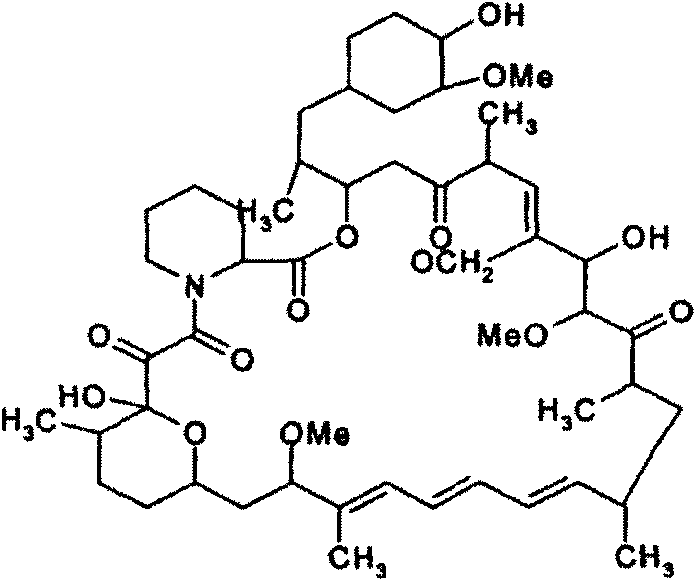

Sirolimus micro-emulsion particles and preparation method and application thereof

A technology of micro- and micro-emulsion granules of sirolimus, applied in the field of pharmaceutical preparations, can solve problems to be improved, etc., and achieve the effects of good stability and simplified operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1, preparation of sirolimus microemulsion particles

[0081] Add 2 g of polyethylene glycol 4000 (Tianjin Tiancheng Pharmaceutical Co., Ltd., Zhunzi H12020043), poloxamer 188 (registration number F20130004, BASF, Germany) 8 g, and 10 g of glycerin into 160 mL of purified water; then add sirolimus Mix 25g evenly, heat and stir in a water bath at 80°C until it reaches a molten state, use a high-speed tissue masher to shear and stir at a speed of 8000 rpm, and shear and stir for 30 minutes to obtain a primary microemulsion, which is then circulated and emulsified by a high-pressure homogenizer 4 times to obtain a microemulsion, and then spray drying to obtain 41.4 g of sirolimus microemulsion particles with a yield of 92.0%.

Embodiment 2

[0084] Embodiment 2, preparation of sirolimus microemulsion particles

[0085] Add 60g of polyethylene glycol 4000, 240g of poloxamer 188, and 100g of glycerin into 3000mL of purified water; then add 50g of sirolimus and mix well, heat and stir in a water bath at 80°C until it melts, and use a high-speed tissue grinder to shear and stir , the rotating speed is 10000 rpm, shearing and stirring for 20 minutes to obtain the primary microemulsion, and then circulate and emulsify for 4 times through the high-pressure homogenizer to obtain the microemulsion, and then freeze-dry in a large plate to obtain 430 g of sirolimus microemulsion particles. The rate is 95.6%.

Embodiment 3

[0088] Embodiment 3, preparation of sirolimus microemulsion particles

[0089] Add 100 g of polyethylene glycol 4000, 400 g of poloxamer 188, and 150 g of glycerin into 3900 mL of water for injection; then add 100 g of sirolimus and mix evenly, heat and stir in a water bath at 80°C until it melts, and use a high-speed tissue grinder to shear Cutting and stirring, the rotating speed is 10000 rpm, shearing and stirring for 20 minutes to obtain the primary microemulsion, and then circulate emulsification 4 times through the high-pressure homogenizer to obtain the microemulsion, then spray dry to obtain 709g of sirolimus microemulsion particles, Yield 94.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com