Acetylglucosamine imprinting material and applications of acetylglucosamine imprinting material in recognition of acetylglucosamine and acetylglucosamine modified peptides

A technology of acetylglucosamine and imprinting materials, applied in other chemical processes, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of low enrichment affinity and insufficient specificity, and achieve low price and fast adsorption , rich interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Preparation of acetylglucosamine bulk imprinted material (MIP1)

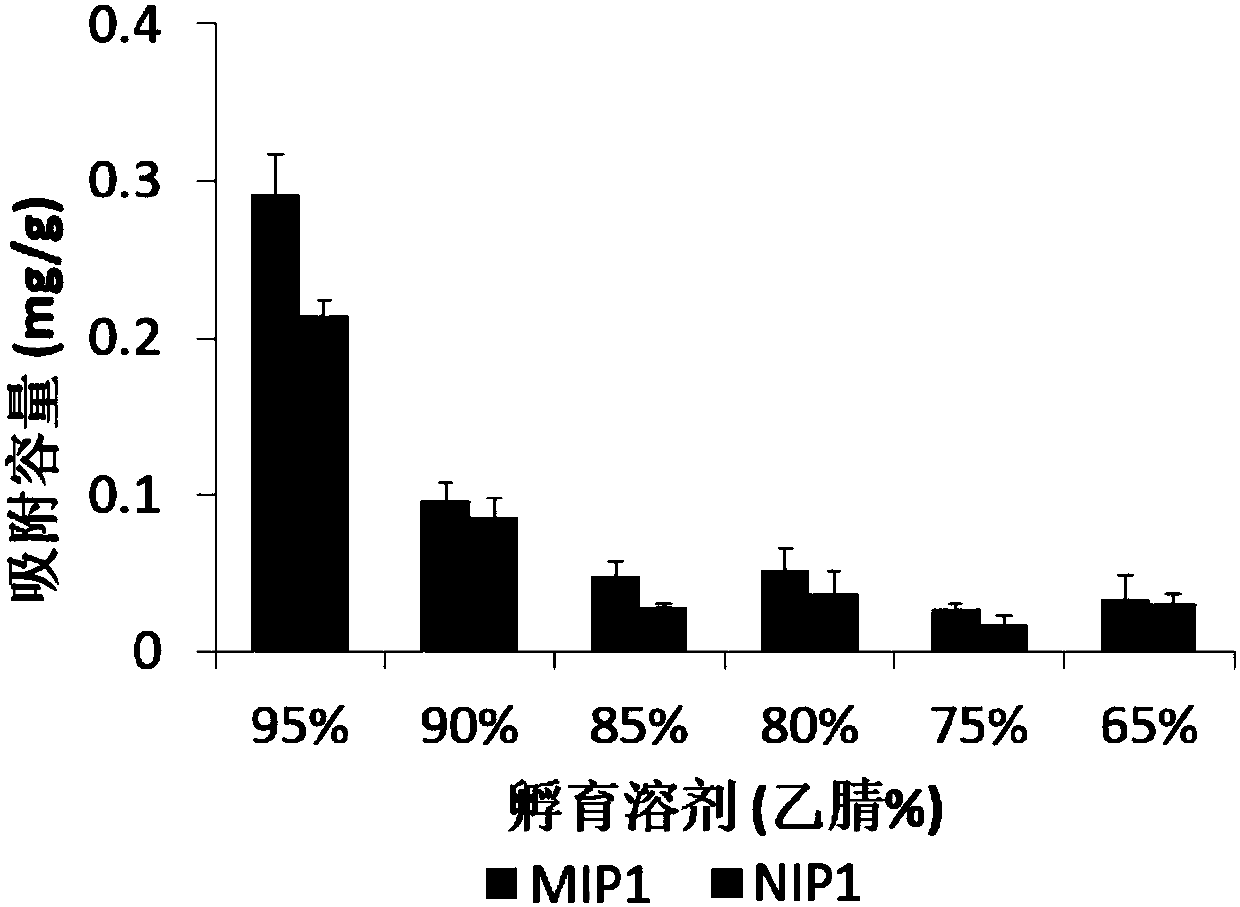

[0048] Dissolve 35mg of N-acetyl-D-glucosamine in 0.5mL of dimethyl sulfoxide, then add 300μL of ethylene glycol dimethacrylate, 50mg of acrylamidoamine, and 3.5mg of azobisisobutyrocyanide until all After the components were completely dissolved, nitrogen gas was passed through the reaction mixture for 10 min. Stand at 4°C for 1h, then react at 65°C for 12h. Remove the blocky material obtained from the reaction, grind it with a mortar, and add 4 mL of template removal solution methanol:acetic acid (9:1) to elute the template 10 times, 5 h each time. Finally, the obtained material was sieved with a 300-mesh sieve, and particles smaller than 300-mesh were retained, and the dried acetylglucosamine bulk imprinted material (MIP1) was obtained.

