Method for preparing stable-dispersibility pigment/polymer core-shell structure composite granules by using by polymer-wrapped pigment particles

A technology for coating pigments and core-shell structures, which is applied in the treatment of dyed polymer organic compounds, organic dyes, fibrous fillers, etc., can solve the problems of incomplete coating, low coating efficiency, etc. Effect of preventing phase separation, improving dispersibility and dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

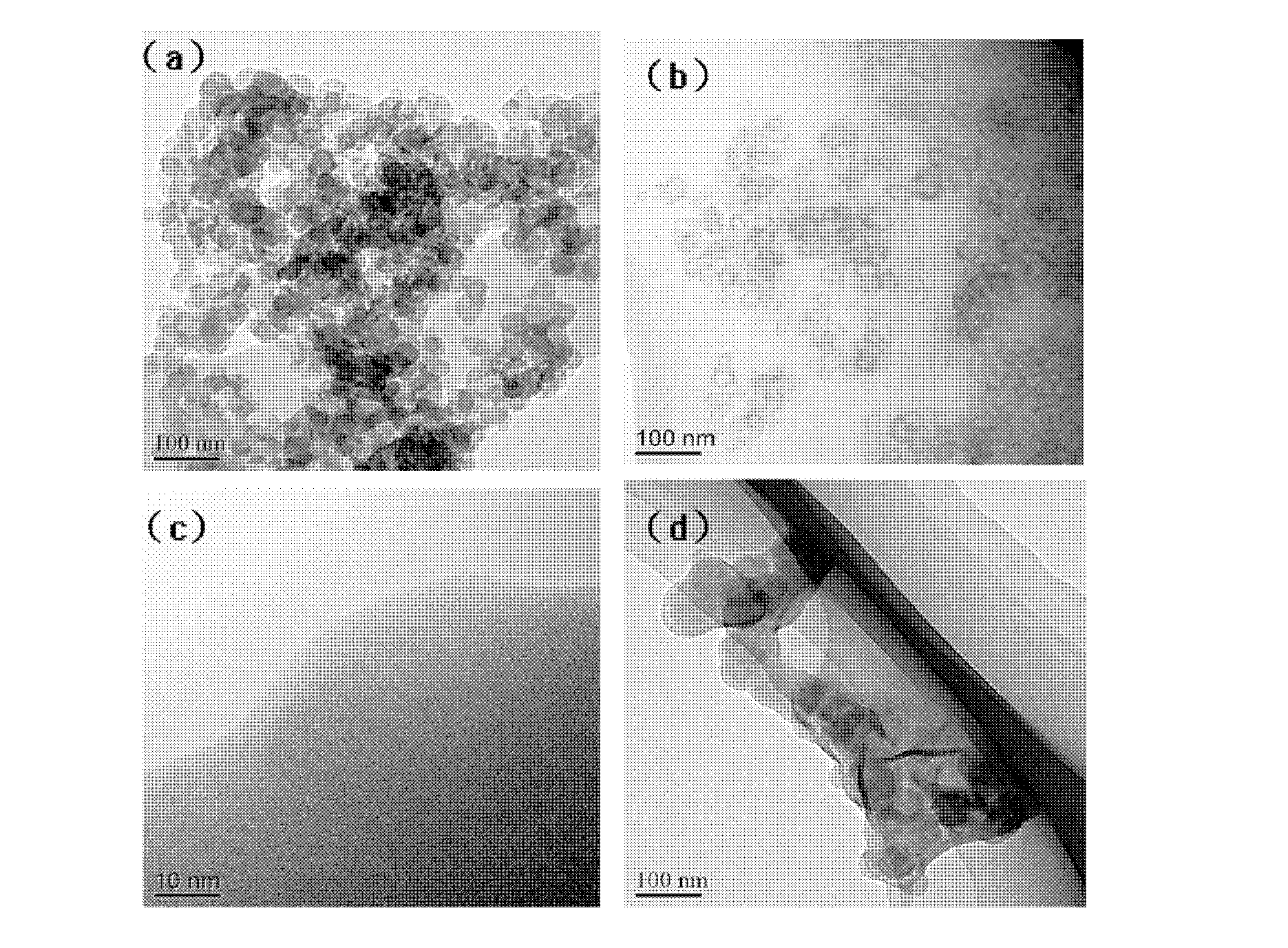

[0039] Example 1: Preparation of carbon black / polymer composite particles without emulsifier

[0040] Add 30mL of water, 0.15g of 1,1-diphenylethylene, 0.8g of acrylic acid, and 1.6g of n-butyl acrylate into a 150mL three-necked flask equipped with an electric stirrer, a condenser tube and a thermometer, and mechanically stir at 300r / min Under heating, the temperature was raised to 80° C., and 10 g of 1.5 wt % potassium persulfate aqueous solution was added to initiate the polymerization reaction. Add 0.8g of carbon black to a beaker containing 30mL of water, use the KQ-300DE ultrasonic instrument produced by Kunshan Ultrasonic Instrument Co., Ltd., and ultrasonically disperse for 30min under the condition of output power of 80%, and in the above polymer precursor synthesis system After 40 minutes of reaction, the ultrasonically dispersed carbon black dispersion was slowly added dropwise to the system within 10 minutes, and the reaction was continued at 80°C for 3 hours, and t...

Embodiment 2

[0041] Embodiment 2: Preparation of carbon black / polymer composite particles, using sodium lauryl sulfate as emulsifier

[0042] Add 30mL of water, 0.15g of 1,1-diphenylethylene, 0.6g of acrylic acid, and 1.8g of n-butyl acrylate into a 150mL three-necked flask equipped with an electric stirrer, a condenser tube and a thermometer, and mechanically stir at 300r / min Under heating, the temperature was raised to 80° C., and 10 g of 1.5 wt % potassium persulfate aqueous solution was added to initiate the polymerization reaction. Add 0.8g of carbon black to a beaker containing 30mL of water, use the KQ-300DE ultrasonic instrument produced by Kunshan Ultrasonic Instrument Co., Ltd., and ultrasonically disperse for 30min under the condition of output power of 80%, and in the above polymer precursor synthesis system After 1.5 hours of reaction, the ultrasonically dispersed carbon black dispersion was slowly added dropwise to the system within 10 minutes, and the reaction was continued ...

Embodiment 3

[0043] Embodiment 3: Preparation of carbon black / polymer composite particles, using cetyl ammonium bromide as emulsifier

[0044] Add 30mL of water, 0.15g of 1,1-diphenylethylene, 1.2g of acrylic acid, and 1.2g of n-butyl acrylate into a 150mL three-necked flask equipped with an electric stirrer, a condenser tube and a thermometer, and mechanically stir at 300r / min Under heating, the temperature was raised to 80° C., and 10 g of 1.5 wt % potassium persulfate aqueous solution was added to initiate the polymerization reaction. Add 0.8g of carbon black to a beaker containing 30mL of water, use the KQ-300DE ultrasonic instrument produced by Kunshan Ultrasonic Instrument Co., Ltd., and ultrasonically disperse for 30min under the condition of output power of 80%, and in the above polymer precursor synthesis system After 40 minutes of reaction, the ultrasonically dispersed carbon black dispersion was slowly added dropwise to the system within 10 minutes, and the reaction was continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com