Fe-Ni-Ce catalyst alloy powder and preparation method and application thereof

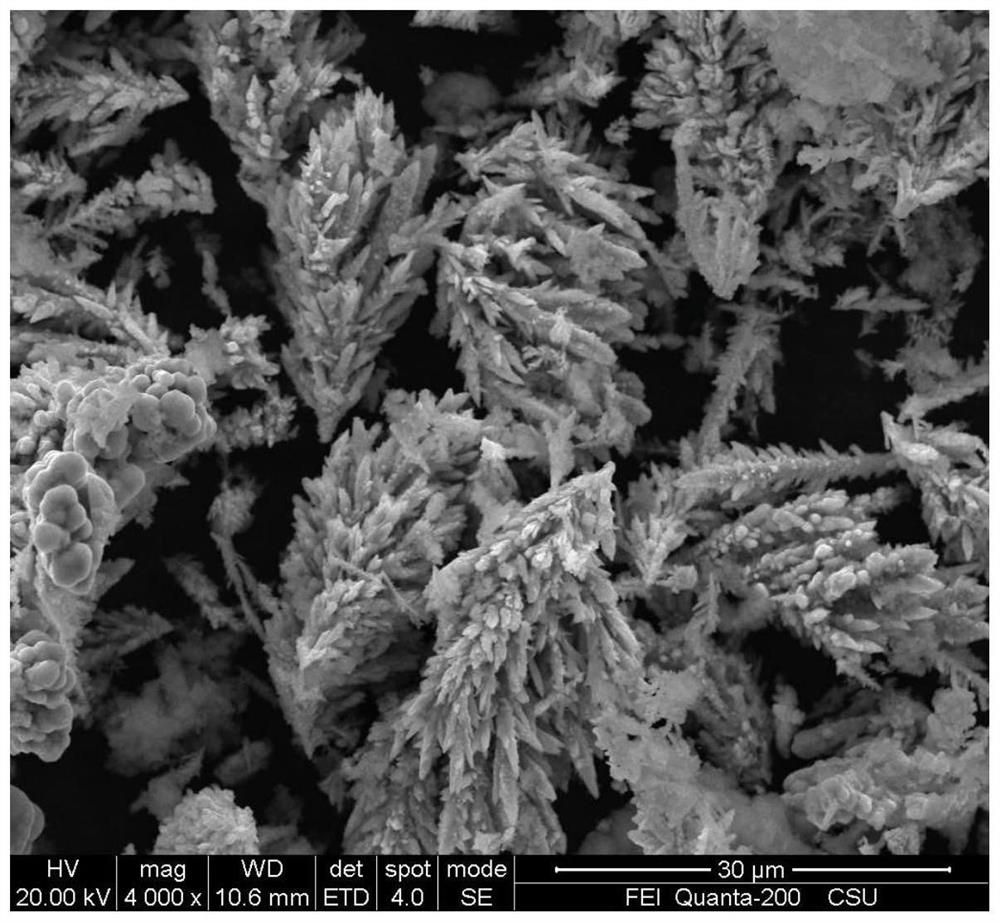

A fe-ni-ce, alloy powder technology, applied in chemical instruments and methods, process using ultra-high pressure, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of high cost, powder oxygen content High, affecting the quality of synthetic diamond and other problems, to achieve the effect of easy operation, large grain size, less defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

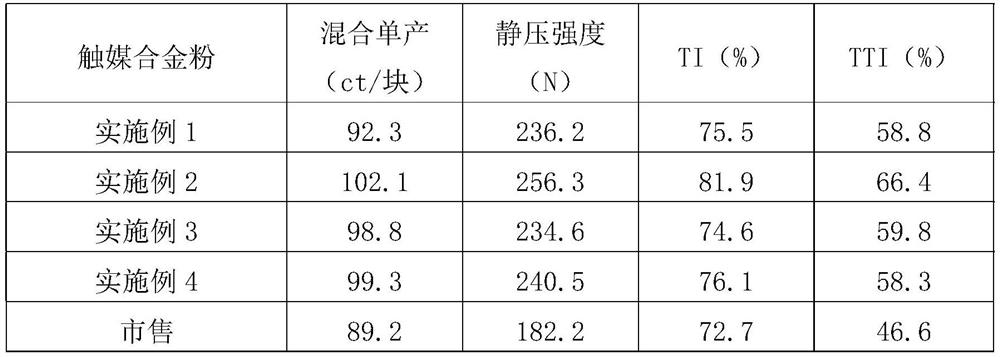

Examples

Embodiment 1

[0032] (1) Pretreatment of nickel mesh

[0033] The nickel mesh cut into 2cm × 2cm was placed in anhydrous ethanol for ultrasonic cleaning for 10 minutes; after being rinsed with deionized water, the nickel foam was soaked in dilute hydrochloric acid for ultrasonic cleaning for 10 minutes; then rinsed with deionized water and dried. spare.

