Production process for high-strength carton

A production process and high-strength technology, applied in the direction of papermaking, layered products, paper/cardboard containers, etc., can solve the problems of people's loss and damage, and achieve the effects of improving bonding strength, preventing falling off, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

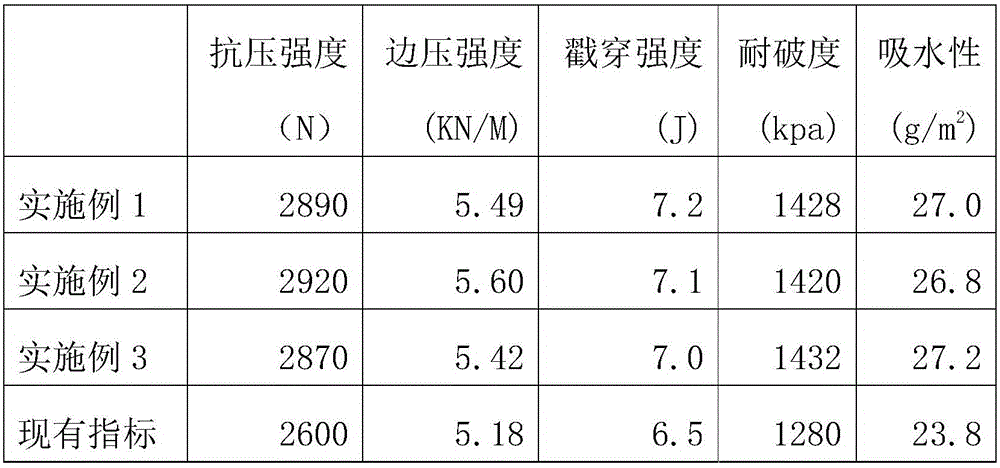

Examples

Embodiment 1

[0018] A production process of high-strength cartons, comprising the following steps:

[0019] 1) To make cardboard, select two pieces of cowhide paper, and bond them together with an adhesive to make cardboard;

[0020] 2) To print graphics and text, select a graphic printing plate, then use an offset printing machine to transfer the ink to the cardboard, and irradiate the ink with ultraviolet rays to make the ink nearly dry, for standby, the printing temperature is 20°C; take the lamination process, and the cardboard is printed One side of the picture and text passes through a film laminating machine, and a layer of film is laminated under the action of the laminating machine, and the temperature during lamination is 80°C.

[0021] 3) cutting the cardboard, using the die-cutting blade on the die-cutting machine to cut the mounted cowhide paper according to its geometry;

[0022] 4) Glue the cardboard, glue the die-cut liner paper through a box gluer to form a finished carto...

Embodiment 2

[0026] A production process of high-strength cartons, comprising the following steps:

[0027] 1) To make cardboard, select two pieces of cowhide paper, and bond them together with an adhesive to make cardboard;

[0028] 2) To print pictures and texts, select a picture and text printing plate, then use an offset printing machine to transfer the ink to the cardboard, and irradiate the ink with ultraviolet rays to make the ink nearly dry, for standby, the printing temperature is 26°C; take the filming process, and the cardboard is printed with The graphic side passes through a film laminating machine, and a layer of film is laminated under the action of the laminating machine. The temperature during lamination is 90°C.

[0029] 3) cutting the cardboard, using the die-cutting blade on the die-cutting machine to cut the mounted cowhide paper according to its geometry;

[0030] 4) Glue the cardboard, glue the die-cut liner paper through a box gluer to form a finished carton.

[0...

Embodiment 3

[0034] A production process for high-strength cartons, comprising the following steps:

[0035] 1) To make cardboard, select two pieces of cowhide paper, and bond them together with an adhesive to make cardboard;

[0036] 2) To print graphics and text, select a graphic printing plate, then use an offset printing machine to transfer the ink to the cardboard, and irradiate the ink with ultraviolet rays to make the ink nearly dry. The printing temperature is 23°C; take the lamination process to print the cardboard with The graphic side passes through the film laminating machine, and a layer of film is laminated under the action of the laminating machine. The temperature during lamination is 85°C.

[0037] 3) cutting the cardboard, using the die-cutting blade on the die-cutting machine to cut the mounted cowhide paper according to its geometry;

[0038] 4) Glue the cardboard, glue the die-cut liner paper through a box gluer to form a finished carton.

[0039] Before the laminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com