High strength fiberboard and production method thereof

A high-strength fiber and production method technology, which is applied in the direction of fiberboard, fiber raw material processing, cellulose raw material pulping, etc., can solve the problems of insufficient strength, and achieve the effects of low cost, convenient collection of raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

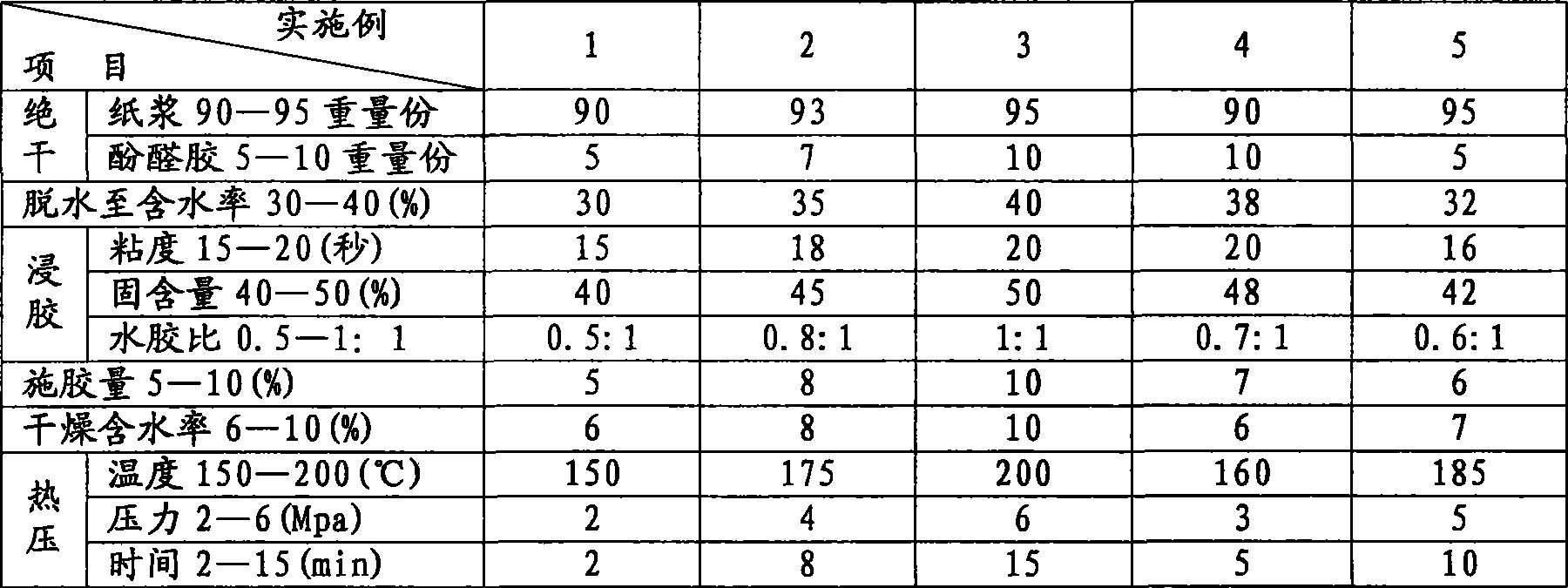

Examples

Embodiment 1

[0016] Embodiment 1 (the value of each item of embodiment 1 in the comparison table): standby is equivalent to 90 parts by weight of raw wood pulp under the dry state, i.e. raw paper pulp or waste paper pulp and 5 parts by weight of phenolic glue through deinking treatment, and put the pulp into In the water, use a beater to beat into micron-level fiber-resolved pulp, remove it to a rolling mill and dehydrate it to a moisture content of 30%, and put it into a phenolic glue pool with a water-to-glue ratio of 0.5:1 for dipping. For the phenolic glue with a viscosity of 15 seconds and a solid content of 40%, stir it for 1 minute, pick it up, squeeze it out until the sizing amount is 5%, dry it at 45-55°C until the moisture content is 6%, and then put it on the belt Grind into micron-sized lint-like materials in a pulverizer with a cooling device, or directly put them into a freezer for freezing and then immediately crush them into micron-sized pulverized materials, and lay them in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Static bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com