Conductive poly 3,4-ethylene dioxy thiophene film and preparation method thereof

A technology of ethylene dioxythiophene and dioxythiophene membrane, which is applied in electrolytic components, electrolytic processes, electrolytic organic production, etc., can solve the problems of unfavorable product separation, unsuitable for large-scale production, human and environmental hazards, etc., and achieves polymerization. The speed is easy to control, easy to separate and purify, and the effect of improving the polymerization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 carries out electrochemical polymerization at the liquid-liquid interface formed by dichloromethane and water

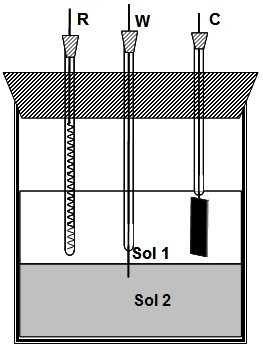

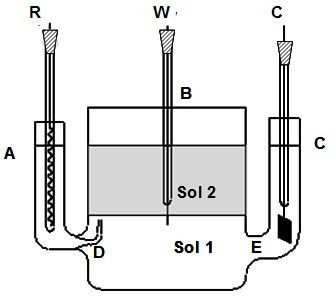

[0027] First take a certain amount of monomer ethylenedioxythiophene (EDOT) and supporting electrolyte lithium perchlorate (LiClO 4 ) were dissolved in the organic solvent chloroform and water respectively to prepare 0.01 mol / L EDOT chloroform solution and 0.1 mol / L LiClO 4 aqueous solution; sequentially take a certain volume of EDOT chloroform solution and LiClO 4 aqueous solution in figure 1 In the single-port polymerization device shown, a clear liquid-liquid interface is formed; then a certain length of platinum wire working electrode (0.5 mm in diameter) is vertically and slowly inserted into the liquid-liquid interface, and the platinum wire is ensured to slightly exceed the liquid-liquid interface and penetrate deep into the liquid-liquid interface. The oil phase is about 0.5 mm, and the platinum auxiliary electrode and saturated calomel ...

Embodiment 1 and comparative example 1

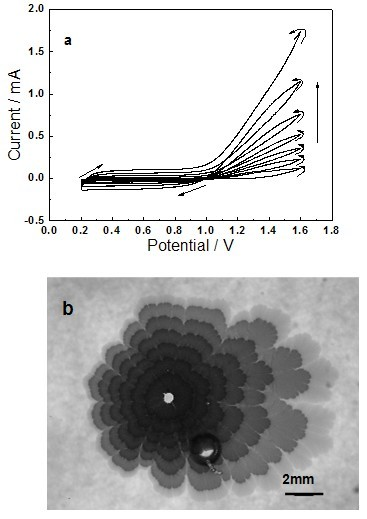

[0031] Embodiment 1 is in 0.01 mol / L EDOT trichloromethane solution and 0.1 mol / L LiClO 4 The liquid-liquid interface formed by the aqueous solution, in comparative example 1, was polymerized by cyclic voltammetry in 0.01 mol / L EDOT aqueous solution, the potential range: 0.2 V ~ 1.6 V, and the scanning speed: 20 mV / s. The cyclic voltammetry curve in the polymerization process of embodiment 1 and the macroscopic appearance of the conductive polymer film of generation see respectively image 3 a, b, the ring voltammetry curve of comparative example 1 polymerization process sees Figure 4 (The arrows in the figure indicate the direction and trend of current change).

[0032] Compared image 3 a and Figure 4It can be clearly seen that the cyclic voltammetry curve of the process of preparing the conductive polymer in the present invention shows a very different behavior from that of the polymerization in the traditional homogeneous system, especially in the oxidation potential ...

Embodiment 2

[0034] First take a certain amount of monomer ethylenedioxythiophene (EDOT) and supporting electrolyte perchloric acid (HClO 4 ) were dissolved in organic solvent dichloroethane and water respectively, and made into 1 mol / L EDOT dichloroethane solution and 2 mol / L HClO 4 aqueous solution; sequentially take a certain volume of EDOT dichloroethane solution and HClO 4 aqueous solution in figure 1 In the single-port polymerization device shown, a clear liquid-liquid interface is formed; then a certain length of platinum wire working electrode (0.5 mm in diameter) is vertically and slowly inserted into the liquid-liquid interface, and the platinum wire is made to slightly exceed the liquid-liquid interface and penetrate into the liquid-liquid interface. The oil phase is about 0.5 mm, and the platinum auxiliary electrode and saturated calomel (SCE) reference electrode are inserted into the upper layer of HClO 4 In aqueous solution; using a constant potential of 1.4V ( vs SCE) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com