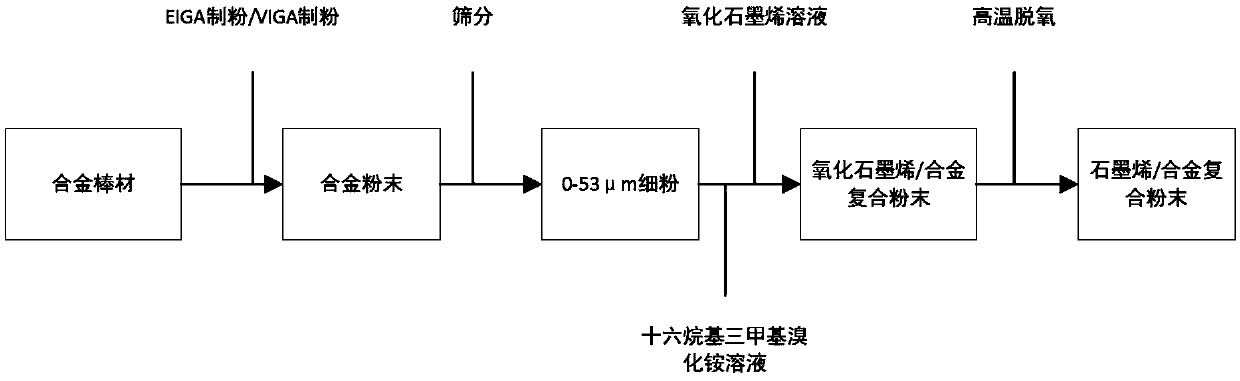

Preparation method of graphene-coated alloy powder composite material for 3D printing

A graphene coating and 3D printing technology, which is applied to graphene, metal processing equipment, chemical instruments and methods, etc., can solve the problems of poor dispersion and easy agglomeration of graphene, and achieve good sphericity, high coverage, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of graphene alloy powder composite material for 3D printing, the specific operation steps and parameters are as follows:

