Metal appearance metal band of high appearance gloss stability

A technology of metal strips and stability, applied in the direction of metal layered products, rigid containers, devices for coating liquid on the surface, etc., can solve problems such as poor thinning rate, uneven whiteness, and poor clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

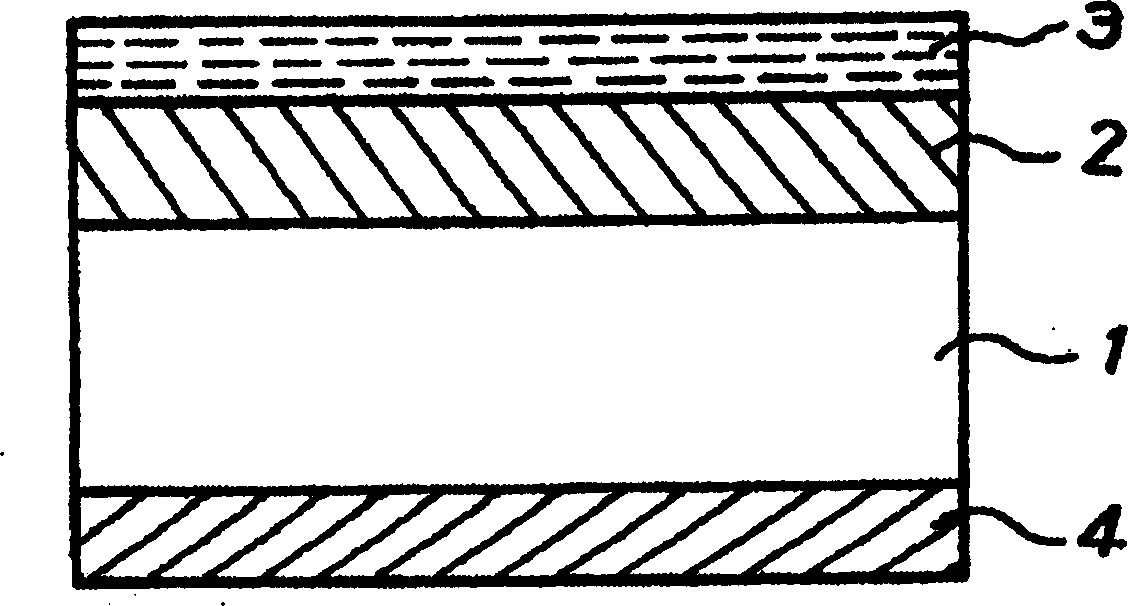

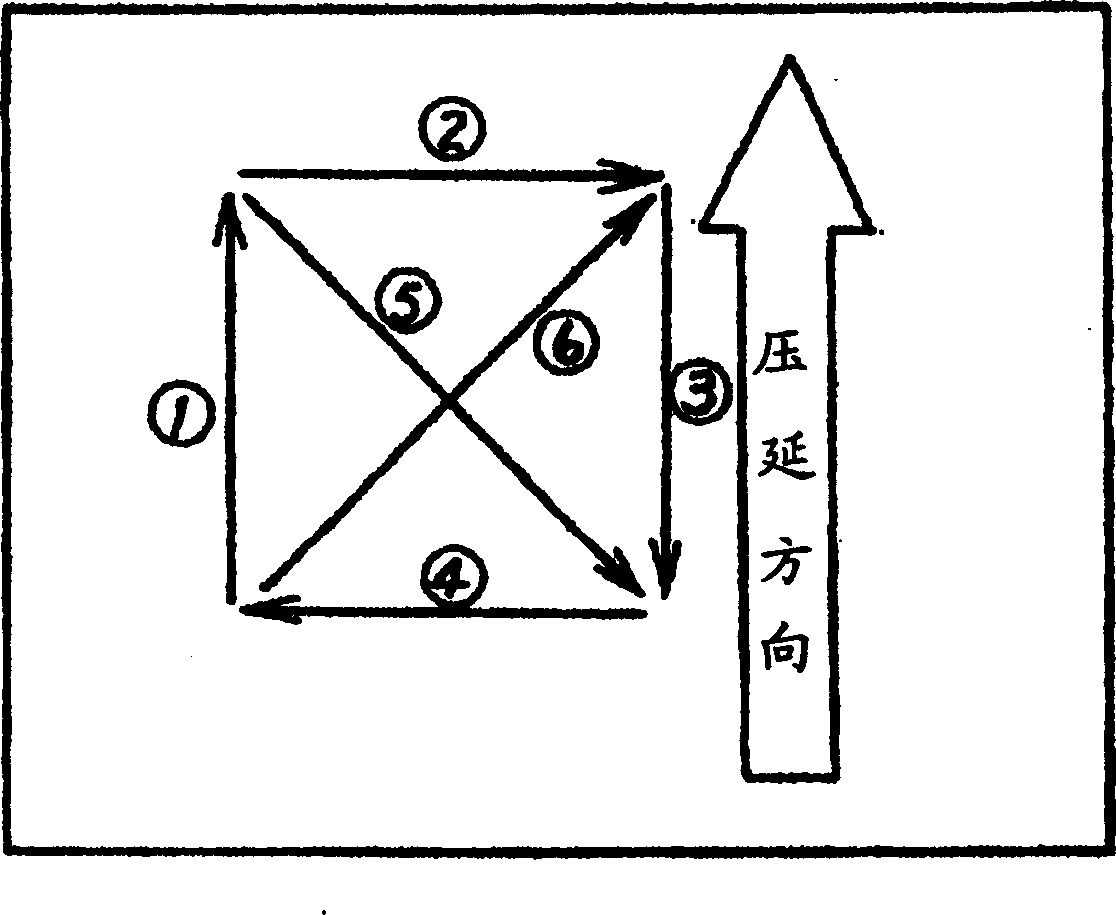

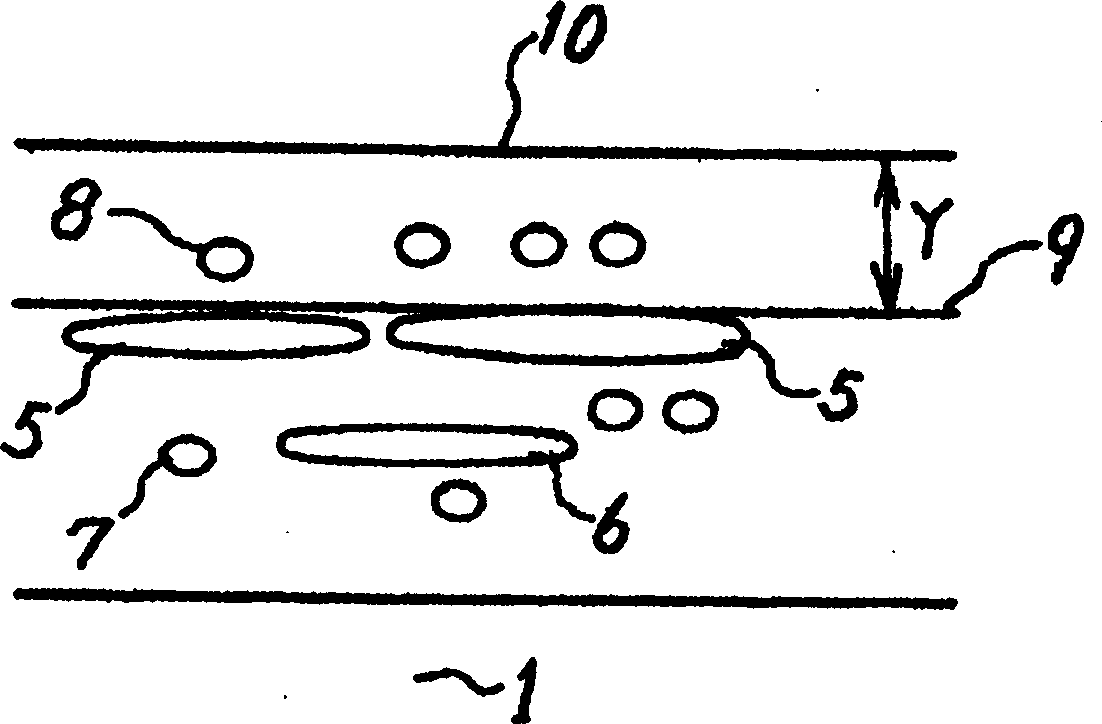

[0050] The hardness of the bright surface of the plate with a thickness of 0.22mm is T-3, and the total chromium adhesion is 80mg / m 2 The tin-free steel plate is used as the metal strip. Each paint was prepared at the compounding ratio shown in Table 1. The compounding ratios in Table 1 are solid content mass ratios. A mixed solvent for coating material (cyclohexanone / xylene: 50 parts by mass / 50 parts by mass) was used to adjust the viscosity to 50 seconds (fo-dock #4, 25° C.). Apply each of the above-mentioned coatings on the steel plate with a rod coater so that the dry film thickness is 5 μm, and sinter for 20 seconds under the condition that the maximum temperature of the raw material is 270°C, thereby making each coated metal plate, and evaluating the physical properties and appearance of the surface Gloss and thinning drawability. The results are shown in Table 2.

[0051] paint

no

polyester resin

Cross-linking agent (%)

inner wax

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com