Double-network ionic gel with stimulation responsiveness and self repairability

A technology of ion gel and double network, applied in the field of material chemistry, can solve the problems of poor mechanical properties of ion gel, and achieve the effect of simple preparation method, high ion conductivity, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Embodiment 1, the synthesis of poly(methyl methacrylate-co-furyl methyl methacrylate) (P(MMA-co-FMA))

[0036] Step 1: Synthesis of furyl methacrylate (FMA)

[0037]

[0038] 9.80 g of furan methanol and 15.2 g of triethylamine were added to a 250 mL dry flask, and dissolved in 100 mL of dichloromethane. Then, the mixture was stirred in an ice bath for 10 min, and 15.6 g of methacryloyl chloride was slowly added dropwise under a nitrogen atmosphere. Continue to react in ice bath for 30 min, and then react at room temperature for 12 h. After the reaction was finished, triethylamine hydrochloride was removed by filtration, and the filtrate was washed successively with saturated brine, saturated sodium bicarbonate solution, and saturated brine, and the organic phase was dried and concentrated, and the column separation method (mobile phase: n-hexane: ethyl acetate Ester ratio 10:1) yielded product 13.6 g, yield 82%.

[0039] Step 2: Synthesis of poly(methyl methacryla...

Embodiment 2

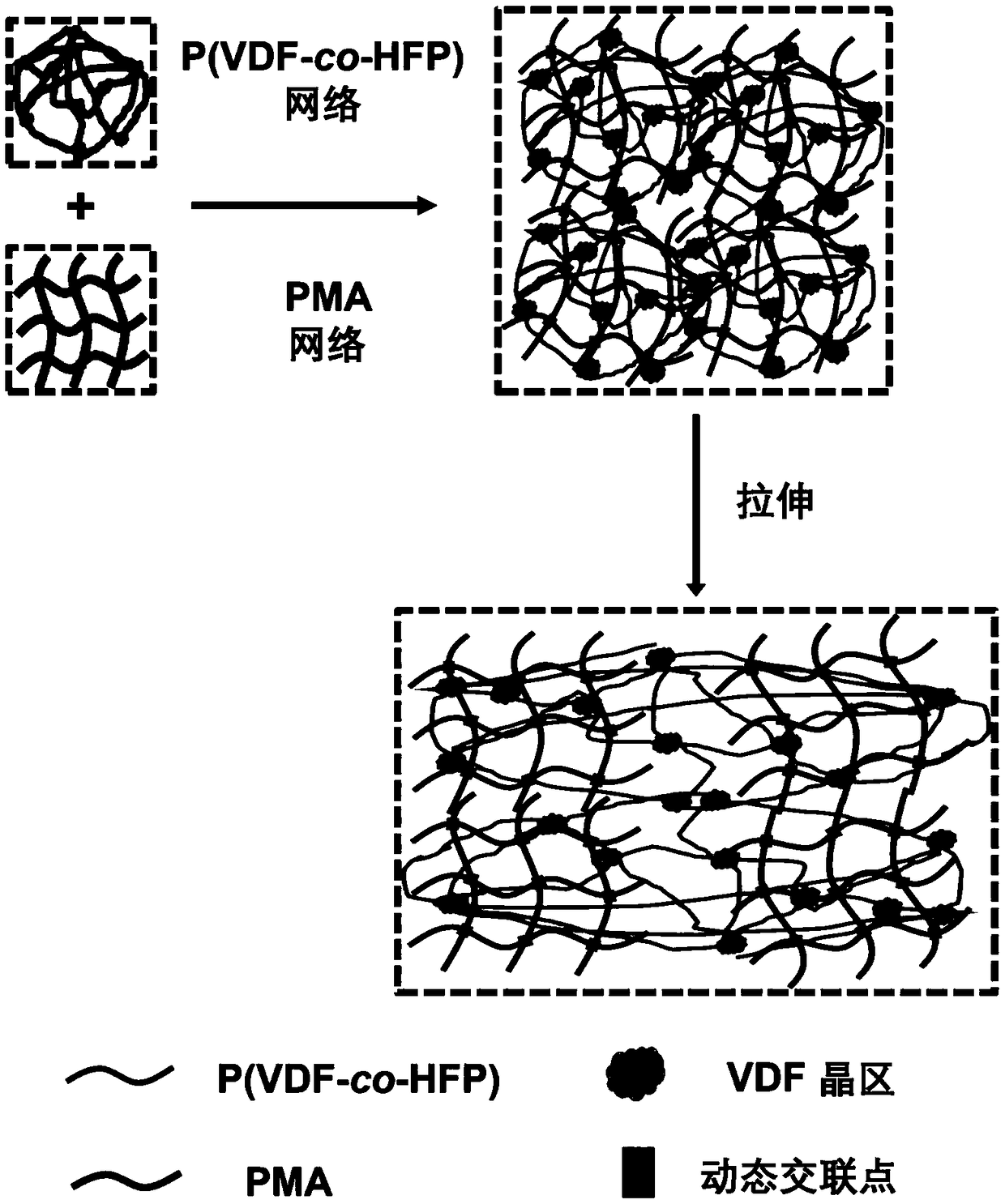

[0042] Embodiment 2, the preparation of double network ion gel

[0043] Dissolve 100 mg of P(MMA-co-FMA) synthesized above with 5 mL of dichloromethane, and 100 mg of P(VDF-co-HFP) with 5 mL of acetone, mix the two polymer solutions, and add 800 mg of ionic liquid: 1-B base-3-methylimidazoline bis(trifluoromethylsulfonyl)imide, and 5 mg of crosslinker N,N'-(4,4'-methylenediphenyl)bismaleimide. Mix and stir for 2h. The mixture was filtered with a 0.22 μm microporous membrane, poured into a suitable mold, and evaporated at room temperature for 12 hours to remove the co-solvent. Put the mold into an oven at 70°C for cross-linking, take it out after 12 hours of reaction, and demould to obtain the double network ion gel.