[0034] (2) Configure the electrolytic aqueous solution

[0035] Weigh NiSO 4 ·6H 2 O, FeSO 4 ·7H 2 O. Ce 2 (SO 4 ) 3 , NH 4 Cl, sodium citrate, H 3 BO 3 Add deionized water, fully stir until completely dissolved, adjust the pH value to 5 with dilute hydrochloric acid to obtain an electrolytic aqueous solution, the electrolytic aqueous solution contains 60g / L NiSO 4 ·6H 2 O, 20g / L FeSO 4 ·7H 2 O, 22g / L Ce 2 (SO 4 ) 3 , 60g / L NH 4 Cl, 50g / L sodium citrate, 35g / LH 3 BO 3 .

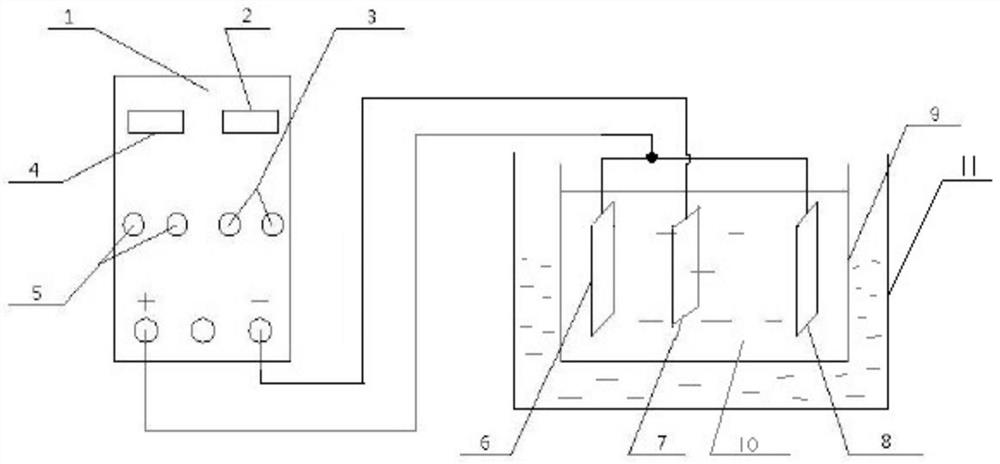

[0036] (3) Fe-Ni-Ce catalyst alloy powder produced by ultrasonic-assisted electrodeposition

[0037] A constant current double anode single cathode ...

Embodiment 2

[0040] (1) Pretreatment of Raney Nickel

[0041] The Raney nickel cut into 2cm×2cm was placed in anhydrous ethanol for ultrasonic cleaning for 10min; after rinsing with deionized water, the nickel foam was soaked in dilute hydrochloric acid for ultrasonic cleaning for 10min; then rinsed with deionized water, Dry and reserve.

[0042] (2) Configure the electrolytic aqueous solution

[0043] Weigh NiSO 4 ·6H 2 O, FeSO 4 ·7H 2 O. Ce 2 (SO 4 ) 3 , NH 4 Cl, sodium citrate, H 3 BO 3 Add in deionized water, fully stir until completely dissolved, adjust the pH value to 6 with dilute hydrochloric acid to obtain an electrolytic aqueous solution, the electrolytic aqueous solution contains 40g / L NiSO 4 ·6H 2 O, 20g / L FeSO 4 ·7H 2 O, 15g / L Ce 2 (SO 4 ) 3 , 50g / L NH 4 Cl, 70g / L sodium citrate, 30g / LH 3 BO 3 .

[0044] (3) Fe-Ni-Ce catalyst alloy powder produced by ultrasonic-assisted electrodeposition

[0045] With the step (3) in the embodiment 1, the difference is: t...

Embodiment 3

[0047] (1) Pretreatment of Raney Nickel

[0048] The Raney nickel cut into 2cm×2cm was placed in anhydrous ethanol for ultrasonic cleaning for 10min; after rinsing with deionized water, the nickel foam was soaked in dilute hydrochloric acid for ultrasonic cleaning for 10min; then rinsed with deionized water, Dry and reserve.

[0049] (2) Configure the electrolytic aqueous solution

[0050] Weigh NiSO 4 ·6H 2 O, FeSO 4 ·7H 2 O. Ce 2 (SO 4 ) 3 , NH 4 Cl, sodium citrate, H 3 BO 3 Add in deionized water, fully stir until completely dissolved, adjust the pH value to 6 with dilute hydrochloric acid to obtain an electrolytic aqueous solution, the electrolytic aqueous solution contains 40g / L NiSO 4 ·6H 2 O, 30g / L FeSO 4 ·7H 2 O, 30g / L Ce 2 (SO 4 ) 3 , 70g / L NH 4 Cl, 80g / L sodium citrate, 40g / LH 3 BO 3 .

[0051] (3) Fe-Ni-Ce catalyst alloy powder produced by ultrasonic-assisted electrodeposition

[0052] With the step (2) in the embodiment 1, the difference is: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com