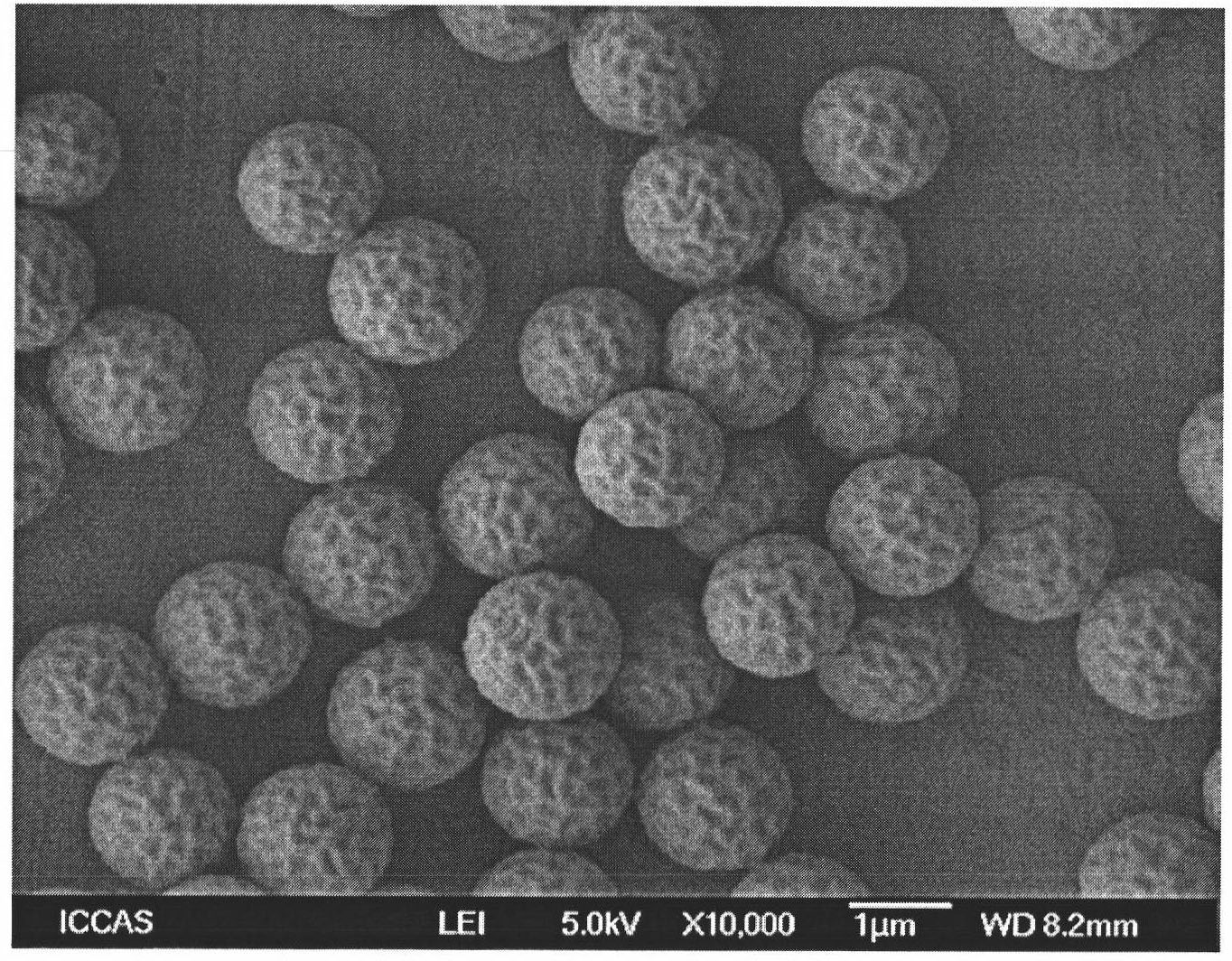

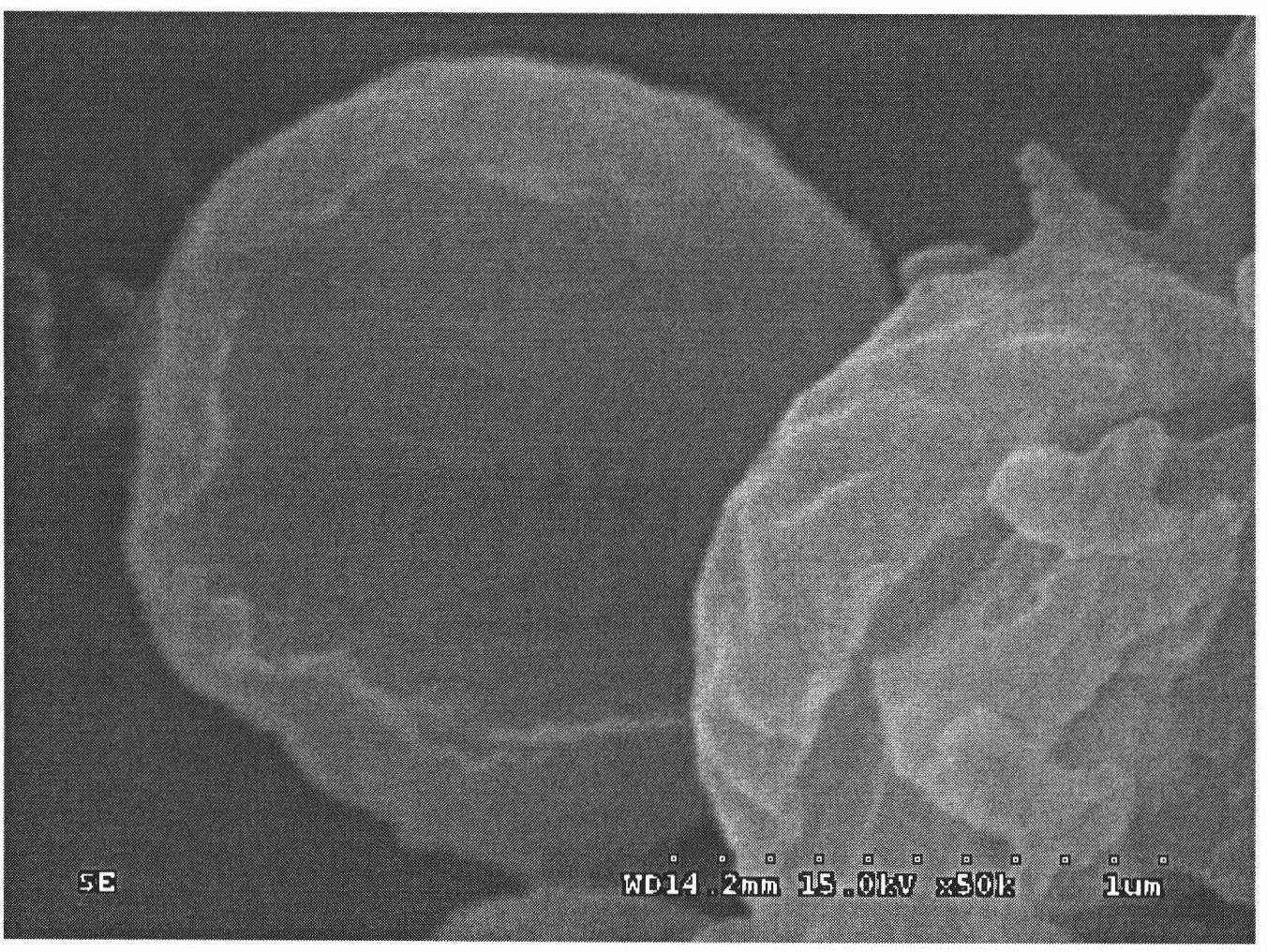

Hollow organosilane microsphere with rough surface structure and preparation method thereof

An organosilane and rough surface technology, applied in the field of organosilane microspheres and their preparation, can solve problems such as sphere damage and uneven particle size, and achieve the effect of solving difficult control and solving process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

