Flame-retardant nonwoven wallpaper and preparation method thereof

A flame-retardant and wallpaper technology, which is applied in the direction of textiles and papermaking, papermaking, paper, etc., can solve the problems of rising production costs, increasing the difficulty of papermaking, and high prices of flame-retardant fibers, so as to achieve complete paper removal, reduce production costs, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Fiber ratio: softwood pulp 50%, hardwood pulp 30%, mixed pulp 20% 0 SR, polyester fiber 20%, 1.5×10mm, base paper weight 100g / m 2 , Dip-coat polyvinyl alcohol, starch and surface sizing agent in the machine, the concentration of the coating solution is 4%, and the coating amount is 6%. Polyvinyl alcohol: starch: surface sizing agent = 4: 1: 0.8 (both refer to the absolute dry weight of the solution), and the base paper weight is 106 g / m 2 .

[0023] External coating 20 g / m 2 , the coating liquid formula, the amount of flame retardant is 60%, the flame retardant is purchased from Hangzhou Tianhao Chemical Co., Ltd. SJ-5 type, the amount of wet strength agent is 20%, the amount of calcium carbonate is 20%, one-time dipping coating molding . The paper index is as follows: quantitative 126g / m 2 , tightness 0.50g / cm 3 , Tensile strength 3.6kn / m, wet strength 1.5 kn / m, surface absorption 30 g / m 2 , the opacity is 80%, the tearing degree is 1600mn vertically, 2000mn hor...

Embodiment 2

[0025] Fiber ratio: softwood pulp 40%, hardwood pulp 30%, pulp density 18 0 SR, soybean protein fiber 30%, 3.5D×5mm, base paper basis weight 83g / m 2 , In-machine dip coating of epoxy resin and surface sizing agent = 10:0.5 (both refer to the absolute dry weight of the solution), the concentration of the coating solution is 4%, and the coating amount is 5%. The basis weight of base paper is 91 g / m 2 .

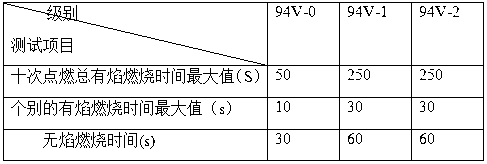

[0026] External coating 30 g / m 2 , Coating liquid formula, the amount of flame retardant is 90%, the flame retardant is purchased from Hangzhou Tianhao Chemical Co., Ltd. SJ-PP type, the amount of wet strength agent is 10%, and the second dipping coating is formed. The paper index is as follows: quantitative 121 g / m 2 , tightness 0.53g / cm 3 , Tensile strength 4.5kn / m, wet strength 1.8 kn / m, surface absorption 32 g / m 2 , the opacity is 80%, the tearing degree is 1650mn vertically, 2100mn horizontally, and the expansion rate is 0.4%. Flame retardant grade V-1.

Embodiment 3

[0028] Fiber ratio: softwood pulp 20%, pulp density 25 0 SR, viscose fiber 80%, 5D×2mm, base paper weight 100g / m 2 , dip-coating styrene-butadiene rubber and surface sizing agent in the machine = 20:1 (both refer to the absolute dry weight of the solution), the concentration of the coating solution is 4%, the coating amount is 6%, and the base paper weight is 106 g / m 2 .

[0029] External coating 40 g / m 2 , Coating liquid formula, the amount of flame retardant is 80%, the flame retardant is melamine phosphate, the amount of wet strength agent is 10%, the amount of calcium carbonate is 10%, and the second dipping coating is formed. The paper index is as follows: quantitative 146 g / m 2 , tightness 0.53g / cm 3 , Tensile strength 4.5kn / m, wet strength 1.8 kn / m, surface absorption 32 g / m 2 , the opacity is 80%, the tearing degree is 1650mn vertically, 2100mn horizontally, and the expansion rate is 0.4%. Flame retardant grade V-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com