Preparation method of propofol fat emulsion injection

A technology for propofol fat and injection, which is applied in the directions of emulsion delivery, devices for making medicines into special physical or taking forms, and active ingredients of hydroxyl compounds, etc. Excessive deviation, easy demulsification of the emulsion, etc., to achieve the effects of stable physical and chemical properties, enhanced particle size uniformity, and reduced pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

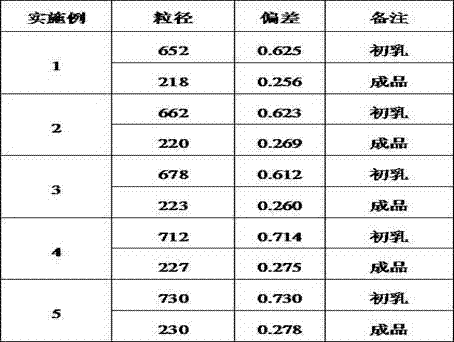

Examples

Embodiment 1

[0017] a. Under the protection of nitrogen, mix 103 grams of soybean oil, 12 grams of lecithin and 1.0 grams of oleic acid and heat up to 70 ℃ ~ 85 ℃, then add 10 grams of propofol to prevent premature oxidation of propofol , so as to achieve an effective therapeutic dose, after the propofol is uniformly dispersed, a clear oil phase is obtained for subsequent use;

[0018] b. Under the protection of nitrogen, mix 22.0 g of glycerin and 880 ml of water for injection, adjust the pH to 7.0 with sodium hydroxide aqueous solution and filter, then heat the filtrate to 45°C-60°C for later use;

[0019] c. Under the protection of nitrogen, the water phase is sheared at a speed of 10000rpm / min, and at the same time, the oil phase at 70 ° C to 85 ° C under the protection of nitrogen is pumped into the FD high-pressure sprayer under the water surface through a peristaltic pump. The sprayer uses a nozzle with a 0.3mm aperture , Spray with a spray volume of 80-145 ml / min, and the atomized ...

Embodiment 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the prescription amount is enlarged by 2 times.

[0023] a. Under the protection of nitrogen, mix 204 grams of soybean oil, 24 grams of lecithin and 2.0 grams of oleic acid and heat up to 70 ℃ ~ 85 ℃, then add 20 grams of propofol, after the propofol is evenly dispersed, Obtain the clarified oil phase for subsequent use;

[0024] b. Under the protection of nitrogen, mix 44.0 g of glycerin and 1760 ml of water for injection, adjust the pH to 7.0 with aqueous sodium hydroxide solution and filter, then heat the filtrate to 45°C to 60°C for later use;

[0025] c. Under the protection of nitrogen, the water phase is sheared at a speed of 10000rpm / min, and at the same time, the oil phase at 70 ° C to 85 ° C under the protection of nitrogen is pumped into the FD high-pressure sprayer under the water surface through a peristaltic pump. The sprayer uses a nozzle with a 0.3mm aperture , Spray with a sp...

Embodiment 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the prescription amount is enlarged by 3 times.

[0029] a. Under the protection of nitrogen, mix 306 grams of soybean oil, 36 grams of lecithin and 3.0 grams of oleic acid and heat up to 70 ℃ ~ 85 ℃, then add 30 grams of propofol, after the propofol is evenly dispersed, Obtain the clarified oil phase for subsequent use;

[0030] b. Under the protection of nitrogen, mix 66.0 g of glycerin and 2640 ml of water for injection, adjust the pH to 7.0 with aqueous sodium hydroxide solution and filter, then heat the filtrate to 45°C to 60°C for later use;

[0031] c. Under the protection of nitrogen, the water phase is sheared at a speed of 10000rpm / min, and at the same time, the oil phase at 70 ° C to 85 ° C under the protection of nitrogen is pumped into the FD high-pressure sprayer under the water surface through a peristaltic pump. The sprayer uses a nozzle with a 0.3mm aperture , Spray with a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com