A kind of chitosan/perovskite nanocomposite film and its preparation method and application

A nanocomposite and chitosan technology, applied in the fields of photoelectrochemistry and polymer chemistry, can solve the problems of poor film-forming properties of perovskite films, achieve excellent mechanical properties, improve film-forming properties, and clean the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

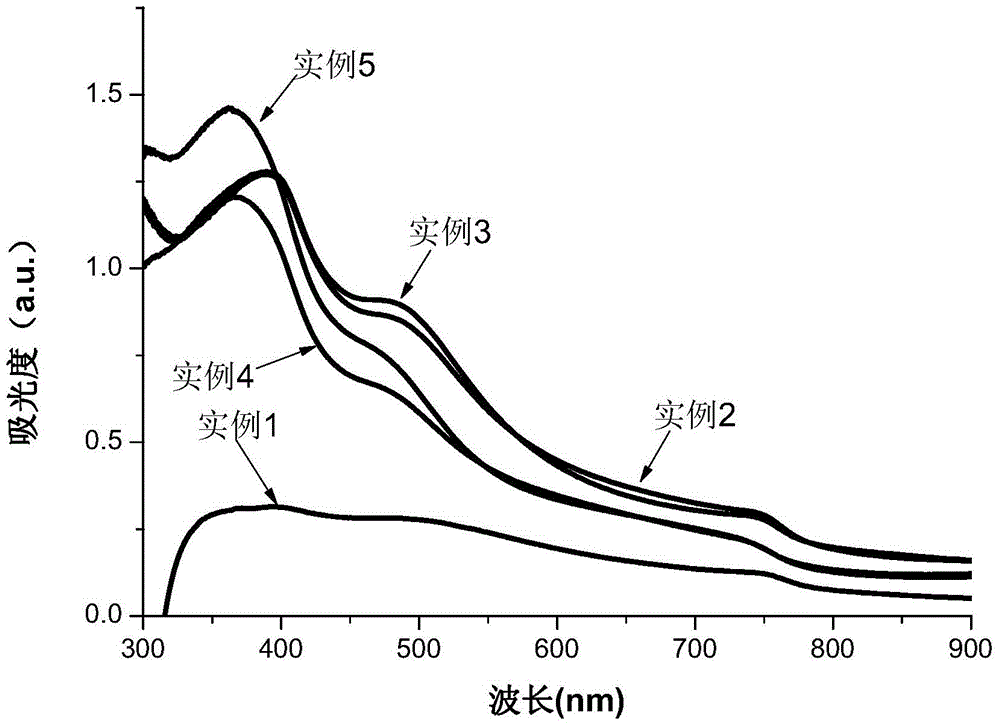

[0035] Weigh 1g of chitosan and dissolve in 100ml 2% (v / v) hydroiodic acid aqueous solution, stir at 1000rpm at 0°C for 8h, add enough acetone to the solution until no precipitation occurs. The obtained precipitate was washed several times with ether until the filtrate was completely colorless, and the obtained solid was chitosan iodide (CS·HI). The obtained solid was dried in a vacuum oven at 50° C. overnight. The preparation method of the methylamine salt is prepared with reference to the literature. Weigh respectively 0.083g methylamine salt, 0.2487g PbI 2 , was dissolved in 2ml of DMF with a density of 0.95g / ml, and after passing nitrogen gas for 10min, it was stirred at 500rpm in the dark at 60°C for 8 hours. After the reaction was completed, the resulting solution was filtered through a PTFE filter with a pore size of 0.45 μm. The resulting solution was spin-coated onto an ITO-coated glass slide. Measure the UV-Vis spectrum.

Embodiment 2

[0037] Weigh 1g of chitosan and dissolve in 100ml 2% (v / v) hydroiodic acid aqueous solution, stir at 1000rpm at 0°C for 8h, add enough acetone to the solution until no precipitation occurs. The obtained precipitate was washed several times with ether until the filtrate was completely colorless, and the obtained solid was chitosan iodide (CS·HI). The obtained solid was dried in a vacuum oven at 50° C. overnight. Weigh 0.0004g CS·HI, 0.083g methylamine salt, 0.2487g PbI 2 , was dissolved in 2ml of DMF with a density of 0.95g / ml, and after passing nitrogen gas for 10min, it was stirred at 500rpm in the dark at 60°C for 8 hours. After the reaction was completed, the resulting solution was filtered through a PTFE filter with a pore size of 0.45 μm. The resulting solution was spin-coated onto an ITO-coated glass slide. Measure the UV-Vis spectrum.

Embodiment 3

[0039] Weigh 1g of chitosan and dissolve in 100ml 2% (v / v) hydroiodic acid aqueous solution, stir at 1000rpm at 0°C for 8h, add enough acetone to the solution until no precipitation occurs. The obtained precipitate was washed several times with ether until the filtrate was completely colorless, and the obtained solid was chitosan iodide (CS·HI). The obtained solid was dried in a vacuum oven at 50° C. overnight. Weigh 0.0008g CS HI, 0.083g methylamine salt, 0.2487g PbI 2 , was dissolved in 2ml of DMF with a density of 0.95g / ml, and after passing nitrogen gas for 10min, it was stirred at 500rpm in the dark at 60°C for 8 hours. After the reaction was completed, the resulting solution was filtered through a PTFE filter with a pore size of 0.45 μm. The resulting solution was spin-coated onto an ITO-coated glass slide. Measure the UV-Vis spectrum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com