Embodiment 3

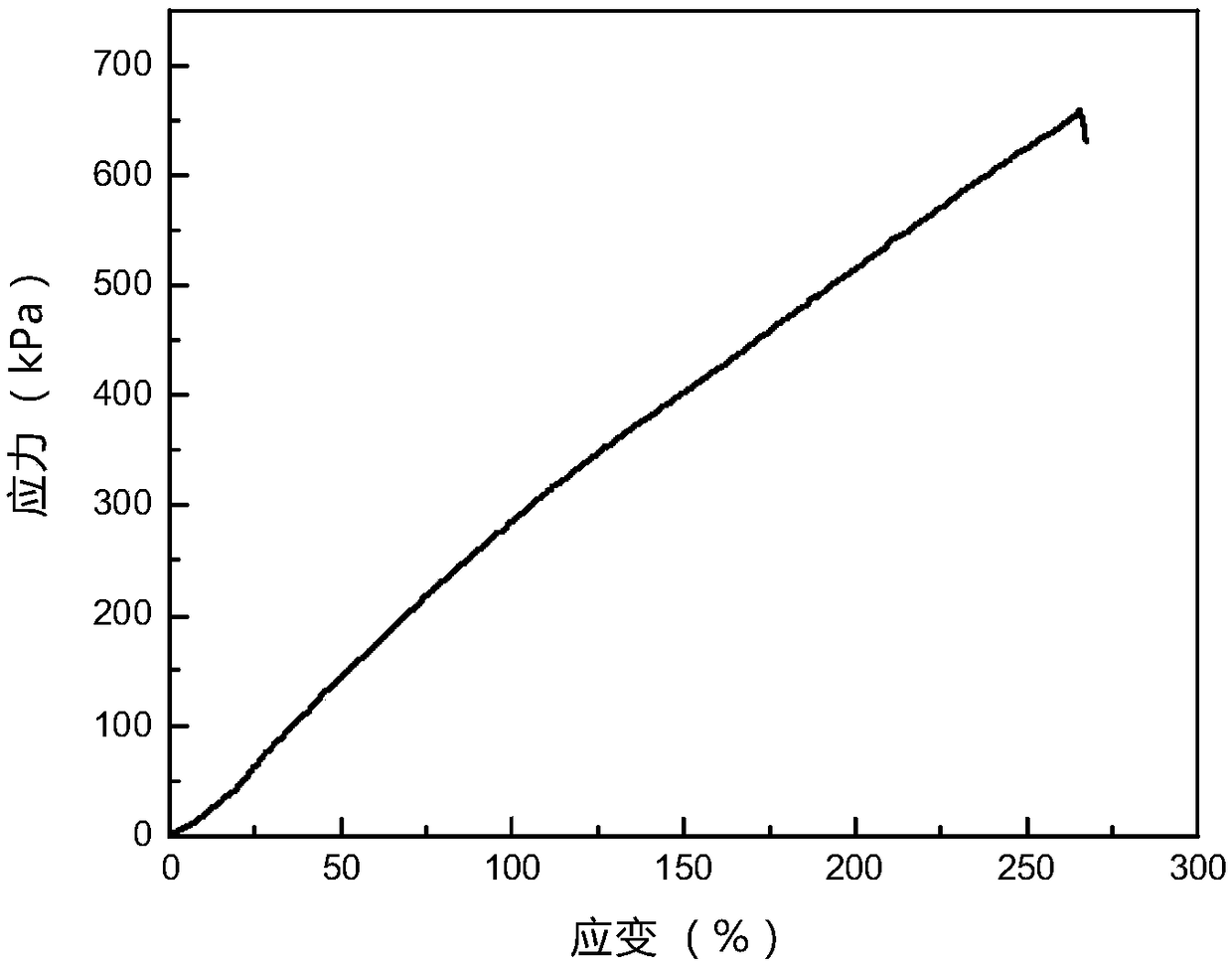

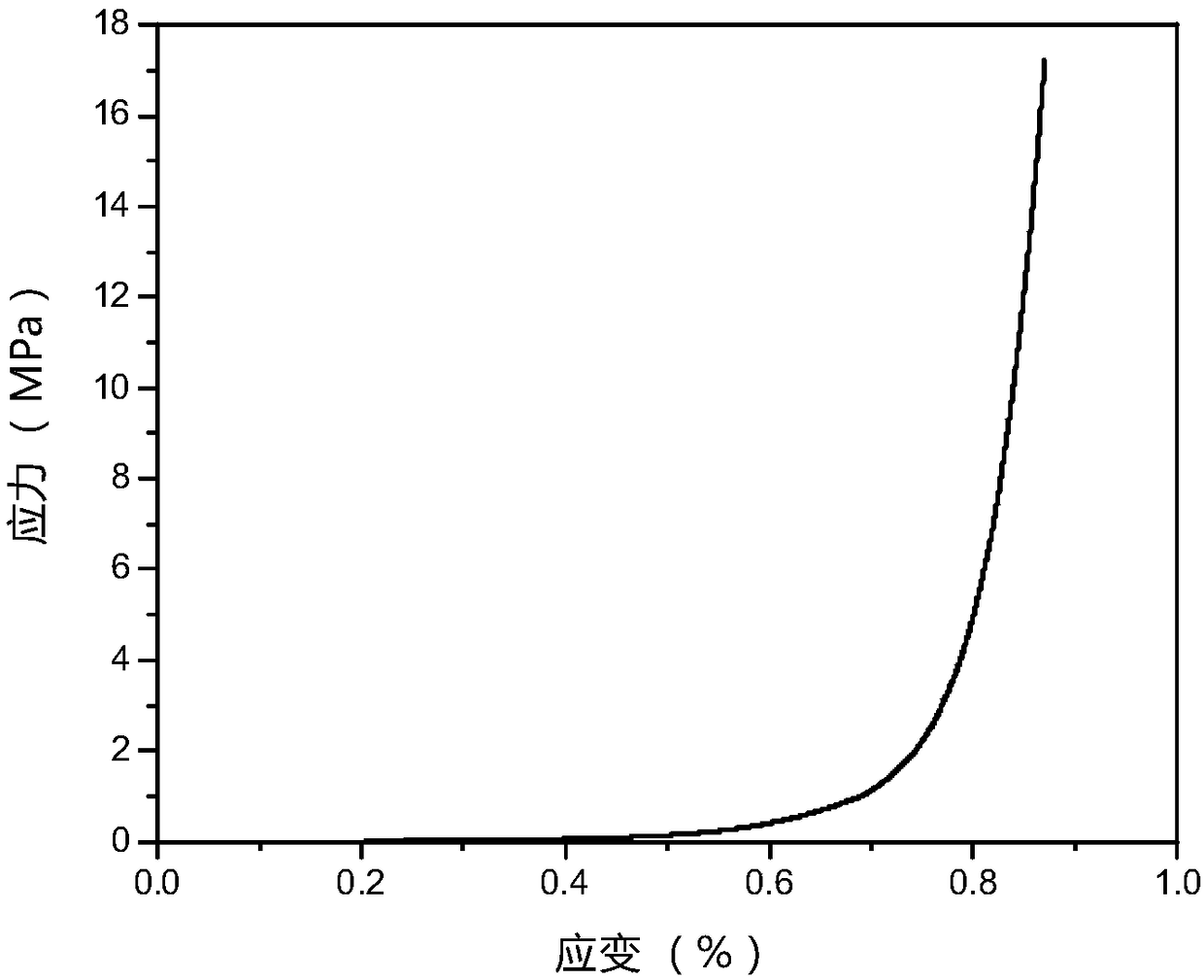

[0044] Embodiment 3, double network ion gel performance test

[0045] For the double-network ionogel film sample prepared above, it is cut into a dumbbell-shaped sample with the narrowest width of 4mm and a length of 3cm. Using a multifunctional testing machine, with a tensile rate of 5mm / min, the test results are obtained. Tensile stress-strain curve, test results see figure 2 . Also use this machine to test a cylindrical sample with a diameter of 1.3cm and a height of 2cm at a compression rate of 5mm / min to obtain its compressive stress-strain curve. The test results are shown in image 3 . From the test results, it can be found that the double network ion gel has excellent mechanical properties. Take about 2 mg of the gel, and use a thermogravimetric-differential thermal simultaneous tester to test its thermal stability. The test results are shown in Figure 4 , the experimental results show that the gel has good thermal stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com