Electronic beam radiopolymerization process of directly synthesizing temperature sensitive hydrogel

A thermosensitive hydrogel, electron beam radiation technology, applied in the field of thermosensitive hydrogel preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

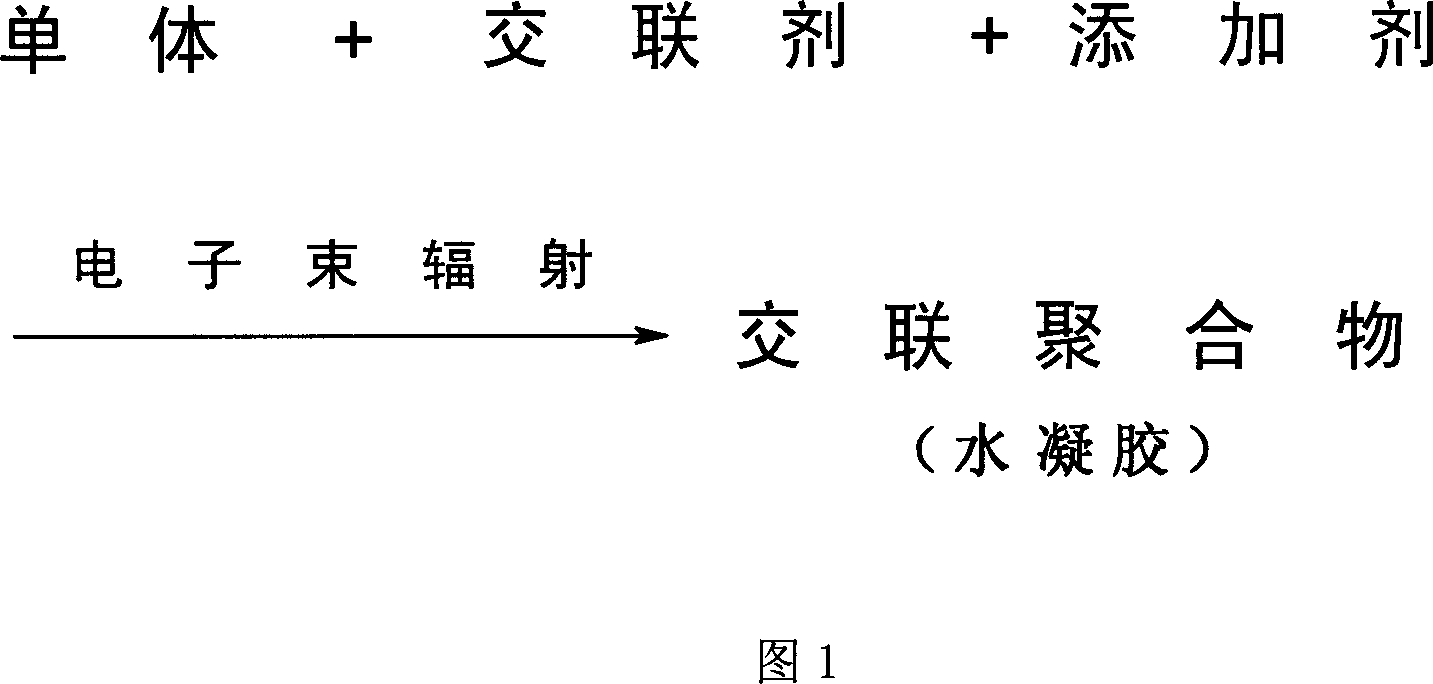

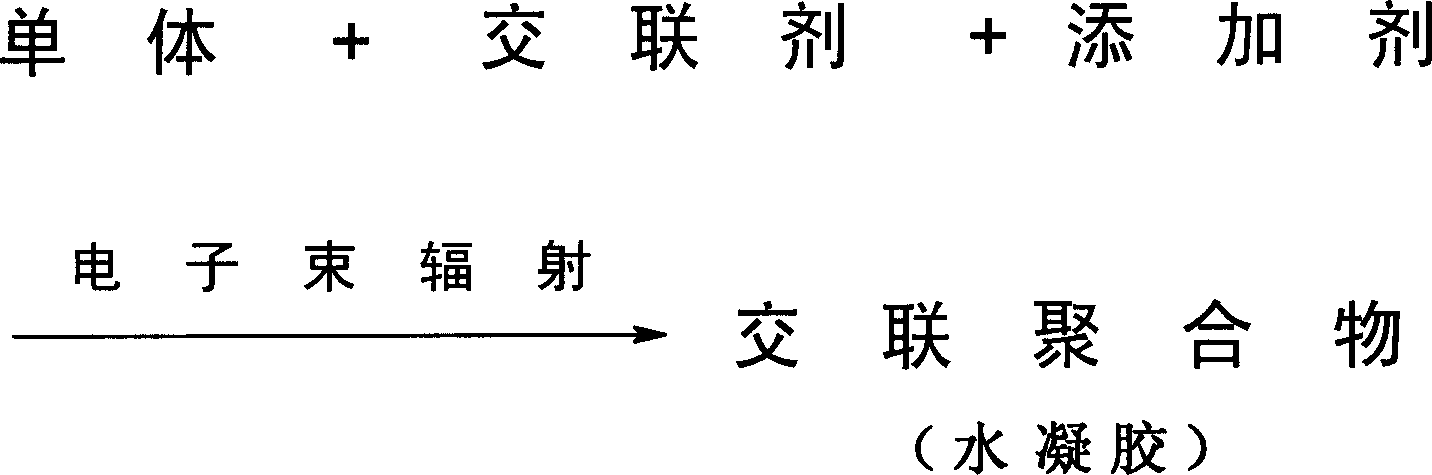

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 3.5 g of monomer (N-isopropylacrylamide), 0.3 g of monomer (acrylic acid), 0.1 g of additive (chitosan), 0.25 g of cross-linking agent (tripolyethylene glycol diacrylate) in 21 mL deionized water. The prepared solution is placed in a beaker, and the cross-linked polymer is obtained by electron beam radiation. Put the cross-linked polymer into a Soxhlet extractor and extract it with boiling deionized water for 24 hours, take it out and put it into a vacuum oven to dry to obtain a temperature-sensitive hydrogel.

Embodiment 2

[0027] Dissolve 3.5g monomer (N-isopropylacrylamide), 1.1g monomer (acrylic acid), 0.2g additive (polyvinyl alcohol), 0.15g crosslinking agent (diethylene glycol diacrylate) in 23mL to ionized water. The prepared solution is placed in a beaker, and the cross-linked polymer is obtained by electron beam radiation. Put the cross-linked polymer into a Soxhlet extractor and extract it with boiling deionized water for 24 hours, take it out and put it into a vacuum oven to dry to obtain a temperature-sensitive hydrogel.

Embodiment 3

[0029] 3.5g monomer (N-isopropylacrylamide), 0.5g monomer (acrylic acid), 0.25g monomer (N, N'-dimethylacrylamide), 0.1g additive (chitosan), 0.25 g Crosslinker (tetrapolyethylene glycol diacrylate) was dissolved in 20 mL of deionized water. The prepared solution is placed in a beaker, and the cross-linked polymer is obtained by electron beam radiation. Put the cross-linked polymer into a Soxhlet extractor and extract it with boiling deionized water for 24 hours, take it out and put it into a vacuum oven to dry to obtain a temperature-sensitive hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com