Biodegradable LA (lactide) oligomer bonding agent, and preparation method and purpose thereof

A biodegradable and adhesive technology, applied in adhesives and other directions, can solve the problems of water-based adhesives, such as poor water resistance and solvent-resistant film strength, not specifying the biodegradation rate of mixture adhesives, and rare adhesives. Controllable viscosity, low toxicity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

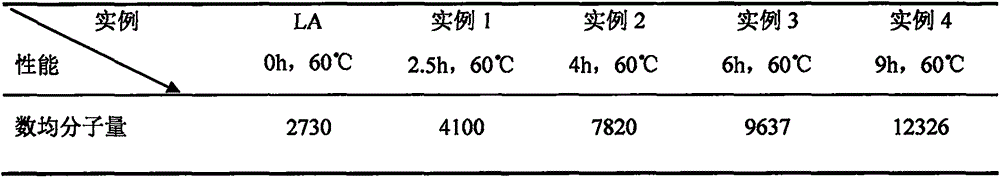

Embodiment 1~4

[0024] (1) LA chemical synthesis product preparation in the embodiment

[0025] Add ethyl acetate solution to the four reactors respectively, and then add LA powder in the proportion of 25% of the mass of the ethyl acetate solution. Under nitrogen protection, control the temperature at 60°C, and the stirring speed is 150r / min. LA is completely After dissolving, add 2.12g of stannous octoate, react for 2.5h, 4h, 6h, and 9h respectively, take out the reactant, purify and centrifuge with absolute ethanol, and obtain the LA chemical synthesis product.

[0026] (2) Performance characterization of LA chemical synthesis product in the embodiment

[0027] ①NMR test

[0028] The experimental conditions of nuclear magnetic resonance are that the solvent is heavy water and the internal standard tetramethylsilane. The quartet center of the methine group of PLA in the NMR diagram is at 5.2ppm, and the methyl shift peak is 1.5ppm, indicating that there are LA macromolecular products in th...

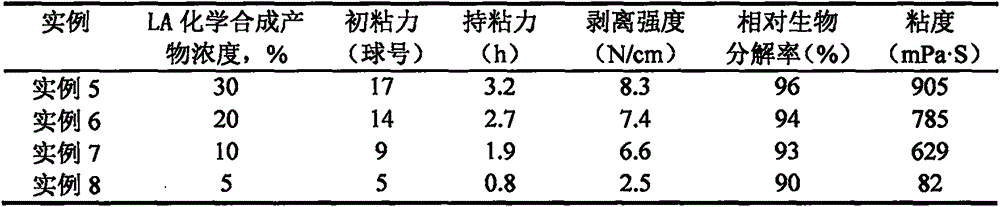

example 5~8

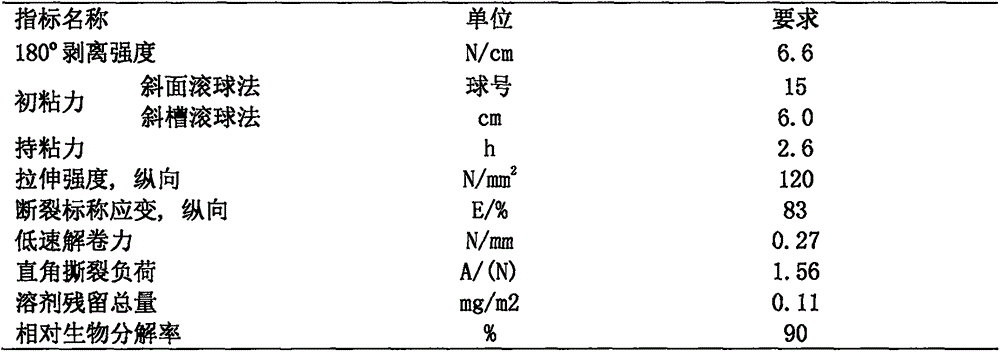

[0034] Dilute the LA chemically synthesized product obtained in Example 4 with ethyl acetate to obtain a biodegradable adhesive. According to the solid content of the solution, take a quantitative solution and apply it evenly on the kraft paper with a scraper, put it in an oven and bake it for 10 minutes, and the obtained glue content is 12mg / cm 2 pressure sensitive tape. Among them, the initial adhesion test adopts the inclined surface rolling ball method in the national standard GB / T4852-2002 (inclination angle of 30°, the length of the sample is more than 250mm, and the width is 10-80mm), and the maximum size of the steel ball that can be adhered to the viscous surface of the specified length is detected. The holding force test adopts the test method of the adhesive tape to the standard test steel plate in the national standard GB / T4851-2014 (the length of the sample is 150mm, and the width is 12±0.5mm), and the adhesive tape to the standard steel plate is measured by the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com