Method for preparing lithium battery anode material precursor

A cathode material and precursor technology, applied in the field of lithium battery material preparation, can solve the problems of low tap density, irregular shape of precursor, large specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

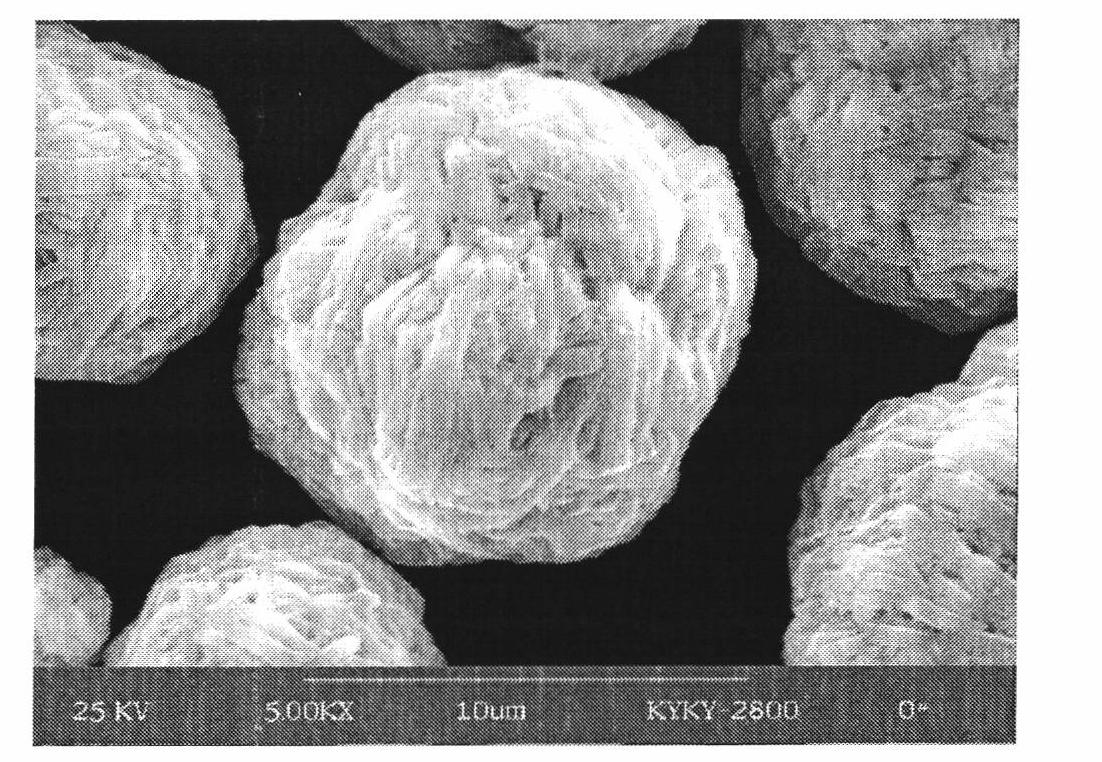

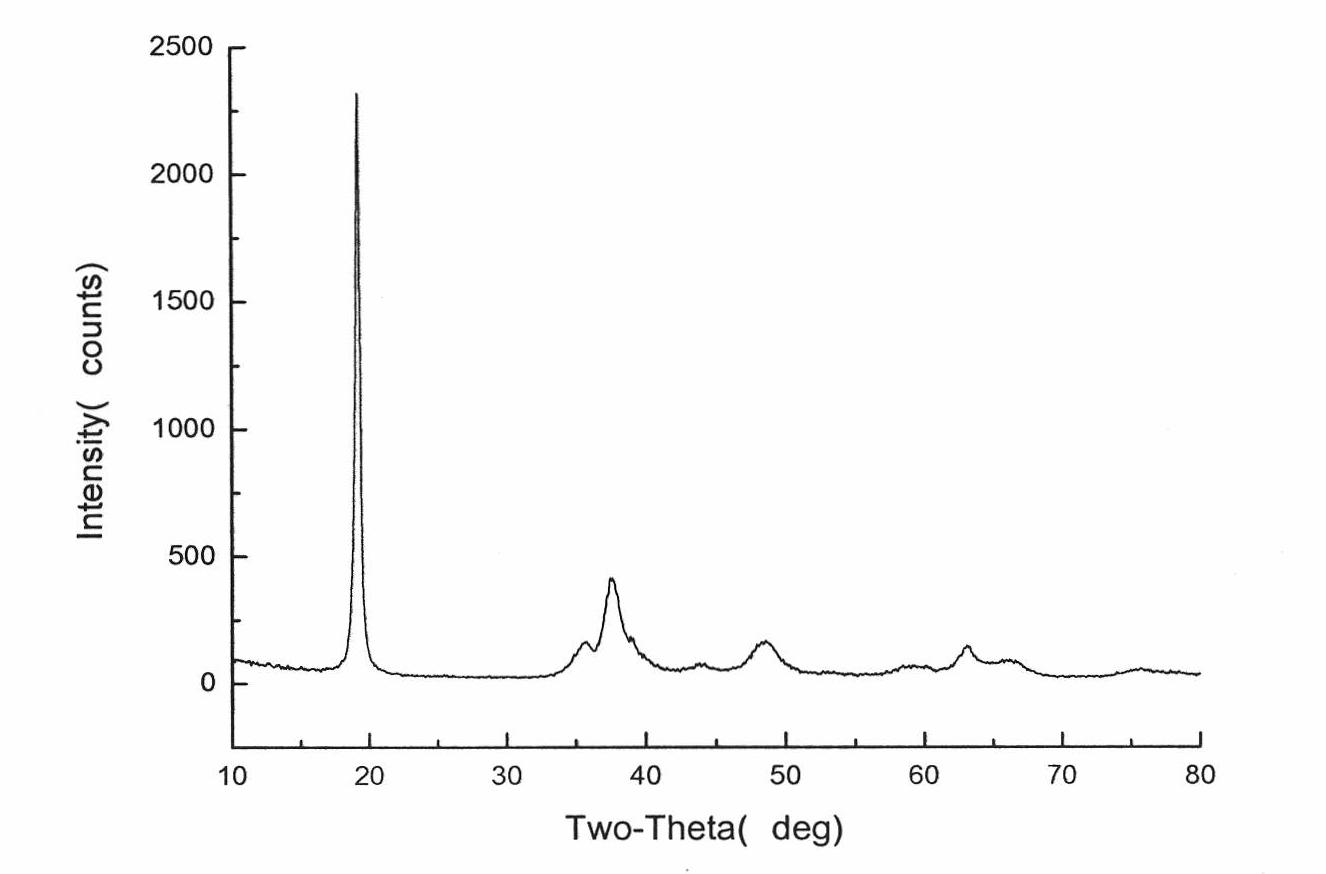

[0030] In Example 1, first add 100ml of a 0.03g / L mixture of sodium dodecylbenzene sulfonate and polyvinyl alcohol into the reaction tank, where the molar ratio of sodium dodecylbenzene sulfonate to polyvinyl alcohol is 1:1, then add the sulphate solution of nickel, manganese, and cobalt with a molar ratio of 0.4:0.4:0.2 (including 3421g nickel sulfate, 2193g manganese sulfate, 1851g cobalt sulfate, 14.5L pure water) 16L and 4mol / L React with 16L of sodium hydroxide, adjust the stirring speed to 200 rpm, the flow rate of the salt solution is 10ml / min, adjust the flow rate of the alkali solution to keep the PH value between 10-11, and carry out the aging reaction. After the reaction is completed, continue to stir After half an hour, put the slurry in the centrifuge, after dewatering, then put it in the oven to dry, get figure 1 , 3 Forebody shown. If the obtained precursor and lithium salt are mixed and ball milled in a certain ratio, and then sintered, Figure 5 The cathode mat...

