Fullerene negative ion dry powder coating and its application method

A dry powder coating and negative ion technology, used in powder coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve problems such as allergies, and achieve the effect of convenient construction and operation and good painting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

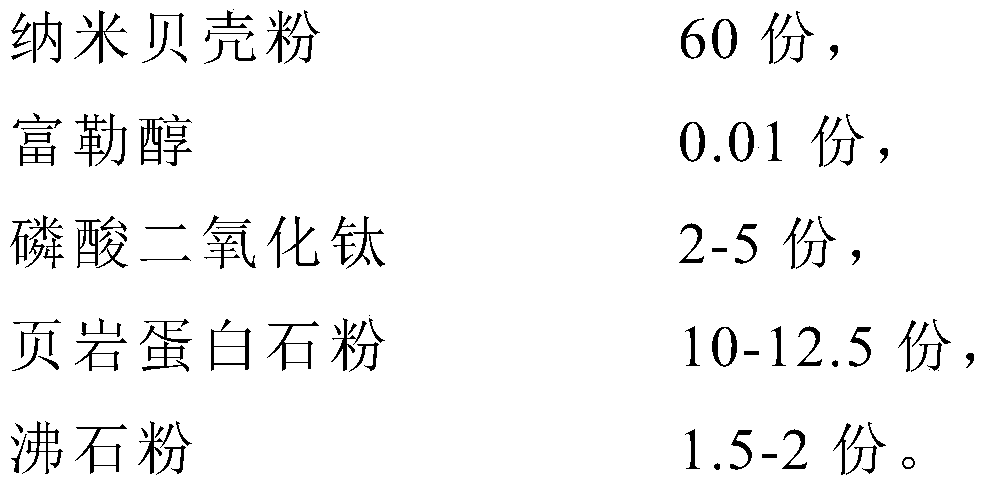

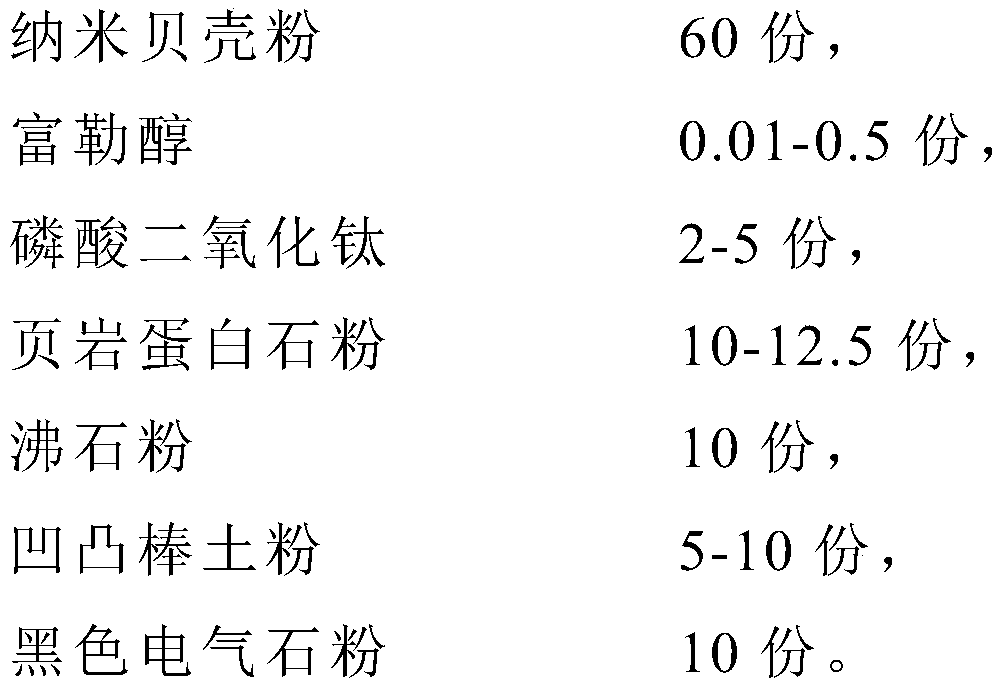

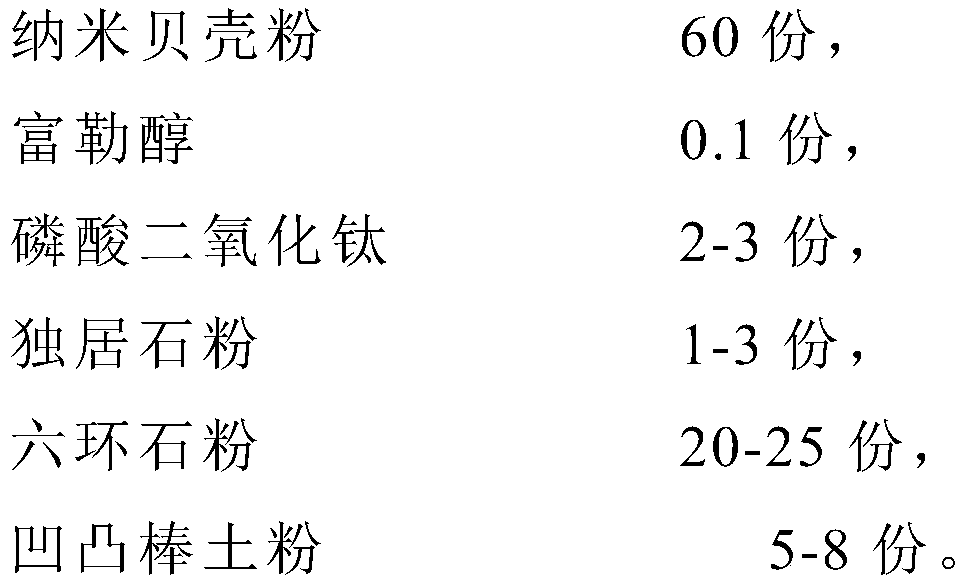

Method used

Image

Examples

Embodiment 1

[0046] A kind of fullerene negative ion dry powder paint, comprises following components: nano shell powder 50kg, fullerene 0.01kg, fullerenol 0.1kg, black tourmaline powder 12kg, phosphoric acid titanium dioxide 13kg, after above-mentioned components are mixed uniformly, obtain final product Fullerene anion dry powder coating.

Embodiment 2

[0048] A kind of fullerene negative ion dry powder coating, comprises following components: nano-shell powder 60kg, fullerol 0.5kg, black tourmaline powder 17kg, phosphoric acid titanium dioxide 18kg, after above-mentioned components are mixed uniformly, obtain fullerene negative ion dry powder coating .

Embodiment 3

[0050] A kind of fullerene negative ion dry powder coating, comprises following components: nano shell powder 55kg, fullerene 0.01kg, black tourmaline powder 15kg, phosphoric acid titanium dioxide 14kg, after above-mentioned components are mixed uniformly, obtain fullerene negative ion dry powder coating .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com