Preparation of silver-doped nickel oxide film and application of nickel oxide film in perovskite solar cell as hole transport layer

A technology of hole transport layer and nickel oxide, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems affecting the use of perovskite thin-film solar cells, restricting commercial applications, and affecting device performance, etc., to achieve high photoelectricity Effects of conversion efficiency and environmental stability, good light transmittance and hole transport ability, and high surface coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

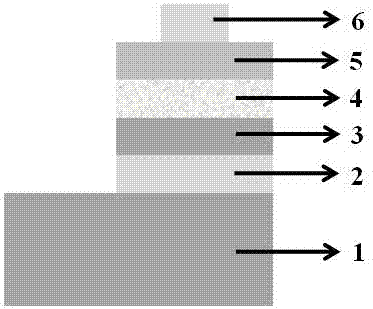

[0023] Example 1: Preparation of silver-doped nickel oxide film (doped atomic ratio is Ag:Ni = 2:98) and its reaction in CH 3 NH 3 PB 3 Applications in Inverse Planar Perovskite Solar Cells.

[0024] Step 1: Clean the surface of the ITO glass, and clean the surface with ultraviolet ozone for 10 minutes.

[0025] Step 2: Preparation of the hole transport layer: Nickel nitrate hexahydrate (Ni (NO 3 ) 2 .6H 2 O) and silver nitrate (AgNO 3 ) according to the molar ratio of 0.98:0.02, the total molar concentration is 1M, dissolved in ethylene glycol solution containing diethylamine, stirred at room temperature for 12 h, and prepared into Ag:NiO x precursor solution. The Ag:NiO x The precursor solution was spin-coated on ITO glass, and then 300 o C heating for 60min.

[0026] Step 3: Preparation of perovskite film precursor solution: PbI 2 and CH 3 NH 3 I was dissolved in N,N-dimethylformamide (DMF) solution containing dimethyl sulfoxide (DMSO) at a molar ratio of 1:1 a...

Embodiment 2

[0030] Example 2: Reverse planar CH with poly(3,4-dioxanethiophene) / (poly(styrene sulfonate) (PEDOT:PSS) as hole transport layer 3 NH 3 PB 3 Fabrication of perovskite solar cells.

[0031] Except for step 2, all steps and methods are exactly the same as in the foregoing embodiment 1.

[0032] Step 2: Preparation of PEDOT:PSS hole transport layer: Spin-coat commercial PEDOT:PSS on ITO glass at a speed of 4000rpm, then in air at 140 o C and heat for 10 minutes.

Embodiment 3

[0033] Example 3: Reverse planar CH with pure nickel oxide as hole transport layer 3 NH 3 PB 3 Fabrication of perovskite solar cells.

[0034] Except for step 2, all steps and methods are exactly the same as in the foregoing embodiment 1.

[0035] Step 2: Preparation of pure nickel oxide hole transport layer: Nickel nitrate hexahydrate (Ni (NO 3 ) 2 .6H 2 O) dissolved in ethylene glycol solution containing diethylamine, the molar concentration was 1M, stirred at room temperature for 12 h, and prepared into Ag:NiO x precursor solution. The Ag:NiO x The precursor solution was spin-coated on ITO glass, and then 300 o C heating for 60min.

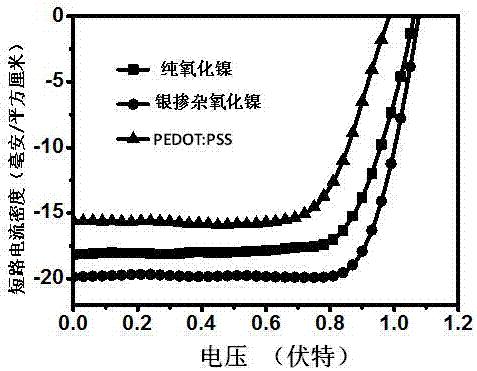

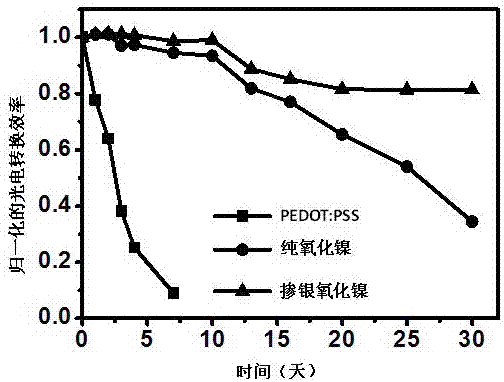

[0036] Implementation effect: Finally, conduct a battery performance test to compare the photoelectric conversion performance of the battery. Store the battery in a glass container with a humidity of 30 ± 2%, measure its efficiency at regular intervals, and compare the stability of the battery.

[0037] In embodiment 1 with Ag:NiO x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com