measured twice are within the range of 0 to 0.02 mm, the stainless steel spring reaches the saturated shot blasting to finish the shot blasting process. The external diameter of the steel shots is 0.4 mm. The method has the advantages that (1), the stability of the external diameter of the spring can be improved; (2), the surface coverage rate of the spring is higher, and the fatigue life is prolonged; and (3), the separation working hours can be reduced, the mounting is more facilitated, and the production efficiency is improved.

Owner:WUXI WEIFU PRECISION MACHINERY MFG

Inorganic low smoke zero halogen fire retardant and preparation method thereof

InactiveCN102532596AHigh surface coverageGood quality and stabilityLow smoke zero halogenActive agent

The invention relates to an inorganic low smoke zero halogen fire retardant and a preparation method thereof, which relates to surface modification processing and a processing method of the inorganic fire retardant and the method for preparing the low smoke zero halogen fire retardant. The method includes starting a heating system, enabling temperature to reach 80-260 DEG C which is required by process requirements, starting a continuous activation machine, adding 0.1 micrometer to 100 micrometer inorganic fire retardant into a feeding system, stably and evenly conveying materials to the activation chamber through the feeding system, conveying mixed liquid composed of coupling agents, adsorbents and dispersing agents dosed through a metering device to a nozzle, spraying the active agents into the active chamber quantitatively through the nozzle, completely mixing the inorganic fire retardants and the active agents under the processing temperature of 80 DEG C to 260 DEG C through an agitator blade of 2000 to 4000 turn / min, processing materials in the active chamber for 5 to 20 minutes and obtaining products through a dust removing system. The products of the fire retardant and the preparation method are good in quality stability, short in product production period, low in cost and friendly to environment and human.

Owner:大连亚泰科技新材料股份有限公司

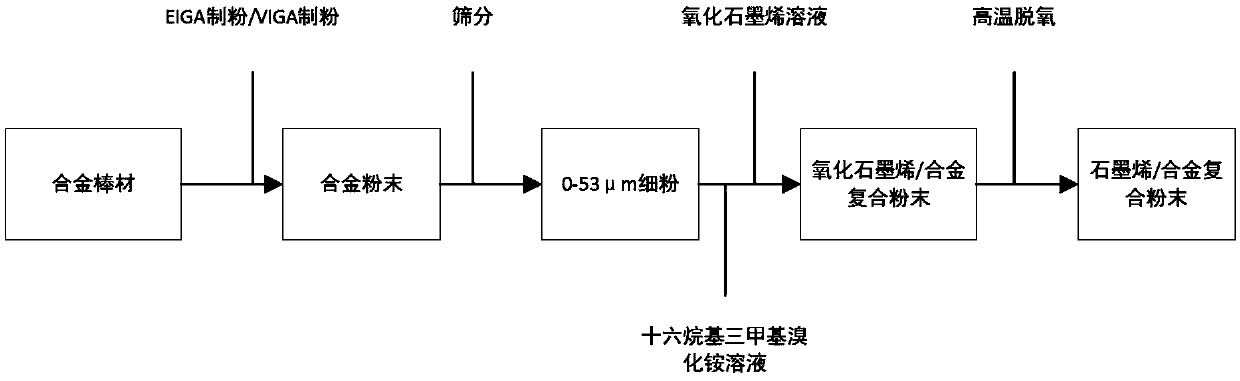

Preparation method of graphene-coated alloy powder composite material for 3D printing

ActiveCN106825552BMeeting urgent needsEasy to operateAdditive manufacturing apparatusTransportation and packagingAlloyElectrostatic interaction

The invention discloses a method for preparing a graphene-coated alloy powder composite material for 3D printing, which belongs to the technical field of graphene composite material preparation. Cover the surface of the alloy powder with a cationic surfactant by mixing and stirring, then blend the graphene oxide with the treated powder, use electrostatic interaction to disperse the graphene oxide on the surface of the alloy powder, and heat the graphite oxide in a vacuum furnace Graphene-coated alloy powder, graphene oxide is reduced to graphene, and a graphene-coated alloy powder composite material is prepared. The advantage is that the electrostatic self-assembly method can make the graphene more uniformly cover the surface of the metal powder, and avoid the agglomeration of the graphene on the metal matrix.

Owner:中航迈特增材科技(北京)有限公司

Metal appearance metal band of high appearance gloss stability

InactiveCN1533854AHigh surface coverageLiquid surface applicatorsSynthetic resin layered productsMetal stripsPolymer science

Provided is a metal strip having metallic appearance and excellent brightness stability used for ironing processing can, which has metallic appearance coatings on outside of the can wherein the coatings comprise at least 5% by mass spreading metal filler and have the glass transition temperature of 50 to 120 deg.C. The metal strip has resin coatings having metallic appearance on outside of can wherein the coatings comprise spreading metallic fillers of at least 5% by mass based on the mass of coatings and have the glass transition temperature of 50 to 120 deg.C. The coatings have the dynamic fraction coefficient of up to 0.3 at test condition of 60 deg.C and pencil hardness of at least H at test condition of 50 deg.C. Also, the metallic appearance coatings is formed by using paint comprising metallic filler and resin components for paint.

Owner:KANSAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com