Method for saturated shot blasting of stainless steel spring

A technology of stainless steel and shot peening, which is applied to heat treatment equipment, furnaces, heat treatment furnaces, etc. It can solve the problems of unclear shot peening time of stainless steel springs and unstable outer diameter expansion, so as to reduce sorting hours, improve production efficiency, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

[0015] Embodiment 1~15: a kind of saturated shot peening method of stainless steel spring, comprises the steps:

[0016] (1) Add 25kg of steel shot with an outer diameter of 0.4mm into the shot blasting machine, and shot blast the stainless steel spring with a specification of 1.7×16.5×26.5mm;

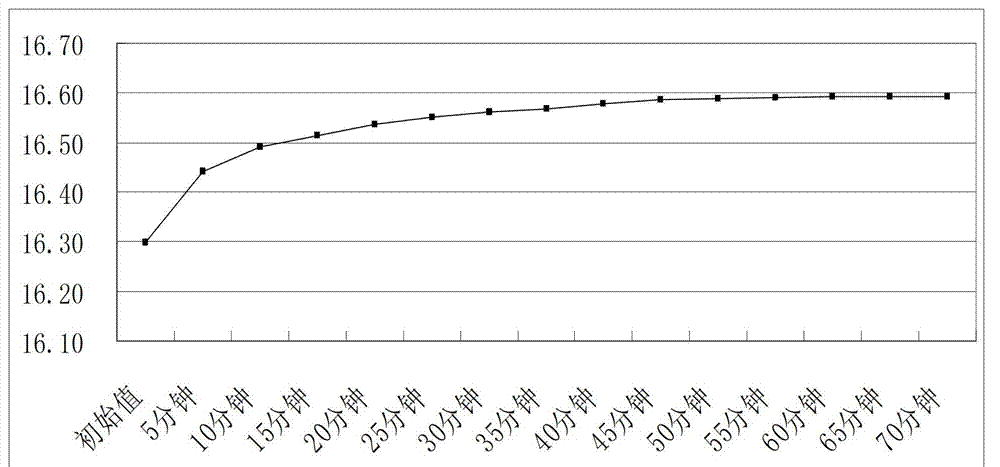

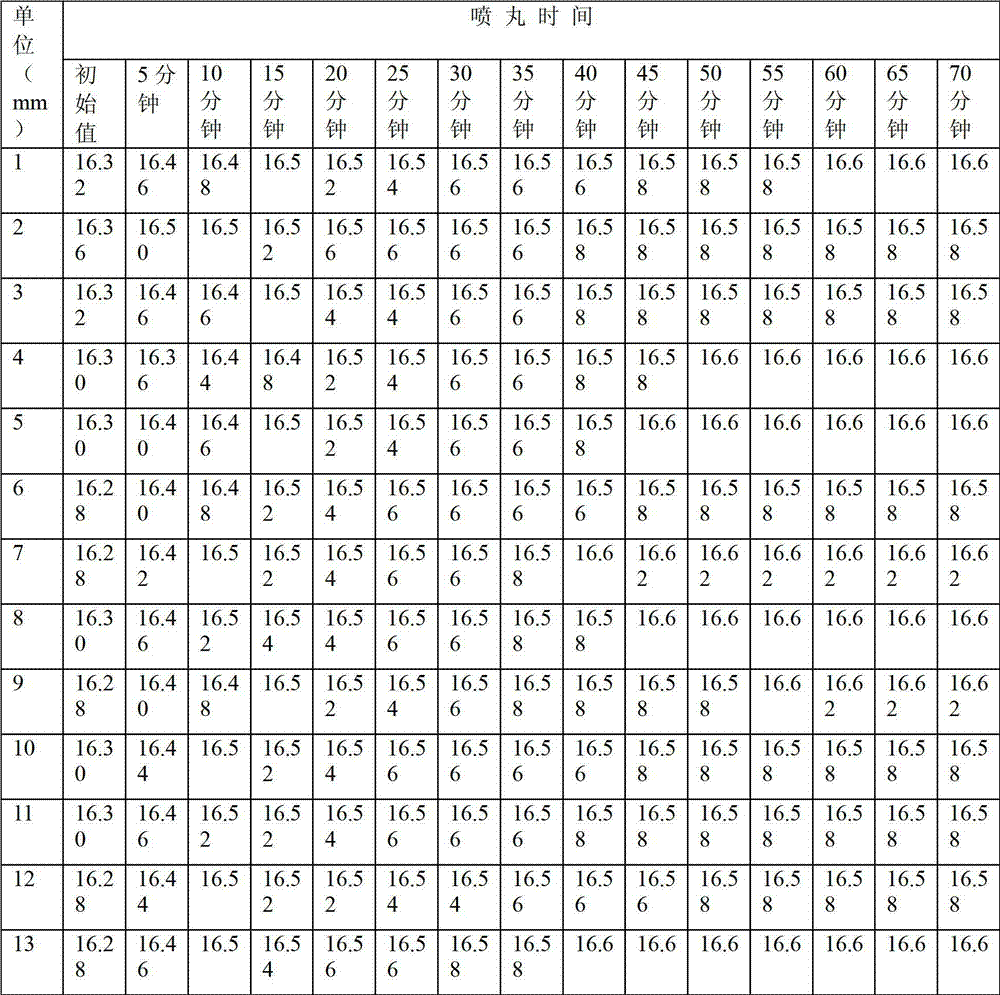

[0017] (2) Use a vernier caliper to measure the outer diameter of the stainless steel spring every 5 minutes (the specific outer diameter measurement values of Examples 1 to 15 within 70 minutes are shown in Table 1), when the outer diameter change value measured twice is within When it is within the range of 0~0.02mm, the stainless steel spring reaches saturated shot peening, and the shot peening process is completed; after 30 minutes of shot peening, the surface coverage of the stainless