Anti-falling internal and external wall basaltic mud coating and preparing method thereof

An internal and external wall, anti-shedding technology, applied in the field of coating preparation, can solve the problems of easy cracking, low strength, falling off, etc., and achieve the effects of strong wall adhesion, strong porous performance, and strong adsorption force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

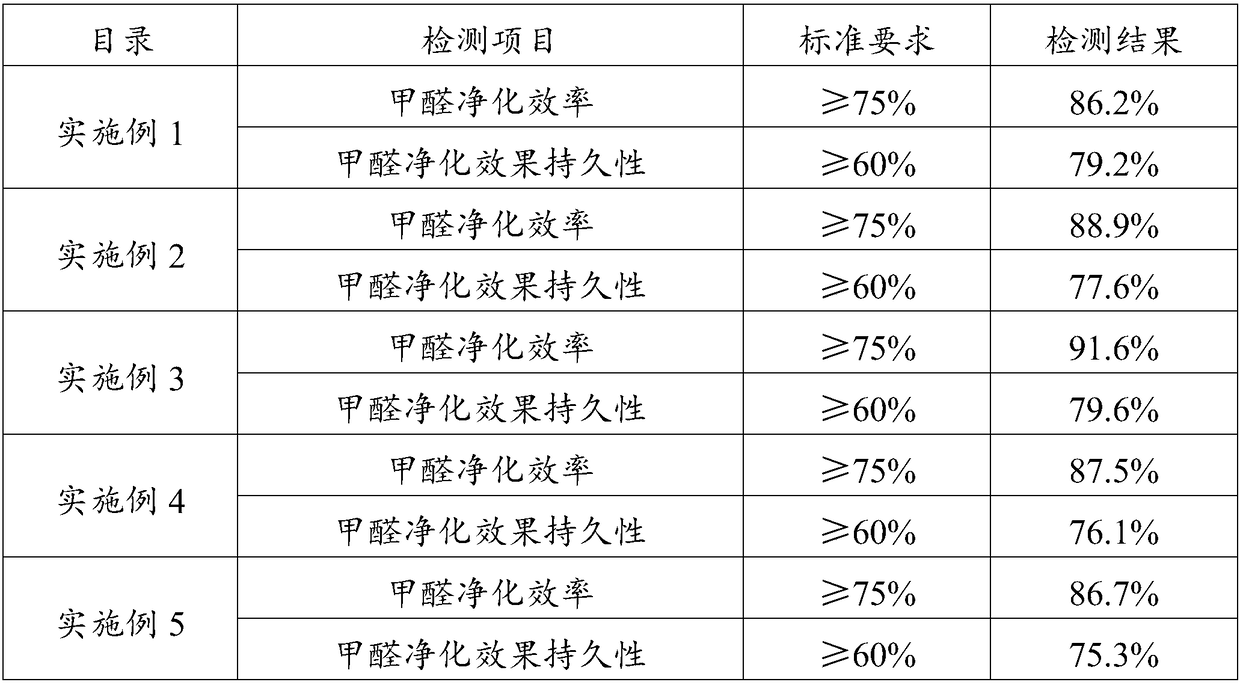

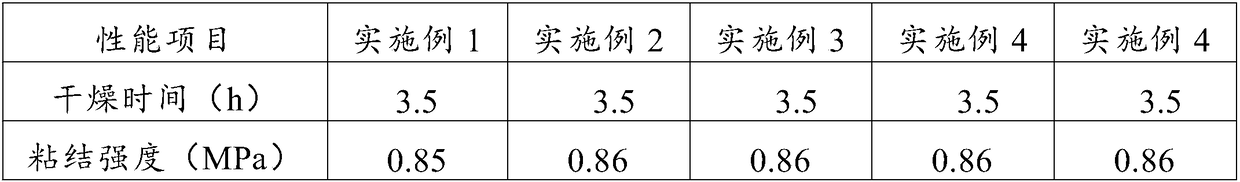

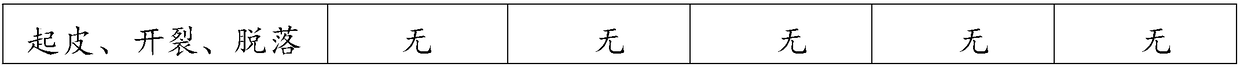

Examples

preparation example Construction

[0022] According to above-mentioned proportioning, the preparation method of a kind of anti-shedding interior and exterior wall basalt mud coating of the present invention comprises the following steps:

[0023] (1) Dissolve the graphene powder in dimethylformamide, then add octaphenyloctasilsesquioxane, stir for 90min with a rotating speed of 2500r / min, after stirring evenly, ultrasonicate for 60 minutes to obtain the previous material 1 ;

[0024] (2) Grind diatomite through a 150-300 mesh sieve, dry to control the moisture content to ≤8%, add basalt powder, heat at 80-110°C, stir at a speed of 1500-2000r / min for 30-50min, then add shell powder , continue to stir for 15 to 30 minutes, and then wash with absolute ethanol and deionized water for 2 to 3 times to obtain the previous material 2;

[0025] (3) Mix sodium carboxymethyl cellulose and activated carbon powder, mix at a stirring speed of 2000-3000r / min for 30-40 minutes to form a porous mixture, add inorganic pigments,...

Embodiment 1

[0035] Embodiment 1 Preparation of basalt mud coating for anti-shedding interior and exterior walls

[0036] (1) Dissolve 0.1 part of graphene powder in 5 parts by weight of dimethylformamide, then add 0.1 part by weight of octaphenyloctasilsesquioxane, stir for 90min with a rotating speed of 2500r / min, after stirring evenly, Ultrasound for 60 minutes to obtain the previous material 1;

[0037] (2) Grind 4 parts of diatomite through a 300-mesh sieve, dry to control the moisture content to ≤8%, add 20 parts of basalt powder, heat at 80°C, stir at a speed of 1500r / min for 50min, then add 8 parts of shell powder, continue Stir for 15 min, then wash twice with absolute ethanol and deionized water to obtain the previous material 2; the basalt powder is soaked in a water mixture of 10% hydrogen peroxide and 25% polyvinyl acetate in mass concentration for 5 hours , and then dried and pulverized at 50°C, the particle size is 200 microns; the shell powder is calcined and pulverized at 1...

Embodiment 2

[0040] Embodiment 2 Preparation of basalt mud coating for anti-shedding interior and exterior walls

[0041] (1) Dissolve 0.2 part of graphene powder in 5 parts by weight of dimethylformamide, then add 0.1 part by weight of octaphenyloctasilsesquioxane, stir for 90min with a rotating speed of 2500r / min, after stirring evenly, Ultrasound for 60 minutes to obtain the previous material 1;

[0042] (2) Grind 5 parts of diatomite through a 200-mesh sieve, dry to control the moisture content to ≤8%, add 22 parts of basalt powder, heat at 90°C, stir at a speed of 2000r / min for 30min, then add 9 parts of shell powder, continue Stir for 20 min, then wash twice with absolute ethanol and deionized water to obtain the previous material 2; the basalt powder is soaked in a water mixture of 15% hydrogen peroxide and 30% polyvinyl acetate in mass concentration for 4 hours , and then dried at 60°C and crushed, with a particle size of 300 microns; the shell powder was calcined and crushed at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com