[0049] In the formula, the mixing mass ratio of acetylglucosamine, functional monomer, crosslinking agent, initiator and solvent is 4:5.6:33.8:0.4:56.2.

[0050] N...

Embodiment 2

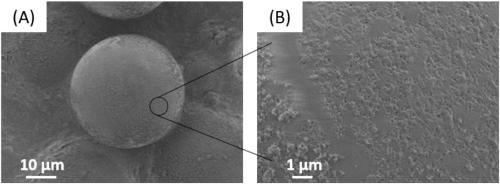

[0054] Preparation of acetylglucosamine surface imprinted material (MIP2) by Pickering emulsion blotting

[0055] Boric acid-modified silicon nanoparticles are used as the matrix material, and the particle size is 30nm. Weigh 100 mg of acetylglucosamine and dissolve it in 1 mL of dimethyl sulfoxide, add 100 mg of boric acid-modified silicon nanoparticles, sonicate for 10 min, and shake at 60°C for 3 h. Centrifuge at 17000rpm for 20min, collect the reaction product, wash once with pure water to prepare silicon nanoparticles bonded with acetylglucosamine, freeze-dry for 50min, and store for later use as a stabilizer for Pickering emulsion.

[0056] Ultrasonically disperse 50 mg of silicon nanoparticles bonded with acetylglucosamine in 2.5 mL of water, add 68 mg of functional monomer acrylamide, and wait for it to completely dissolve and let stand at 4°C for 50 min to serve as the aqueous phase of the Pickering emulsion . Add 15mg of azobisisobutyronitrile into 0.342mL of ethyl...

Embodiment 3

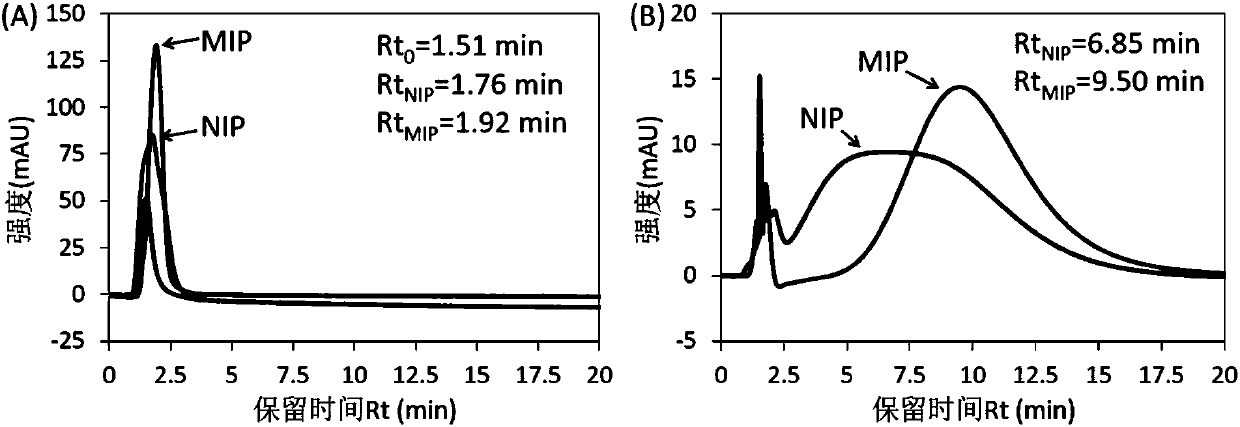

[0061] Recognition of acetylglucosamine and acetylglucosamine-modified peptides by MIP2

[0062] Take 700 mg of MIP2 / NIP2 and add them into 40 mL of homogenate 50% acetonitrile, and ultrasonicate for 5 min to form a homogeneous suspension. The column was loaded under a pressure of 30MPa, and the size of the column tube used was 2.1×150mm. After the column was packed, wash the column with 50% acetonitrile at a flow rate of 0.1 mL / min for 2 h, then wash the column with 0.2 mL / min 80% acetonitrile for 2 h, and save it for later use.

[0063] Using Hitachi High-tech Chromaster chromatography system, using different proportions of acetonitrile as mobile phase, flow rate 0.2mL / min, inject 5μL 0.1mg / mL acetylglucosamine, detection wavelength 200nm, measure the retention time of acetylglucosamine on MIP2 and NIP2 columns (t R ). Inject 5 μL of 20% acetone, and take its peak time as the dead time of the system (t 0 ). By the formula k=(t R -t 0 ) / t 0 Calculate the retention fac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com