Compositions for visualization of cleaning efficacy and product coverage

a technology of product coverage and compositions, applied in detergent compositions, detergent dyes, detergent compounding agents, etc., can solve the problems of serious illness, inadequate sanitary design of equipment, and contamination of chemical and microorganisms, and achieve the effect of improving the hygienic sanitation conditions of processing equipment and improving the performance of antimicrobial processing aides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

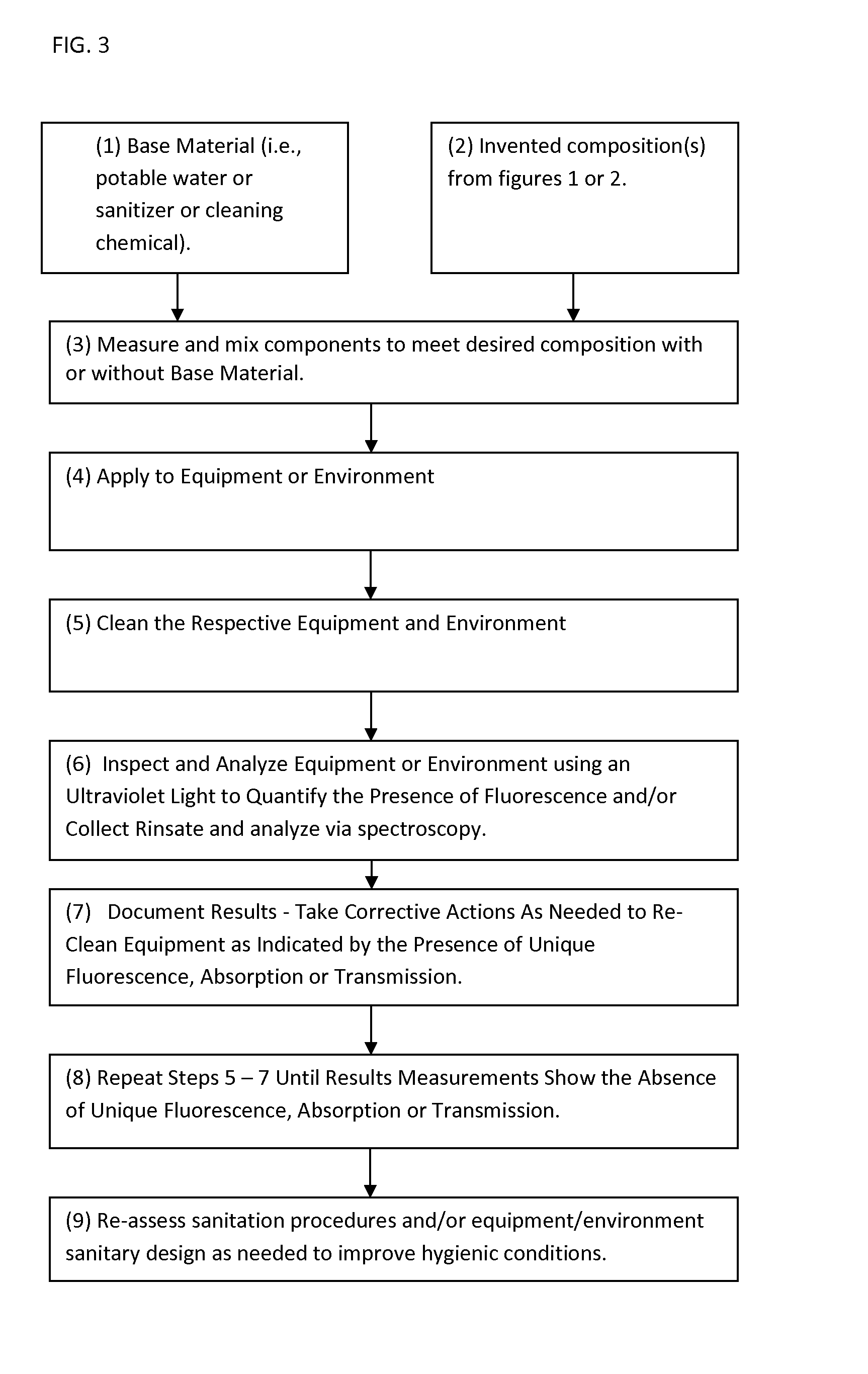

example 1

[0047]The current inventors tested the use of Sodium Lauryl Sulfate (STEPANOL® WA-100 NF / USP) and Glyceryl Laurate (Colonial Monolaurin-Ultra-Pure Glyceryl Laurate) to increase the coverage and penetration of component solutions applied to processing equipment in which the solution is removed from food, feed or pharmaceutical contact surfaces prior to production. Glyceryl Laurate and a mixture of propylene glycol and ethyl- W-lawoyl-L-arginate hydrochloride (A&B Ingredients CytoGuard LA) was used by the inventors for applications associated with direct food contact and was shown to increase coverage and adherence / contact time. Food grade Riboflavin, Folic Acid and Quinine were selected from the many fluorphores available because they were shown to have synergy for the purpose of the tracer concept of the invention.

[0048]All three tracer substances Riboflavin, Folic Acid and Quinine have unique molecular structures that enable them to mix into base solutions with varying polar and no...

example 2

[0049]Very low concentrations of Riboflavin and Folic Acid mixtures can be detected by visible fluorescence and spectroscopy (Table 2 and Table 3).

TABLE 2Transmission, Absorption (360 nm) and Fluorescence of Riboflavin (B2) and Folic Acid (B9) in Neutral and Acidic Distilled Water Solutions.0.5 ppm 0.5 ppm Riboflavin and Riboflavin and 0.5 ppm Folic0.5 ppm FolicDistilledAcid in DistilledAcid inWaterDistilled WaterWaterDistilled WaterpH7.537.843.953.83Transmission10089.710089.0Absorption00.04700.51Concentration00.0500.05FluorescenceVoidSlight+VoidSlightTransmission, Absorption and Concentration measured at 360 nm on Milton Roy Spec 21D at 360 nm on High Intensity. Fluorescence was visually measured in dark while exciting the sample via Mid and Long Wave Ultraviolet Light from 9 watt Way Too Cool Model WTC 9ML 110 at 6 inches. The pH was lowered by adding DL-Tartaric Acid, 99%.

TABLE 3Transmission, Absorption (360 nm) and Fluorescence of Quaternary Ammonia (Quat) Base Material containi...

example 3

[0058]Tests were performed on two stainless steel meat tenderizer rollers. The tenderizer knife rollers are made of 48 circular knives with ¼ inch circular spacers in between the blades. At each blade spacer junction there is a micro niche. Two formula compositions in potable water base material were compared for performance, one with and one without surfactant or emulsifier. Formula 1 contained 750 ppm Riboflavin, 300 ppm Folic Acid as fluorescent tracers, 750 ppm of the surfactant Sodium Lauryl Sulfate, 1,500 ppm of the acidulate Citric Acid Monohydrate and 750 ppm of the emulsifier Glycerol Monolaurate (Monolaurin) in potable water base material. Formula 2 contained 750 ppm Riboflavin, 300 ppm Folic Acid as fluorescent tracers and 1,500 ppm Citric Acid Monohydrate in potable water but did not contain Sodium Lauryl Sulfate or Monolaurin. Approximately 30 lbs of raw beef cutlets were made on the tenderizer each day of the tests. The tenderizer parts were labeled part 1 and part 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com