Method for preparing micro-sized monodisperse polyuria microspheres

A monodisperse, micron-scale technology, which is applied in the field of high-yield preparation of micron-scale monodisperse polymer microspheres and precipitation polymerization to prepare monodisperse polyurea microspheres, which can solve the problems of long polymerization time, low yield of microspheres, residual monomer Difficult separation and other problems, to achieve the effect of single raw material and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

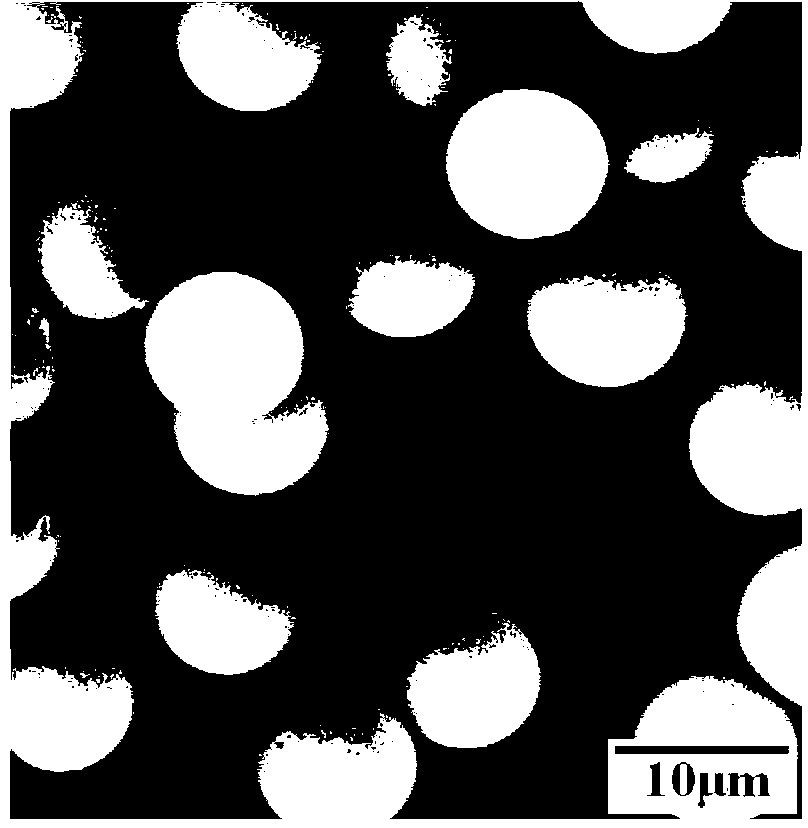

[0038] At room temperature, first add 94.0 g of water / acetone mixed solvent with a mass ratio of 3 / 7 to a 120 mL glass reaction bottle, shake well and then add 6.0 g of monomeric isophorone diisocyanate (CAS No.: 4098-71 -9), the reaction bottle was sealed and placed in a constant temperature water bath shaker at a temperature of 30° C., and the system began to become cloudy after reacting at a vibration frequency of 120 times / min for 56 minutes, and then continued to react for 2 hours. After the reaction, take a certain amount of sample and add it to a centrifuge tube, centrifuge at 12000r / min for 5min with a high-speed centrifuge, take out the supernatant, wash the microspheres twice with acetone, and then dry them in an oven at 80°C for 12h Polyurea microspheres were obtained.

[0039] The productive rate of gained polyurea microsphere is 84.21%, and the average particle diameter of microsphere is 9.024 μ m, and the polydispersity coefficient of particle diameter is 1.004, ...

