Parallel Flow Heat Exchanger With Crimped Channel Entrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

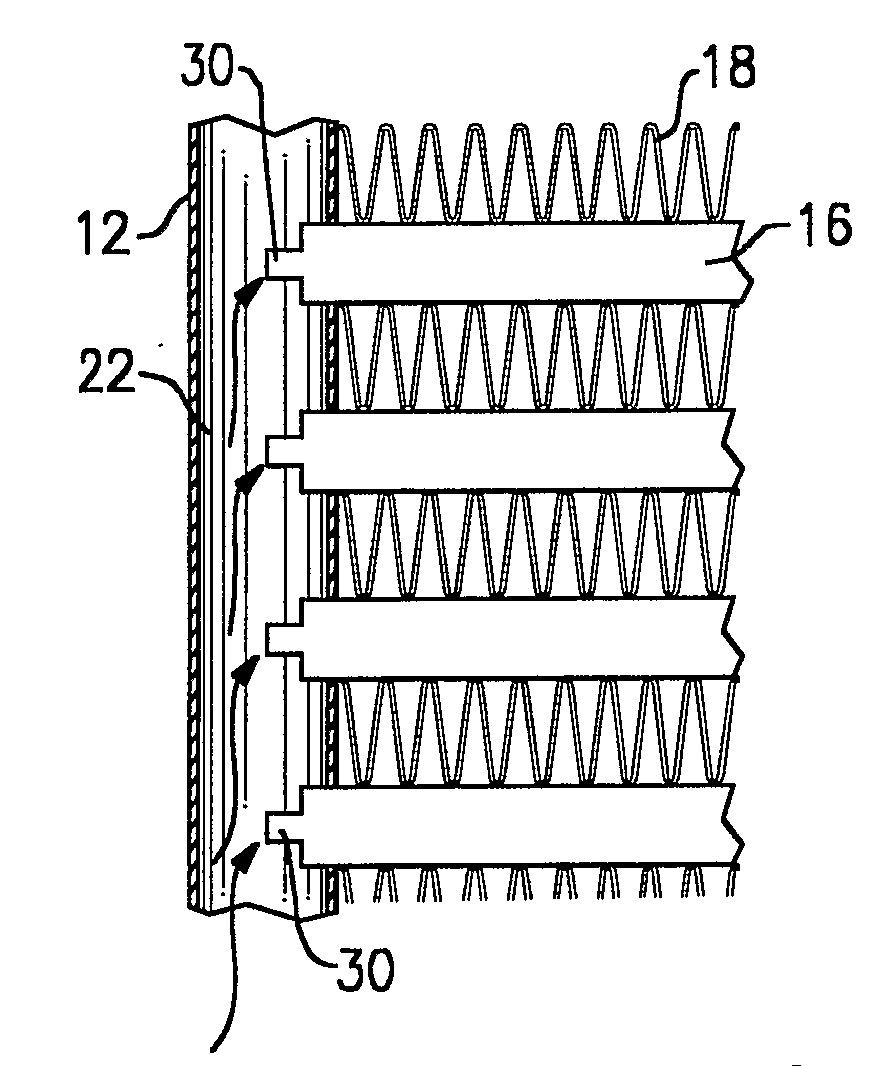

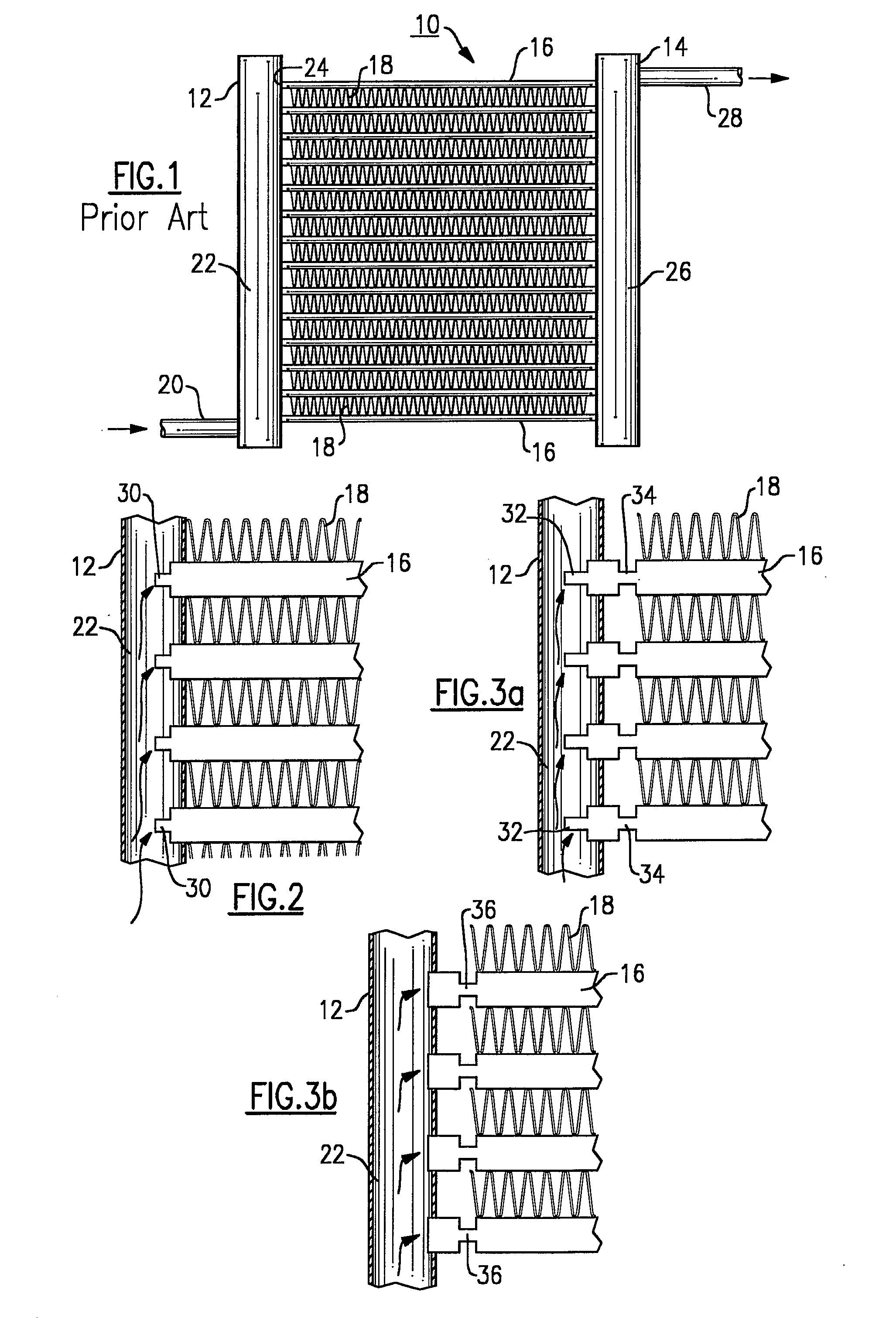

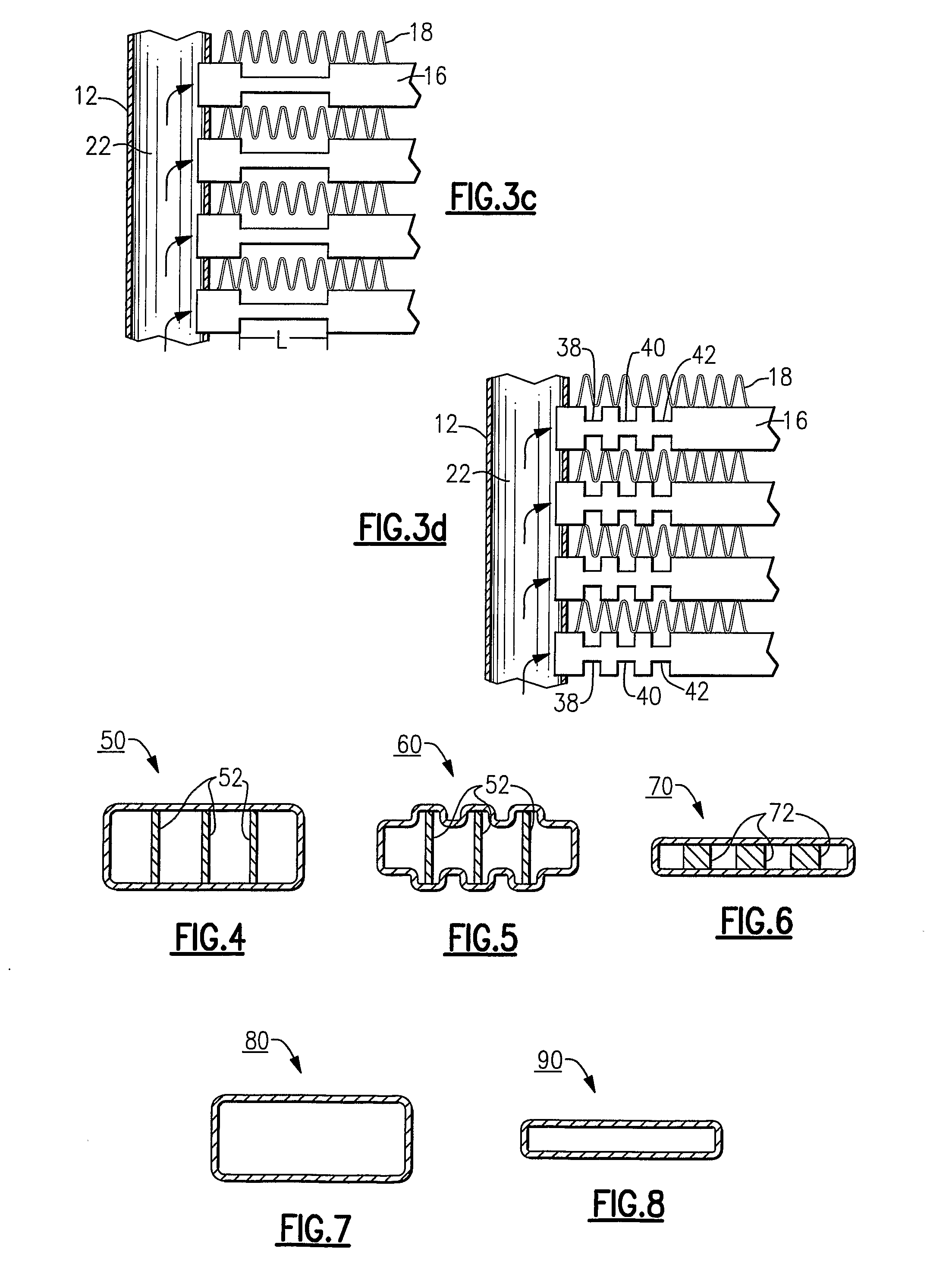

[0030]In the invention, as illustrated in FIG. 3a, the channels are crimped at the very end 32 and at a point 34, some distance away from the end and the attachment point to the manifold 12.

third embodiment

[0031]In a third embodiment, as illustrated in FIG. 3b, the channels are crimped at a single location 36, a predetermined distance from the channel end and, once again, away form the attachment point to the manifold 12, in order not to interfere with the attachment process.

fourth embodiment

[0032]In a fourth embodiment, as illustrated in FIG. 3c, the channels are crimped for a predetermined length or distance “L” near the channel ends but with less cross-section area alteration / reduction than in FIGS. 2, 3a and 3b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com