Method for enhancing whiteness of coated paper or coated paper board with starch

A technology of coated paperboard and coated paper, which is applied in the field of improving the whiteness of coated paper or coated paperboard with starch, which can solve the problems of low affinity and reduced whitening efficiency of OBA, and achieves a wide range of applications and is beneficial to the environment. Protect and reduce the effect of negative impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

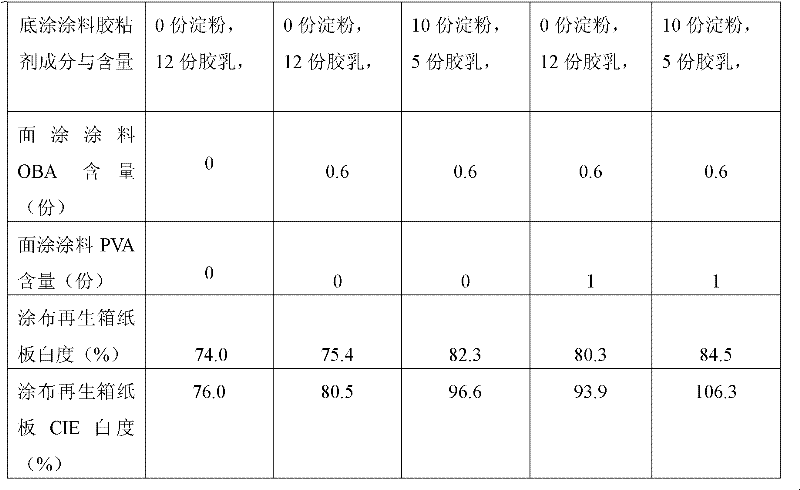

[0028] A method of using starch to improve the whiteness of coated paper or coated cardboard. This embodiment relates to the effect of substituting starch for part of the latex in the primer coating on the whiteness of coated recycled cardboard:

[0029] (1) Apply the primer coating at a quantitative rate of 141g / m 2 , on recycled cardboard paper with a whiteness of 15.8%, the coating amount of primer is 10±1g / m 2 . The solid content of the paint is about 60%, and the pH is about 8.5. The primer paint includes:

[0030] 60 parts of kaolin (more than 90% less than 2 microns), 40 parts (grade 55) of calcium carbonate, 5 parts of styrene-butadiene latex, 10 parts of starch,

[0031] Other auxiliary materials: dispersant (sodium polyacrylate), 0.2 part; defoamer (polyethylene glycol), 0.03 part; lubricant (calcium stearate), 0.3 part; water-resistant agent (polyamide polyurea resin), 0.5 part.

[0032] (2) As a comparative sample, the starch-free primer coating is applied at a ...

Embodiment 2

[0040] A method for improving the whiteness of coated paper or coated paperboard with starch, this embodiment relates to the influence of OBA carrier in the top coating on the whiteness of coated cardboard paper:

[0041] (1) Containing 0.6 parts of 4S type fluorescent whitening agent and 1 part of OBA carrier (PVA) top coating paint application on the regenerated cardboard paper that contains 10 parts of starch and 5 parts of latex primer in embodiment 1 . The solid content of the paint is about 60%, and the pH is about 8.5. The top coat includes:

[0042] 60 parts of fine-grained kaolin (more than 92% less than 2 microns), 40 parts (grade 98) of calcium carbonate, 12 parts of styrene-butadiene latex, 0.6 parts of 4S type fluorescent whitening agent, 1 part of polyvinyl alcohol (PVA as OBA carrier), Other auxiliary materials: 0.2 parts of dispersant; 0.03 parts of defoamer, 0.3 parts of lubricant, and 0.5 parts of anti-water agent.

[0043] Top coat coating amount is 17±1g / ...

Embodiment 3

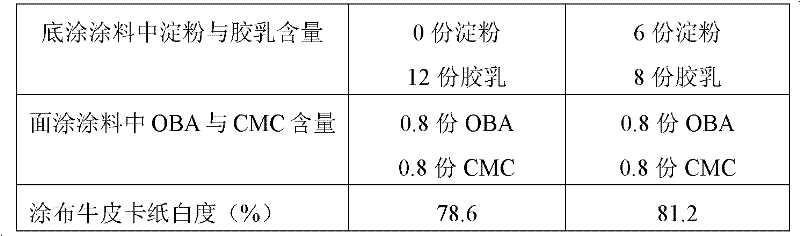

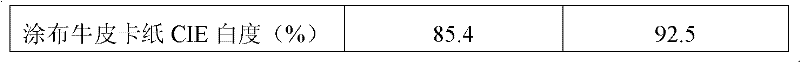

[0049] A method of using starch to improve the whiteness of coated paper or coated board, this example relates to the effect of starch replacing latex on the whiteness of coated kraft cardboard

[0050] (1) Use unbleached softwood kraft pulp to make unbleached kraft linerboard, and the weight of the base paper made is 100±2g / m 2 , the whiteness is 20.5%, and it is used as coated kraft card base paper.

[0051] (2) Using a coating device, the primer is coated on the above-mentioned kraft cardboard. The primer includes 60 parts of kaolin (more than 90% less than 2 microns), 40 parts (grade 55) of calcium carbonate, and 8 parts of styrene-butadiene Latex, 6 parts of starch, other commonly used coating additives such as: dispersant, anti-water agent, defoamer, lubricant. Coating amount is 12±1g / m 2 .

[0052] (3) Using a coating device, the top coating is applied on the primed kraft cardboard, wherein the top coating includes 60 parts of fine-grained kaolin (more than 92% is le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com