Waterproof ink-jet printing engineering blueprinting paper

An engineering blueprint and inkjet printing technology, which is applied in paper, papermaking, paper coating, etc., can solve the problems of environmental hazards, poor printing ink absorption, damage to drawings, etc., and achieve excellent flexibility, folding resistance, and ink absorption performance Excellent, smooth and delicate surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

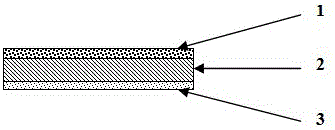

[0061] Such as figure 1 As shown, the waterproof inkjet printing engineering blueprint includes a three-layer structure of top coat 1, base paper layer 2 and back coat 3; the top coat paint includes silica, blue color paste, adhesive, color fixing agent and water-resistant agent; backcoat paint includes polyvinyl alcohol.

[0062] The formula of top coat paint comprises by following weight parts: 12 parts of silicon dioxide; portion of fluorescent whitening agent.

[0063] Waterproof inkjet printing engineering blueprints are prepared through the following steps:

[0064] (1) Substrate selection: Select the coated base paper that can meet the coating processing requirements of inkjet printing engineering blueprint paper as the substrate;

[0065] (2) Preparation of top coat paint: add the above top coat paint into deionized water according to parts by weight to adjust the solid content of the paint to 12%, and continue to disperse for 15 minutes to complete the preparation ...

Embodiment 2

[0071] Such as figure 1 As shown, the waterproof inkjet printing engineering blueprint includes a three-layer structure of top coat 1, base paper layer 2 and back coat 3; the top coat paint includes silica, blue color paste, adhesive, color fixing agent and water-resistant agent; backcoat paint includes polyvinyl alcohol.

[0072] The formula of top coat paint comprises by following parts by weight: 15 parts of silicon dioxide; portion of fluorescent whitening agent.

[0073] Waterproof inkjet printing engineering blueprints are prepared through the following steps:

[0074] (1) Substrate selection: Select the coated base paper that can meet the coating processing requirements of inkjet printing engineering blueprint paper as the substrate;

[0075] (2) Preparation of top coat paint: add the above top coat paint into deionized water according to parts by weight to adjust the solid content of the paint to 14%, and continue to disperse for 25 minutes to complete the preparati...

Embodiment 3

[0081] Such as figure 1 As shown, the waterproof inkjet printing engineering blueprint includes a three-layer structure of top coat 1, base paper layer 2 and back coat 3; the top coat paint includes silica, blue color paste, adhesive, color fixing agent and water-resistant agent; backcoat paint includes polyvinyl alcohol.

[0082] The formula of top coat paint comprises by following parts by weight: 13 parts of silicon dioxide; portion of fluorescent whitening agent.

[0083] Waterproof inkjet printing engineering blueprints are prepared through the following steps:

[0084] (1) Substrate selection: Select the coated base paper that can meet the coating processing requirements of inkjet printing engineering blueprint paper as the substrate;

[0085] (2) Preparation of top coat paint: add the above top coat paint into deionized water according to parts by weight to adjust the solid content of the paint to 13%, and continue to disperse for 19 minutes to complete the preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com