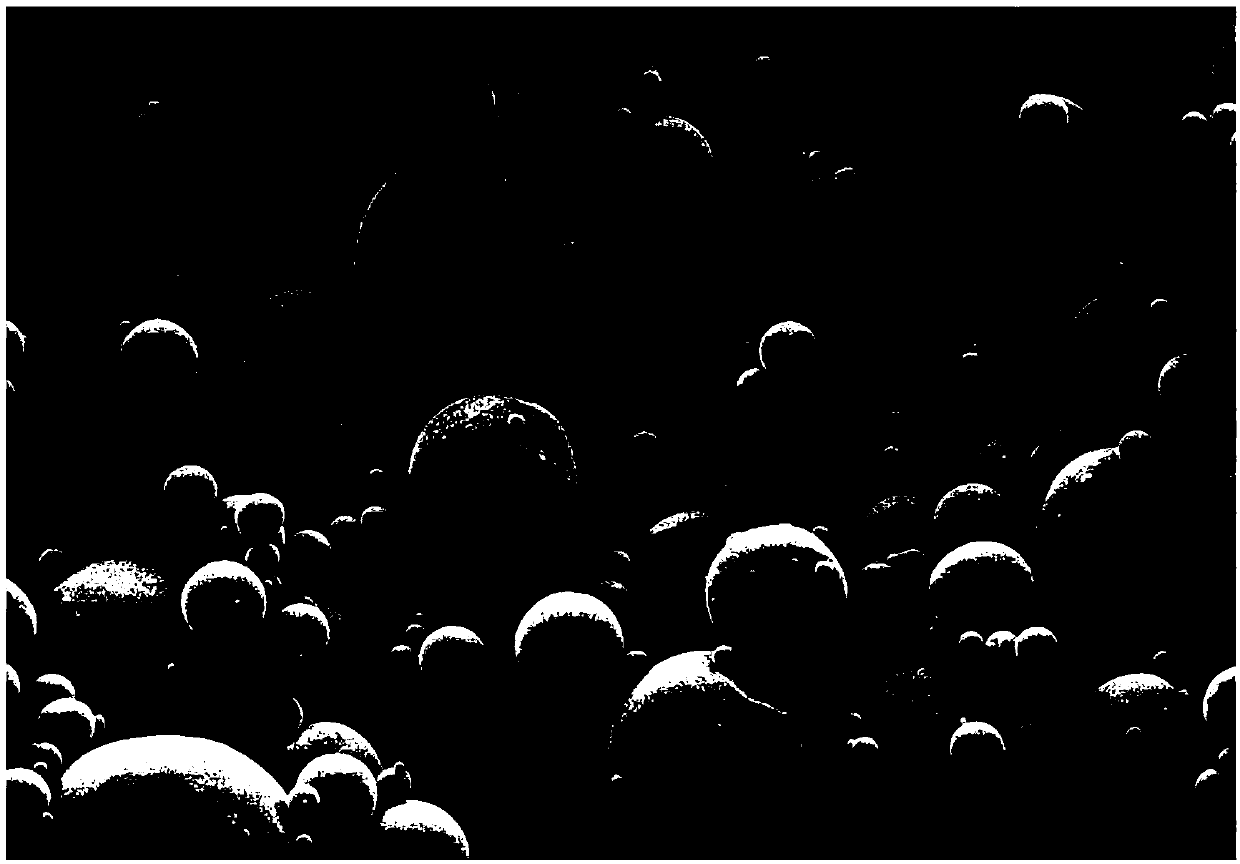

[0024] For the preparation of alloy powder, the coating raw material is TC4 powder, and the alloy powder is prepared by electrode induction gas atomization (EIGA). The powder is sieved three times with an ultrasonic vibrating sieving machine to obtain TC4 fine powder with a particle size of 0<≤53 μm.

[0025] Get 0-53 μm TC4 fine powder 1kg, add the surfactant cetyltrimethylammonium bromide solution 2L that mass fraction is 0.5% wherein, stir 1h at room temperature, wash with distilled water, remove surfactant, will The obtained composite powder was placed in a vacuum oven and dried at 100 °C for 5 h.

