Low-cost internal-external wall porcelain-imitated coating

A low-cost, porcelain coating technology, applied in the direction of coating, can solve the problems of easy powder removal, easy discoloration and decolorization, and achieve the effects of low cost, convenient construction and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

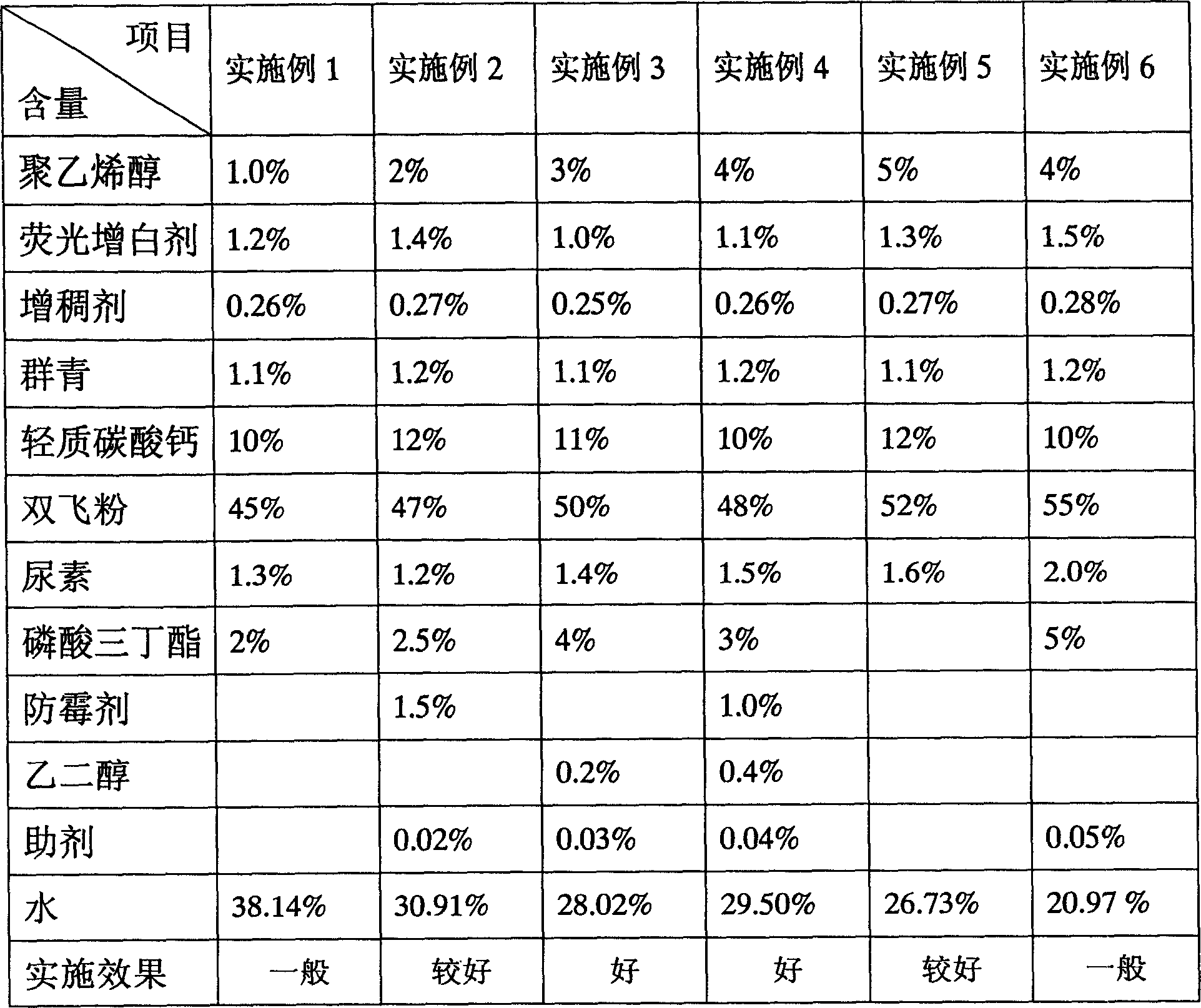

Examples

Embodiment 1

[0015] Embodiment 1: 38.14 kilograms of water are injected into the stirring tank, and 1.0 kilograms of polyvinyl alcohol, 1.2 kilograms of 2,2-(4,4-distyryl) bisbenzoxazole, and 1.3 kilograms of urea are sequentially added during the stirring process , heated to 60-70°C under normal pressure, and then kept stirring for no less than 0.5-1 hour. After all the materials were dissolved, stop the heat preservation, and put in ultramarine (Na 6 al 4 Si 6 S 4 o 20 ) 1.1 kg, 10 kg of light calcium carbonate, 45 kg of Shuangfei powder (heavy calcium carbonate), tributyl phosphate [(C 4 h 9 O) 3 PO 4 ] 2 kg, 0.26 kg of thickener, when the above mixture is evenly stirred to transparent and non-caking powder, filter at a medium speed with an 80-mesh filter sieve, and after cooling, put it in barrels and seal it, which is the preparation of low-cost imitation porcelain paint for interior and exterior walls. finished product.

[0016] For the dosage of various materials in Embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com