Manufacturing technology of efficient dust collecting sleeve paper for vacuum cleaners

A vacuum cleaner and dust bag technology, applied in the field of air purification, can solve the problems of low air permeability and poor burst resistance, and achieve the effects of good air permeability and strength, high strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

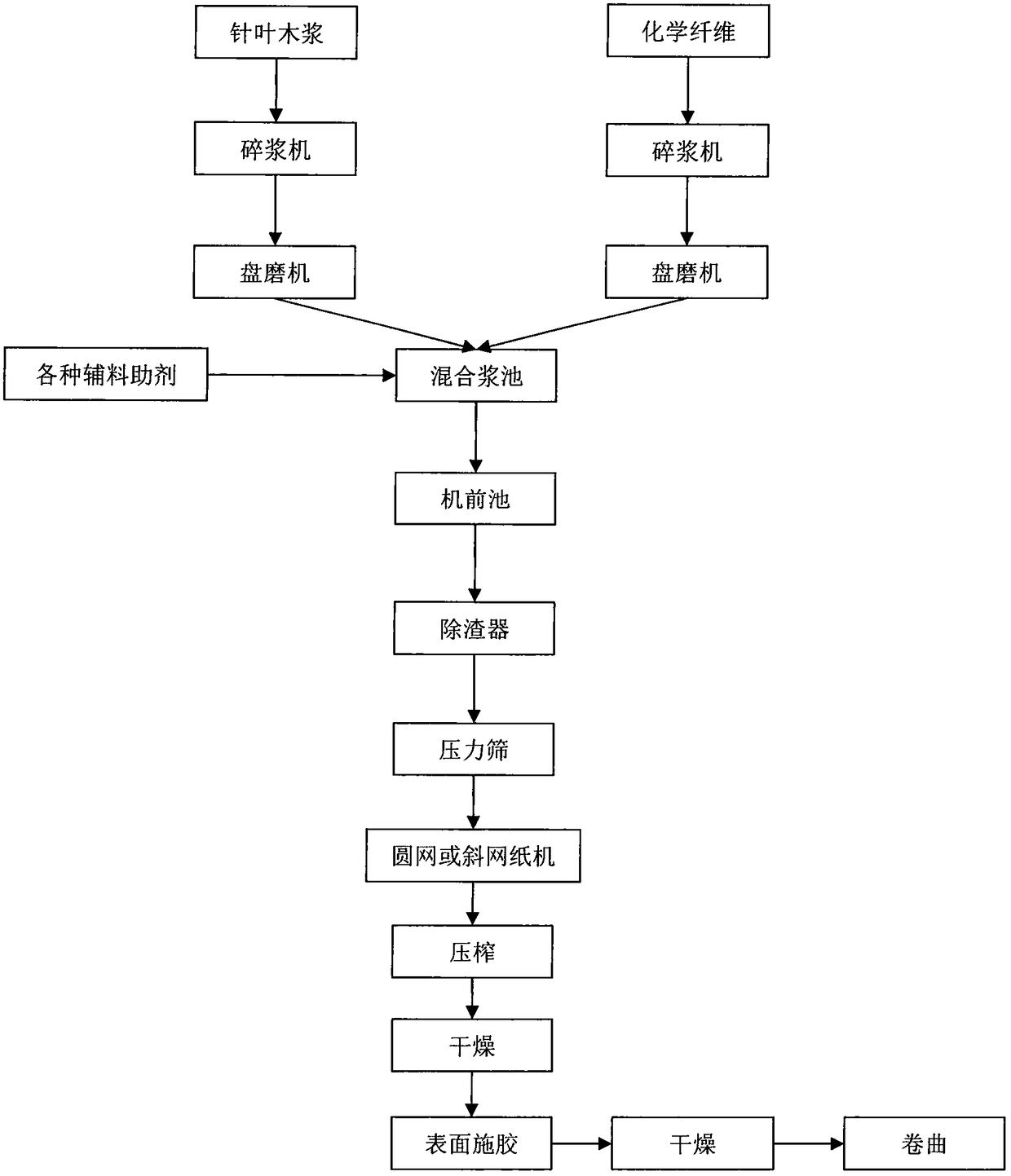

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: softwood pulp: chemical fiber 1=80:20, beating degree is about 12 ° SR, PAE 0.5%, acrylamide polymer 0.5%, cationic starch 2.0%;

Embodiment 2

[0019] Embodiment 2: softwood pulp: chemical fiber 1=80:20, beating degree is about 20 ° SR, PAE 0.5%, acrylamide polymer 0.5%, cationic starch 2.0%;

Embodiment 3

[0020] Embodiment three: coniferous wood pulp: chemical fiber 1=80:20, beating degree is about 30 ° SR, PAE 0.5%, acrylamide polymer 0.5%, cationic starch 2.0%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com