Perovskite LED taking ZnO nanometer wall network as electron injecting layer and preparation method thereof

A technology of electron injection layer and nano wall, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of increasing the probability of non-radiative recombination of carriers, the decrease of device luminous efficiency, and poor film formation, so as to promote high efficiency The effect of radiative recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

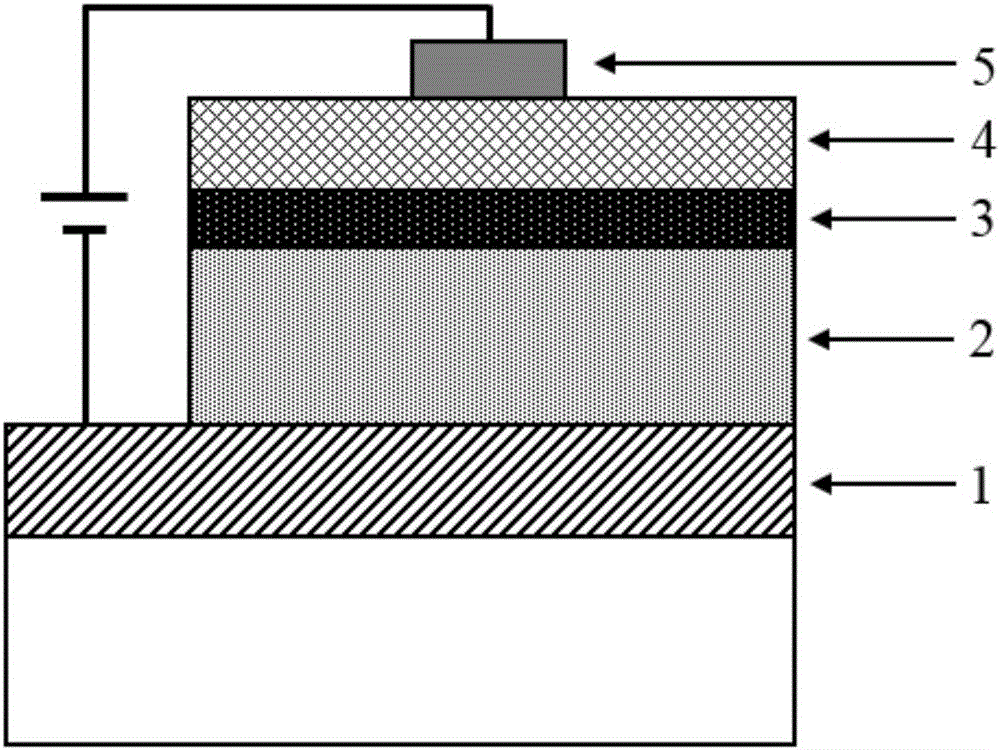

[0037] A preparation method of a perovskite LED using a ZnO nanowall network as an electron injection layer, the steps are as follows:

[0038] (1) cleaning the transparent conductive substrate 1;

[0039] (2) Epitaxial growth of n-type ZnO nanowall network 2 on substrate 1 by MOCVD method;

[0040] (3) Preparation of CH on n-type ZnO nanowall network 2 by low-temperature solution method 3 NH 3 PbBr 3 Light-emitting layer 3;

[0041] (4) in CH 3 NH 3 PbBr 3 Prepare a p-type hole-providing layer 4 on the light-emitting layer 3;

[0042] (5) A circular translucent electrode 5 is prepared on the p-type hole-providing layer 4 by thermal evaporation.

[0043] Preferably, the MOCVD preparation of the n-type ZnO nanowall network 2 in step (2) adopts a two-step growth method.

[0044] Step (3) CH 3 NH 3 PbBr 3 The preparation of the light-emitting layer 3 is a one-step low-temperature solution method or a two-step low-temperature solution method.

[0045] In step (4), the p...

Embodiment 1

[0048] 1) Use commercially available transparent and conductive ITO glass as the substrate 1, cut it into a required 20mm×20mm square, and then perform chemical cleaning on it. The specific cleaning steps are:

[0049] First, wash the substrate in detergent (Liby brand liquid detergent) for 15 minutes, then rinse it with tap water; then use acetone and ethanol solutions to ultrasonically clean it for 10 minutes each, and recirculate once; then rinse it with deionized water After cleaning, dry it with high-purity nitrogen before use.

