Method of preparing protein modified polyacrylonitrile fibre

A technology of polyacrylonitrile fiber and polyacrylonitrile, which is applied in cellulose/protein conjugated rayon, spinning solution preparation, wet spinning, etc. The branch rate is difficult to control and other problems, so as to increase economic benefits, improve production efficiency, and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Raw material: silk protein, protein content 90%;

[0043] Polyacrylonitrile, viscosity average molecular weight 2.0×10 4 , is a copolymer comprising a first monomer, a second monomer and a third monomer, wherein the first monomer is 81.8% by mass of acrylonitrile, and the second monomer is 18% by mass of methyl acrylate %, the content of the third monomer itaconic acid is 0.2%;

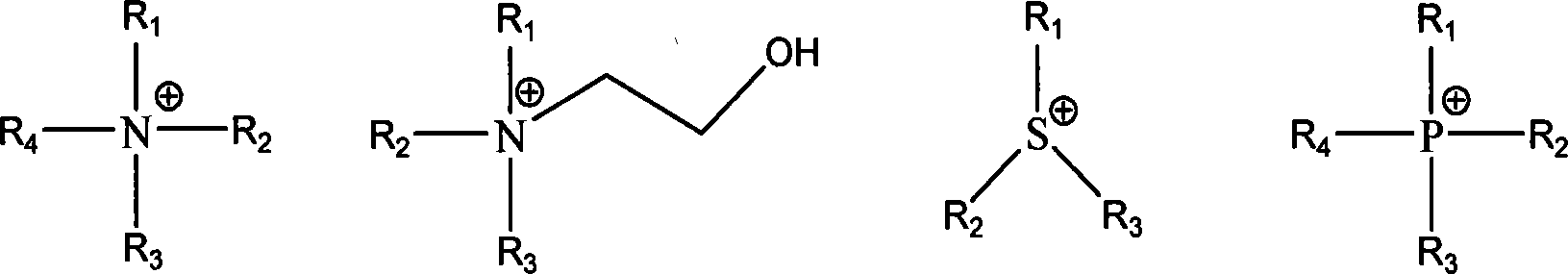

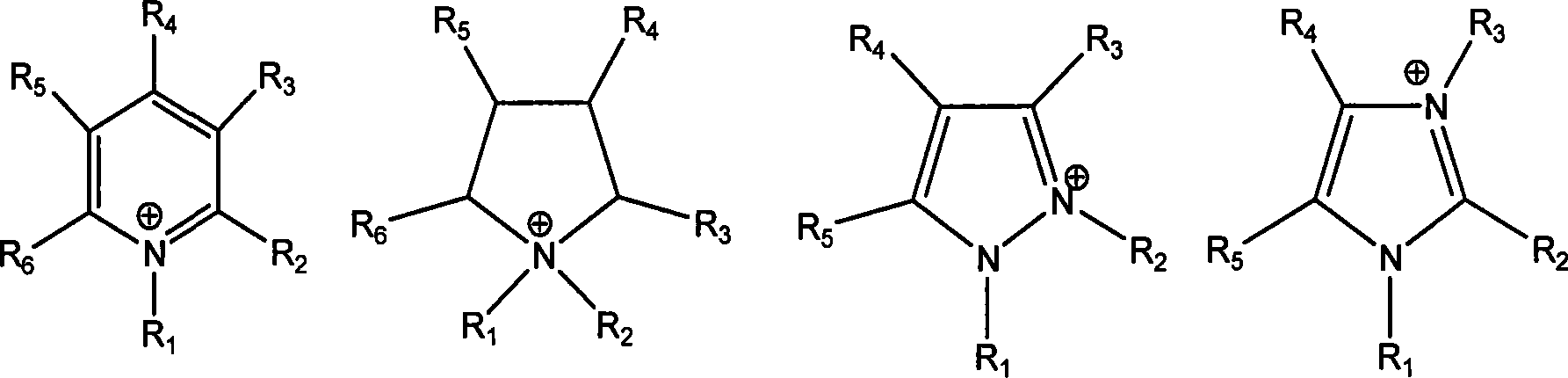

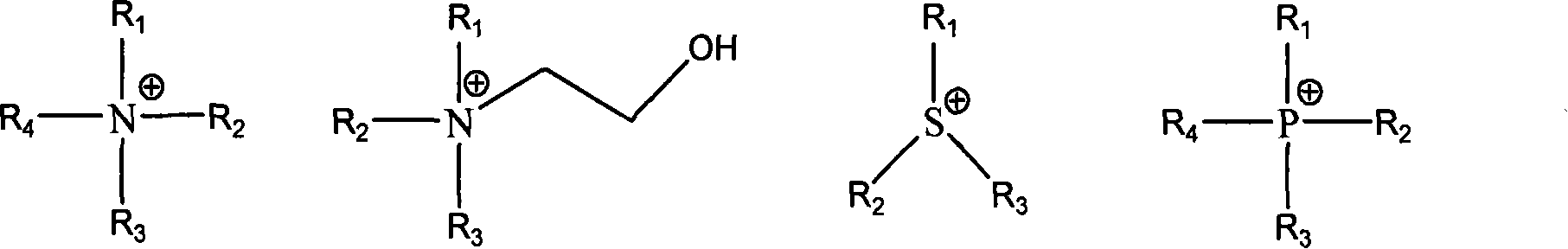

[0044] Ionic liquid, 1-allyl-3-methylimidazolium chloride.

[0045] Mix dry silk protein with a mass percentage of 1% and dry polyacrylonitrile with a mass percentage of 99%, add it to 1-allyl-3-methylimidazolium chloride, and dissolve it at 50°C for 2 hours to obtain a stable Uniform spinning solution, the mass percentage of 1-allyl-3-methylimidazolium chloride in the solution is 95%, the spinning solution is filtered and defoamed at 50°C, extruded through a metering pump and a spinneret, and passed through 1cm layer of humid air, temperature is 5°C, humidity is 95%, enters a coagulation ba...

Embodiment 2

[0047] Raw material: wool protein, protein content 92%;

[0048] Polyacrylonitrile, viscosity average molecular weight 2.0×10 5 , is a copolymer comprising a first monomer and a second monomer, wherein the content of the first monomer is 90% of acrylonitrile, and the content of the second monomer of methyl methacrylate is 10%;