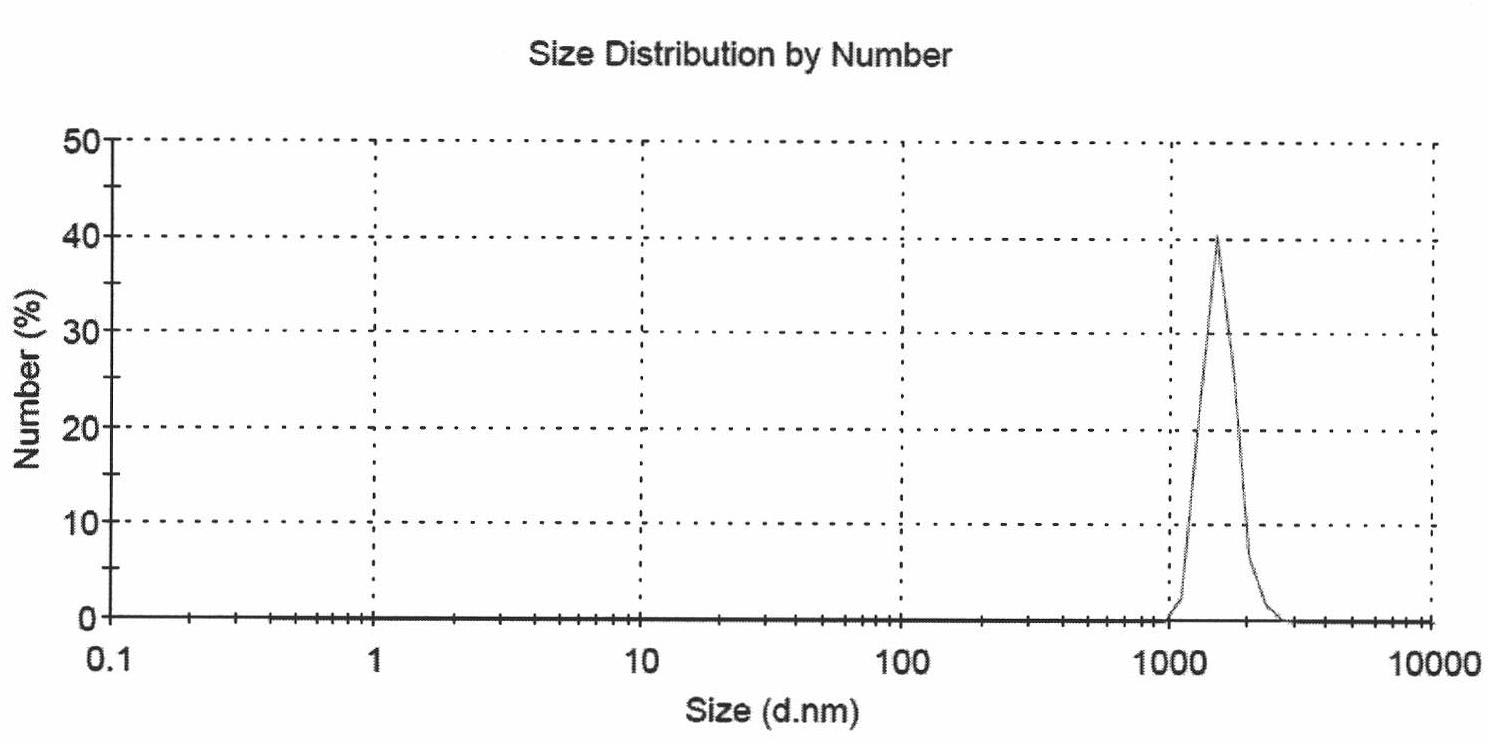

[0043] Disperse 0.01 gram of 25% ammonia water into 10 gram of pure water to form a homogeneous solution, mix vinyltrimethoxysilane and ethyl orthosilicate with a mass ratio of 4:1, stir at 200 rpm for 30 minutes, then mix 1.5 gram of the above-mentioned organic The silane mixture was slowly added dropwise to the pre-mixed ammonia solution, heated to 70°C, reacted at 200rpm for 8h, and then aged at 70°C for 15h; finally centrifuged, washed repeatedly with pure water, freeze-dried, and the resulting particles averaged The particle size is 0.87 μm, the particle size distribution is 0.7 μm-1.2 μm, and the yield is 37%.

Embodiment 2

[0045] Disperse 0.5 g of 25% ammonia water into 10 g of pure water to form a uniform solution, mix phenyltrimethoxysilane and ethyl orthosilicate with a mass ratio of 4:1, stir at 200 rpm for 30 min, then mix 1.6 g of the above organic The silane mixture was slowly added dropwise to the pre-mixed ammonia solution, placed in the ice-water mixture, reacted at 200 rpm for 8 hours, and then aged in the ice-water mixture at 0°C for 15 hours; finally centrifuged, washed repeatedly with pure water, After freeze-drying, the average particle size of the generated particles is 2.48 μm, the particle size is mainly distributed in the range of 2.2 μm-2.6 μm, and the yield is 41%.

Embodiment 3

[0047] Disperse 0.5 g of 25% ammonia water into 10 g of pure water to form a homogeneous solution, mix methyltrimethoxysilane and ethyl orthosilicate at a mass ratio of 4:1, stir at 200 rpm for 30 min, then mix 1.2 g of the above organic The silane mixture was slowly added dropwise to the pre-mixed ammonia solution, placed in a room temperature of 20°C, reacted at 200 rpm for 2 hours, and then aged at room temperature for 15 hours; finally centrifuged, washed repeatedly with pure water, and freeze-dried to produce The average particle size of the particles is 1.5 μm, the particle size is mainly distributed in the range of 1.3 μm-1.7 μm, and the yield is 46%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com