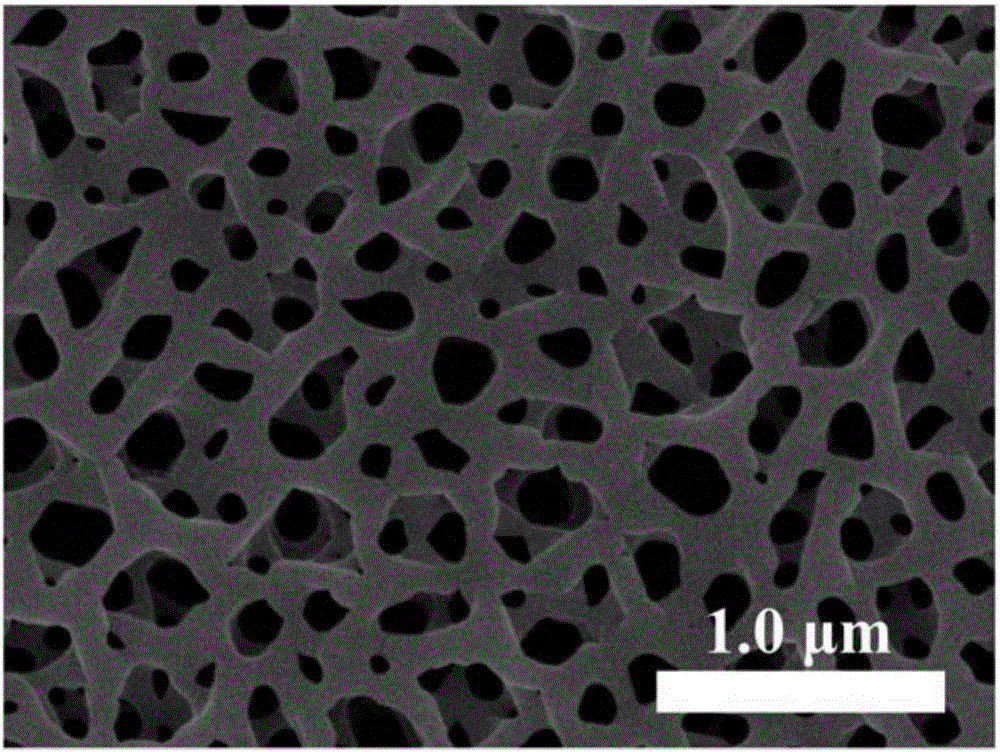

[0050] 2) Put the cleaned ITO glass on the graphite tray in the MOCVD (vapor phase deposition) reaction chamber, and grow a two-dimensional n-type ZnO nanowall network 2 as the electron injection layer of the LED by a two-step growth method. The specific growth conditions are as follows:

[0051] In the first step, the input amount of the zinc source is 6.5 micromoles per minute, the input amount of the oxygen source is 8.0 millimoles per minute...

Embodiment 2

[0059] 1) Commercially available transparent and conductive ITO glass is used as the substrate 1 . The method for cleaning the ITO glass substrate in this embodiment is the same as that in Embodiment 1.

[0060] 2) epitaxially grow a two-dimensional n-type ZnO nanowall network 2 on the cleaned ITO glass substrate 1 as the electron supply layer of the LED. The method for obtaining the n-type two-dimensional ZnO nanowall network 2 in this embodiment is the same as that in Embodiment 1.

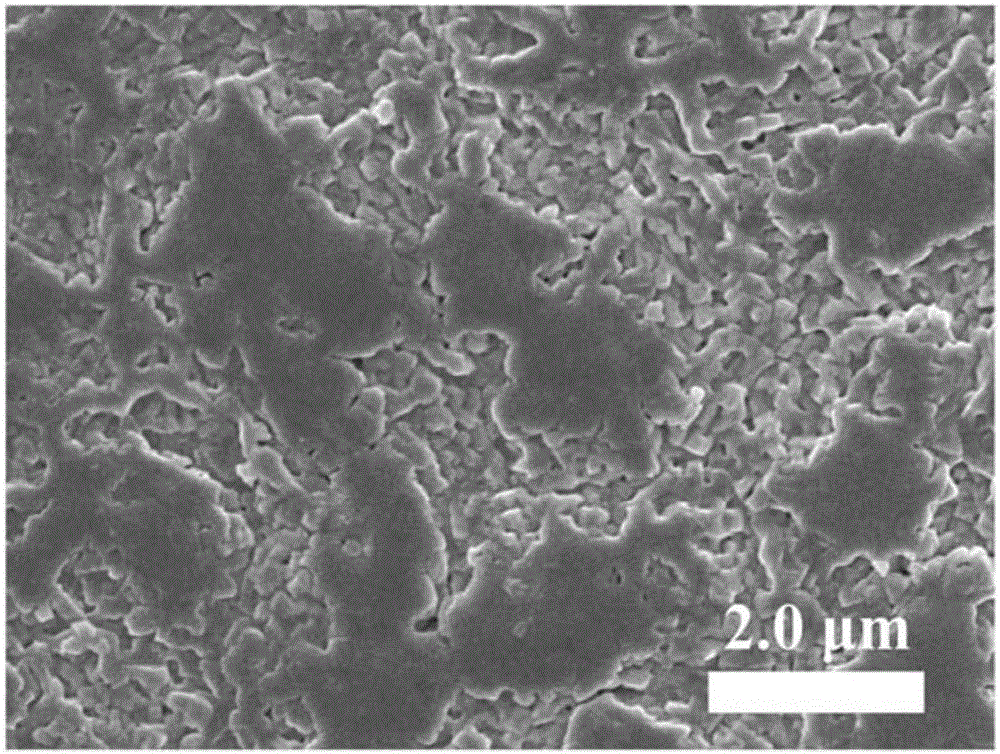

[0061] 3) Preparation of CH by a two-step solution method 3 NH 3 PbBr 3 Light-emitting layer 3, the specific steps are as follows:

[0062] First, 1.15 g of PbBr 2 (Aldrich brand) powder was dissolved in dimethylformamide to prepare a solution with a concentration of 1 mole per liter, and stirred with a magnetic stirrer at 70°C for 3 hours for later use; 0.395 grams of CH 3 NH 3 Br (Aldrich brand) powder isopropanol is prepared with a concentration of 10 mg per milliliter solution for sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com