Functional moxibustion sheet and preparation method thereof

A functional, moxibustion technology, applied in the direction of making medicines into special physical or taking form devices, heating/cooling reflection point instruments, etc. Problems such as poor uniformity, to achieve high density, wide range of uses, and overcome the effects of low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

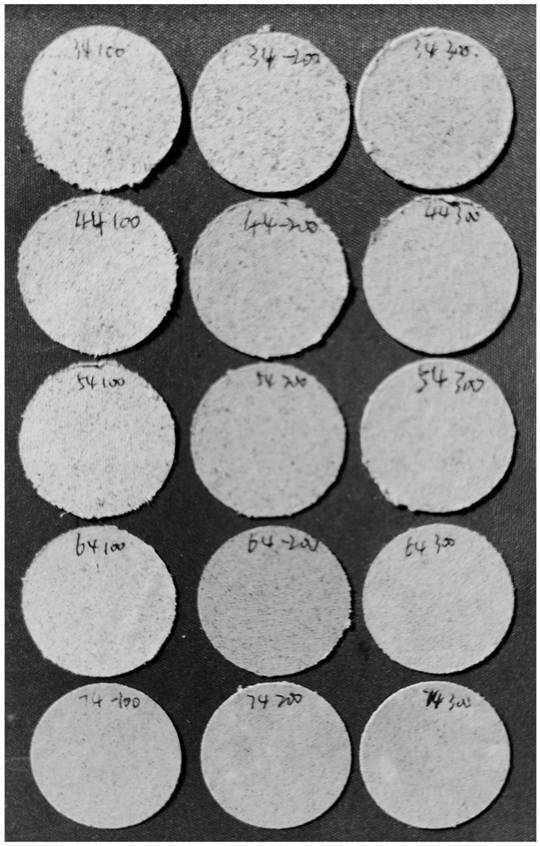

Image

Examples

preparation example Construction

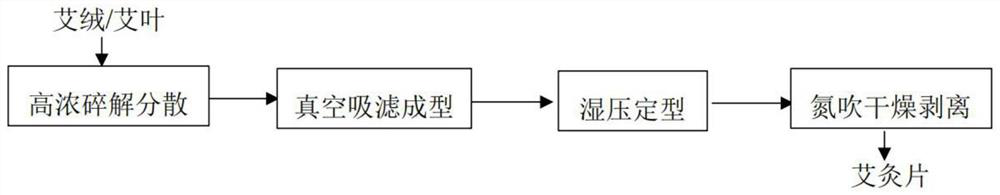

[0031] The invention provides a kind of preparation method of moxibustion sheet, comprises the following steps:

[0032] disintegrate and disperse the wormwood raw material in water to obtain a wormwood fiber aqueous dispersion, the wormwood raw material includes mugwort leaves and / or mugwort;

[0033] Dehydrating the wormwood fiber aqueous dispersion to form a wet base sheet of wormwood fiber;

[0034] The wormwood fiber wet-base sheet is wet-pressed and shaped to obtain a moxa-moxibustion sheet.

[0035] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known to those skilled in the art.

[0036] In the present invention, the mugwort raw material is disintegrated and dispersed in water to obtain the mugwort fiber aqueous dispersion liquid, and the mugwort raw material includes mugwort leaves and / or mugwort velvet.

[0037] In the present invention, the herb-harvesting raw materials include mugwort leaves a...

Embodiment 1

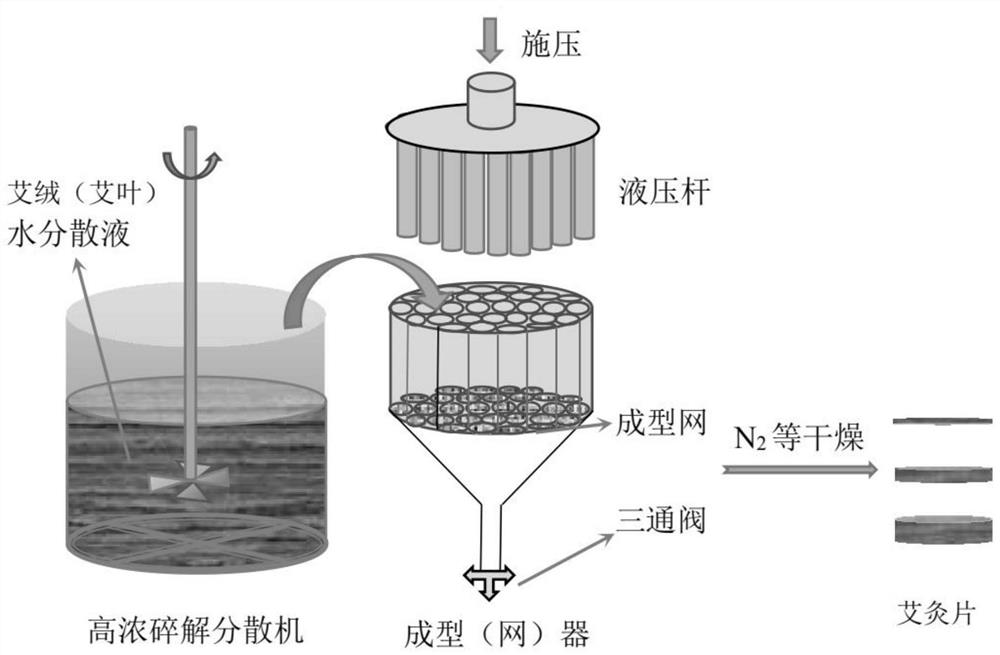

[0096] (1) Use a high-concentration crushing and dispersing machine to crush and disperse 5% moxa in water at a high speed for 10 minutes to obtain a high-concentration moxa fiber aqueous dispersion. The size of the dispersed moxa fiber is about 100 microns to 1 mm between.

[0097] (2) Get 20 milliliters of moxa fiber aqueous dispersion and place in a forming mold in the moxa flake forming device with vacuum suction system, and suck for 5 minutes under 20kPa vacuum to form the moxa bottom layer.

[0098] (3) Take 0.5 g of dried rose petals, soak them in 20 ml of water, and crush and disperse the dried rose petals with a crushing and dispersing machine. The rose dried flower dispersion is poured on the moxa bottom layer that has been formed, and sucked for 10 minutes under a vacuum of 15kPa to form a rose core layer on the moxa bottom layer.

[0099] (4) get 20 milliliters of 5% high-concentration moxa fiber aqueous dispersions prepared in step (1), it is poured into the form...

Embodiment 2

[0102] (1) Utilize the high-concentration crushing and dispersing machine to disperse 10% moxa (artemisia argyi) in water at a high speed for 15 minutes to obtain a high-concentration moxa fiber aqueous dispersion, and the size of the dispersed moxa fiber is about 100 microns to 1 between millimeters.

[0103] (2) get 10 milliliters of moxa velvet (Folium Artemisiae) fiber aqueous dispersion and place in a forming mold in the moxa velvet (Folium Artemisiae Argyi) sheet former with vacuum suction system, suction 5 minutes under 20kPa vacuum degree, The bottom layer of moxa is formed.

[0104] (3) Take 1 gram of dried jasmine flowers, soak them in 20 ml of water, and disintegrate and disperse the dried jasmine flowers with a pulverizer. The dried jasmine flower dispersion is poured onto the formed moxa moxa bottom layer, and sucked for 8 minutes under a vacuum of 12kPa to form a jasmine flower core layer.

[0105] (4) get 20 milliliters of 10% high-concentration moxa (artemisi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com