Embodiment 2

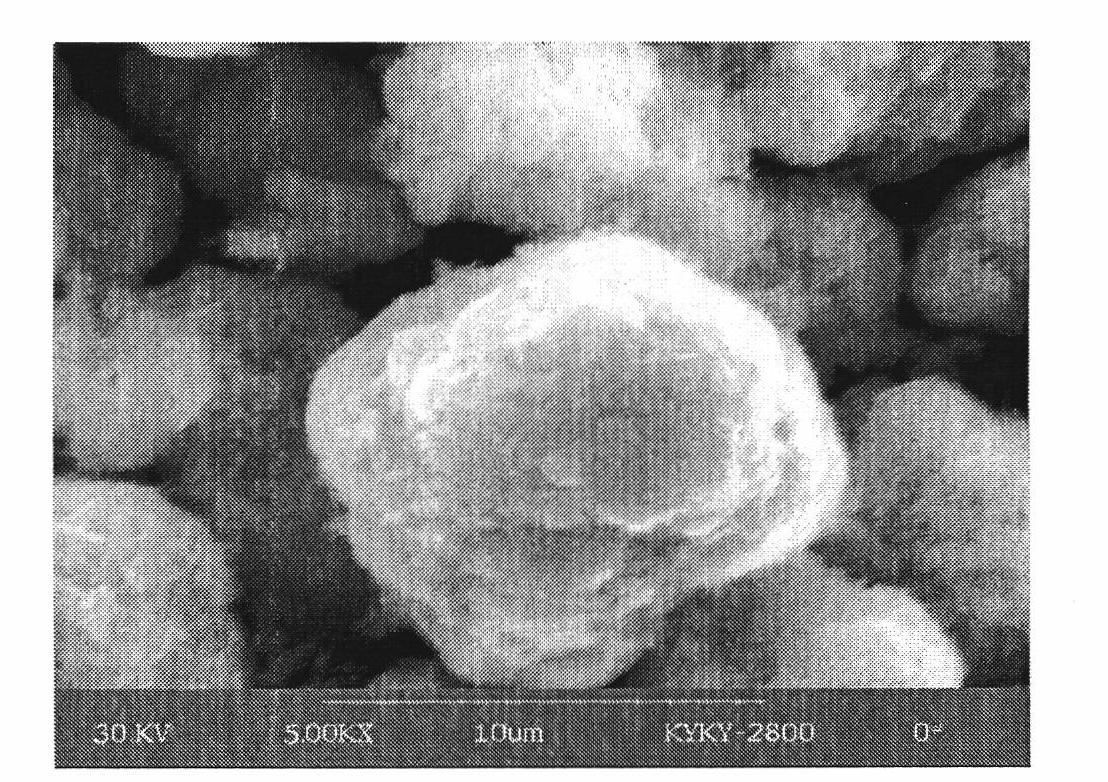

[0031] Example 2: Adding a nickel, manganese, and cobalt sulfate solution with a molar ratio of 0.4:0.4:0.2 (including 3421g nickel sulfate, 2193g manganese sulfate, 1851g cobalt sulfate, 14.5L pure water,) 16L and 4mol / L sodium hydroxide For 16L reaction, adjust the stirring speed to 200 rpm, the salt solution flow rate to 10ml / min, adjust the alkali solution flow rate to keep the pH value between 10-11, and carry out the aging reaction. After the reaction is completed, continue to stir for half an hour. Then put the slurry in a centrifuge, after dewatering, and then put it in an oven to dry. In this example, no surfactant was added to obtain figure 2 , 4 As shown in the precursor, the obtained precursor and lithium salt are mixed and ball milled in a certain ratio, and then sintered to obtain Image 6 The cathode material for the lithium battery shown.

Embodiment 3

[0032] Example 3: First add 100 mL of a mixture of 0.15g / L sodium dodecylbenzene sulfonate and polyvinyl alcohol into the reaction tank, where the molar ratio of sodium dodecylbenzene sulfonate to polyvinyl alcohol is 1:1, then add the nickel, manganese, cobalt sulfate solution with a molar ratio of 0.475:0.475:0.05 to react with 4mol / L of sodium hydroxide 16L, the stirring speed is 150 revolutions / min, and the salt solution flow rate is 8ml / min. The remaining steps are the same as in Example 1, and will not be repeated here. The reaction obtains a nickel-manganese binary precursor doped with cobalt, which has a morphology as Figure 7 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com