[0049] Ionic liquid, 1-butyl-3-methylimidazolium chloride.

[0050] Mix 20% wool protein with 80% polyacrylonitrile, add 1-butyl-3-methylimidazolium chloride, swell at 30°C for 2 hours, dehydrate, dissolve at 120°C for 1.5 hours, Obtain a stable and uniform spinning solution, the mass percentage of 1-butyl-3-methylimidazolium chloride in the solution is 92%, filter and defoam at 120°C, extrude through a metering pump and a spinneret, and pass through a 2cm wet The air layer, the temperature is 15°C, the humidity is 80%, enters the coagulation bath of 0°C, the mass percentage of 1-butyl-3-methylimidazolium chloride in the coagulation bath is 5%, enter...

Embodiment 3

[0052] Raw materials: soybean protein, protein content 94%;

[0053] Polyacrylonitrile, viscosity average molecular weight 5.0×10 4 , is acrylonitrile homopolymer;

[0054] Ionic liquid: 1-butyl-2-methylpyrazole bromide.

[0055] Mix 1% of dry soybean protein with 99% of 1-butyl-2-methylpyrazole bromide in mass percentage, dissolve at 70°C for 2 hours to obtain solution ①; mix 15% of Mix dry polyacrylonitrile with 85% by mass of 1-butyl-2-methylpyrazole bromide, dissolve at 80°C for 1 hour to obtain solution ②, then mix equal amounts of solution ①②, and stir at 80°C After 0.5 hours to obtain a stable and uniform spinning solution, filter and defoam at 80°C, extrude through a metering pump and a spinneret, pass through a 3cm layer of humid air at a temperature of 15°C and a humidity of 75%, and enter a coagulation bath at 20°C. The mass percent of 1-butyl-2-methylpyrazole bromide in the coagulation bath is 8%, and enters the hot water bath of 50 ℃ through the guide roller fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com