steel spring is > 90% by visual inspection with a 10 times magnifying glass, and the coverage rate increases, and the spring life The outer diameter of the stainless steel spring tends to be satura...

Embodiment 16~30

[0023] Embodiment 16~30: a kind of saturated shot peening method of stainless steel spring, comprises the steps:

[0024] (1) Add 30kg of steel shot with an outer diameter of 0.4mm into the shot blasting machine, and blast the stainless steel spring with a specification of 1.4×11.5×16.72mm;

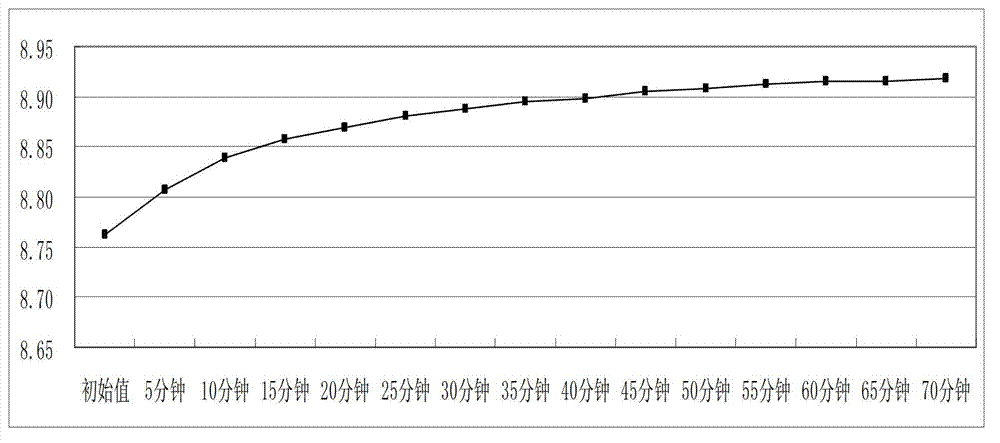

[0025] (2) Use a vernier caliper to measure the outer diameter of the stainless steel spring every 5 minutes (the specific outer diameter measurement values of Examples 16-30 within 70 minutes are shown in Table 2), when the outer diameter change value measured twice is within When it is within the range of 0~0.02mm, the stainless steel spring reaches saturated shot peening, and the shot peening process is completed; after 30 minutes of shot peening, the surface coverage of the stainless steel spring is > 90% by visual inspection with a 10 times magnifying glass, and the coverage rate increases, and the spring life The outer diameter of the stainless steel spring tends to be saturated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com