Preparation method for perovskite thin film capable of improving purity and reducing pin holes

A technology of perovskite and thin film, which is applied in the field of solar cells, can solve the problems of pinhole formation of perovskite thin film, affect photovoltaic performance, reduce film quality, etc., achieve low hysteresis effect, simple and controllable preparation process, repeatability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

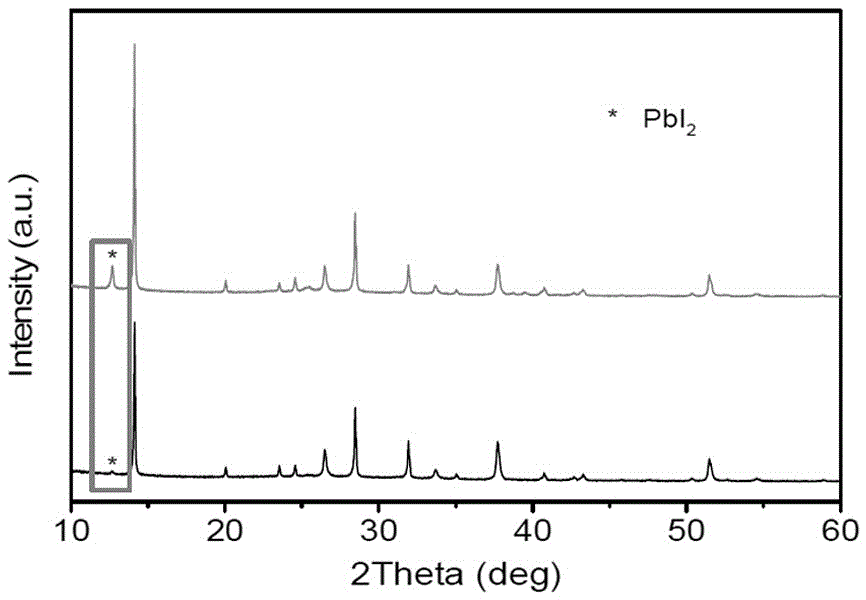

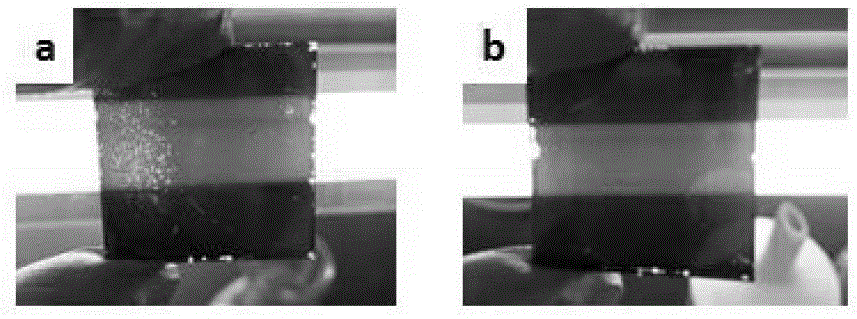

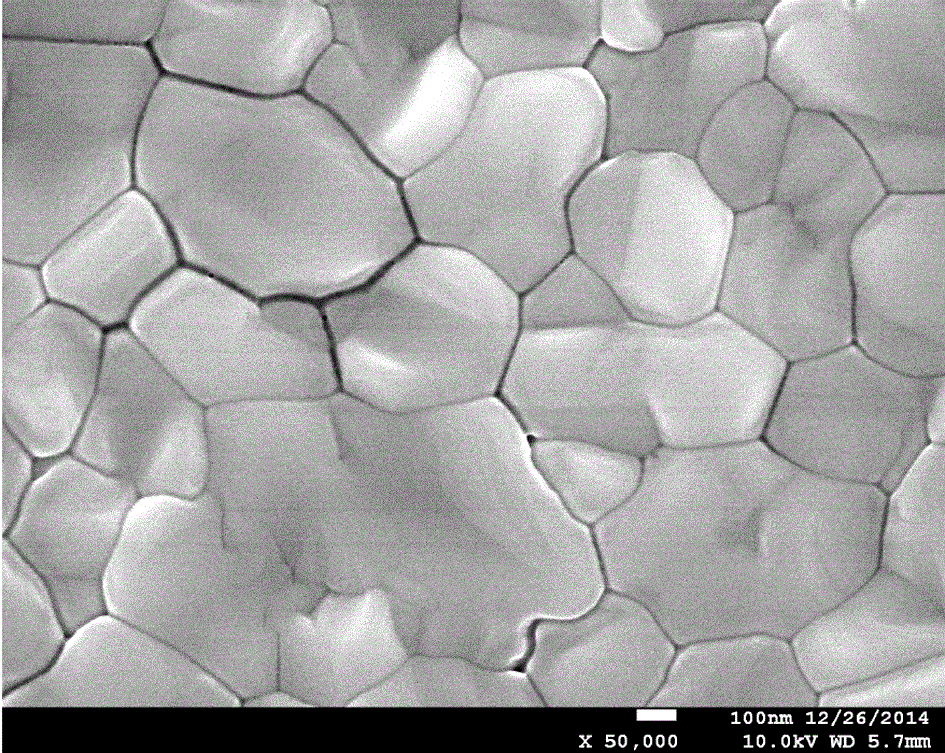

Image

Examples

Embodiment 1

[0031] Embodiment 1, the preparation method of perovskite solar cell.

[0032] The first step: conductive glass cleaning.

[0033] Cut the conductive glass (the conductive glass in this embodiment is FTO, and the conductive glass in other embodiments can also be ITO, etc.) to a specified size; use an ultrasonic cleaner to clean the cut conductive glass in deionized water, acetone, and ethanol in sequence. Ultrasonic cleaning for 10 min, followed by N 2 Blow dry and put into oxygen plasma for 3min.

[0034] The second step: TiO 2 Preparation of dense layers.

[0035] (1) Configure dense layer precursor:

[0036] ①. Measure 2.5mL of absolute ethanol, and measure 35μL of 2mol / L HCl, add the measured HCl into absolute ethanol, and stir well;

[0037] ②. Measure 2.5mL of absolute ethanol, and measure 350μL of isopropyl titanate, add the measured isopropyl titanate into absolute ethanol, and stir evenly;

[0038] ③. Use a pipette to absorb the solution in step ②, and add it dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com