Method and device for repairing concrete crack by pulse electrodeposition

A pulse electrodeposition, concrete technology, applied in water conservancy engineering, marine engineering, building components and other directions, to achieve the effect of good effect, simple repair device structure, and improved pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

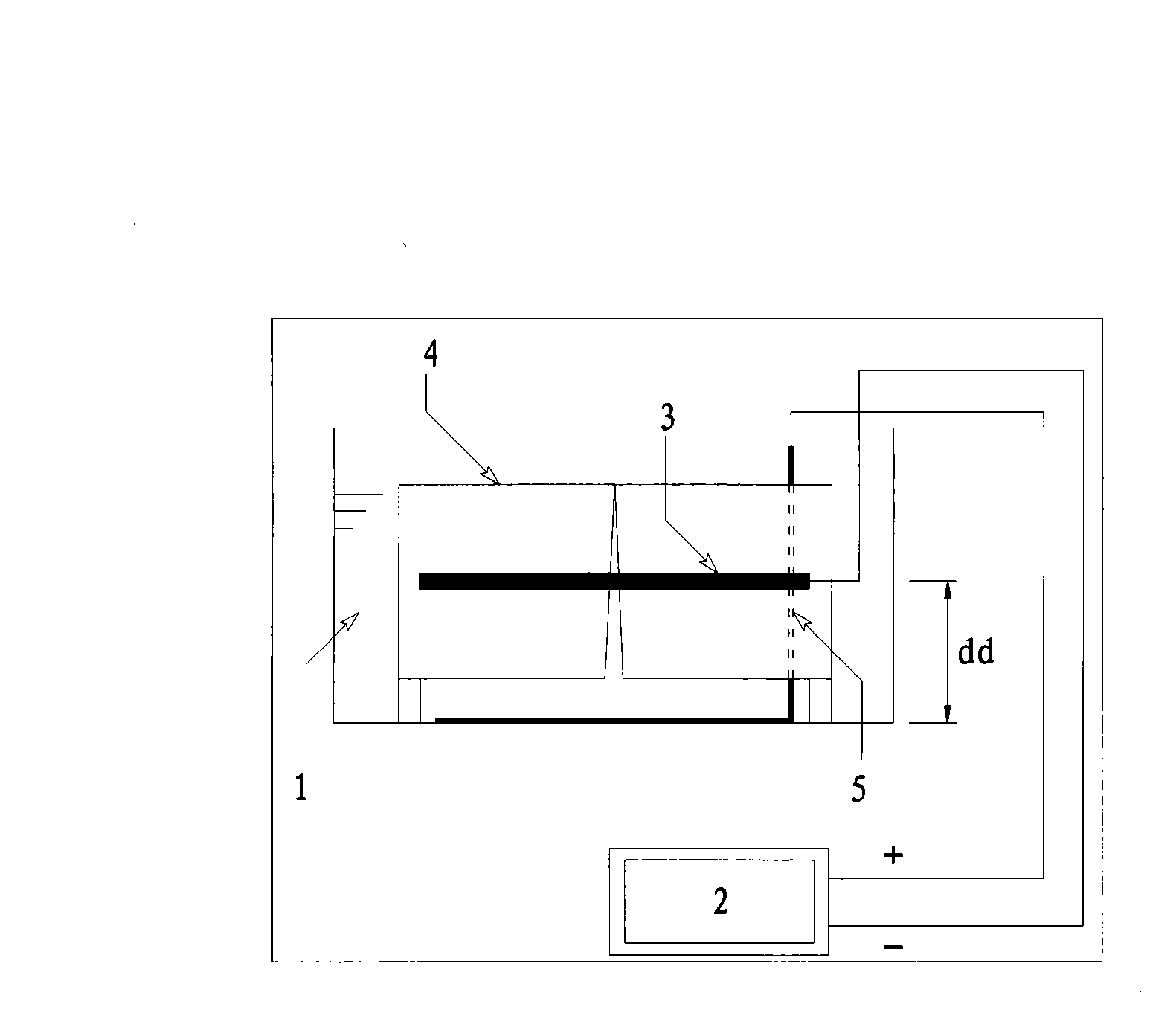

Image

Examples

Embodiment 1

[0024] Using ZnSO 4 It is an electrodeposition solution with a concentration of 0.15mol / L, a pulse on / off time of 0.6ms / 0.8ms, and a current density of 0.5A / m on the concrete surface 2 , The electrode distance is 40mm. The electrodeposition solution was replaced every 7 days, and the test piece was taken out on the 21st day, and the crack healing rate reached 100%.

Embodiment 2

[0026] Using MgSO 4 It is an electrodeposition solution, the concentration is 0.1mol / L, the pulse on / off time is 0.8ms / 0.8ms, and the current density on the concrete surface is 0.5A / m 2 , The electrode distance is 40mm. The electrodeposition solution was replaced every 7 days, and the test piece was taken out on the 21st day, and the crack healing rate reached 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com