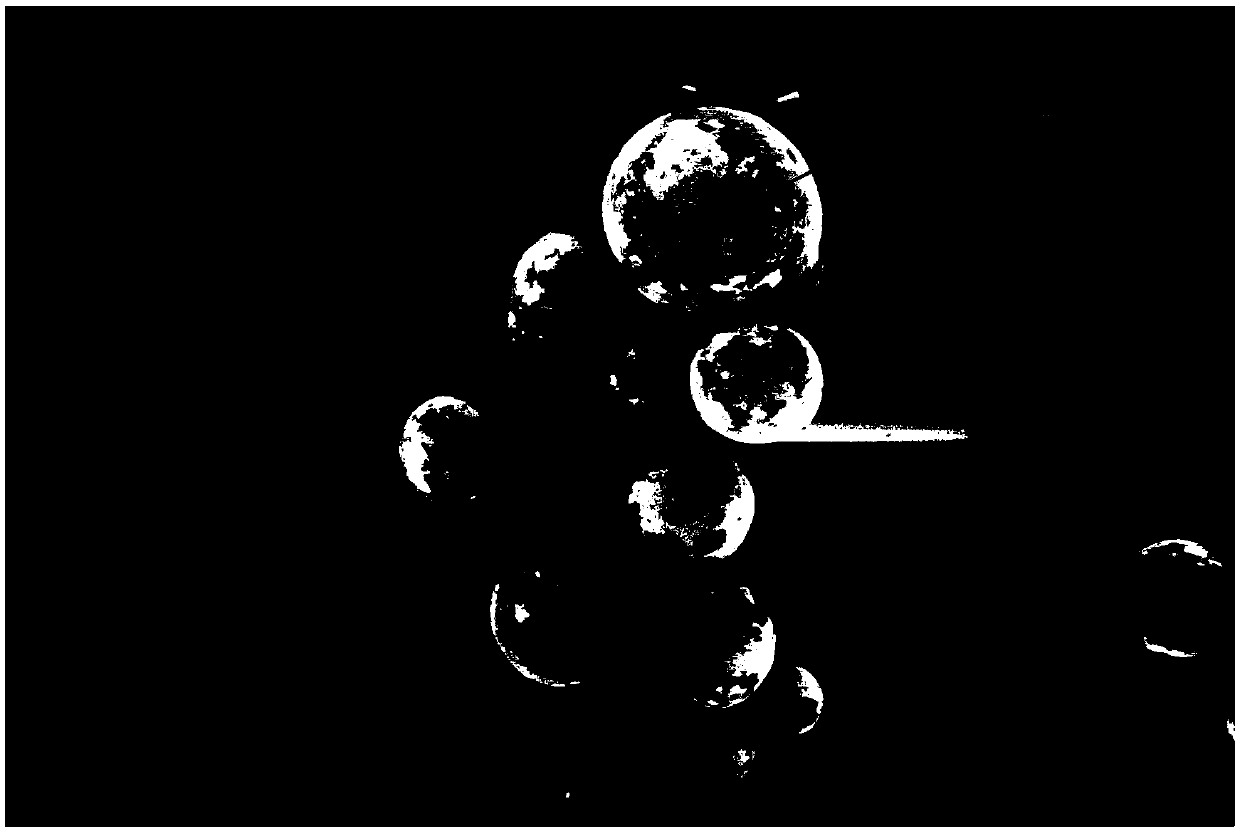

[0026] Add 200ml of graphene oxide solution with a mass fraction of 0.5% to the dried composite powder, stir until the color of the solution turns from dark brown to transparent, and dry in a vacuum oven at 100°C for 5 hours to o...

Embodiment 2

[0029] A method for preparing a graphene alloy powder composite material for 3D printing, the specific operation steps and parameters are as follows:

[0030] For the preparation of alloy powder, the coating raw material is TA0 powder. The powder is prepared by EIGA method, and the powder is sieved three times with an ultrasonic vibrating sieving machine to obtain TA0 fine powder with a particle size of 0<≤53 μm.

[0031] Take 1 kg of TA0 fine powder of 0-53 μm, add 0.5% surfactant cetyltrimethylammonium bromide solution 2L to it, stir at room temperature for 1 h, wash with distilled water, remove the surfactant, and The obtained composite powder was placed in a vacuum oven and dried at 100 °C for 10 h.

[0032] Add 400ml of graphene oxide solution with a mass fraction of 0.5% to the dried composite powder, stir until the color of the solution turns from dark brown to transparent, and dry in a vacuum oven at 100°C for 10 hours to obtain graphene oxide alloy composite powder. ...

Embodiment 3

[0035] The coating raw material is AlSi10Mg powder, which is prepared by VIGA method, and the powder is sieved three times with an ultrasonic vibrating sieving machine to obtain AlSi10Mg fine powder with a particle size of 0<≤53 μm.

[0036] Take 1 kg of AlSi10Mg fine powder of 0-53 μm, add 2 L of surfactant cetyltrimethylammonium bromide solution with a mass fraction of 0.5%, stir at room temperature for 1 h, wash with distilled water, remove the surfactant, and The obtained composite powder was placed in a vacuum oven and dried at 100 °C for 5 h.

[0037] Add 400ml of graphene oxide solution with a mass fraction of 0.4% to the dried composite powder, stir until the color of the solution turns from dark brown to transparent, and dry in a vacuum oven at 100°C for 5 hours to obtain graphene oxide alloy composite powder.

[0038] Put the graphene oxide alloy composite powder into a vacuum furnace at 6X10 -3 Pa vacuum environment, 900 ° C, sintering for 1 h to obtain graphene al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com