Embodiment 2

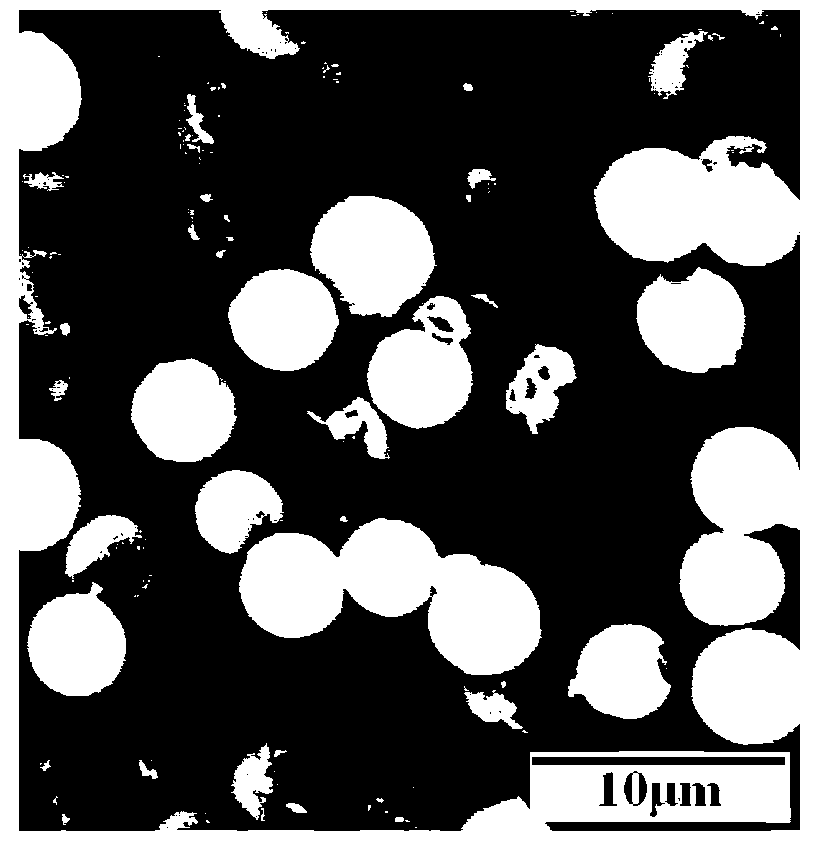

[0041] At room temperature, first add 98.4 g of water / acetone mixed solvent with a mass ratio of 3 / 7 to a 120 mL glass reaction bottle, shake well and then add 1.6 g of 4,4′-dicyclohexylmethane diisocyanate (CAS No.: 5124-30-1) monomer, seal the reaction bottle and place it in a constant temperature water bath shaker at a temperature of 30°C. After reacting for 47 minutes at a vibration frequency of 120 times / min, the system starts to become cloudy, and then continue to react for 2 hours. After the reaction, take a certain amount of sample and add it to a centrifuge tube, centrifuge at 12000r / min for 5min with a high-speed centrifuge, take out the supernatant, wash the microspheres twice with acetone, and then dry them in an oven at 80°C for 12h Polyurea microspheres were obtained.

[0042] The productive rate of gained polyurea microsphere is 60.23%, and the average particle diameter of microsphere is 4.023 μ m, and the polydispersity coefficient of particle diameter is 1.060...

Embodiment 3

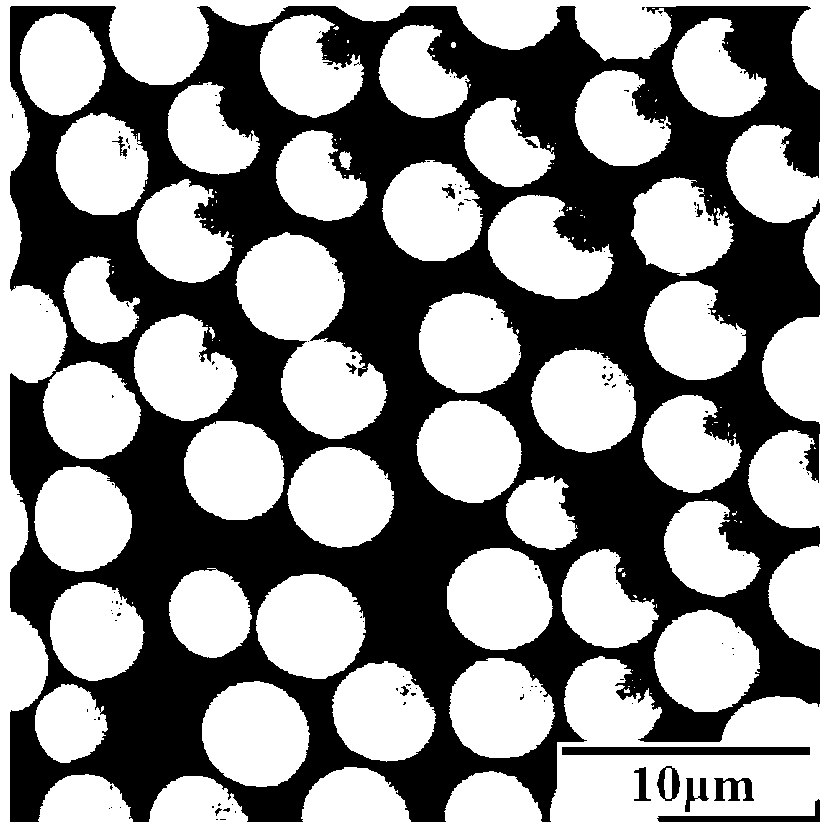

[0044] At room temperature, first add 98.4g of water / acetone mixed solvent with a mass ratio of 3 / 7 to a 120mL glass reaction bottle, shake well and then add 1.6g of 1,6-hexamethylene diisocyanate (CAS No.: 822-06- 0) Monomer, seal the reaction bottle and place it in a constant temperature water bath shaker at a temperature of 30°C. After reacting for 45 minutes at a vibration frequency of 120 times / min, the system starts to become cloudy, and then continue to react for 2 hours. After the reaction, take a certain amount of sample and add it to a centrifuge tube, centrifuge at 12000r / min for 5min with a high-speed centrifuge, take out the supernatant, wash the microspheres twice with acetone, and then dry them in an oven at 80°C for 12h Polyurea microspheres were obtained.

[0045] The productive rate of gained polyurea microsphere is 65.73%, and the average particle diameter of microsphere is 4.192 μ m, and the polydispersity coefficient of particle diameter is 1.015, and its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com